Research of electric pole saw based on ergonomics

-

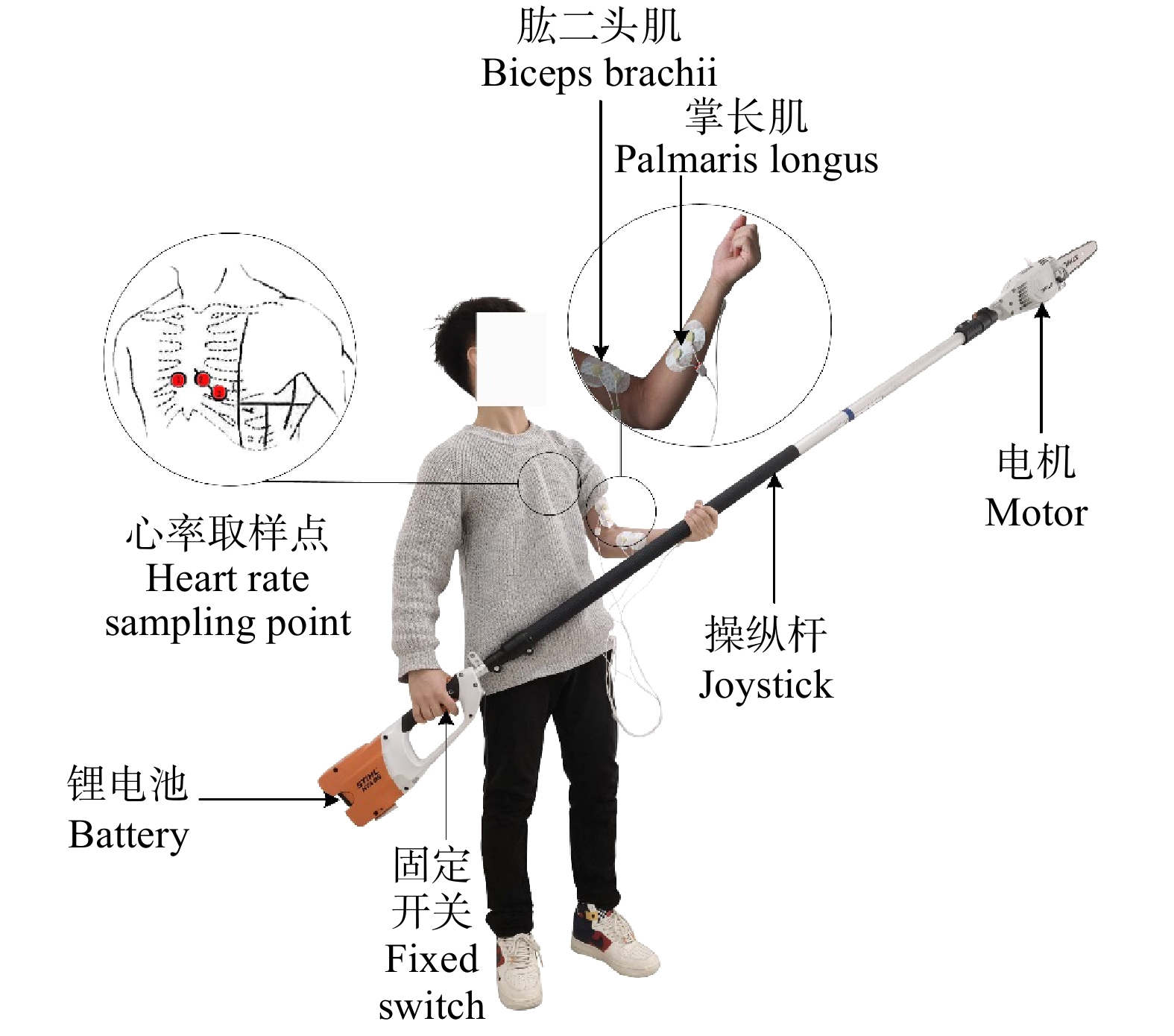

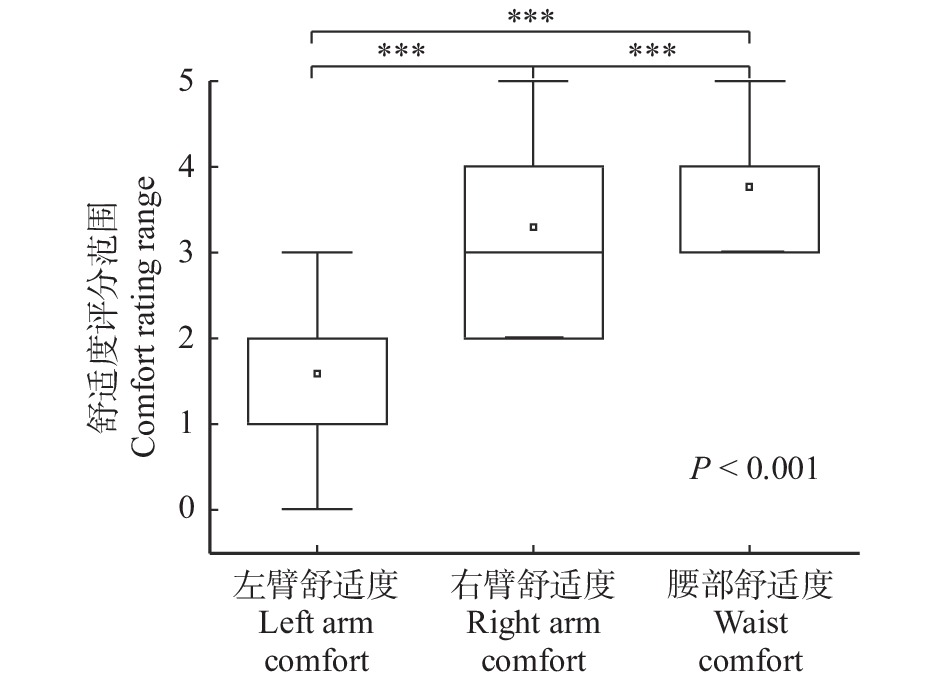

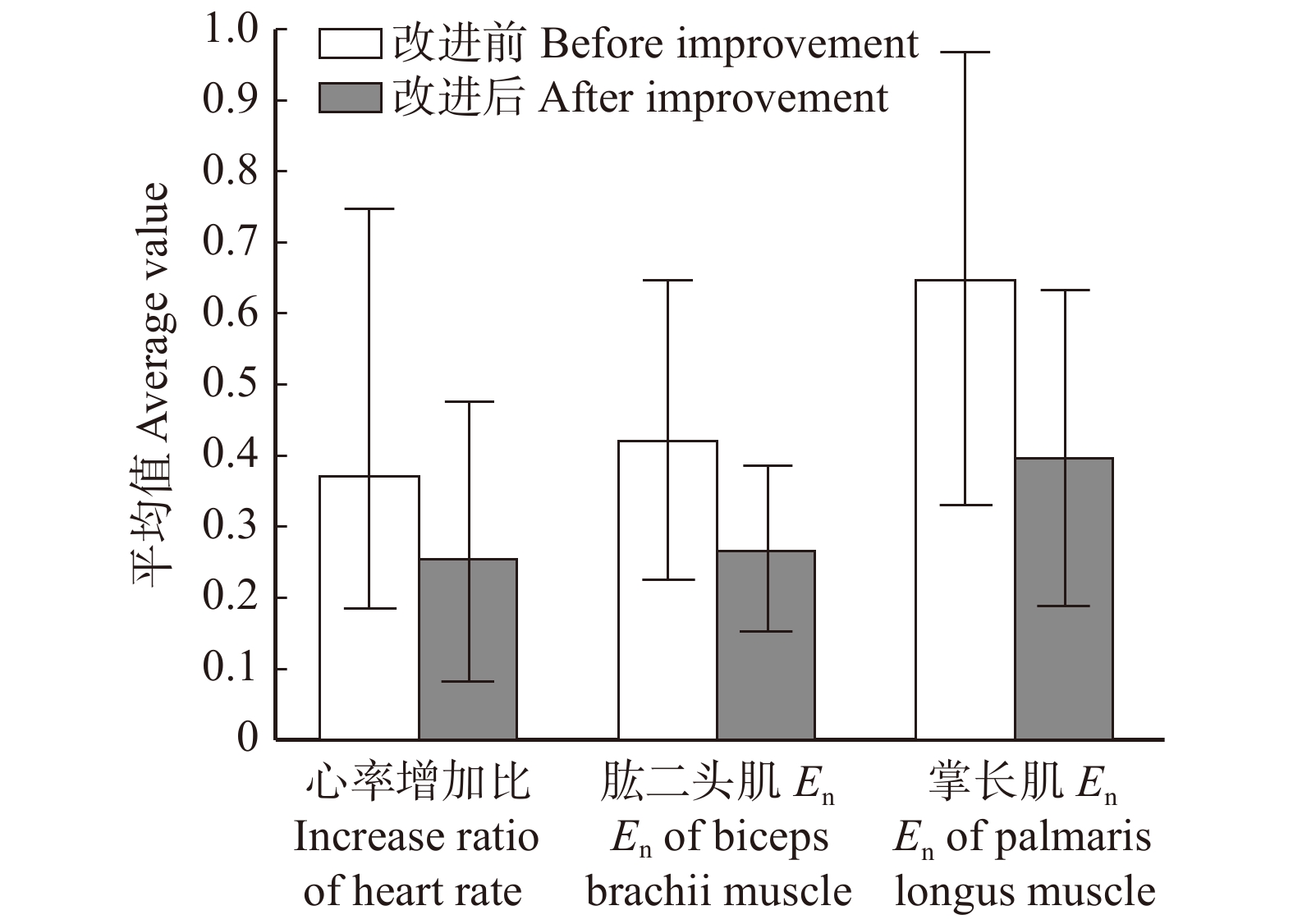

摘要:目的 在林木剪枝作业环节中,高枝杆锯作为一种高效便捷的工具降低了林业工人爬树剪枝的风险。本研究对市场上典型的电动高枝杆锯进行人机工程学评价,针对其缺陷提出了一种增加可移动手柄的改进方案,通过对比实验来证明改进方案的有效性,为同类型工具提供改进思路。方法 可移动手柄通过改变握持点到重心的距离,调节工具本身重量对手臂及全身的疲劳负荷。实验选取17名男性操作者,收集操作原有电动高枝杆锯过程中被试人员的心率,肱二头肌和掌长肌的表面肌电信号,握持距离和主观评价结果等数据来选择改进方案。同等实验条件下,对比改进后的实验数据,确定改进效果。结果 改进前被试人员的心率增加比均大于18%,表明人体全身疲劳负荷过大。肱二头肌和掌长肌归一化的表面肌电信号分别高于20%和30%,呈现出局部肌肉高度疲劳特征。通过配对样本t检验的方法,计算得出改进前后的心率增加比,肱二头肌和掌长肌的归一化表面肌电信号,主观评价和握持距离均有显著差异(P < 0.05)。结论 综合评价结果表明改进之后的电动高枝杆锯可以允许操作人员利用可移动手柄自由调节双手间的握持距离,从而降低手臂及全身的疲劳负荷,最终使得操作舒适性得到明显提升。改进成本控制在百元以下,提高了普遍推广的可行性。Abstract:Objective In the process of tree pruning, pole chain saw as an efficient and convenient tool effectively reduces the risk of climbing trees for forest workers. In this work, the ergonomic evaluation of typical electric pole saws in the market was carried out, and an improvement scheme with movable handle was proposed for its defects. The effectiveness of the modified scheme was proved by comparative experiments, which provided an improvement idea for the same type of tools.Method The movable handle can be used to adjust the fatigue load of the tool on the arm and the whole body by changing the distance between the holding point and the center of gravity. Seventeen males were selected to perform the experiment, during which their heart ratio, surface electromyography signals of biceps brachii and palmar longus, grip distance and subjective assessment were measured during the operation of the original electric pole saw, and to select improvements based on these data.The improvement effect was evaluated by comparing the improved experimental data with that of the control group.Result Before the improvement,the increase ratio of heart rate of the subjects was greater than 18%, indicating that the whole body fatigue load was too large. Besides, the normalized surface electromyographic signals of biceps brachii and palmar longus were higher than 20% and 30%, respectively, which revealed excessive local fatigue. By paired sample t test method, the increasing ratio of heart rate, the normalized surface electromyographic signals of biceps brachii and palmar longus, subjective assessment, and grip distance were significantly different before and after the improvement (P < 0.05).Conclusion The overall evaluation results show that the modified electric pole chain which allows the operator to adjust the grip distance between the hands freely by the movable handle can effectively reduce the fatigue load of the arm and the whole body, and finally improve the operation comfort. Moreover, the additional cost of the modification is controlled below 100 CNY, which increases the feasibility of universal promotion.

-

Keywords:

- electric pole saw /

- ergonomics /

- surface electromyography /

- heart rate /

- subjective assessment

-

异形叶性是植物在长期进化过程中,基于表型可塑性演化出的在同一植株上出现多种形态成熟叶片的现象[1]。异形叶性在水生植物中较为普遍而陆生植物中相对少见,如慈姑(Sagittaria trifolia)[2]、黄睡莲(Nuphar lutea)[3]、银杏(Ginkgo biloba)[4]等。植物作为固着生存的生物,适应环境对其生存至关重要。基于植物异形叶性的形成原因,异形叶植物成为研究植物响应环境的典型植物。在水蓑衣(Hygrophila difformis)对温度响应的研究中,发现在20 ℃时产生羽状深裂叶片,在26 ℃时产生叶缘完整的单叶[5]。异形叶植物在响应环境过程中,不仅外部形态会发生变异,其内部功能性状也产生适应性变化。对臭柏(Sabina vulgaris)的鳞叶和刺叶水分特性的比较研究中发现,鳞叶的保水及渗透调节能力较强,适应干旱的能力比刺叶强[6]。

miRNA是一类生物体内源存在的非编码RNA,一般长度介于18 ~ 24 nt之间。miRNA最早在线虫(Caenorhabditis elegans)中被发现[7],随着测序技术及生物信息学的发展,在拟南芥(Arabidopsis thaliana)[8]、玉米(Zea mays)[9]、苔藓[10]等植物中也发现了各类miRNA。研究表明,miRNA通过与靶基因结合,切割靶基因或抑制靶基因的翻译来对生物的基因表达进行转录后水平的负调控。由于植物中miRNA大多与靶基因目标区域完全互补配对,所以植物中miRNA主要通过切割靶基因来调控编码基因的表达且具有高度保守性[11]。近年的研究表明,miRNA能够响应环境的变化对植物基因表达进行调控,在植物对环境的适应中起到重要作用。耐热性较强的蕹菜(Ipomoea aquatica)经高温处理后,miR166的表达量下降[12]。水稻(Oryza sativa )经干旱处理后,miR164、miR167、miR169、miR319和miR398下调表达,相关的靶基因也同时表现为差异表达,表明miRNA通过调控靶基因而参与植物的干旱胁迫响应[13]。对盐胁迫下胡杨(Populus euphratica)miRNA表达分析发现miR156、miR157、miR165、miR166和miR167的表达量提高,表明这些miRNA及其靶基因可能参与胡杨的盐胁迫响应过程[14]。

胡杨属于杨柳科(Salicaceae)杨属(Populus),是干旱荒漠区重要的建群树种,具有较强的耐盐耐旱性,其异形叶性是胡杨环境适应性的表现。成年胡杨植株从树冠底部到顶部分布有披针形叶、卵圆形叶、锯齿卵圆形叶及其他过渡态叶片[15],各形态叶片不仅结构存在明显差异,其生理特性,如光合作用、水分生理、抗氧化酶活性等也存在显著差异。研究表明,锯齿卵圆形叶的抗氧化能力较披针形叶强,具有较强的抗逆性[16],较强的光合能力,比披针形叶更适应冠层上部的高光强环境[17],其饱和膨压渗透势和零膨压渗透势都小于披针形叶,具有较好的渗透调节能力,较适应干旱环境[18]。此外针对胡杨异形叶蛋白质组学的研究发现,与光合等相关的蛋白质在披针形叶和锯齿卵圆形叶中差异表达,表明胡杨生理特性的差异是通过其编码基因的差异表达来实现的[19]。

胡杨作为典型的木本异形叶植物,是研究植物环境适应性的良好实验材料。前期研究发现其具代表性的披针形叶和锯齿卵圆形叶在结构,生理特性,蛋白表达方面存在差异。虽有人对盐胁迫后胡杨幼苗中miRNA的表达进行了分析[14],但对于胡杨异形叶的miRNA表达特征的研究尚未见报道。本文以胡杨披针形叶和锯齿卵圆形叶为材料,利用高通量测序和生物信息学分析技术,对差异表达miRNA及其靶基因功能进行分析,以揭示胡杨叶片形态及其生理变化的分子调控机制。

1. 实验材料和研究方法

1.1 实验材料

本实验选用的典型的披针形和锯齿卵圆形成熟叶,分别取自于生长在北京林业大学苗圃的3株健康成年胡杨(树龄30年,株高9 m,胸径17 cm)的冠层下部和上部。将采集的叶片立即清理干净,每种形态叶各3份,迅速置于液氮中速冻后于− 80 ℃超低温冰箱中保存备用。

1.2 RNA提取、小RNA文库建立及高通量测序

利用Trizol法分别提取披针形叶和锯齿卵圆形叶的总RNA,每种叶片3个生物学重复,使用Nanodrop对总RNA纯度进行质检。文库制备采用TruSeq Small RNA Sample Prep Kits(Illumina, San Diego, USA)试剂盒,使用T4 RNA连接酶分别于small RNA5′端和3′端连上接头,随后进行反转录反应,对反转录产生的cDNA序列进行PCR扩增。最后,对140 ~ 160 bp长度范围的PCR产物进行胶回收,完成文库制备。对构建好的文库使用Illumina Hiseq2500测序,测序读长为单端1 × 50 bp。

1.3 数据质控及过滤

原始序列通过Illumina FastQC进行数据质量评估,获取Q30数据后,将由于样本制备、测序接头、非典型miRNA特征序列以及测序仪器光学数码处理而产生的非纯序列(N特征序列)进行清理。随后,进行长度筛选,保留碱基长度在18 ~ 25 nt的序列,再将剩余序列与各种RNA数据库序列(不包含miRNA),如mRNA、RFam(包含rRNA、 tRNA、 snRNA、 snoRNA等)和重复序列数据库(repbase)进行比对并过滤。

1.4 miRNA的鉴定

利用Bowtie软件将过滤后的小RNA有效序列与miRBase21.0数据库中胡杨miRNA成熟体和前体序列进行同源比对,鉴定样品中的已知miRNA。对未匹配上注释信息的小RNA进行新miRNA的预测,使用RNAfold软件对目标RNA位点的上下游分别延伸的120 nt长度的序列进行二级结构预测,同时通过Mireap软件进行评测,筛选二级折叠结构严格符合miRNA前体特征的序列作为预测的新miRNA。

1.5 差异表达miRNA筛选及其靶基因预测

基于鉴定的miRNA在各样本文库的相对表达丰度,利用DEGseq和DEseq R语言包进行差异表达miRNA的筛选,筛选条件设置为|log2foldchange| ≥ 1(即表达差异倍数大于2),P < 0.05。运用TargetFinder对差异表达的miRNA进行靶基因预测[20]。

1.6 靶基因的GO及KEGG分析

依据生物过程,所处细胞位置,分子功能3种GO类别,利用GO数据库(http://geneontology.org/)对差异miRNA的靶基因进行GO功能注释。采用超几何分布检验对差异miRNA的靶基因进行GO富集分析。此外,利用KEGG数据库(https://www.genome.jp/kegg/)对差异miRNA的靶基因进行代谢途径(pathway)注释,并应用超几何分布检验进行差异miRNA靶基因富集代谢途径的显著性检验。

1.7 差异表达miRNA和靶基因的实时荧光定量PCR检测

使用RNAprep Pure多糖多酚植物总RNA提取试剂盒(北京天根)提取胡杨异形叶总RNA。采用茎环引物反转录法(stem-loop RT)实时荧光定量PCR对差异表达miRNA进行表达量验证。采用实时荧光定量PCR对靶基因进行表达量检测。选取HIS和RP为内参基因[21],使用Bio-Rad Mini Opticon荧光定量PCR仪进行扩增。扩增条件设置为:95 ℃ 5 min预变性,随后95 ℃ 10 s,60 ℃ 30 s,35个循环。所有反应均进行3次重复,用2− ΔΔCT方法计算各样本相对表达量,式中,CT为阈值循环数[22]。

2. 结果与分析

2.1 胡杨异形叶miRNA测序结果统计

应用高通量测序技术,分别对胡杨披针形叶(lanceolate leaf)和锯齿卵圆形叶(dentate broad-ovate leaf)(图1)进行小RNA测序,每种叶片3个重复,共构建6个小RNA文库。如表1所示,各文库获得总原始读段(total raw reads)的数量为9 811 531 ~ 10 994 672条,唯一原始读段(unique raw reads)为830 479 ~ 1 813 462种。对数据去除测序接头、垃圾序列,并过滤掉比对至mRNA数据库,Rfam(包含rRNA、tRNA、snRNA、snoRNA等)数据库和重复序列数据库(repbase)的序列。最终获得6 008 394 ~ 8 333 317条总有效读段(total valid reads),约占总原始读段(total raw reads)的56% ~ 81%。其中得到527 874 ~ 1 130 544种唯一有效读段(unique valid reads),约占唯一原始读段(unique raw reads)的53% ~ 74%。进一步对总有效读段(total valid reads)以及唯一有效读段(unique valid reads)长度分布统计。如图2A所示,其中长度为21 nt的读段数量较多,约占总有效读段(total valid reads)的30%,而长度为21与24 nt的读段种数较多,分别约占有唯一有效读段(unique valid reads)的20%(图2B)。大部分胡杨异形叶miRNA序列长度分布在20 ~ 24 nt,符合Dicer酶切割的典型特征,可对所得的有效序列进行下一步的miRNA鉴定分析。

表 1 胡杨异形叶小RNA测序统计Table 1. sRNA sequencing data from heteromorphic leaves in P. euphratica文库 Library Lan_1 Lan_2 Lan_3 Db_1 Db_2 Db_3 总原始读段

Total raw reads10 994 672 10 095 826 9 811 531 9 849 631 10 445 363 10 587 269 唯一原始读段

Unique raw reads1 813 462 991 857 999 928 830 479 1 096 378 921 232 总3ADT及长度筛选

Total 3ADT & length filter4 491 129 3 357 910 1 750 389 1 604 935 4 096 241 1 930 624 总垃圾读段

Total junk reads28 511 11 988 15 331 15 505 12 559 16 490 总Rfam

Total Rfam168 570 95 671 79 962 93 630 53 066 112 629 总mRNA

Total mRNA300 609 128 948 131 286 148 439 143 075 196 224 总重复序列

Total repeats4 002 1 575 1 600 1 779 1 519 1 740 总有效读段

Total valid reads6 008 394 (54.65%) 6 502 632 (64.41%) 7 835 125 (79.86%) 7 988 626 (81.11%) 6 140 459 (58.79%) 8 333 317 (78.71%) 唯一有效读段

Unique valid reads1 130 544 (62.34%) 527 874 (53.22%) 745 979 (74.6%) 589 777 (71.02%) 664 491 (60.61%) 658 041 (71.43%) 注:Lan为披针形叶;Db为锯齿卵圆形叶。下同。Notes: Lan is lanceolate leaves; Db, dentate broad-ovate leaves. The same below. 2.2 miRNA的比对及预测

将过滤筛选后获得有效序列与miRBase 21.0数据库中的胡杨及近缘物种的miRNA成熟体和前体序列进行比对。如表2所示,以胡杨 作为首选物种,共鉴定得到517个已知miRNA。根据比对的匹配程度分为3个组别(group 1、group 2、group 3),其中group 1(4个)是胡杨中已报道的miRNA;group 2(513个)是在其他近缘物种中已报道的miRNA;group 3中筛选得到的127个miRNA为新预测miRNA。依据植物miRNA的5′端第1个碱基对U有较强的偏好性而对G则有抗性的特征,对检出的所有miRNA进行U碱基偏好性分析。如图3a所示,U碱基在第1位碱基中占比最高,约占55%,也远高于其他位次碱基中U碱基所占比例。而G在第1位碱基中所占比例最低,仅占10%,该比例也明显低于其他位次碱基中G碱基所占比例,表明胡杨异形叶中检测得到的miRNA符合植物miRNA的碱基偏好性特征,匹配结果准确可靠。此外进一步的家族分析发现,有389条序列能够匹配到54个已知的miRNA家族,并且匹配序列数超过10的miRNA家族有14个(图3b)。其中MIR166家族匹配到的成员数最多,为26个,其次是MIR169_1和MIR167_1家族,各匹配到21个成员。对鉴定的已知miRNA和新发现miRNA的长度进行统计,结果显示miRNA长度峰值在21 nt。其中,已知miRNA长度分布在18 ~ 25 nt,主要分布于20 ~ 22 nt区间;新发现miRNA长度在19 ~ 24 nt,主要分布于21 ~ 23 nt区间(图3c)。

表 2 胡杨异形叶miRNA鉴定统计Table 2. Statistics of miRNA identification in heteromorphic leaves of P. euphratica组别

GroupLan_1 Lan_2 Lan_3 Db_1 Db_2 Db_3 总数

Total组1

Group 13 4 3 3 3 4 4 组2

Group 2466 409 409 413 409 419 513 组3

Group 3114 79 97 98 90 97 127 ![]() 图 3 胡杨异形叶中miRNA统计分析a. 胡杨异形叶miRNA碱基偏好性分析;b. 胡杨异形叶miRNA家族统计;c. 胡杨异形叶小RNA测序鉴定的已知miRNA及新发现miRNA的长度分布。a, miRNA nucleotide bias analysis of heteromorphic leaves in P. euphratica; b, miRNA family statistics of heteromorphic leaves in P. euphratica; c, length distribution of known miRNAs and novel miRNAs identified from sRNA sequencing for heteromorphic leaves in P. euphratica.Figure 3. Statistical analysis of miRNA identified in heteromorphicleaves of P. euphratica

图 3 胡杨异形叶中miRNA统计分析a. 胡杨异形叶miRNA碱基偏好性分析;b. 胡杨异形叶miRNA家族统计;c. 胡杨异形叶小RNA测序鉴定的已知miRNA及新发现miRNA的长度分布。a, miRNA nucleotide bias analysis of heteromorphic leaves in P. euphratica; b, miRNA family statistics of heteromorphic leaves in P. euphratica; c, length distribution of known miRNAs and novel miRNAs identified from sRNA sequencing for heteromorphic leaves in P. euphratica.Figure 3. Statistical analysis of miRNA identified in heteromorphicleaves of P. euphratica2.3 差异miRNA鉴定

基于miRNA比对结果,对miRNA在两种异形叶中的表达进行统计。通过维恩图分析(图4A、4B)可知,在披针形叶片组内鉴定出419个miRNA,在锯齿卵圆形叶片组内鉴定出411个miRNA。在两种异形叶中共同检出的miRNA数量为369个。此外50个miRNA在披针形叶中特异性表达,42个miRNA在锯齿卵圆形叶中特异性表达(图4C)。基于miRNA在各样本中的表达丰度进行miRNA差异表达分析,结果发现共有22个miRNA在披针形叶与锯齿卵圆形叶中差异表达,其中包括植物中保守的miR167、miR172、miR166、miR169、miR168、miR160等。与披针形叶相比,miR167、miR172、miR166等7个miRNA在锯齿卵圆形叶中上调表达,miR169、miR168、miR160等15个miRNA下调表达(图4D)。

![]() 图 4 胡杨异形叶miRNA检测的韦恩图及差异表达miRNAA. 披针形叶片miRNA检测的韦恩图分析;B. 锯齿卵圆形叶片miRNA检测的韦恩图分析;C. 锯齿卵圆形与披针形叶片比较组中miRNA检测的韦恩图分析;D. 锯齿卵圆形与披针形叶片比较组中差异表达miRNA。A, Venn diagram of miRNA detected in lanceolate leaves; B, Venn diagram of miRNA detected in dentate broad-ovate leaves; C,Venn diagram of miRNA detected in dentate broad-ovate leaves vs lanceolate leaves group; D, differentially expressed miRNAs in dentate broad-ovate leaves vs lanceolate leaves group. Lan, lanceolate leaves; Db, dentate broad-ovate leaves.Figure 4. Venn diagram of miRNA detected and differentially expressed miRNAs in heteromorphic leaves of P. euphratica

图 4 胡杨异形叶miRNA检测的韦恩图及差异表达miRNAA. 披针形叶片miRNA检测的韦恩图分析;B. 锯齿卵圆形叶片miRNA检测的韦恩图分析;C. 锯齿卵圆形与披针形叶片比较组中miRNA检测的韦恩图分析;D. 锯齿卵圆形与披针形叶片比较组中差异表达miRNA。A, Venn diagram of miRNA detected in lanceolate leaves; B, Venn diagram of miRNA detected in dentate broad-ovate leaves; C,Venn diagram of miRNA detected in dentate broad-ovate leaves vs lanceolate leaves group; D, differentially expressed miRNAs in dentate broad-ovate leaves vs lanceolate leaves group. Lan, lanceolate leaves; Db, dentate broad-ovate leaves.Figure 4. Venn diagram of miRNA detected and differentially expressed miRNAs in heteromorphic leaves of P. euphratica2.4 靶基因的GO注释

miRNA通过对靶基因表达的调控来影响植物的各项生命活动,为揭示miRNA在胡杨异形叶中的作用,本研究采用TargetFinder软件对胡杨异形叶中差异表达的miRNA进行靶基因预测,并利用GO数据库信息对差异miRNA的靶基因进行功能注释。基于GO三类本体的分类,如图5所示,在生物过程(biological_process)大类中,异形叶差异miRNA的靶基因主要分布在生物过程(29个),转录调控-DNA模板(regulation of transcription, DNA-templated)(24个),转录-DNA模板(transcription, DNA-templated)(21个)等GO条目中。在所处的细胞位置(cellular component)大类中,差异miRNA的靶基因聚集在细胞核(nucleus)(83个),质膜(plasma membrane)(48个),细胞质(cytoplasm)(44个)等GO条目中。对于分子功能(molecular_function)大类,差异miRNA的靶基因集中在序列特异性DNA结合转录因子活性(sequence-specific DNA binding transcription factor activity)(15个),DNA结合(DNA binding)(15个),蛋白结合(protein binding)(14个)等条目中。

2.5 靶基因的GO及KEGG富集分析

为找出差异miRNA的靶基因中显著富集的GO条目,本研究对异形叶差异miRNA靶基因进行GO富集分析。如图6A所示,差异miRNA的靶基因主要富集于细胞对盐胁迫的响应(cellular response to salt stress),磷脂酰肌醇脱磷酸作用(phosphatidylinositol dephosphorylation),mRNA剪接位点选择(mRNA splice site selection)等GO条目。为进一步阐明差异miRNA的靶基因主要参与的代谢途径,对异形叶差异miRNA靶基因进行了KEGG通路富集性分析,发现差异miRNA的靶基因主要参与RNA降解(RNA degradation),磷酸肌醇代谢(inositol phosphate metabolism),角质、软木脂和蜡的生物合成(cutin, suberine and wax biosynthesis),碱基切除修复(base excision repair)等代谢途径(图6B)。这些结果表明胡杨异形叶中的差异miRNA可能通过调控参与以上过程的靶基因的表达来影响异形叶发育及响应环境。

![]() 图 6 差异miRNA靶基因的GO及KEGG通路富集性分析A. 差异miRNA靶基因的GO富集性分析;B. 差异miRNA靶基因的KEGG通路富集性分析。A, analysis of GO enrichment of genes targeted by differentially expressed miRNAs; B, analysis of KEGG pathway enrichment of genes targeted by differentially expressed miRNAs.Figure 6. Analysis of GO enrichment and KEGG pathway enrichment of genes targeted by differentially expressed miRNAs

图 6 差异miRNA靶基因的GO及KEGG通路富集性分析A. 差异miRNA靶基因的GO富集性分析;B. 差异miRNA靶基因的KEGG通路富集性分析。A, analysis of GO enrichment of genes targeted by differentially expressed miRNAs; B, analysis of KEGG pathway enrichment of genes targeted by differentially expressed miRNAs.Figure 6. Analysis of GO enrichment and KEGG pathway enrichment of genes targeted by differentially expressed miRNAs2.6 异形叶发育及环境响应相关靶基因

异形叶差异miRNA的靶基因中包含各类与发育及环境响应相关的转录因子及关键基因。如表3所示,锯齿卵圆形叶中下调表达的miR169参与调控3个核转录因子Y(XM_011048135.1、XM_011048134.1、XM_011048132.1)和两个GATA转录因子(XM_011024766.1、XM_011024764.1)的表达。下调表达的miR396能够调控F-box蛋白(XM_011046985.1)的表达。此外,miR167的靶基因中包含4个bHLH转录因子(XM_011030586.1、XM_011030585.1、XM_011030587.1、XM_011026286.1)和5个E3泛素蛋白连接酶(XM_011027709.1、XM_011027715.1、XM_011027701.1、XM_011023286.1、XM_011023287.1)。miR1450参与调控2个阳离子质子反向运输载体(XM_011028646.1、XM_011028647.1),3个ABC转运蛋白(XM_011033752.1、XM_011047107.1、XM_011047106.1)及热休克蛋白(XM_011036267.1)的表达。下调表达的miR3627可调控NAC转录因子(XM_011044984.1)的表达,影响植物的抗逆性。以上各类转录因子及关键基因在植物响应逆境及发育调控过程中发挥重要作用,表明异形叶中差异表达miRNA能够通过对靶基因的调控影响异形叶的生长发育过程及环境响应能力。

表 3 植物发育及环境响应相关的靶基因Table 3. Target genes involved in plant development and environmental response差异 miRNA

Differentially expressed miRNA差异表达

Differential expression靶基因登录号

Accession No. of target gene靶基因功能注释

Annotation of target geneptc-MIR169s-p3 下调

Down-regulatedXM_011048135.1, XM_011048134.1,

XM_011048132.1核转录因子Y

Nuclear transcription factor YXM_011024766.1, XM_011024764.1 GATA转录因子

GATA transcription factorptc-MIR396b-p3 下调

Down-regulatedXM_011046985.1 F-box蛋白

F-box proteinptc-miR167e 上调

Up-regulatedXM_011030586.1, XM_011030585.1,

XM_011030587.1, XM_011026286.1bHLH转录因子

bHLH transcription factorXM_011027709.1, XM_011027715.1,

XM_011027701.1, XM_011023286.1,

XM_011023287.1E3泛素蛋白连接酶E3

Ubiquitin-protein ligaseptc-MIR1450-p5_1ss12CG 下调

Down-regulatedXM_011028646.1, XM_011028647.1 阳离子质子反向运输载体

Cation/H(+)antiporterXM_011033752.1, XM_011047107.1,

XM_011047106.1ABC转运蛋白

ABC transporterXM_011036267.1 热休克蛋白

Heat shock proteinptc-MIR3627b-p3_2ss19TA20GA 下调

Down-regulatedXM_011044984.1 NAC转录因子

NAC transcription factor2.7 差异miRNA及靶基因表达量的qRT-PCR检测

为验证sRNA-seq结果的可靠性,利用茎环反转录法设计引物(表4),并通过实时荧光定量PCR对胡杨异形叶差异表达miRNA及对应靶基因进行表达量检测。如图7A所示,ptc-miR167e、lus-miR172j_L+1R-1、ptc-miR169q_R+1_1ss14CT、ptc-miR160b-3p、ptc-MIR6474-p3_1ss21GT在披针形叶和锯齿卵圆形叶中的表达趋势与高通量测序结果(图4D)相似,说明本次测序结果真实度较高。此外,对应的靶基因与以上差异表达miRNA在两种叶片中呈现出相反的表达趋势(图7),表明以上差异表达miRNA可能通过抑制相关靶基因的表达来参与调控异形叶形态及其生理特性。

表 4 实时荧光定量PCR引物序列Table 4. Primer sequence for quantitative real-time PCRmiRNA/mRNA 序列 Sequence (5′−3′) miRNA AGCAGGGTCCGAGGTATTC ptc-miR167e GTCGTATCCAGTGCAGGGTCCGAGGTATTCGCACTGGATACGACCAGATC ptc-miR167e CCGCGTGAAGCTGCCAGCAT lus-miR172j_L+1R-1 GTCGTATCCAGTGCAGGGTCCGAGGTATTCGCACTGGATACGACGGGAAT lus-miR172j_L+1R-1 CCGCGTGCAGCATCATCAAG ptc-miR169q_R+1_1ss14CT GTCGTATCCAGTGCAGGGTCCGAGGTATTCGCACTGGATACGACACAGGC ptc-miR169q_R+1_1ss14CT CCAGGCTAGCCAAGGACGATTT ptc-miR160b-3p GTCGTATCCAGTGCAGGGTCCGAGGTATTCGCACTGGATACGACTATGCA ptc-miR160b-3p CCAGCGTG GCGTATGAGGAGC ptc-MIR6474-p3_1ss21GT GTCGTATCCAGTGCAGGGTCCGAGGTATTCGCACTGGATACGACACTGTG ptc-MIR6474-p3_1ss21GT CCAGTCGACTATCTACGG XM_011030586.1 GATTTAGTGGAAGTTTTGCC XM_011030586.1 TAGCCTCTGTCATTTCATTG XM_011027061.1 ATGACGACGAGCACCCAA XM_011027061.1 CCATCTCAGACAATCCCTTT XM_011048135.1 CTGTTCAGGGAGCCATTT XM_011048135.1 CCATCATTCAACTCTTTCGT XM_011032166.1 CCAGGCATTGTTTATCGG XM_011032166.1 CCACAGTTGGGACATCAAGTATTA XM_011048960.1 AGTTAGTTTCAGAGGGTTGTG XM_011048960.1 CTTGTGGCAGCCATGTAG ![]() 图 7 胡杨异形叶差异表达miRNA及靶基因的表达量分析A. 差异miRNA的表达量分析;B. 差异miRNA的靶基因的表达量分析。图中误差棒表示平均值的标准偏差。A, analysis of expression level of the differentially expressed miRNAs; B, analysis of expression level of the target genes of differentially expressed miRNAs. Error bars show standard deviation of the average value.Figure 7. Analysis of expression levels of the differentially expressed miRNAs and their target genes in heteromorphic leaves of P. euphratica

图 7 胡杨异形叶差异表达miRNA及靶基因的表达量分析A. 差异miRNA的表达量分析;B. 差异miRNA的靶基因的表达量分析。图中误差棒表示平均值的标准偏差。A, analysis of expression level of the differentially expressed miRNAs; B, analysis of expression level of the target genes of differentially expressed miRNAs. Error bars show standard deviation of the average value.Figure 7. Analysis of expression levels of the differentially expressed miRNAs and their target genes in heteromorphic leaves of P. euphratica3. 讨论与结论

3.1 胡杨异形叶miRNA的差异表达及其靶基因的功能

异形叶性是植物基于表型可塑性在响应环境过程中形成的特殊现象,在植物对微环境适应以及资源利用中发挥重要的作用[1]。前期的研究表明,异形叶形态和功能特性的差异与其对所处不同微环境的适应密切相关[6, 23-24],而这些差异源于编码基因转录水平的差异表达。miRNA作为内源非编码RNA能够在转录水平对植物的基因表达进行调控,通过抑制靶编码基因的表达来参与植物的生长发育和环境响应[25]。本文通过sRNA高通量测序,建立了木本异形叶植物胡杨的披针形叶和锯齿卵圆形叶sRNA文库(表1),共鉴定获得517个已知miRNA(表2),分别属于MIR166、MIR169_1、MIR167_1等54个miRNA家族中(图3b)。这些结果表明胡杨异形叶中广泛存在各类保守miRNA,可能对异形叶形态和生理特性起着重要的调控作用。

在植物对环境响应的过程中,miRNA能够通过调控靶基因来影响植物的生理功能。本研究共鉴定获得22个在披针形叶和锯齿卵圆形叶中差异表达miRNA。基于对差异miRNA进行靶基因预测及靶基因的GO和KEGG功能分析,我们发现这些靶基因主要参与细胞对盐胁迫的响应(cellular response to salt stress),磷酸肌醇代谢(inositol phosphate metabolism),角质、软木脂和蜡的生物合成(cutin, suberine and wax biosynthesis),碱基切除修复(base excision repair)等植物逆境响应过程(图6),表明胡杨异形叶差异表达miRNA通过调控对环境适应相关靶基因的表达,影响不同形态叶片的抗逆性。这些分析结果与前期胡杨异形叶抗逆性的研究一致[16, 26-28]。磷酸肌醇代谢与植物响应胞外刺激及信号转导过程密切相关[29]。本研究发现,差异表达miRNA通过调节其靶基因参与调控磷酸肌醇代谢过程,引起两种形态叶对环境适应性的差异。表皮蜡质有利于植物叶片减少水分散失并抵御强光损伤[30]。之前研究发现胡杨的锯齿卵圆形叶比披针形叶具有更厚的蜡质层[31]。我们的研究发现,差异miRNA的靶基因在角质、软木脂和蜡的生物合成代谢途径中富集,由此推测胡杨miRNA的差异表达可能是引起胡杨锯齿卵圆形叶片蜡质层增厚的原因,从而使处于冠层上部的锯齿卵圆形叶适应其相对高光强及水分限制的微环境。碱基切除修复主要参与修复逆境对植物造成的DNA损伤,维持植物在逆境下遗传物质的稳定性[32]。本研究中,差异miRNA的靶基因在碱基切除修复途径存在富集,表明两种形态叶对DNA损伤的修复能力存在差异,锯齿卵圆形叶在逆境胁迫中能够较好地维持DNA的稳定性。胡杨不仅具有较强的抗旱性,还对盐胁迫有一定耐受性[33]。本研究中差异表达miRNA的靶基因在盐胁迫的响应功能中富集,推测锯齿卵圆形叶和披针形叶的耐盐性可能存在差异。

3.2 保守miRNA参与调控异形叶生长发育及环境响应

由于植物miRNA与靶基因结合区具有严格的序列互补性,所以植物miRNA具有功能保守性。研究发现,一些保守的miRNA在不同植物的生长调节及环境响应过程中具有相似的作用[34]。譬如,miRNA167能够参与调控植物形态发育过程,过表达水稻miR167能够使植株矮化并增大其分蘖角度[35]。本研究发现,与披针形叶相比,miR167在锯齿卵圆形叶中上调表达,推测miR167可能参与了调控胡杨异形叶的形态发育过程。此外,有研究报道miR166能够调控叶片的极性建成,最终影响叶片的形态[36]。我们的结果发现胡杨两种形态的叶片中miR166的表达存在差异,表明miR166可能影响了胡杨异形叶极性建成等叶片发育过程。因此,我们推测胡杨披针形叶和锯齿卵圆形叶显著差异的叶片形态(图1)可能与调控叶片发育的miR167和miR166在两种叶片中差异表达有关。

前期的研究表明,为了适应冠层上部相对水分亏缺的环境,胡杨锯齿卵圆形叶相对其他形态叶具有较好的抗旱性[18]。研究发现,miR172是一类能够响应水分亏缺的植物保守miRNA,过表达拟南芥miR172能够增强转基因植株对缺水条件的耐受性,减轻其生长受抑制的情况[37]。此外,大豆miR172也参与植株的水分亏缺的应答,过表达大豆miR172能增强其植株的抗旱性[38]。本研究发现,miR172在胡杨锯齿卵圆形叶中上调表达(图4D),表明miR172上调表达可能使锯齿卵圆形叶具有相对较好的抗旱保水能力。miR169参与植物对水分亏缺的应答,在对玉米[39]和水稻[13]研究中发现,植株在水分限制条件下叶片miR169呈现下调趋势。我们的结果发现,与披针形叶相比,miR169在锯齿卵圆形叶的表达量下调,表明miR169在胡杨锯齿卵圆形叶应对水分亏缺条件中起着重要作用。由于生长于冠层上部,自然光照射强度较大,通常锯齿卵圆形叶片温度也高于中下部的叶片温度[26],其对高温的耐受程度也优于披针形叶[28]。miR396参与植物的高温胁迫响应,在高温处理下,水稻中的miR396b呈现下调表达以应对高温环境[40]。本研究发现,miR396在锯齿卵圆形叶中的表达量低于披针形叶,可能与胡杨异形叶响应不同冠层温度有关。综上,差异表达miRNA可能是披针形叶和锯齿卵圆形叶之间形态差异的原因,同时也是两种形态叶表现出抗逆性强弱不同的潜在机制。与披针形叶相比,锯齿卵圆形叶更好地适应冠层上部相对水分亏缺和高温的环境。这与我们前期有关胡杨异形叶形态与生理特性的研究结果相一致。

3.3 差异miRNA的靶基因参与胡杨抗逆及异形叶发育

胡杨异形叶差异miRNA能够调控各类转录因子及重要功能基因,影响胡杨的抗逆性及异形叶发育。核转录因子Y是参与调控植物逆境响应的重要转录因子,研究表明毛果杨核转录因子Y能够增强植株对非生物胁迫的耐受性[41]。在胡杨的研究中也发现,在胡杨叶片中表达的核转录因子Y参与植株对干旱胁迫的响应[42]。本研究中,锯齿卵圆形叶中下调表达的miR169参与调控3个核转录因子Y(XM_011048135.1、XM_011048134.1、XM_011048132.1)的表达(表3),表明该形态叶具有较好的对抗干旱胁迫的能力。GATA转录因子是一类具有锌指结构的转录因子,相关研究在杨树(Populus spp.)中证明其能够调控植株的光合作用[43]。本研究中,两个GATA转录因子(XM_011024766.1、XM_011024764.1)受到miR169的调控(表3),能够参与胡杨异形叶光合作用的调控,使不同形态异形叶光合能力存在差异。F-box蛋白参与植物对逆境的响应,在胡杨的研究中发现,F-box能够受盐处理、高温、干旱等诱导,且过表达F-box能够提高胡杨的耐逆性[44]。本研究发现,锯齿卵圆形叶中下调表达的miR396参与调控F-box基因(XM_011046985.1)的表达(表3),能够使锯齿卵圆形叶中F-box基因具有较高表达量,进而使该形态叶片具有较好的抗逆性。bHLH转录因子在植物的生长发育过程中发挥重要作用,早期研究表明其参与调控拟南芥和水稻的细胞伸长和发育过程[45]。随后,在胡杨的研究中发现,胡杨bHLH转录因子参与调控植株气孔发育和光合作用[46]。本课题组前期关于胡杨异形叶的研究发现胡杨不同异形叶片气孔特征和光合特性存在差异[26]。本研究中,4个bHLH转录因子(XM_011030586.1、XM_011030585.1、XM_011030587.1、XM_011026286.1)作为锯齿卵圆形叶中上调表达的miR167的靶基因(表3),能够参与调控胡杨异形叶气孔发育及光合作用,导致不同异形叶在气孔特征和光合能力的差异。E3泛素蛋白连接酶在非生物胁迫的信号传递中具有重要作用,早先的研究表明胡杨E3泛素蛋白连接酶的表达量影响植株对干旱胁迫响应能力[47]。近期有研究通过在木本植物中的遗传转化实验,证明了胡杨E3泛素蛋白连接酶参与调控植株的抗旱性[48]。本研究发现,miR167的靶基因包含5个E3泛素蛋白连接酶基因(XM_011027709.1、XM_011027715.1、XM_011027701.1、XM_011023286.1、XM_011023287.1)(表3),表明其可能通过对E3泛素蛋白连接酶的调控影响胡杨不同异形叶的抗旱性。

一些非保守的差异表达miRNA也参与调控转录因子及重要功能基因,进而调控胡杨异形叶的抗逆性。胡杨具有较好的耐盐性,主要通过阳离子质子反向运输载体将吸收的盐离子于液泡中进行区隔化,避免盐离子对细胞质的损害[49]。近年来,相关研究也证明了胡杨阳离子质子反向运输载体在盐离子区隔化及增强植株耐盐性中的重要作用[50-51]。本研究中,锯齿卵圆形叶中下调表达的miR1450参与调控两个阳离子质子反向运输载体(XM_011028646.1、XM_011028647.1)(表3)的表达,能够使锯齿卵圆形叶具有较好的盐离子区隔化能力,增强其耐盐性。ABC转运蛋白参与植物次生代谢物的跨膜转运,其在植物表皮蜡的转运过程中发挥重要作用[52]。植物表皮蜡有利于植株抵御干旱、强光等不利环境条件,研究发现过表达ABC转运蛋白能够增加植物的表皮蜡,提升植物对非生物胁迫的耐受性[53]。胡杨异形叶表皮结构的研究发现,与披针形叶相比,胡杨锯齿卵圆形叶的表皮蜡质沉积较多[31]。本研究中,3个ABC转运蛋白(XM_011033752.1、XM_011047107.1、XM_011047106.1)(表3)受在锯齿卵圆形叶中下调的miR1450调控,能够参与胡杨异形叶表皮蜡跨膜转运,使锯齿卵圆形叶具有较多的表皮蜡质,进而具有较好的抗逆性。热休克蛋白是一种分子伴侣,能够参与植物的非生物胁迫响应。研究表明,胡杨热休克蛋白HSP70和HSP90在植株应对长期干旱胁迫过程中发挥重要作用[54]。本研究发现,锯齿卵圆形叶中下调的miR1450参与调控热休克蛋白(XM_011036267.1)(表3)的表达,能够使锯齿卵圆形叶对干旱胁迫具有较好的耐受性。NAC转录因子广泛存在于陆生植物中,主要参与植物的胁迫应答。早期研究发现,胡杨NAC转录因子能够增强转基因植株的耐盐性[55]。近期,有研究通过过表达手段同时对3个胡杨NAC转录因子进行功能研究,发现胡杨NAC转录因子提升了转基因植株的耐盐性和抗旱性[56]。本研究中,NAC转录因子(XM_011044984.1)作为在锯齿卵圆形叶中下调的miR3627的靶基因(表3),能够参与调控胡杨异形叶的抗旱性及耐盐性,使锯齿卵圆形叶对不利环境条件具有较好耐受性。以上研究结果表明,胡杨通过miRNA的差异表达能够调控各类转录因子及关键基因,影响异形叶的生长发育,使锯齿卵圆形叶具有较好的耐盐性及抗旱性。

-

表 1 实验电动高枝杆锯参数表

Table 1 Electric pole saw parameter table

名称

Name供电方式

Power

supply mode电机位置

Motor

position电机功率

Motor

power/w链条速度

Chain

speed/(m·s−1)电机转速

Motor speed/

(rad·min−1)最大切割直径

Maximum cut

diameter/cm电动锯质量

Pole saw

mass/kg电池重量

Battery

mass/kg杆长范围

Pole length

range/cm斯蒂尔

STIHL直流

Direct current锯头位置

Position of saw head1 500 13.3 7 800 30 4.5 1.7 270 ~ 390 表 2 生理数据配对样本t检验

Table 2 Paired sample t test of physiological data

测试指标

Test indicator配对差值 Paired difference t值

t valuedf P 平均值

MeanSD MSD 差值的95%置信区间

95% confidence interval of difference下限 Lower limit 上限 Upper limit 心率增加比

Increase ratio of heart rate0.108 0.120 0.029 0.046 0.170 3.707 16 0.002 肱二头肌En

En of biceps brachii muscle0.207 0.309 0.075 0.048 0.366 2.759 16 0.014 掌长肌En

En of palmaris longus muscle0.247 0.139 0.034 0.176 0.318 7.347 16 < 0.001 握持距离

Grip distance14.147 6.566 1.593 10.771 17.523 8.883 16 < 0.001 表 3 主观评价数据配对样本t检验

Table 3 Paired sample t test of subjective evaluation data

身体部位

Body part配对差值 Paired difference t 值

t valuedf P 平均值

MeanSD MSD 差值的95%置信区间

95% confidence interval of difference下限 Lower limit 上限 Upper limit 左臂 Left arm −1.471 1.007 0.244 −1.989 −0.953 −6.019 16 < 0.001 右臂 Right arm −1.235 1.200 0.291 −1.853 −0.618 −4.243 16 0.001 腰部 Waist −1.000 1.000 0.243 −1.514 −0.486 −4.123 16 0.001 -

[1] 孙健峰, 霍东飞, 李波, 等. 基于仿生微织构的电动修剪机刀具磨损性能研究[J]. 农业机械学报, 2020, 51(增刊 2):593−602. Sun J F, Huo D F, Li B, et al. Wear Performance of electric pruning scissors based on bionic micro-structure[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Suppl. 2): 593−602.

[2] 李扬, 侯加林, 苑进, 等. 基于改进PSO的模糊PID高枝修剪机械臂末端抑振算法与试验[J]. 农业工程学报, 2017, 33(10):49−58. Li Y, Hou J L, Yuan J, et al. Experiment and vibration suppression algorithm for high-branch pruning manipulator based on fuzzy PID with improved PSO[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(10): 49−58.

[3] Fu G H, Liu X M, Chen Y F, et al. Fast-growing forest pruning robot structure design and climbing control[J]. Advances in Manufacturing, 2015, 3(2): 166−172. doi: 10.1007/s40436-015-0114-5

[4] 康峰, 仝思源, 张汉石, 等. 苹果枝条往复式切割剪枝参数分析与试验[J]. 农业工程学报, 2020, 36(16):9−16. Kang F, Tong S Y, Zhang H S, et al. Analysis and experiments of reciprocating cutting parameters for apple tree branches[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(16): 9−16.

[5] 郑永军, 江世界, 陈炳太, 等. 丘陵山区果园机械化技术与装备研究进展分析[J]. 农业机械学报, 2020, 51(11):1−20. Zheng Y J, Jiang S J, Chen B T, et al. Review on technology and equipment of the mechanization in hilly orchard[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(11): 1−20.

[6] Chen J, Li W, Li W, et al. Humanized design of portable forestry machinery[C]//Shadeed S. 1st International Conference on Arts, Design and Contemporary Education (ICADCE 2015). Moscow: Atlantis Press, 2015: 495−498.

[7] 李文彬, 安静贤. DG3型割灌机的噪声分析及其作业环境的评价[J]. 北京林业大学学报, 1994, 16(3):75−79. Li W B, An J X. Noise analysis and assessment of working environment on DG3-brush cutter[J]. Journal of Beijing Forestry University, 1994, 16(3): 75−79.

[8] 李文彬, 安静贤. 人体手臂的机械阻抗与振动能量吸收[J]. 北京林业大学学报, 1995, 17(增刊 2):1−6. Li W B, An J X. Mechanical impedance and vibrating energy absorption of human arms[J]. Journal of Beijing Forestry University, 1995, 17(Suppl. 2): 1−6.

[9] Cerruto E, Manetto G, Schillaci G. Vibration produced by hand-held olive electrical harvesters[J]. Journal of Agricultural Engineering, 2012, 43(2): 109−112.

[10] 陈净莲. 基于人类工效学的森林灭火手泵操作生物力学研究[D]. 北京: 北京林业大学, 2010. Chen J L. Study on biomechanics of operating forest fire suppression hand pump based on ergonomics[D]. Beijing: Beijing Forestry University, 2010.

[11] 李文彬, 何伟敏. 油锯人机界面的优化研究[J]. 北京林业大学学报, 2000, 22(5):58−64. Li W B, He W M. On optimization of man-machine interface of chain saw[J]. Journal of Beijing Forestry University, 2000, 22(5): 58−64.

[12] 段铁成, 王立海. 基于人机工程学对油锯伐木作业姿势的研究[J]. 东北林业大学学报, 2009, 37(4):48−49. Duan T C, Wang L H. Postures for chain saw logging operations based on ergonomics[J]. Journal of Northeast Forestry University, 2009, 37(4): 48−49.

[13] Wang L J, Li W B, Chen J L. Ergonomic evaluation of the operating characteristics of the 6MF-30 portable pneumatic extinguisher[J]. Applied Ergonomics, 2015, 51: 39−43. doi: 10.1016/j.apergo.2015.04.009

[14] 董金宝, 李文彬. 便携式割灌机U型手柄的人机工程学优化研究[J]. 北京林业大学学报, 2008, 30(3):144−146. Dong J B, Li W B. Optimization of U-handle of portable brush cutter based on ergonomics[J]. Journal of Beijing Forestry University, 2008, 30(3): 144−146.

[15] Reinvee M, Aia S, Pääsuke M, et al. Ergonomic benefits of an angle grinder with rotatable main handle in a cutting task[J]. Human Factors: the Journal of the Human Factors and Ergonomics Society, 2019, 61(7): 1112−1124. doi: 10.1177/0018720819827184

[16] Putz-Anderson V. Cumulative trauma disorders[M]. London: CRC Press, 1988.

[17] Kulkarni M, Shinde S B. Effect of occupational load specific exercise protocol on cumulative trauma disorder of upper limb in construction workers[J]. Age, 2020, 25(30): 31−45.

[18] Chan Y W, Huang T H, Tsan Y T, et al. The risk classification of ergonomic musculoskeletal disorders in work-related repetitive manual handling operations with deep learning approaches [C]//IEEE. 2020 International Conference on Pervasive Artificial Intelligence (ICPAI). Taiwan: Institute of Electrical and Electronics Engineers Inc, 2020: 268−271.

[19] Dianat I, Afshari D, Sarmasti N, et al. Work posture, working conditions and musculoskeletal outcomes in agricultural workers[J]. International Journal of Industrial Ergonomics, 2020, 77: 1−9.

[20] 黄宛. 黄宛临床心电图学[J]. 中国医刊, 2009(11):80. Huang W. Huang Wan clinical electrocardiology[J]. Chinese Journal of Medicine, 2009(11): 80.

[21] 吕孟宽, 杨欣, 霍鹏, 等. 苹果苗木机械化起苗技术研究进展[J/OL]. 果树学报[2021−03−02]. https://doi.org/10.13925/j.cnki.gsxb.20200464. Lü M K, Yang X, Huo P, et al. Research progress in mechanized digging technology of apple seedlings[J/OL]. Journal of Fruit Science [2021−03−02]. https://doi.org/10.13925/j.cnki.gsxb.20200464.

[22] 刘丽, 高登涛, 魏志峰, 等. 矮砧苹果细长纺锤形整形技术[J]. 果农之友, 2020(7):15−17. Liu L, Gao D T, Wei Z F, et al. Slender spindle shaping technology of dwarf rootstock apple[J]. Friends of Fruit Farmers, 2020(7): 15−17.

[23] 杨雪峰, 李应珍, 樊冬温. 新旧版便携式林业机械和园林机械振动测定规范国际标准的分析与研究[J]. 林业机械与木工设备, 2013, 41(4):35−41. doi: 10.3969/j.issn.2095-2953.2013.04.011 Yang X F, Li Y Z, Fan D W. Analysis and study of new and old international standards of vibration test code for portable forestry and gardening machinery[J]. Forestry Machinery & Woodworking Equipment, 2013, 41(4): 35−41. doi: 10.3969/j.issn.2095-2953.2013.04.011

[24] Hsu S H, Chuang M C, Chang C C. A semantic differential study of designers’ and users’ product form perception[J]. International Journal of Industrial Ergonomics, 2000, 25(4): 375−391. doi: 10.1016/S0169-8141(99)00026-8

[25] Kumar R, Chaikumarn M, Lundberg J. Participatory ergonomics and an evaluation of a low-cost improvement effect on cleaners’ working posture[J]. International Journal of Occupational Safety & Ergonomics, 2005, 11(2): 203−210.

下载:

下载: