Preparation and property characterization of crack-filled type microwave puffed wood based metal composites

-

摘要:目的 以高能微波处理后的木材增值利用为研究目标,制备填缝型微波膨化木基金属复合材料(WMC),为微波处理人工林实木增值利用提供参考。方法 采用抽真空浸渍方法,以锡铋低熔点合金和辐射松微波膨化木为原料,制备填缝型WMC,通过扫描电镜、能谱分析、计算机层析成像、动态热机械分析、热重分析、差示扫描量热分析、X射线衍射分析、红外光谱等测试技术,表征和分析WMC的微观形貌、热稳定性、表面接触角等性能。结果 锡铋合金填充在微波膨化木的缝隙处,与木材形成“机械互锁”方式的啮合结构,使其在缝隙处紧密结合,提高了界面结合强度。WMC中锡和铋的质量分数分别为25.97%和31.13%,计算机层析扫描图像重构了锡铋合金在WMC中的空间分布位置,实现了WMC可视化的三维渲染,展示了其独特的纹理。WMC与基材相比具有更高的贮存模量、损耗模量和残炭量,热稳定性得到提高。WMC未出现新的酯类、醚类等官能团特征峰,晶体结构未受到破坏,结晶度呈现上升趋势,由基材的25.9%增加至38.6%。60 s时接触角比基材提高了172%,疏水性显著提高。结论 本研究制备了填缝型微波膨化木基金属复合材料,观察与模拟了锡铋合金在微波膨化木中的分布,表征了其热稳定性与表面接触角等性能,为基于高能微波处理木材研制新型木质产品提供了新思路。Abstract:Objective To achieve the value-added utilization of wood after high energy density microwave treatment, crack-filled type microwave puffed wood based metal composites (WMC) was prepared, which provided a reference for the efficient utilization of planted solid wood treated by microwave.Method Tin-bismuth low melting point alloy (LMA) was used to impregnate microwave puffed Pinus radiata wood to prepare WMC by vacuum impregnation method. The micro-morphology, thermal stability, surface contact angle and other properties of WMC were characterized and analyzed by SEM, EDS, CT, DMA, TG, DSC, XRD, FTIR, etc. Meanwhile, the compound mechanism of LMA and microwave puffed wood was discussed.Result LMA was filled in the cracks of the microwave puffed wood and formed a mechanical interlocking meshing structure with wood, making it tightly combined at the cracks and improving the interface bonding strength. The mass percentages of Sn and Bi in WMC were 25.97% and 31.13%, respectively. The CT scan image reconstructed the spatial distribution of LMA in WMC, realized three-dimensional rendering of WMC visualization, and showed its unique texture. Compared with the untreated wood sample, WMC had higher storage modulus, loss modulus and char yield, and the thermal stability was improved. In addition, there were no new functional group characteristic peaks such as esters and ethers in WMC. The crystal structure of WMC was not destroyed, and the crystallinity of WMC showed an upward trend, increasing from 25.9% of the untreated wood sample to 38.6%. The surface contact angle was 172% higher than that of the untreated wood sample at 60 s, and the hydrophobicity was significantly improved.Conclusion In this study, a crack-filled microwave puffed wood based metal composites was prepared, the distribution of tin-bismuth alloy in microwave puffed wood was observed and modeled, and thermal stability and surface contact angle were characterized, which provided a new idea for the development of new wood products based on high energy density microwave treatment of wood.

-

以速生材为代表的人工林木材存在着耐久性差、强度低等缺陷,需对其功能化改性以满足不同工业制品的性能需求。提升木材渗透性,有助于功能剂更深且更为均匀地渗入木材细胞中。木材微波膨化,是将一定含水率的木材在微波场中受热,使内部水分迅速汽化,水蒸气因体积膨胀从而破坏木材弱相结构,在木材表面产生宏观裂隙的过程。经微波膨化处理后的,内部具有一定大小和均匀性的裂隙木材,称为微波膨化木[1-2]。依据微波处理效果,微波膨化木可分为3个等级[3],其中III级膨化木的表面与内部因产生大量的宏观裂隙,形成了新的流体通道,适合难浸渍型改性剂的填充固化[4]。

金属与木材复合,可以利用金属具有的硬度高、耐磨性好、易导电导热等特性,提升木材在力学强度、导电导热等方面的性能,实现功能化木材的开发。利用化学镀法在木材表面形成Cu-Ni金属层,增加了木材表面粗糙度和电导率,使复合木材具有疏水性和电磁屏蔽性[5];金属钠填充于碳化木材微通道中,制备出的木质电极具有优异的导电性能和循环稳定性,能够以1.0 mA/cm2的速度持续运行500 h[6]。在金属材料选择中,低熔点合金(low melting point alloy,LMA)具有良好的性能稳定性、较高的导热系数,且在低温度条件下可由固体转换为液态形式,避免固体形态下与其他材料结合性差的问题,因此多作为导热填料引入复合材料的制备中。例如,Ge等[7]将LMA均匀包覆氮化硼纳米片,并以此为改性剂制备了界面热阻仅为0.547 (℃·cm2)/W的导热硅脂,作为散热性强的热界面材料。Huang等[8]将LMA与膨胀石墨均匀共混,制备出导热性能优异的相变材料,可用于电子元件的散热。Wan等[9]利用木材各向异性,将LMA固化于木材孔腔中,制备出的木质复合材料呈现出不同热流方向下导热各向异性。然而研究发现密度达7.1 g/cm3的LMA填充于木材细胞腔中,所制备出的木质复合材料密度过重,为4.78 g/cm3,是普通木材密度的10倍,从表面色泽与触感上均呈现金属的冷硬感,失去了木材质感且不利于成本控制[10]。

本研究依据高能微波膨化处理技术在木材内部形成宏观缝隙,将LMA填充于木材缝隙,而不进入到木材管胞中,降低微波膨化木基金属复合材料(wood-based metal composite,WMC)密度,使该复合材料进一步轻量化,利于成本控制和工业化生产的思路。LMA物理填充于微波膨化处理后产生的缝隙中,使得WMC兼具实木质感与金属良好的导热性,有望应用于地采暖地板基材。基于此,利用扫描电镜、能谱分析与计算机层析成像技术观察与模拟LMA与木材的结合,通过动态热机械分析、热重分析、差示扫描量热分析等技术表征WMC的热稳定性,并结合X射线衍射分析与红外光谱测试技术,探明真空浸渍LMA对微波膨化木理化性能的影响。

1. 材料与方法

1.1 材 料

辐射松(Pinus radiata)微波膨化木的制备:将含水率为30% ~ 50%的辐射松锯材(规格为800 mm × 90 mm × 50 mm)以3 500 kW/m3的微波功率处理26 s,获得III级微波膨化木[3],体积膨胀率为9%,裂隙率 ≥ 14%,裂隙数量 ≥ 6 000个/m2。锡铋(Sn-Bi)低熔点合金,熔点138 ℃,密度7.1 g/cm3,购于河南长葛市铄辰金属有限公司。

1.2 研究方法

1.2.1 微波膨化木基金属复合材料制备

将同一辐射松经微波膨化处理(南京三乐微波技术有限公司,WXD200L)后锯制成50 mm(长) × 50 mm(宽) × 15 mm(厚)的两组试件,一组为试样组,用于制备WMC,另一组为对照组,制备出热处理微波膨化木(heat-treated puffed wood,HPW)。首先将固体LMA均匀地放置于铝制容器中并放入真空干燥箱(上海风棱设备有限公司,DZF-6050),将加热温度调至163 ℃使其迅速熔化,获得LMA熔融液体;将试样组置于LMA熔融液体中,在真空度0.1 MPa、温度145 ℃的条件下真空浸渍处理16 h,浸渍期间LMA液面始终高于试样。同时将微波膨化木置于真空干燥箱中,进行相同时间、真空度和温度条件下的处理,但不浸渍处理(对照组,HPW)。处理结束后对真空箱进行卸压,为避免LMA在固化过程中从微波膨化木裂缝处流出,迅速取出试样放入冷水中浸泡,使微波膨化木缝隙中的LMA快速固化,冷却后去除试样表面LMA,获得WMC。

1.2.2 微观形貌和性能表征

1.2.2.1 微观形貌表征

采用切片机制取若干块面积为5 mm × 5 mm、厚度为2 ~ 3 mm的横切面、径切面和弦切面的木薄片,用导电胶固定在金属底座上,表面喷金处理,通过扫描电镜(SEM,日本日立公司,S-4800)观察WMC试件中LMA与木材结合部分的微观形貌,并用X射线光电子能谱仪(EDS,美国赛默飞世尔公司,ESCALAB-250Xi)测量缝隙周边Sn、Bi元素的分布及其含量。采用微计算机层析成像系统(CT,中国科学院高能物理研究所)以360°旋转、步长0.5°的方式对20 mm × 20 mm × 20 mm的试件进行扫描,扫描电压为160 kV,电流为120 μA,CT图像分辨率为14.9 μm,通过Feldkamp算法进行计算,共重建1 387张图像,每张图片分辨率为1 520像素 × 1 514像素。

1.2.2.2 热稳定性分析

制取规格为25 mm(长)× 8 mm(宽) × 1.5 mm(厚)的试件,在三点弯曲的加载模式下,将支架跨距设为10 mm,以频率1 Hz、振幅10 μm、温度−20 ~ 100 ℃、升温速度3 ℃/min、氮气氛围的条件下测试WMC的动态热机械性能(DMA,德国耐驰仪器公司,DMA 242)。将具有LMA分布的WMC试件、辐射松基材、HPW试件通过高速粉碎机磨成3种类型粉末,经120目筛选后称取10 mg。在升温速度10 ℃/min、测试温度0 ~ 600 ℃、氮气条件下进行热重分析(TG,德国耐驰仪器公司,STA 449 F3)。分别将 10 mg这3种类型粉末在测试温度25 ~ 500 ℃、升温速率5 ℃/min、氮气条件下进行差示扫描量热分析(DSC,德国耐驰仪器公司,DSC 200 F3)。

1.2.2.3 晶体结构与红外光谱分析

将3种粉末在辐射管电压40 kV、电流40 mA、扫描范围5° ~ 45°、扫描速率2°/min的条件下进行X射线衍射分析(XRD,德国布鲁克AXS公司,D8 ADVANCE)。使用溴化钾压片法,按质量比1∶80对粉末和无水溴化钾进行充分混合研磨后,压制成薄片,波长测量范围为400 ~ 4 000 cm−1,在扫描次数32次、光谱分辨率4 cm−1的条件下对每个样品重复扫描3次,进行傅里叶红外光谱分析(FTIR,美国尼高力公司,Nicolet 6700)。

1.2.2.4 表面接触角分析

将规格为50 mm(长) × 20 mm(宽) × 15 mm(厚)的试件放置于干燥箱中进行绝干处理,每种试件设3个重复样,每个样品选取3个点进行测定,最后取平均值。在温度25 ℃、采样间隔1 s、平台移动距离7 mm、旋转速度0.5 r/min、旋转角度90°、最大录像时长10 s的条件下以一次性针头滴液,液体为蒸馏水,注液体积为8 μL,进行表面接触角测试(上海中晨数字技术设备有限公司,JC 200D)。

2. 结果与分析

2.1 WMC的微观形貌

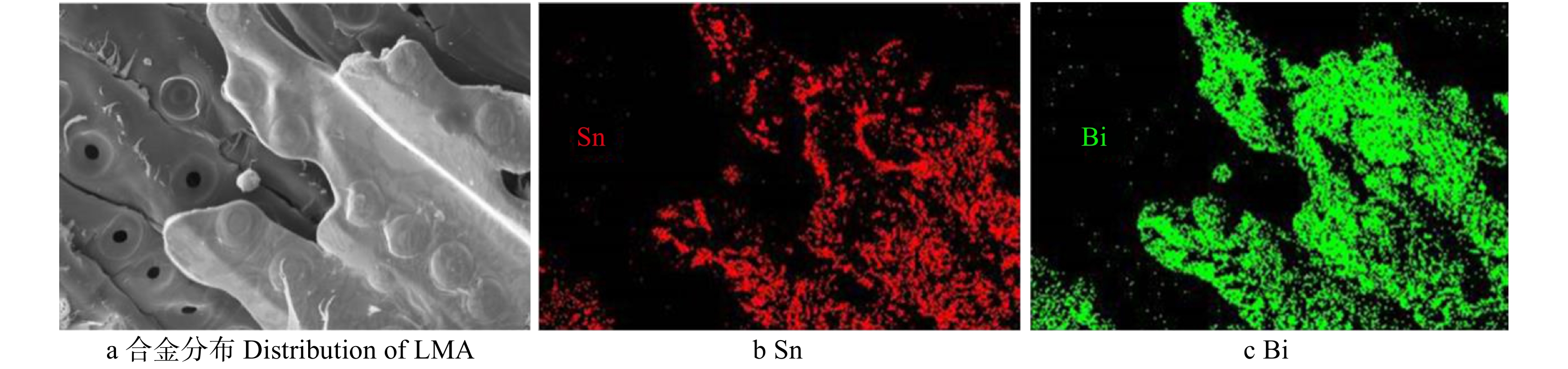

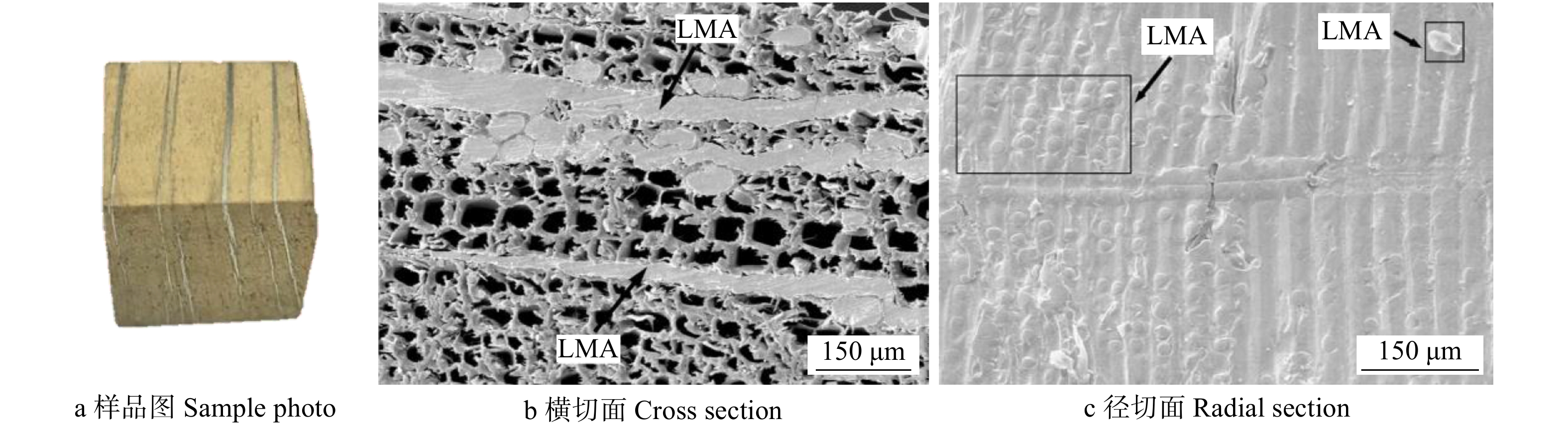

经高频微波处理后的微波膨化木材,表面产生较大的缝隙,为浸渍剂的填充创造空间,从WMC(图1a)微观形貌观察发现LMA在横切面(图1b)或径切面(图1c)上均以固态形式填充在膨化木的缝隙中,LMA未完全进入木材管胞组织。膨化木缝隙处的木材表面有很多凹凸不平的高低沟槽、孔穴等结构,当液态LMA填充到这些孔隙结构后,其与木材表面相互流动、挤压、浸透,从而与木材之间以“机械互锁”的方式形成啮合结构,类似于船锚的作用,界面结合强度较高[11]。SEM结合EDS可以准确测定元素的分布及含量(见图2),WMC试件中LMA与木材结合的缝隙填充处主要为LMA的Sn(红色表示)与Bi(绿色表示)元素,质量分数分别为25.97%和31.13%。木材自身含有的C和O元素的质量分数分别为8.63%和21.74%,说明观测位置内金属部分占主体(见表1)。

表 1 WMC中主要元素含量Table 1. Main element content of WMC元素

Element质量分数

Mass fraction/%原子百分比

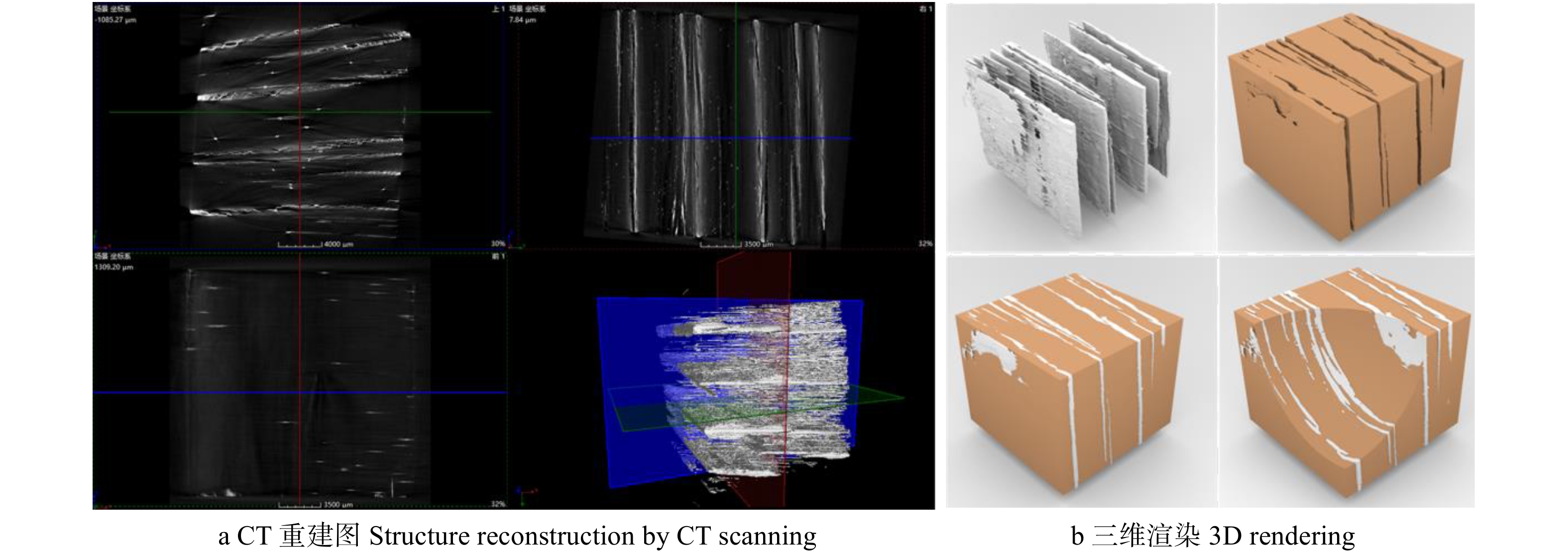

Atomic percentage/%C 8.63 28.47 O 21.74 53.82 Sn 25.97 8.67 Bi 31.13 5.90 通过CT扫描能够得到WMC内部的三维重建图,再与木材三维表面轮廓相组合,即可在非破坏条件下,展示材料内部组织的三维结构信息,能够清晰观察WMC内部的三维缝隙结构。图3a为WMC不同方向的整体投影图像,图像上观测到的白色部分是LMA,而黑色部分为木材,也就是膨化木聚集的区域。从图像中可以清晰地看到缝隙处LMA的形状以及在膨化木中所处的空间位置,缝隙填充分布整体较为分散,缝隙间跨度较大,且缝隙所占比例不大。为了进一步观察LMA在膨化木缝隙中的分布,运用三维建模软件对WMC的CT图像进行三维渲染图重建(图3b),图中分别展示了LMA、膨化木部分以及两部分的复型结构,模拟了LMA在WMC中的位置分布,WMC独特的金属与木材交错纹理有利于其作为装饰材应用。

2.2 WMC的热稳定性分析

3种类型试件的贮存模量均随着温度的升高而降低(见图4),这是因为随着温度的升高,木材细胞壁聚合物组分的链迁移率增加,使木材的贮存模量降低[12]。50 ℃温度下,WMC、基材与HPW的贮存模量分别为6 651、4 462、1 239 MPa,相较于基材WMC的贮存模量增加了49%,这与WMC的内部结构有关,当LMA填充或部分填充被粘物表面的凹面或空隙后,分子相互之间接触并发生不规则的表面渗透,从而与木材表面形成“钩、钉、锚”的啮合结构,这些不规则的表面渗透作用类似于机械锚,即使在其他相互作用很弱的情况下,也能获得较高的界面结合强度,此种方式的结合限制了LMA的运动,不仅增强其在膨化木中的沉积,也增强了两相界面的交互作用,界面相互作用越多,界面处的应力传递越高,因此WMC的贮存模量得到提高[13]。HPW是经高能微波处理以后形成的试材,微波处理过程中,处理材内部的水蒸气压力迅速增加,从而使强度较弱的组织(如射线薄壁细胞)发生破坏并形成微裂纹[14],当水蒸气压力逐渐增加时,微裂纹会发展成影响试件力学性能的宏观裂纹,因此HPW的贮存模量最低。

损耗模量与摩擦和内部运动所损失的能量有关,反映了材料的黏滞行为[15],WMC、基材与HPW的损耗模量如图4b所示。WMC的损耗模量均高于基材和HPW,在50 ℃时,WMC、基材与HPW的损耗模量分别为618、361、75 MPa,表明LMA与膨化木的结合增强了两种材料之间的界面相互作用,使WMC在动载荷作用下的弹性和黏滞性有所提高,因此WMC具有更高的损耗模量。HPW含有的宏观裂纹仍是影响其损耗模量的主要因素,其损耗模量最低。

图5为WMC、基材、HPW和LMA的DSC曲线。由图5可知基材和HPW均有两个吸热阶段和一个放热阶段。50 ~ 150 ℃为第一个吸热阶段,此阶段内水分的蒸发需要吸热,因此基材和HPW在此阶段出现一个明显较大面积的吸热峰;300 ~ 360 ℃为第二个吸热阶段,是由木材中纤维素分解吸热引起;360 ~ 500 ℃为放热阶段,该放热行为是木材中纤维素、半纤维素和木质素的热解以及戊聚糖和抽提物等综合造成。LMA仅在138 ℃附近出现一个吸热峰,这是源于LMA的熔点为138 ℃,在此温度下固态LMA吸收热量而熔化,在DSC曲线上表现为吸热峰。WMC在50 ~ 150 ℃处出现一个吸热峰,为木材中水分蒸发所致,其反应热为131.6 J/g,较基材(161.1 J/g)和HPW(154.7 J/g)均有所降低。WMC在138 ℃左右处有一个较弱的吸热峰,为LMA熔化所致。WMC在300 ~ 360 ℃处产生第二个吸热峰,是木材中的纤维素分解所致,其反应热为77.3 J/g,较HPW的83.5 J/g有所降低,较基材的174.3 J/g降低更多。总体来看,WMC、基材和HPW的DSC曲线变化趋势基本一致,但WMC的吸热峰相比于基材和HPW都小,并且整个曲线未随着温度的升高出现大的波动,说明WMC在受热过程中吸放热很平缓。原因可能有两方面:一是当WMC受热温度超过138 ℃时,内部的LMA吸热熔化为液态,从而隔绝空气,防止氧气与木材接触,即LMA既能熔化吸热又能隔绝空气,可间接起到阻燃剂的作用,因此,随着温度的不断升高,整个曲线出现的波动较小,WMC在受热过程中吸放热较基材和HPW平和,说明其热稳定性较好;二是WMC在制备过程中经历了数小时的热处理,热处理材的峰面积一般小于基材,与已有研究结果[16]类似。

图6为WMC、基材、HPW及LMA的热重(TG)和微商热重(DTG)曲线,氮气氛围下的基材、HPW和WMC的热分解过程分为4个阶段[17],将TG曲线中各阶段的温度分界点设为T1、T2、T3,各阶段温度轴线则分别为失水阶段(25 ℃ ~ T1)、微质量损失阶段(T1 ~ T2)、热解阶段(T2 ~ T3)、炭化阶段(T3 ~ 900 ℃),不同热分解阶段的温度分界点与各试件在4个阶段的质量损失(W1、W2、W3、W4)见表2。在TG曲线中,第一阶段热分解主要放出自由水,化学反应较为缓慢,基材、HPW、WMC的W1较小且相差不大,范围在3.38% ~ 5.08%;第二阶段缓慢吸热,W2非常小,范围在1.06% ~ 1.82%;第三阶段,纤维素发生降解、脱水、脱乙酸,基材、HPW和WMC的W3达到峰值,分别为59.78%、60.90%和49.17%。WMC的W3低于基材和膨化木,导致了更多的残炭,残炭率为23.91%。同时此阶段下3种试件的DTG曲线均出现了一个较宽峰,WMC最大质量损失速率与基材和HPW相比,分别降低了44.16%和43.82%,说明该阶段WMC的热稳定性优于基材和HPW。第四阶段主要是木质素的热解和炭化纤维素的分解,DTG曲线表明WMC在该阶段的质量变化速率趋于缓慢,可能由于LMA在木材周围形成了保护层隔绝木材和空气的接触延缓了热分解,使木材只能脱水炭化,从而对木材起到保护作用使WMC具有较好的热稳定性。

表 2 不同热分解阶段试件的温度分界点与质量损失Table 2. Temperature split point and mass loss of samples in different thermal degradation stages试件 Sample T1/℃ T2/℃ T3/℃ W1/% W2/% W3/% W4/% 残炭率 Char yield/% 基材 Untreated sample 150 250 370 5.08 1.06 59.78 14.42 19.66 HPW 150 250 370 3.38 1.62 60.90 18.50 15.60 WMC 100 250 370 4.12 1.82 49.17 20.98 23.91 注:T1、T2、T3为各阶段的温度分界点;W1、W2、W3、W4为各阶段的质量损失。Notes:T1, T2, T3 represent the temperature split points of each stage; W1, W2, W3, W4 represent the mass loss of each stage. 2.3 晶体结构与红外光谱分析

图7a为基材、HPW和WMC的XRD图谱,扫描角度2θ为17°、22.5°、35°附近,3种类型试件均出现了衍射峰,分别是木材纤维素(101)、(002)和(040)结晶面的衍射峰[18],WMC衍射峰位置未发生变化,表明经过LMA浸渍处理后的WMC的晶胞参数未发生改变,即WMC的晶体结构没有受到破坏。由于LMA中锡铋元素的存在,WMC试件出现若干独立衍射峰,扫描角度2θ为32.0°、45.0°、27.3°、39.8°,分别对应锡(101)、锡(211)、铋(012)、铋(110)的晶面衍射峰,锡、铋等晶态物质的存在使得WMC结晶度提高,分别比基材和HPW提高了49.0%和52.6%。图7b为基材、HPW和WMC的红外光谱图。WMC谱图与基材和HPW的谱图没有明显的差异,即两者的特征官能团相似,未发现新的酯类、醚类等官能团特征峰,表明LMA在膨化木中为物理填充作用。3 400 cm−1处的吸收峰是木材中O-H的伸缩振动引起,经LMA浸渍热处理后,WMC试件中O-H吸收峰有明显减弱的趋势,羟基的数量与亲疏水性有关,导致木材的吸湿性发生变化[19]。2 930 cm−1处的峰值与C-H拉伸有关[20],C-H带发生偏移可能是由于纤维素结晶度的改变影响了C-H和O-H拉伸频率[21]。WMC在1 728 cm−1处的C=O表现出增加的趋势,这可能是木聚糖中乙酰基的羰基所引起[22],1 570 cm−1处的吸收带对应于苯环的碳骨架振动,该波带强度的增加表明半纤维素开始降解,因此木质素含量增加,1 198 cm−1处的峰代表纤维素和半纤维素的O-H面内弯曲振动,WMC在此处O-H峰减弱[23]。

2.4 表面接触角分析

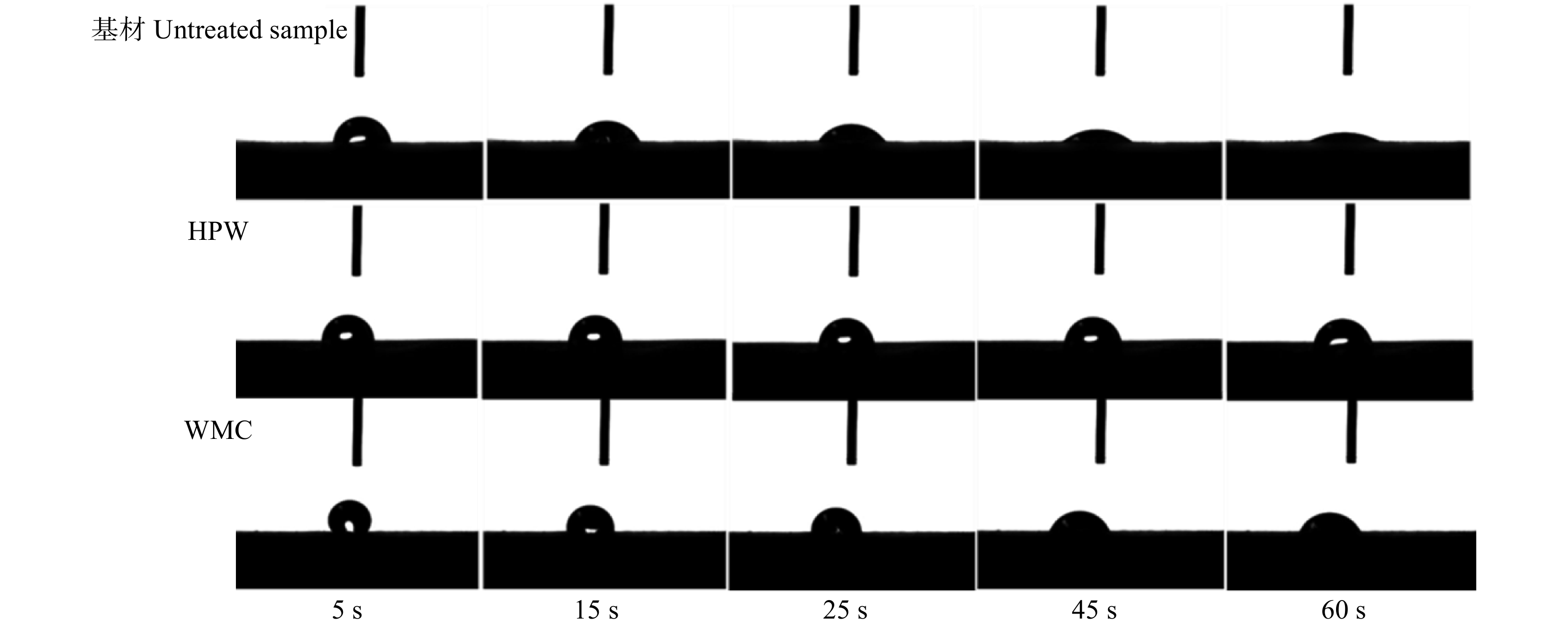

图8和表3为60 s内蒸馏水在3种类型试件表面接触角的测试结果。在第5 s时,基材表面的接触角最小为84.4°,HPW次之为91.8°,WMC最大为121°;15 ~ 25 s时,WMC的接触角均大于HPW;45 ~ 60 s时,HPW的接触角较WMC大,60 s时基材的接触角仅为28.8°,此时蒸馏水几乎渗入到基材里面,而HPW的接触角仍为78.2°。经热处理的试材的接触角较大,是源于热处理材微纤丝的非结晶区部分结晶化,纤维素的结晶度有所提高,在纤维素内部形成氢键和醚键,半纤维素也因受热而引起纤维素内胶着和脱水现象,导致自由羟基的减少[24],与水的亲和力降低。WMC在制备过程中也经历了与HPW相同的热处理时间和温度,因此WMC表面接触角也表现出与HPW相同的变化规律。

表 3 不同时间点下3种试件的表面接触角Table 3. Contact angle of samples at different time points(°) 试件 Sample 时间 Time/s 5 15 25 35 45 60 基材 Untreated sample 84.4 65.1 55.6 47.6 40.1 28.8 HPW 91.8 88.0 84.0 82.7 80.5 78.2 WMC 121.0 96.4 88.7 75.2 67.2 63.7 3. 结 论

采用LMA对 III 级微波膨化木基材进行浸渍填充,制备了微波膨化木基金属复合材料(WMC),探讨了LMA浸渍热处理对微波膨化木的微观结构、化学基团、热分解过程、表面性能影响以及LMA在木材中的分布与结合,主要结论如下:

(1)LMA以固态的形式填充在膨化木的缝隙处而未进入管胞组织中,LMA与木材形成“机械互锁”方式的啮合结构,类似于船锚作用,使其在缝隙处的结合更加紧密,获得较高的界面结合强度。能谱分析表明在WMC中Sn和Bi的质量分数分别为25.97%和31.13%,而原子百分比分别为8.67%和5.90%。CT扫描图像清晰显示了缝隙处合金的形貌以及在WMC中所处的空间位置。

(2)WMC具有更高的贮存模量和损耗模量,其次为基材,而HPW最低。WMC、基材和HPW均具有相似的TG和DSC曲线变化规律,但WMC具有更低的质量损失速率和更高的残炭量,在受热过程中吸放热较为缓和,热稳定性得到提高。

(3)LMA与膨化木之间的结合方式为物理结合,未发生化学反应,LMA浸渍处理并未改变膨化木基体的晶胞参数,即没有破坏木材原有的物理结构,但WMC的结晶度略有增加,高温处理使WMC的热稳定性和表面接触角较基材和HPW均有所提高。

-

表 1 WMC中主要元素含量

Table 1 Main element content of WMC

元素

Element质量分数

Mass fraction/%原子百分比

Atomic percentage/%C 8.63 28.47 O 21.74 53.82 Sn 25.97 8.67 Bi 31.13 5.90 表 2 不同热分解阶段试件的温度分界点与质量损失

Table 2 Temperature split point and mass loss of samples in different thermal degradation stages

试件 Sample T1/℃ T2/℃ T3/℃ W1/% W2/% W3/% W4/% 残炭率 Char yield/% 基材 Untreated sample 150 250 370 5.08 1.06 59.78 14.42 19.66 HPW 150 250 370 3.38 1.62 60.90 18.50 15.60 WMC 100 250 370 4.12 1.82 49.17 20.98 23.91 注:T1、T2、T3为各阶段的温度分界点;W1、W2、W3、W4为各阶段的质量损失。Notes:T1, T2, T3 represent the temperature split points of each stage; W1, W2, W3, W4 represent the mass loss of each stage. 表 3 不同时间点下3种试件的表面接触角

Table 3 Contact angle of samples at different time points

(°) 试件 Sample 时间 Time/s 5 15 25 35 45 60 基材 Untreated sample 84.4 65.1 55.6 47.6 40.1 28.8 HPW 91.8 88.0 84.0 82.7 80.5 78.2 WMC 121.0 96.4 88.7 75.2 67.2 63.7 -

[1] 徐恩光, 林兰英, 李善明, 等. 木材微波处理技术与应用进展[J]. 木材工业, 2020, 34(1):25−29, 34. Xu E G, Lin L Y, Li S M, et al. Wood microwave treatment technology and its applications[J]. China Wood Industry, 2020, 34(1): 25−29, 34.

[2] Torgovnikov G, Vinden P. Microwave wood modification technology and its applications[J]. Forest Products Journal, 2010, 60(2): 173−182. doi: 10.13073/0015-7473-60.2.173

[3] 浙江富得利木业有限公司. 膨化基材: Q/FDL 001—2017[S]. 绍兴: 浙江富得利木业有限公司, 2017. Zhejiang Fudeli Flooring Co., Ltd. Puffed wood: Q/FDL 001—2017[S]. Shaoxing: Zhejiang Fudeli Flooring Co., Ltd., 2017.

[4] Muga M O. Mechanical properties of wood following microwave and resin modification[D]. Melbourne: University of Melbourne, 2002.

[5] Pan Y F, Yin D W, Yu X F, et al. Multilayer-structured wood electroless Cu-Ni composite coatings for electromagnetic interference shielding[J]. Coatings, 2020, 10(8): 740. doi: 10.3390/coatings10080740

[6] Luo W, Zhang Y, Xu S M, et al. Encapsulation of metallic Na in an electrically conductive host with porous channels as a highly stable Na metal anode[J]. Nano Letters, 2017, 17(6): 3792. doi: 10.1021/acs.nanolett.7b01138

[7] Ge X, Zhang J Y, Zhang G Q, et al. Low melting-point alloy-boron nitride nanosheet composites for thermal management[J]. ACS Applied Nano Materials, 2020, 3(4): 3494−3502. doi: 10.1021/acsanm.0c00223

[8] Huang Z W, Luo Z G, Gao X N, et al. Preparation and thermal property analysis of wood’s alloy/expanded graphite composite as highly conductive form-stable phase change material for electronic thermal management[J]. Applied Thermal Engineering, 2017, 122: 322−329. doi: 10.1016/j.applthermaleng.2017.04.154

[9] Wan J Y, Song J W, Yang Z, et al. Highly anisotropic conductors[J]. Advanced Materials, 2017, 29(41): 1703331. doi: 10.1002/adma.201703331

[10] Chai Y, Liang S Q, Zhou Y D, et al. Low-melting-point alloy integration into puffed wood for improving mechanical and thermal properties of wood-metal functional composites[J]. Wood Science and Technology, 2020(54): 637−649.

[11] 秦理哲, 林兰英, 傅峰. 木材胶合界面微观结构样品制备新方法—激光烧蚀技术[J]. 林业科学, 2018, 54(4):93−99. doi: 10.11707/j.1001-7488.20180411 Qin L Z, Lin L Y, Fu F. Novel sample preparation methodology of wood/adhesive interphase for microstructure study: laser ablation technique[J]. Scientia Silvae Sinicae, 2018, 54(4): 93−99. doi: 10.11707/j.1001-7488.20180411

[12] Islam M S, Hamdan S, Hasan M, et al. Effect of coupling reactions on the mechanical and biological properties of tropical wood polymer composites (WPC)[J]. International Biodeterioration and Biodegradation, 2012, 72: 108−113. doi: 10.1016/j.ibiod.2012.05.019

[13] Cai X L, Riedl B, Zhang S Y, et al. The impact of the nature of nanofillers on the performance of wood polymer nanocomposites[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(5): 727−737. doi: 10.1016/j.compositesa.2008.02.004

[14] 周志芳, 江涛, 王清文. 高强度微波处理对落叶松木材力学性质的影响[J]. 东北林业大学学报, 2007, 35(2):7−8. doi: 10.3969/j.issn.1000-5382.2007.02.003 Zhou Z F, Jiang T, Wang Q W. Influence of intensive microwave treatment on mechanical properties of larch wood[J]. Journal of Northeast Forestry University, 2007, 35(2): 7−8. doi: 10.3969/j.issn.1000-5382.2007.02.003

[15] Menard K P, Menard N R. Dynamic mechanical analysis[M]. Boca Raton: CRC Press, 2020.

[16] 史蔷, 鲍甫成, 江京辉, 等. 热处理圆盘豆木材的热分析研究[J]. 木材加工机械, 2012(2):26−30. Shi Q, Bao F C, Jiang J H, et al. The thermal analysis of the heat-treated okan wood[J]. Wood Processing Machinery, 2012(2): 26−30.

[17] Sun L C, Wu Q L, Xie Y J, et al. Thermal degradation and flammability properties of multilayer structured wood fiber and polypropylene composites with fire retardants[J]. RSC Advance, 2016, 6(17): 13890−13897. doi: 10.1039/C5RA23262G

[18] 江泽慧, 费本华, 杨忠. 光谱预处理对近红外光谱预测木材纤维素结晶度的影响[J]. 光谱学与光谱分析, 2007, 27(3):435−438. doi: 10.3321/j.issn:1000-0593.2007.03.006 Jiang Z H, Fei B H, Yang Z. Effects of spectral pretreatment on the prediction of crystallinity of wood cellulose using near infrared spectroscopy[J]. Spectroscopy and Spectral Analysis, 2007, 27(3): 435−438. doi: 10.3321/j.issn:1000-0593.2007.03.006

[19] Tjeerdsma B F, Militz H. Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood[J]. Holz Roh Werkst, 2005, 63(2): 102−111. doi: 10.1007/s00107-004-0532-8

[20] Popescu M C, Froidevaux J, Navi P, et al. Structural modifications of Tilia cordata wood during heat treatment investigated by FT-IR and 2D IR correlation spectroscopy[J]. Journal of Molecular Structure, 2013, 1033: 176−186. doi: 10.1016/j.molstruc.2012.08.035

[21] Herrera R, Erdocia X, Llano-Ponte R, et al. Characterization of hydrothermally treated wood in relation to changes on its chemical composition and physical properties[J]. Journal of Analytical and Applied Pyrolysis, 2014, 107: 256−266. doi: 10.1016/j.jaap.2014.03.010

[22] Esteves B, Velez M A, Domingos I, et al. Chemical changes of heat treated pine and eucalypt wood monitored by FTIR[J]. Maderas Ciencia Y Tecnlogía, 2013, 15(2): 245−258.

[23] Okon K E, Lin F, Lin X, et al. Modification of Chinese fir (Cunninghamia lanceolata L.) wood by silicone oil heat treatment with micro-wave pretreatment[J]. European Journal of Wood and Wood Products, 2018, 76(1): 221−228. doi: 10.1007/s00107-017-1165-z

[24] 刘元. 热处理对水与木材接触角的影响[J]. 中南林业科技大学学报, 1993, 13(2):136−141. Liu Y. The impact of heat treatment on the contact angle between wood and water[J]. Journal of Central South University of Forestry and Technology, 1993, 13(2): 136−141.

-

期刊类型引用(5)

1. 林海,高大中,张童,崔国发. 基于卷积神经网络的无人机遥感影像水鸟自动识别. 动物学杂志. 2024(03): 450-459 .  百度学术

百度学术

2. 齐建东,郑尚姿,陈子仪,马鐘添. 基于ConvNeXt的北京地区红外相机野生动物图像识别改进模型构建. 林业科学. 2024(08): 33-45 .  百度学术

百度学术

3. 贾一鸣,张长春,胡春鹤,张军国. 基于少样本学习的森林火灾烟雾检测方法. 北京林业大学学报. 2023(09): 137-146 .  本站查看

本站查看

4. 齐建东,马鐘添,张德怀,田赟. 基于BS-ResNeXt-50的密云地区野生动物图像识别. 林业科学. 2023(08): 112-122 .  百度学术

百度学术

5. 戎战磊,高雅月,陈生云,张同作. 祁连山国家公园青海片区雪豹栖息地适宜性评价. 兽类学报. 2022(05): 553-562 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: