Spatial and temporal distribution characteristics and discoloration law of Fraxinus mandshurica knot

-

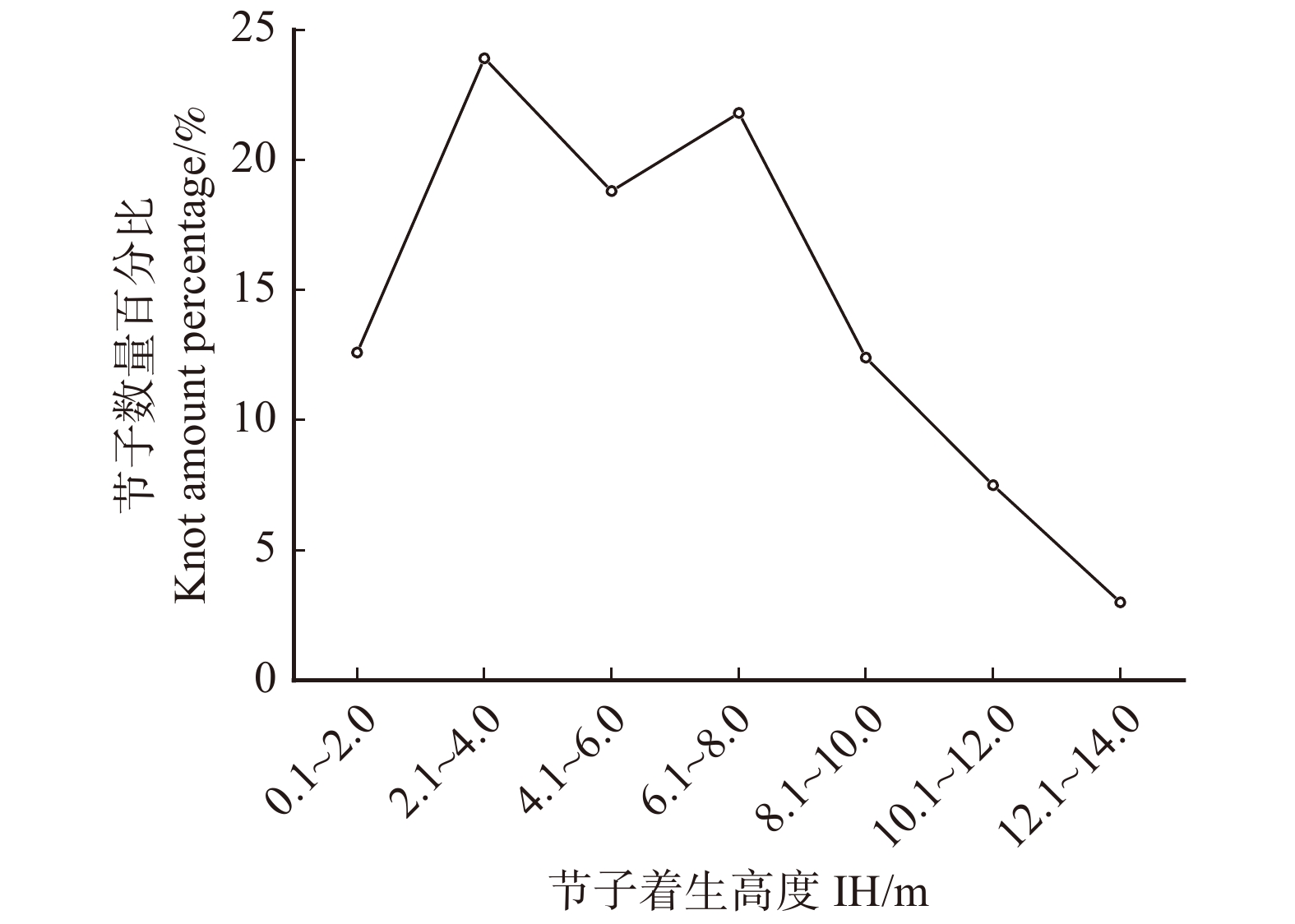

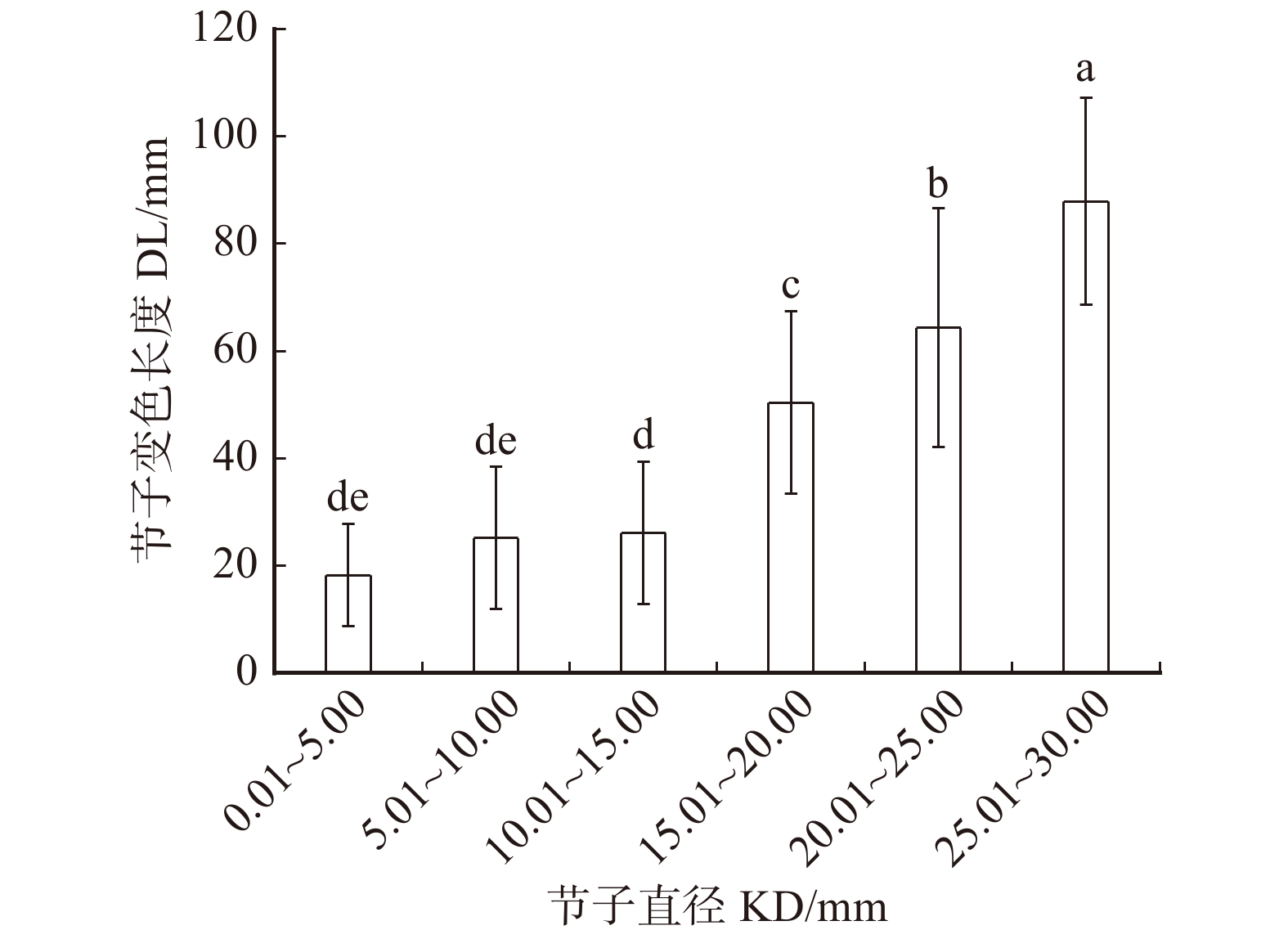

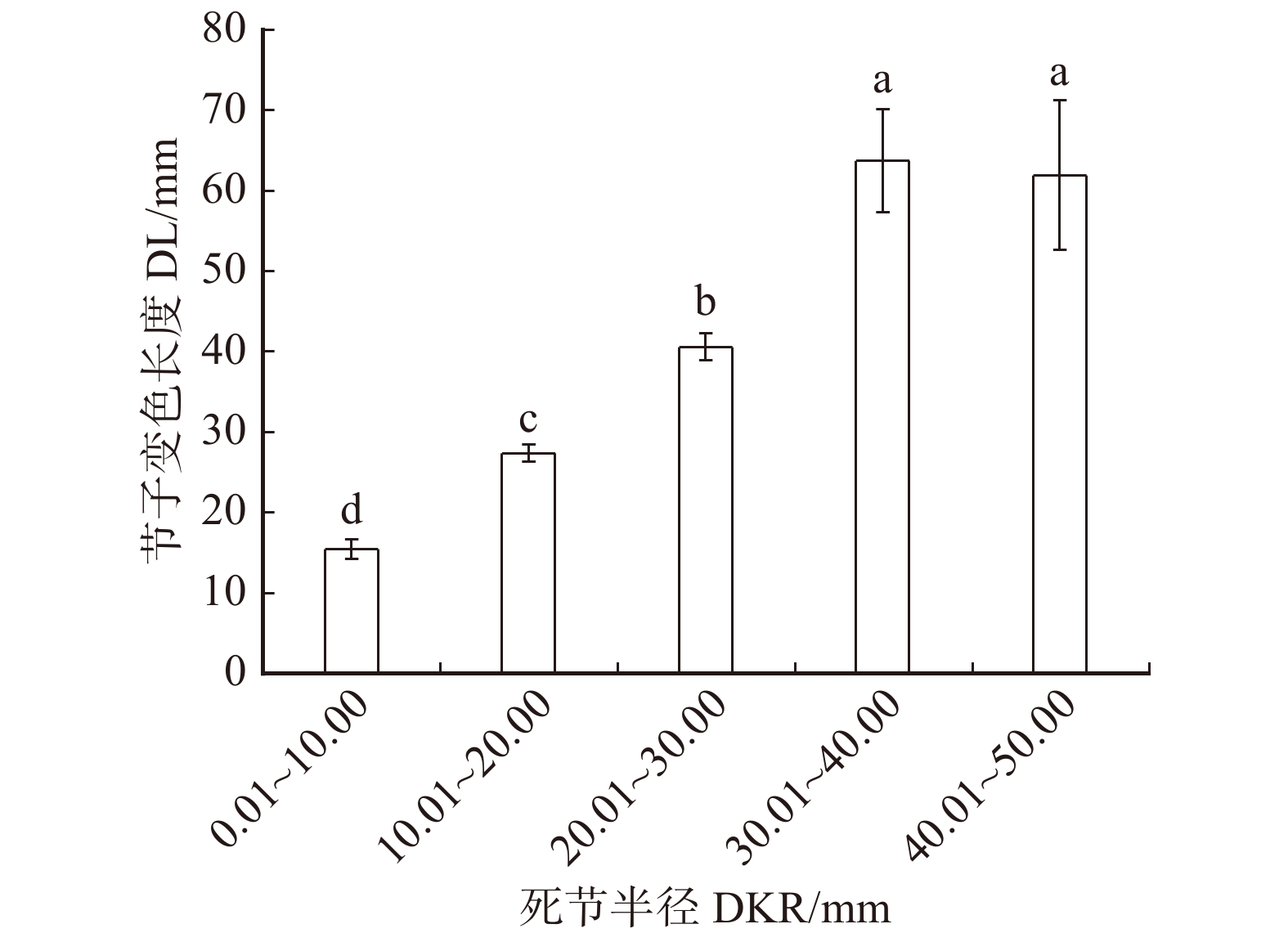

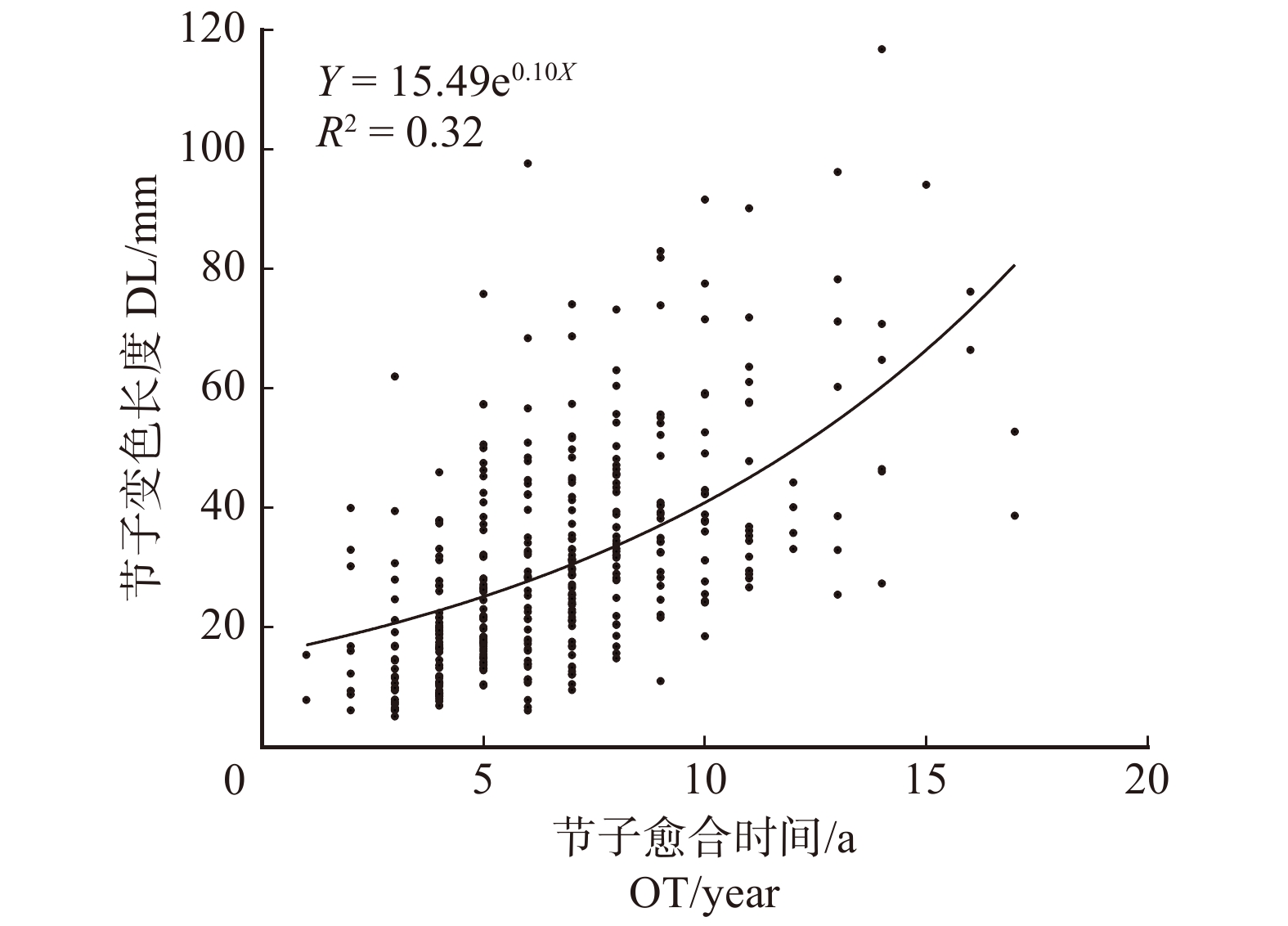

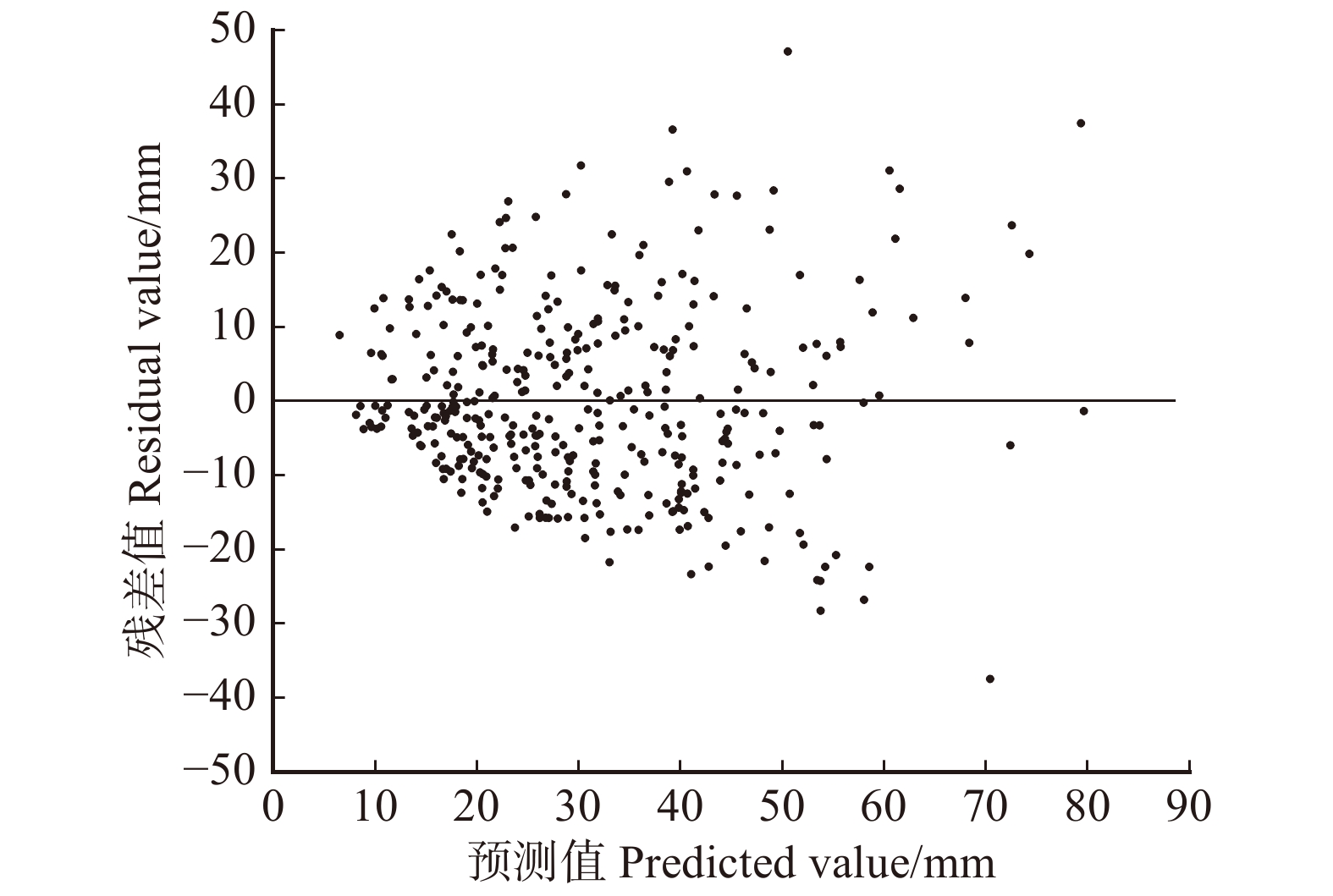

摘要:目的 为了解水曲柳节子时空分布特征和变色规律,并建立节子变色长度的预测模型。方法 在49年生的水曲柳和长白落叶松人工混交林中,选取16株水曲柳样木,采用油锯对节子进行解剖,并在实验室内利用20倍放大镜测量节子的属性。结果 (1)水曲柳节子径向生长的第1 ~ 5年形成的节子数量最多,占98.1%;第6 ~ 15年形成的死节数量较多,占94.1%;第11 ~ 20年完全愈合的节子数量较多,占73.6%;(2)在垂直分布上,89.5%的节子分布在树干高度10.0 m以下,10.5%的节子分布在树干10.1 ~ 14.0 m的范围;(3)节子变色长度随着节子直径的增加而逐渐增大,当节子直径大于15.00 mm时,变色长度明显增大;(4)节子变色长度随着生角度的增加而显著减小(P < 0.05),但会随着死节半径和节子愈合时间的增加而显著增大(P < 0.05);(5)通过逐步回归分析,筛选出节子直径(KD)、节子总半径(TRK)和节子愈合时间(OT)3个影响节子变色的关键因子,建立了节子变色长度多元回归模型:YDL = 1.557XKD + 0.382XTRK + 1.140XOT - 7.523,相关性达到极显著水平。结论 自然整枝条件下,水曲柳节子易发生变色,节子直径、节子总半径以及节子愈合时间是决定节子变色长度的关键因子。在节子直径超过15.00 mm时,变色长度明显增大,因此,当水曲柳枝条直径超过15.00 mm时应及时修枝。Abstract:Objective The study aims to explore the spatial and temporal distribution characteristics and discoloration law of Fraxinus mandshurica knot, and establish the predicting model of discoloration length of knot.Method We selected 16 F. mandshurica sample trees from artificial mixed forests of 49-year-old F. mandshurica and Larix olgensis, and dissected knots with a chainsaw and measured the knot properties using a 20 × magnifying glass in the laboratory.Result (1) The number of formed knots from 1st to 5th radial growth year accounted for the most, reaching 98.1%; the number of dead knots formed from 6th to 15th year accounted for 94.1%; the number of completely occluding knots from 11th to 20th year accounted for 73.6%. (2) 89.5% knots located below 10.0 m, and 10.5% knots located between 10.1 and 14.0 m of trunk height in the vertical distribution. (3) The discoloration length of knot increased with the increase of knot diameter. When the knot diameter was greater than 15.00 mm, the discoloration length of knot increased significantly. (4) The discoloration length of knot significantly decreased with the increase of insertion angle of knot (P < 0.05), but significantly increased with the increase of radius of dead knot and the occlusion time of knot (P < 0.05). (5) The study filtered three key factors, i.e. knot diameter (KD), total radius of knot (TRK) and occlusion time of knot (OT) , to establish a multiple regression model of the discoloration length of knot by the stepwise regression method: YDL = 1.557XKD + 0.382XTRK + 1.140XOT − 7.523. The correlation reached a significant level.Conclusion Under the condition of natural pruning, F. mandshurica knot discolors easily. KD, TRK and OT are key factors affecting the discoloration length of knot. When the knot diameter exceeds 15.00 mm, the discoloration length of knot increases significantly. Therefore, when the branch diameter of F. mandshurica exceeds 15.00 mm, pruning should be taken in time.

-

竹材具生长周期短、硬度强、韧性高、可降解的生物性材料。且在现有木材资源不能适应家具产业发展迫切需要的情况下,竹材是取代实木的最理想材料[1],竹集成材作为保持了竹材优异的物理力学性能的竹制家具用材,具有良好的发展前景。众所周知,竹材容易受外界环境如光照、水、微生物等的侵害而发生变色、腐朽[2],竹集成材亦如是。对竹集成材进行表面涂饰是最能够有效保护其性能的方法之一。

以水作为溶剂的水性漆与传统油性漆相比,不含挥发性有机物(volatile organic compounds,VOCs),具有绿色环保、节约资源的特性[3]。伴随着国家环保政策的不断完善和绿色环保理念的普及,水性漆在家具、室内装饰、建筑等领域将逐步替代传统涂料[4]。然而竹集成材水性漆涂饰面临着竹集成材密度大,纹孔少,横向渗透困难等问题[5],使得水性漆漆膜附着力差,竹集成材水性漆涂饰工业化进度缓慢。为了克服这些问题,Lu[6]通过对毛竹表面进行过氧化氢表面预处理的方法,提高了水性漆在毛竹表面的附着力。此外其他研究人员通过使用湿热处理[7-8]、碱液浸泡处理[9]等方法,也在一定程度上提高了竹材表面的润湿性和粗糙度,改善了水性漆等流体在竹材内部的渗透效率,漆膜的附着力由此增强。涂饰工艺对涂料性能的发挥有着重要影响,是涂饰过程中的关键技术环节。但目前有关水性涂饰工艺的研究还着重于水曲柳、杨木等木质材料上[10-12],对竹集成材涂饰工艺研究较少,且未有水性清漆和色漆对竹集成材硬度、附着力等漆膜性能影响方面的研究。

为了解决竹集成材水性涂装这些难题,本研究以家具中最为常用的毛竹集成材为基材,在省去预处理的基础上优化了竹集成材水性涂饰工艺,提高了水性涂饰工艺的效率,系统地探究了竹集成材清漆与色漆涂饰性能的影响及竹集成材水性漆漆膜的附着机理,为竹家具的水性化涂装提升提供理论支持和科学依据。

1. 材料与方法

1.1 材 料

选取含水率为11%的毛竹集成材,制成尺寸为100 mm(长) × 100 mm(宽) × 10 mm(厚)的试样18块,并对试样在室温和湿度为(65 ± 3)%的环境下进行打磨。选用涂料为自制水性底漆和商业水性面漆(分为清漆与色漆两种类型,主要成分为水性聚氨酯树脂,底漆固体含量为39.2%,面漆固体含量为34.6%)。

1.2 基材涂饰

依次用80目、120目、180目和240目砂纸对基材进行顺纹打磨并用羊毛刷除尘。涂饰前底漆与面漆分别添加5% 和8%的去离子水进行调配。调配底漆涂布量为80 g/m2,面漆涂布量为120 g/m2,在室温下均匀地喷涂底漆3遍、面漆1遍,每遍喷涂干燥之后再次顺纹打磨1遍(图1)。涂饰完后基材后在室温下干燥8 h。

1.3 测试方法

将无差别的18个样品分为A、B和C这3组,每组6个,按照字母加数字的方式编号成A1 ~ A6、B1 ~ B6和C1 ~ C6。

1.3.1 漆膜硬度、附着力、光泽度测试

选取A组试样进行漆膜的硬度测试。根据ISO 15184—1998 《色漆和清漆 铅笔法测定漆膜硬度》标准测试。选取B组试样进行漆膜的附着力测定。根据ISO 2409—2013《色漆和清漆交叉切割试验》中的检测标准,按照规定的步骤,使用QFH漆膜划格仪依次对每个试样进行测定。参照ISO 2813—2014《色漆和清漆在20°、60°和85°非金属色漆漆膜镜面光泽的测定》使用60°光泽度仪对C组和对照试样进行光泽度测试。

1.3.2 表面粗糙度测试

参照GB/T 12472—2003《产品几何量技术规范(GPS) 表面结构 轮廓法 木制件表面粗糙度参数及其数值》,使用TR240便携式表面粗糙度仪测试试样的表面粗糙度,将触针的运动转变为电信号,测量出各粗糙度参数。设置取样长度为2.5 mm,为了提高准确率,在每一块试件上选取4 个点测试,并对测试结果进行记录。

1.3.3 色度值测试

使用SP60色差仪按照国际照明委员会CIE标准色度系统对C组试样基材涂饰前后的颜色变化进行定量的度量。CIE由L*、a*、b*这3个数值进行评估。L*表示亮度;a*表示红绿,数值变化由正到负,表示颜色从红(正)到绿(负);b*表示黄蓝,数值变化由正到负,表示颜色从黄(正)到蓝(负)。总色差值ΔE表示颜色知觉差异,数值越小则表示颜色变化越小。ΔE由公式(1)确定:

ΔE=√ΔL∗2+Δa∗2+Δb∗2 (1) 式中:ΔL*、Δa* 和Δb*分别为涂饰前后的L*、a*和b*差值。

1.3.4 扫描电镜(scanning electron microscope,SEM)分析

使用场发射环境扫描电镜(FEG-ESEM,XL30ESEMFEG,FEI Company,USA)观察并记录基材涂饰前后的表面形态。将加速电压设置为7 kV后,着重对涂饰后基材与漆膜界面结合处的形态进行观察。

1.3.5 傅里叶变换红外光谱(Fourier transform infrared spectroscopy,FTIR)分析

用溴化钾压片法分别测定涂饰前后试样的FTIR。设置光谱分辨率为4 cm−1,在500 ~ 4 000 cm−1范围内,利用傅里叶变换红外光谱仪(Nicolet6700傅里叶红外光谱仪,Thermo Scientific, Waltham, USA)扫描得到清漆、色漆、竹集成材、清漆和色漆涂饰后的基材的5种FTIR。测试完成后,将所有5个样品的光谱绘制成图表,分析每个样品的特征峰的变化,并据此探究水性漆与竹集成材的结合机理。

2. 结果与讨论

2.1 漆膜硬度与附着力

漆膜硬度代表了涂饰在基材上的漆膜的机械强度,反映了漆膜对来自外界的碰擦、刺划等机械作用的耐受能力[13]。从表1可以看出:清漆的漆膜硬度为1H,而色漆的漆膜硬度为2H。这是因为漆膜的硬度是由成膜物质的性能所决定的,色漆中含有较高硬度的颜料,因而色漆的硬度优于清漆。但两者的硬度均能够满足GB/T 3324—2017《木家具通用技术条件》中室内装饰、实木地板的使用要求[14]。此外,我们发现清漆和色漆的漆膜硬度均比之前研究的水性漆涂饰水曲柳所得的硬度高[12],这充分说明了水性漆采用喷涂的涂饰工艺能在竹集成材上产生能媲美在木材上的效果。

表 1 水性漆漆膜的硬度与附着力Table 1. Hardness and adhesion of film of waterborne paint清漆 Varnish 色漆 Color paint 试件 Sample 硬度 Hardness 附着力 Adhesion 试件 Sample 硬度 Hardness 附着力 Adhesion A1 1H 0级 Grade 0 B1 2H 1级 Grade 1 A2 1H 0级 Grade 0 B2 2H 1级 Grade 1 A3 1H 0级 Grade 0 B3 2H 1级 Grade 1 A4 1H 0级 Grade 0 B4 2H 1级 Grade 1 A5 1H 0级 Grade 0 B5 2H 1级 Grade 1 A6 1H 0级 Grade 0 B6 2H 1级 Grade 1 平均值 Average value 1H 0级 Grade 0 平均值 Average value 2H 1级 Grade 1 漆膜附着力是指导家具涂装工艺优化方向的关键数据,也是影响漆膜性能的重要指标之一[15-16]。由表1可知:清漆漆膜的附着力比色漆漆膜的附着力更高,可达为最高的0级,这是由于色漆由于含有颜料,其固含量高于清漆,所以清漆具有更高的渗透能力,因而清漆能更好地填充在基材的细胞腔里。从SEM图中也能清晰地看到涂饰前后的差别。在未涂饰基材图(图2a、2b)中可以看到有较大的导管存在基材的横切面上,而纵切面上较多的则是裸露的细胞腔,基材表面裸露的细胞腔为水性漆在基材表面良好的附着性能提供了一定的基础。基材涂饰清漆和色漆后(图2c、2d),沟槽状的细胞腔和细胞胞间层中都有成膜物填充,因而达到较强的附着力。且从图2c、2d中也能看出:因清漆的渗透性能更好,使得在相同涂布量下,色漆的漆膜厚度明显高于清漆。此外,竹集成材水性清漆涂饰的漆膜附着力与之前研究的木材水性漆涂饰的附着力相当[12]。这也再次证明了使用“三低一面”的喷涂涂饰工艺能达到较好的漆膜性能。

2.2 光泽度

漆膜的光反射能力是通过漆膜的光泽度来衡量的,在一定范围内,随着竹材基材的表面光泽度增加,视觉效果变好[17]。涂饰前后基材的光泽度一般区分为垂直竹材纹理的光泽度值(gloss value of vertical bamboo texture,GZT)和平行竹材纹理的光泽度值(gloss value of parallel bamboo texture,GZL)。由图3可得涂饰后试样光泽度明显高于未涂饰试样,这是因为水性漆成膜物的光泽度比竹材自身的光泽度高。清漆涂饰后的平均GZT和GZL分别为19.83和21.24,色漆涂饰后的分别为21.39和22.93,均比未涂饰时提高了5倍以上,大大提升了竹集成材的装饰效果。且色漆因颜料填料含量较高,成膜物质在竹材表面固着占比更多,从而使得色漆光泽度均高于清漆。通过进一步对比发现试样的GZL均高于GZT,这是因为竹材大多数细胞是轴向排列的,在平行纹理方向,大部分细胞被剖开,细胞腔呈沟槽状暴露出来,因此成膜物容易填充到腔径大的细胞腔中;细胞壁的相对含量在垂直纹理方向上较多,因此成膜物很难渗透到具有纳米级孔的细胞壁中,导致平行纹理方向上成膜物的含量高于垂直纹理方向上的含量,因此其光泽度也显著增加[18-19]。

![]() 图 3 基材涂饰前后光泽度GZT为光泽度仪垂直于木材纹理方向时所测得的光泽度值;GZL为光泽度仪平行于木材纹理方向时所测得的光泽度值。 GZT is the glossiness value measured when glossmeter is perpendicular to the direction of wood texture. GZL is the glossiness value measured when glossmeter is parallel to the direction of wood texture.Figure 3. Glossiness of substrate before and after painting

图 3 基材涂饰前后光泽度GZT为光泽度仪垂直于木材纹理方向时所测得的光泽度值;GZL为光泽度仪平行于木材纹理方向时所测得的光泽度值。 GZT is the glossiness value measured when glossmeter is perpendicular to the direction of wood texture. GZL is the glossiness value measured when glossmeter is parallel to the direction of wood texture.Figure 3. Glossiness of substrate before and after painting2.3 表面粗糙度

表面粗糙度是指竹材在加工的过程中表面留下的各种不同程度的微观加工痕迹或不平度,常被用来评价竹材表面的质量,将会直接影响竹材的涂饰效果以及涂料的用量,常用轮廓算数平均偏差Ra、轮廓算数均方偏差Rq、微观不平度十点高度Rz和轮廓最大高度Ry表示[20]。本实验主要采用Ra表征试样的表面粗糙度,Ra的值越小,说明其表面越光滑平整。不同涂饰情况对应试样的表面粗糙度和电镜图见图4和图5。涂饰后的Ra值均小于未涂饰的Ra值,从SEM图也可以清楚地看出基材裸露的细胞腔被水性漆覆盖,表面粗糙度降低。且清漆涂饰后的Ra值比色漆涂饰后的Ra值小。这是因为色漆中含有颜料颗粒(图5b),可能影响成膜的交联程度,这导致涂饰色漆后表面粗糙度高于涂饰清漆后的表面粗糙度。

![]() 图 4 涂饰前后试样表面粗糙度平均值Ra为评定轮廓的算数平均偏差; Rz为微观不平度十点高度,是指在取样长度内5 个最大的轮廓峰高的平均;Rq为评定轮廓的算数均方偏差;Ry为轮廓最大高度,是指在取样长度内,轮廓峰顶线和轮廓谷底线之间的距离。Ra is the arithmetical mean deviation of assessed profile; Rz is the height of ten points of micro unevenness, which refers to the average of five maximum contour peak heights within the sampling length; Rq is the root mean square deviation of the assessed profile; Ry is the maximum height of profile, which refers to the distance between the contour peak line and the contour bottom line within the sampling length.Figure 4. Surface roughness of substrate before and after painting

图 4 涂饰前后试样表面粗糙度平均值Ra为评定轮廓的算数平均偏差; Rz为微观不平度十点高度,是指在取样长度内5 个最大的轮廓峰高的平均;Rq为评定轮廓的算数均方偏差;Ry为轮廓最大高度,是指在取样长度内,轮廓峰顶线和轮廓谷底线之间的距离。Ra is the arithmetical mean deviation of assessed profile; Rz is the height of ten points of micro unevenness, which refers to the average of five maximum contour peak heights within the sampling length; Rq is the root mean square deviation of the assessed profile; Ry is the maximum height of profile, which refers to the distance between the contour peak line and the contour bottom line within the sampling length.Figure 4. Surface roughness of substrate before and after painting2.4 色度值

色差是指两种颜色之间的差异。色差值是色差的数值表达。色差和色差值受涂料成分、涂饰工艺等因素的影响[21]。涂膜前后的色度值变化如图6所示。涂饰清漆前L*值为72.38,涂饰清漆后降低至64.37;a*值由原来的7.03增加到10.12;b*值由24.48增加到30.64。结果表明,涂层后基材表面明度略有下降,红色和黄色指数略有增加。ΔE较小为10.56,说明涂饰清漆前后竹集成材的表面颜色相差不大。这是因为水性清漆不含颜料,在竹集成材表面固化后是透明的,能较好地保持竹集成材本身的颜色。而涂饰色漆后L*值降低至34.74;a*值增加到12.03;b*值降低至18.30。说明涂层后基材表面明度有一定程度的下降,红色和蓝色指数略有增加。ΔE值较大,为38.46,这表明竹集成材表面的色彩特征因色漆中颜料的颜色发生了较大程度的改变。

2.5 FTIR分析

图7显示了各试样的FTIR,可以看出:3 436 cm−1处吸收峰是由−OH伸缩振动引起的,与其他谱线相比,竹材谱线在这一位置的峰值明显最强,且涂饰后色漆和清漆在1 724 cm−1处(C=O的拉伸振动特征峰)的强度分别较纯色漆与清漆小得多,在1 143 cm−1处(酯基中C−O伸缩振动峰)的峰值比竹材谱线的更强,说明水性漆中的极性分子(如羧基、羟基)与基材中的羟基结合后,水性底漆中的羧基与基材中的羟基发生了酯化反应,两者之间形成了氢键使结合更加稳固[22-23]。此外色漆在2 921 cm−1(−CH2反对称伸缩振动峰)、1 724 cm−1(C=O的拉伸振动特征峰)、1 460 cm−1(−CH2弯曲振动峰)、1 143 cm−1(C−O伸缩振动)处的峰值均比清漆所在的峰值高,这是由于色漆中相应的基团的占比比清漆中的高。所以水性底漆除物理结合外,还会与基材发生化学反应,使成膜物能很好地附着在竹集成材表面。

3. 结 论

本研究所获得的清漆的漆膜硬度为1H,色漆的漆膜硬度为2H。涂饰后,水性漆与竹集成材以机械互锁的物理形式和化学反应结合的形式使成膜物质能很好地附着在基材表面。由于色漆中含有颜料,清漆的附着性能优于色漆,可达最高的0级,与木材水性涂饰的附着性能相当。而颜料颗粒的存在影响了成膜的交联程度,使得色漆的表面粗糙度高于清漆。清漆和色漆涂饰后基材的光泽度提高了5倍以上,且平行纹理方向上的光泽度高于垂直纹理方向上。因色漆含有颜料,清漆涂饰前后总色差值较低,较好地保持了竹集成材本身优美的颜色。因此,本水性涂饰工艺在竹集成材上能获得较好的漆膜性能和较强的附着力,并能在很大程度上提升了竹集成材的装饰效果,为竹材及其制品的水性化涂装提供了重要的理论和技术支持。

-

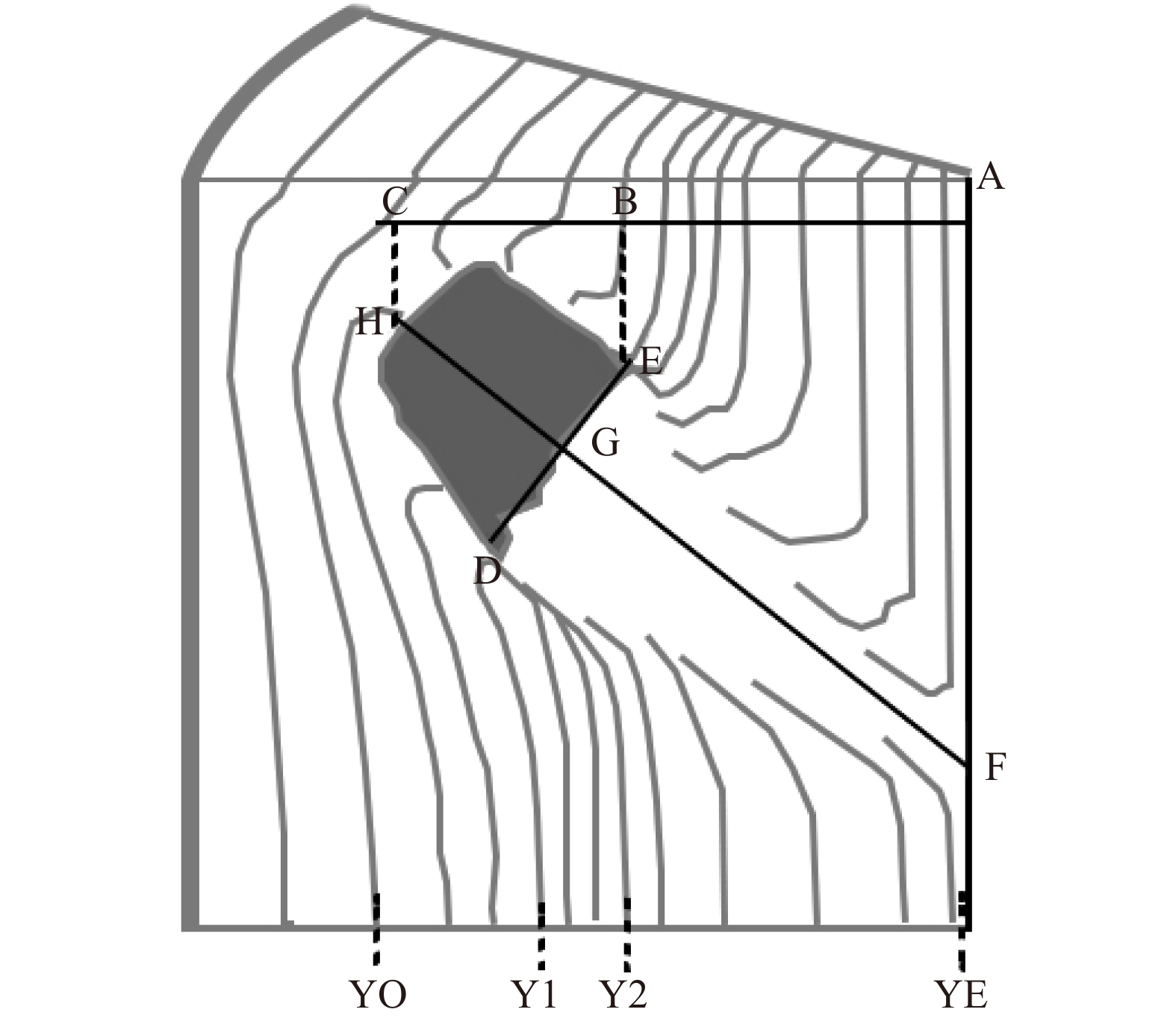

图 1 节子剖面

¯AB:活节半径;¯BC:死节半径;¯AC:节子总半径;¯DE:节子直径;∠AFG:节子着生角度;FH:节子髓心;AF:树干髓心;YE:节子形成年份;Y1:节子开始愈合的年份;Y2:节子径向生长的最后年份;YD:节子死亡年份,YD =(Y1 + Y2)/2;YO:节子完全愈合年份;¯GH:节子变色长度。其中,线段FH与DE相互垂直,G点是线段DE的中点,灰色区域表示死节和变色部分。节子剖面图参考文献[7]。¯AB:radius of live knot;¯BC:radius of dead knot;¯AC: total radius of knot;¯DE:knot diameter;∠AFG:insertion angle of knot;FH:knot pith;AF:stem pith;YE:emergencing year of knot;Y1:the year of knot occlusion beginning;Y2:the last year of radial growth of knot; YD:death year of knot,YD =(Y1 + Y2)/2;YO:completely occluding year of knot;¯GH:discoloration length of knot. Among which, the line segment FH is perpendicular to DE, and the G spot is the midpoint of line segment DE. The grey area represents the dead knot and discoloration part. Knot profile refers to reference [7].

Figure 1. Knot profile

表 1 水曲柳人工林样地和样木因子统计表

Table 1 Statistics in sample plots and sample tree factors for Fraxinus mandshurica plantation

因子 Factor 变量 Variable 最小值 ~ 最大值 Min. − Max. 平均值 Mean 标准差 SD 样地因子

Sample plot factor树高 Tree height/m 7.40 ~ 31.90 18.36 4.01 胸径 DBH/cm 8.32 ~ 25.01 15.29 3.40 冠幅 Crown width/m 1.50 ~ 9.31 4.42 1.34 冠长 Crown length/m 1.70 ~ 21.20 9.10 3.67 冠基 Crown base/m 3.10 ~ 15.20 9.26 2.32 样木因子

Sample tree factor树高 Tree height/m 14.40 ~ 26.00 19.54 3.10 胸径 DBH/cm 8.38 ~ 24.63 15.84 3.55 冠幅 Crown width/m 2.00 ~ 5.80 4.23 0.98 冠长 Crown length/m 4.70 ~ 18.40 9.85 3.54 冠基 Crown base/m 3.10 ~ 14.60 9.68 3.09 注:样地因子的样本数为312株,样木因子的样本数为16株。Notes:the sample numbers of sample plot factors and sample tree factors are 312 and 16, respectively. 表 2 水曲柳人工林节子属性统计表

Table 2 Statistics in knot variables for F. mandshurica plantation

n = 372 节子属性 Knot variable 最小值 ~ 最大值 Min. − Max. 平均值 Mean 标准差 SD 节子着生高度 Insertion height of knot (IH) /m 0.5 ~ 14.6 5.7 3.2 节子着生角度 Insertion angle of knot (IA))/(°) 16 ~ 86 52 13 节子直径 Knot diameter (KD) /mm 2.45 ~ 28.43 9.43 4.98 死节半径 Radius of dead knot (DKR) /mm 3.76 ~ 50.57 17.54 7.06 节子形成年份/a Emergencing year of knot (YE) /year 1 ~ 9 2 1 节子死亡年份/a Death year of knot (YD) /year 4 ~ 27 10 3 节子完全愈合年份/a Completely occluding year of knot (YO)/year 6 ~ 34 17 5 节子愈合时间/a Occlusion time of knot (OT) /year 1 ~ 17 7 3 节子变色长度 Discoloration length of knot (DL)/mm 5.08 ~ 116.77 30.93 18.68 表 3 节子变色长度模型参数估计值和拟合统计量

Table 3 Estimated parameter values and fitted statistics values of DL model

参数

Parameter估计值

Estimated valueSD t值

t valueP 残差平方和

Residual sum of squaresR2 a0 − 7.523 2.397 − 3.138 0.002 57 715.334 0.556 a1 1.557 0.186 8.374 0.000 a2 0.382 0.088 4.348 0.000 a3 1.140 0.312 3.648 0.000 注:a0是常数,a1、a2和a3分别是模型中节子直径、节子总半径和节子愈合时间的参数。Notes:a0 is constant, a1, a2 and a3 are the parameters of KD, TRK and OT, respectively in the model. -

[1] Sohngen B, Mendelsohn R, Sedjo R. A global model of climate change impacts on timber markets[J]. Journal of Agricultural and Resource Economics, 2001, 26(2): 326−343.

[2] Mäkinen H. Effect of stand density on the branch development of silver birch (<italic>Betula pendula</italic> Roth) in central Finland[J]. Trees, 2002, 16(4): 346−353. doi: 10.1007/s00468-002-0162-x

[3] Alcorn P J, Bauhus J, Thomas D S, et al. Photosynthetic response to green crown pruning in young plantation-grown <italic>Eucalyptus pilularis</italic> and <italic>E. cloeziana</italic>[J]. Forest Ecology and Management, 2008, 255(11): 3827−3838. doi: 10.1016/j.foreco.2008.03.030

[4] Lowell E C, Maguire D A, Briggs D G, et al. Effects of silviculture and genetics on branch/knot attributes of coastal pacific northwest Douglas-fir and implications for wood quality:a synthesis[J]. Forests, 2014, 5(7): 1717−1736. doi: 10.3390/f5071717

[5] Vestøl G I, Høibø O A. Prediction of knot diameter in <italic>Picea abies</italic> (L.) Karst[J]. Holz Als Roh-Und Werkstoff, 2001, 59(1−2): 129−136.

[6] Hein S, Spiecker H. Comparative analysis of occluded branch characteristics for <italic>Fraxinus excelsior</italic> and <italic>Acer pseudoplatanus</italic> with natural and artificial pruning[J]. Canadian Journal of Forest Research, 2007, 37(8): 1414−1426. doi: 10.1139/X06-308

[7] Hein S. Knot attributes and occlusion of naturally pruned branches of <italic>Fagus sylvatica</italic>[J]. Forest Ecology and Management, 2008, 256(12): 2046−2057. doi: 10.1016/j.foreco.2008.07.033

[8] Wang C S, Zhao Z G, Hein S, et al. Effect of planting density on knot attributes and branch occlusion of <italic>Betula alnoides</italic> under natural pruning in southern China[J]. Forests, 2015, 6(12): 1343−1361.

[9] Hemery G, Spiecker H, Aldinger E, et al. COST Action E42 : growing valuable broadleaved tree species[R/OL]. Berlin: ResearchGate, 2008[2019−12−25]. https://www.researchgate.net/publication/235710146.

[10] Oosterbaan A, Hochbichler E, Nicolescu V N, et al. Silvicultural principles, goals and measures in growing valuable broadleaved tree species[J]. Die Bodenkultur, 2009, 60(3): 45−51.

[11] Gerrand A M, Neilsen W A, Medhurst J L. Thinning and pruning eucalypt plantations for sawlog production in Tasmania[J]. Tasforests, 1997, 9: 15−34.

[12] Wardlaw T J, Neilsen W A. Decay and other defects associated with pruned branches of <italic>Eucalyptus nitens</italic>[J]. Tasforests, 1999, 11: 49−57.

[13] Wiseman D, Smethurst P, Pinkard L, et al. Pruning and fertiliser effects on branch size and decay in two <italic>Eucalyptus nitens</italic> plantations[J]. Forest Ecology and Management, 2006, 225(1): 123−133.

[14] Sandi M, Sandi W, Nicolescu V N. Wood discoloration in relation to wound size in northern red oak (<italic>Quercus rubra</italic> L.) trees subject to artificial pruning[J]. Spanish Journal of Rural Development, 2012, 3(1): 53−60.

[15] Metzler B. Quantitative assessment of fungal colonization in Norway spruce after green pruning[J]. Forest Pathology, 1997, 27(1): 1−11. doi: 10.1111/j.1439-0329.1997.tb00848.x

[16] Dănescu A, Ehring A, Bauhus J, et al. Modelling discoloration and duration of branch occlusion following green pruning in <italic>Acer pseudoplatanus</italic> and <italic>Fraxinus excelsior</italic>[J]. Forest Ecology and Management, 2015, 335: 87−98. doi: 10.1016/j.foreco.2014.09.027

[17] Wang C S, Hein S, Zhao Z G, et al. Branch occlusion and discoloration of <italic>Betula alnoides</italic> under artificial and natural pruning[J]. Forest Ecology and Management, 2016, 375: 200−210. doi: 10.1016/j.foreco.2016.05.027

[18] Mäkinen H, Ojansuu R, Sairanen P, et al. Predicting branch characteristics of Norway spruce (<italic>Picea abies</italic> (L.) Karst.) from simple stand and tree measurements[J]. Forestry, 2003, 76(5): 525−546. doi: 10.1093/forestry/76.5.525

[19] Petruncio M, Briggs D, Barbour R J. Predicting pruned branch stub occlusion in young, coastal Douglas-fir[J]. Canadian Journal of Forest Research, 1997, 27(7): 1074−1082. doi: 10.1139/x97-037

[20] Trincado G, Burkhart H E. A framework for modeling the dynamics of first-order branches and spatial distribution of knots in loblolly pine trees[J]. Canadian Journal of Forest Research, 2009, 39(39): 566−579. doi: 10.1139/X08-189

[21] Grotta A T, Gartner B L, Radosevich S R. Influence of species proportion and timing of establishment on stem quality in mixed red alder and Douglas-fir plantations[J]. Canadian Journal of Forest Research, 2004, 34(4): 863−873. doi: 10.1139/x03-259

[22] 陈东升, 孙晓梅, 李凤日, 等. 落叶松人工林节子内部特征变化规律研究[J]. 北京林业大学学报, 2015, 37(2):16−23. Chen D S, Sun X M, Li F R, et al. Changes of the internal characteristics of knots in larch plantation[J]. Journal of Beijing Forestry University, 2015, 37(2): 16−23.

[23] Qin G M, Hao J, Yang J C, et al. Branch occlusion and discoloration under the natural pruning of Mytilaria laosensis[J/OL]. Forests, 2019, 10(10): 892 [2019−12−10]. https://www.researchgate.net/publication/336403320.

[24] 范志强, 沈海龙, 王庆成, 等. 水曲柳幼林适生立地条件研究[J]. 林业科学, 2002, 38(2):38−43. doi: 10.3321/j.issn:1001-7488.2002.02.008 Fan Z Q, Shen H L, Wang Q C, et al. Study on the site conditions suitable for young plantation of <italic>Fraxinus mandshurica</italic>[J]. Scientia Silvae Sinicae, 2002, 38(2): 38−43. doi: 10.3321/j.issn:1001-7488.2002.02.008

[25] 郝玉琢, 王树力. 水曲柳人工纯林与混交林土壤生态化学计量特征的比较[J]. 东北林业大学学报, 2018, 46(3):54−58. Hao Y Z, Wang S L. Soil ecological stoichiometric characteristics between pure <italic>Fraxinus mandshurica</italic> plantation and mixed <italic>F. mandshurica</italic> plantation[J]. Journal of Northeast Forestry University, 2018, 46(3): 54−58.

[26] 那萌, 刘婷岩, 张彦东, 等. 林分密度对水曲柳人工林碳储量的影响[J]. 北京林业大学学报, 2017, 39(1):20−26. Na M, Liu T Y, Zhang Y D, et al. Effects of stock density on carbon storage in <italic>Fraxinus mandshurica</italic> plantations[J]. Journal of Beijing Forestry University, 2017, 39(1): 20−26.

[27] 郝建, 蒙明君, 黄德卫, 等. 格木人工林节子的分布特征及预测模型[J]. 南京林业大学学报(自然科学版), 2017, 41(3):100−104. Hao J, Meng M J, Huang D W, et al. Distribution and statistical analysis of knots in <italic>Erythrophleum fordii</italic> plantations[J]. Journal of Nanjing Forestry University (Natural Sciences Edition), 2017, 41(3): 100−104.

[28] Hein S, Weiskittel A R, Kohnle U. Effect of wide spacing on tree growth, branch and sapwood properties of young Douglas-fir (<italic>P</italic>s<italic>eudotsuga menziesii</italic> (Mirb.) Franco) in south-western Germany[J]. European Journal of Forest Research, 2008, 127(6): 481−493.

[29] Weiskittel A R, Maguire D A, Monserud R A. Response of branch growth and mortality to silvicultural treatments in coastal Douglas-fir plantations: implications for predicting tree growth[J]. Forest Ecology and Management, 2007, 251(3):182-194.

[30] 王春胜. 西南桦人工中幼林密度效应和修枝研究[D]. 北京: 中国林业科学研究院, 2015. Wang C S. Studies on the effect of planting density and artificial pruning on young and middle aged Betula alnoides plantation[D]. Beijing: Chinese Academy of Forestry, 2015.

[31] Forrester D I, Baker T G. Growth responses to thinning and pruning in <italic>Eucalyptus globulus</italic>, <italic>Eucalyptus nitens</italic>, and <italic>Eucalyptus grandis</italic> plantations in southeastern Australia[J]. Canadian Journal of Forest Research, 2012, 42(1): 75−87. doi: 10.1139/x11-146

[32] Forrester D I, Collopy J J, Beadle C L, et al. Effect of thinning, pruning and nitrogen fertiliser application on light interception and light-use efficiency in a young <italic>Eucalyptus nitens</italic> plantation[J]. Forest Ecology and Management, 2013, 288: 21−30.

[33] Wang C S, Zeng J, Hein S, et al. Crown and branch attributes of mid-aged <italic>Betula alnoides</italic> plantations in response to planting density[J]. Scandinavian Journal of Forest Research, 2017, 32(8): 679−687. doi: 10.1080/02827581.2016.1261936

[34] Wang C S, Tang C, Hein S, et al. Branch development of five-year-old Betula alnoides plantations in response to planting density[J/OL]. Forests, 2018, 9(1): 42[2019−12−10]. https://www.sci-hub.pl/10.3390/f9010042.

[35] 王志海, 尹光天, 杨锦昌, 等. 不同造林密度对米老排人工林枝条发育的影响[J]. 林业科学研究, 2019, 32(2):78−86. Wang Z H, Yin G T, Yang J C, et al. Effects of planting density on branch development of <italic>Mytilaria laosensis</italic> plantations[J]. Forest Research, 2019, 32(2): 78−86.

-

期刊类型引用(2)

1. 谷国泽,宋魁彦. 水性清漆涂饰对皮影表面的装饰效果. 家具. 2025(01): 19-22 .  百度学术

百度学术

2. 钟成龙,侯贤锋,卓光武,高振忠,涂登云,胡传双. 重组竹表面涂饰工艺研究. 竹子学报. 2023(02): 41-47 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: