Numerical simulation on the influence of wall wood column defects on the safety of ancient building

-

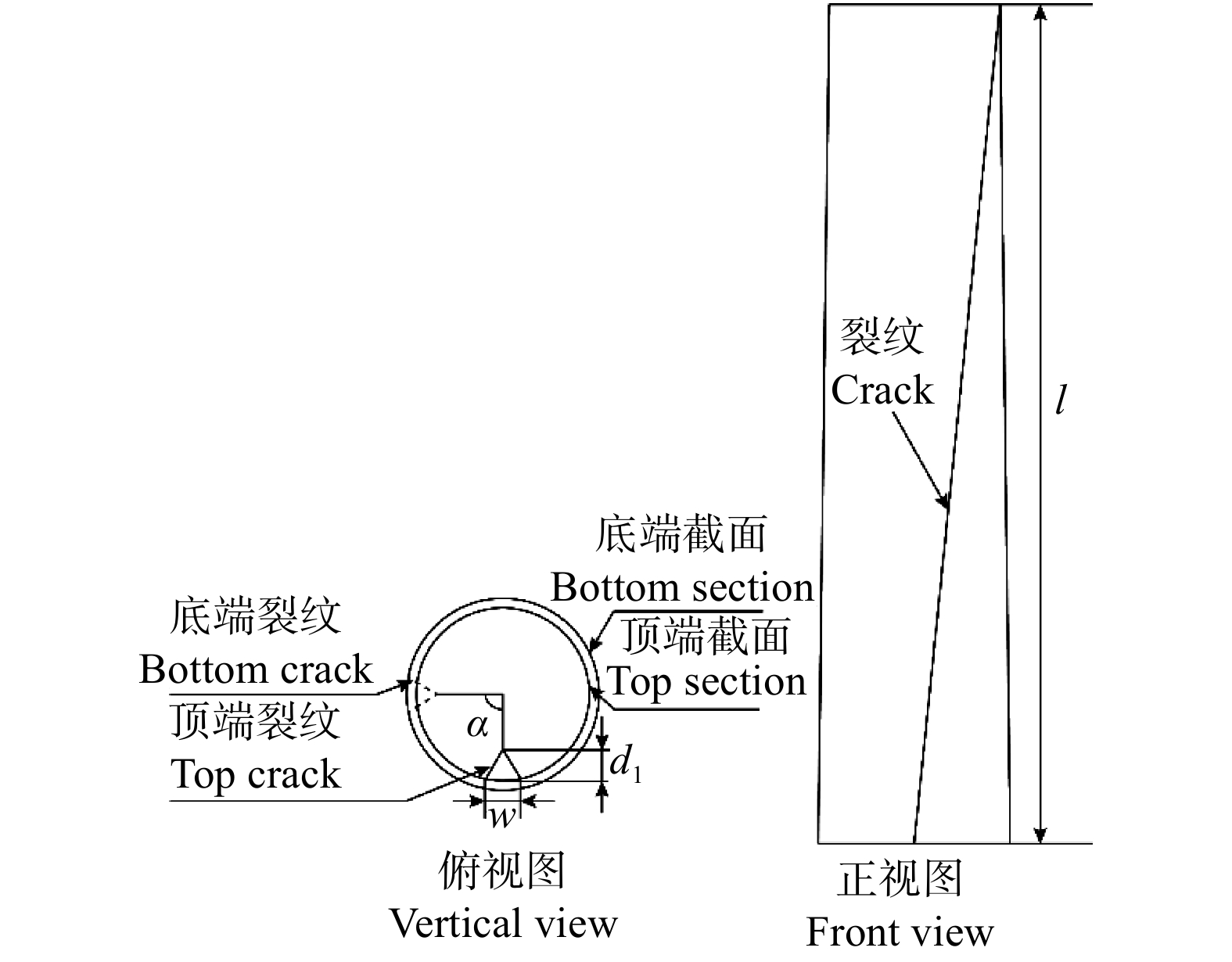

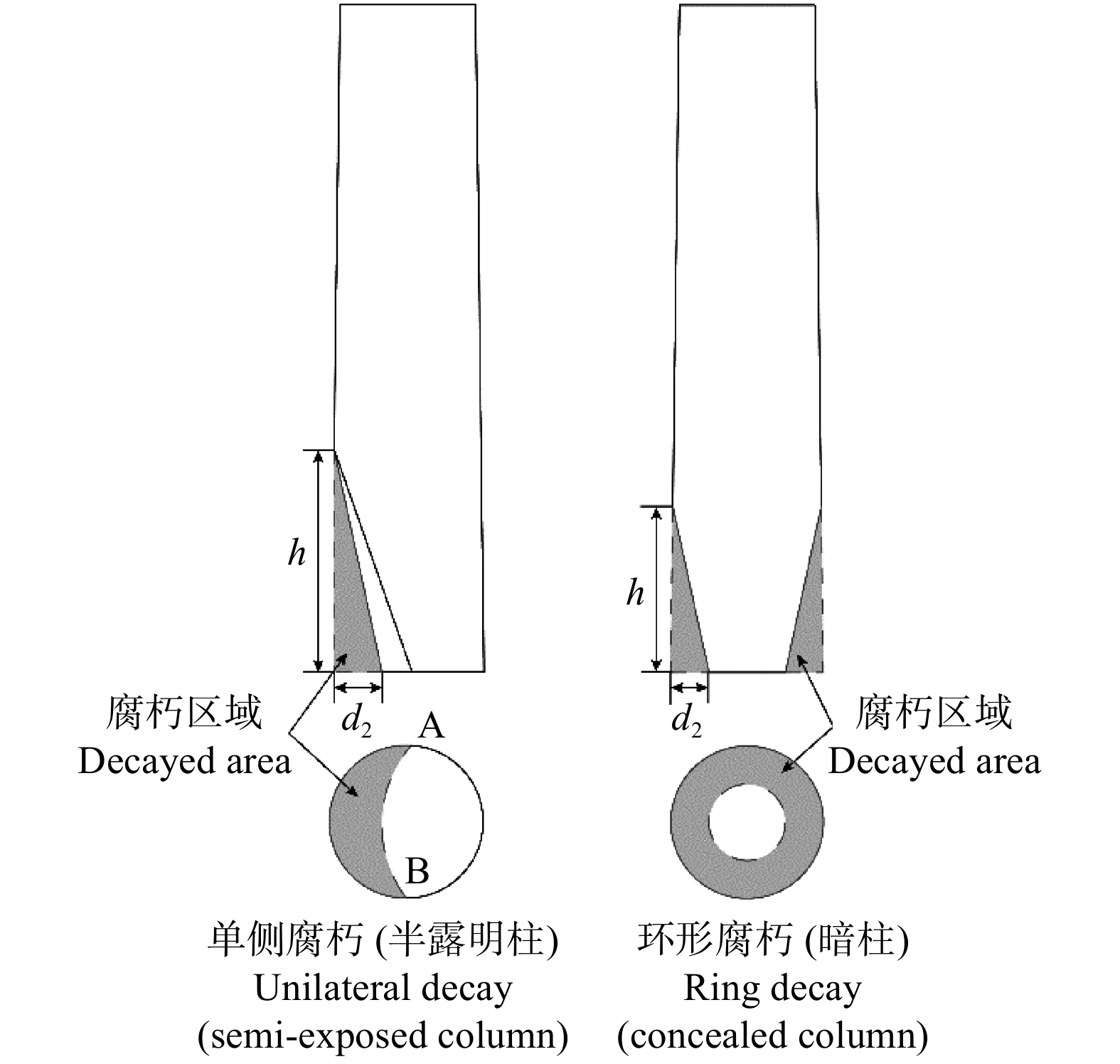

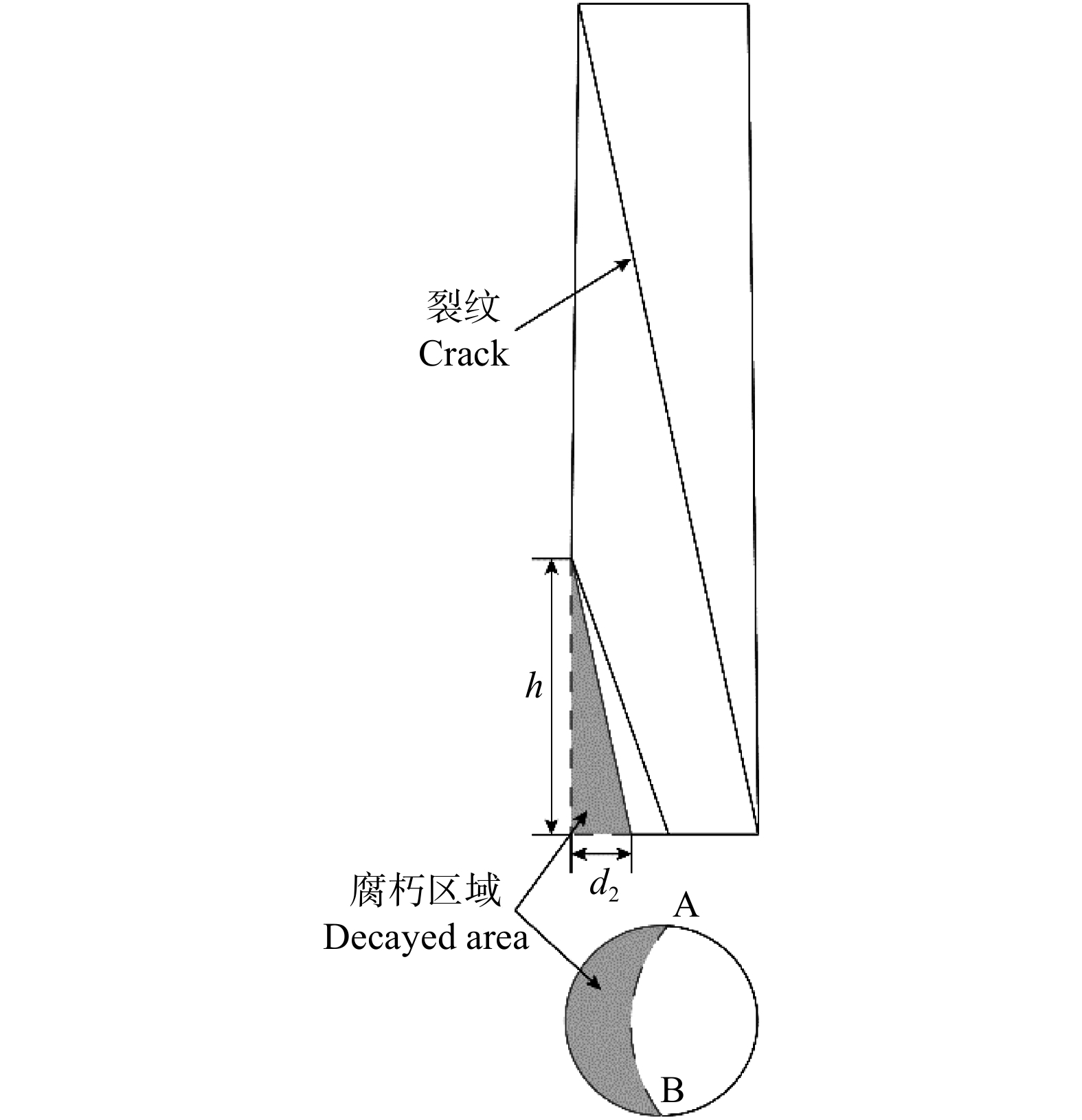

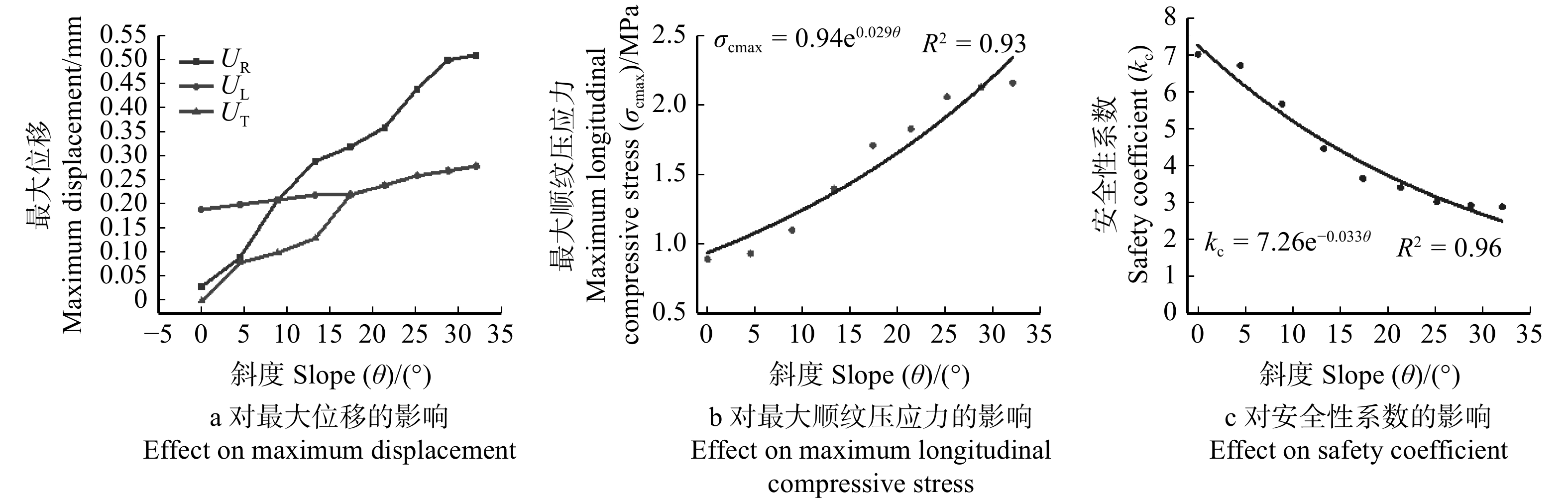

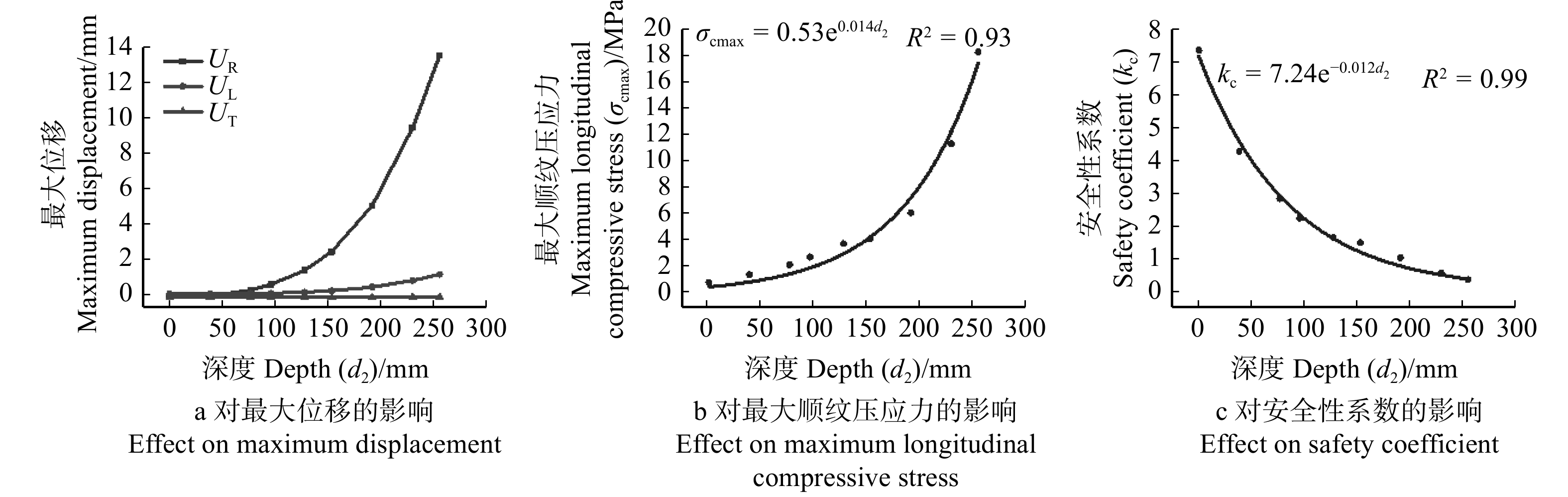

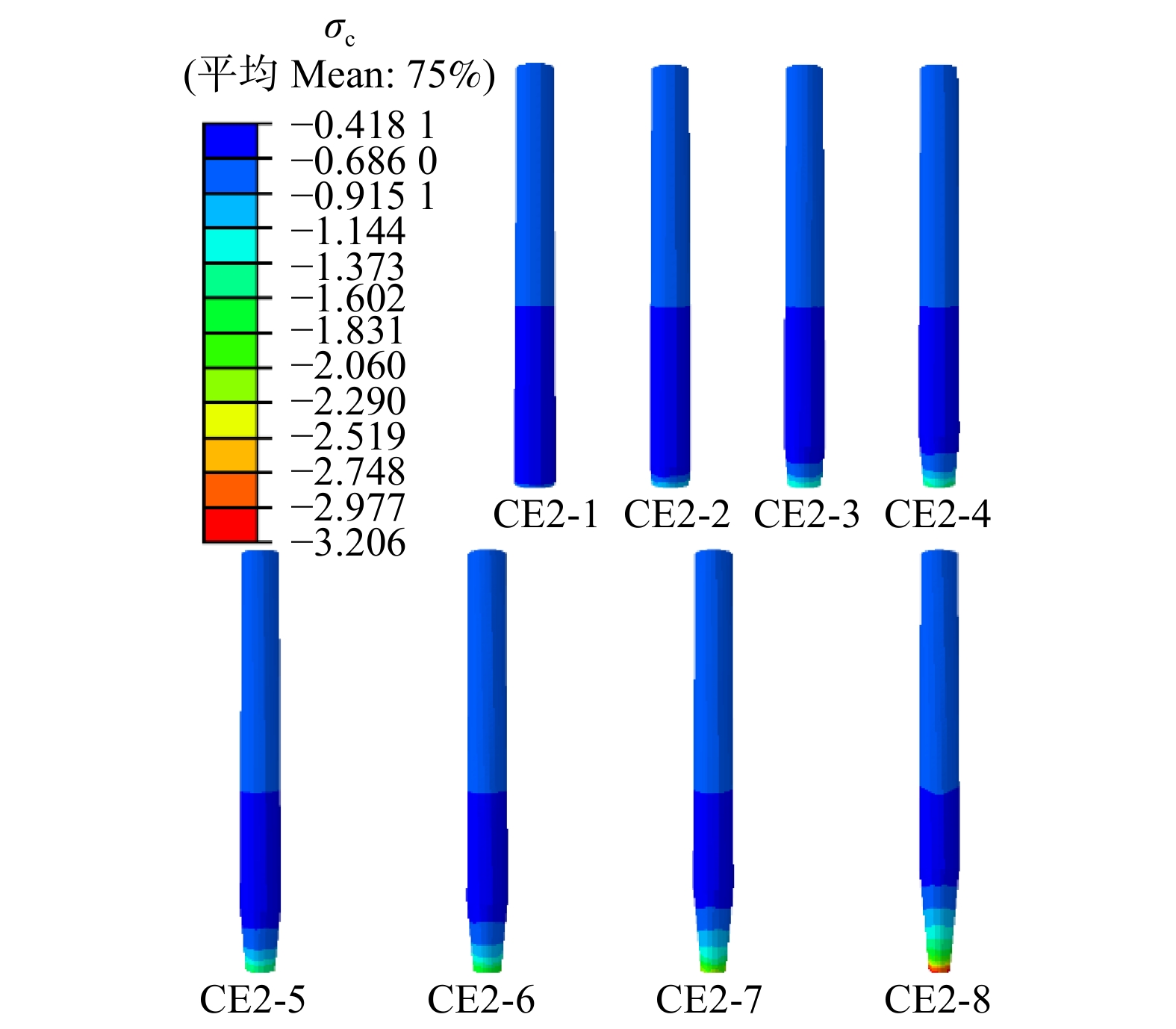

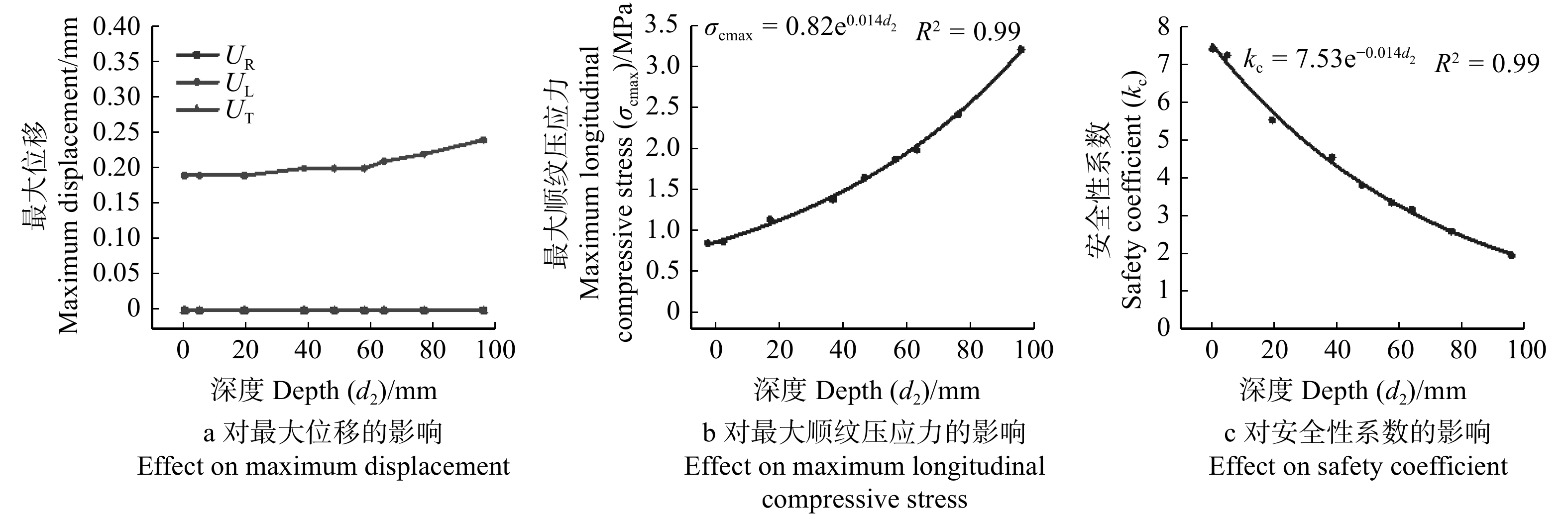

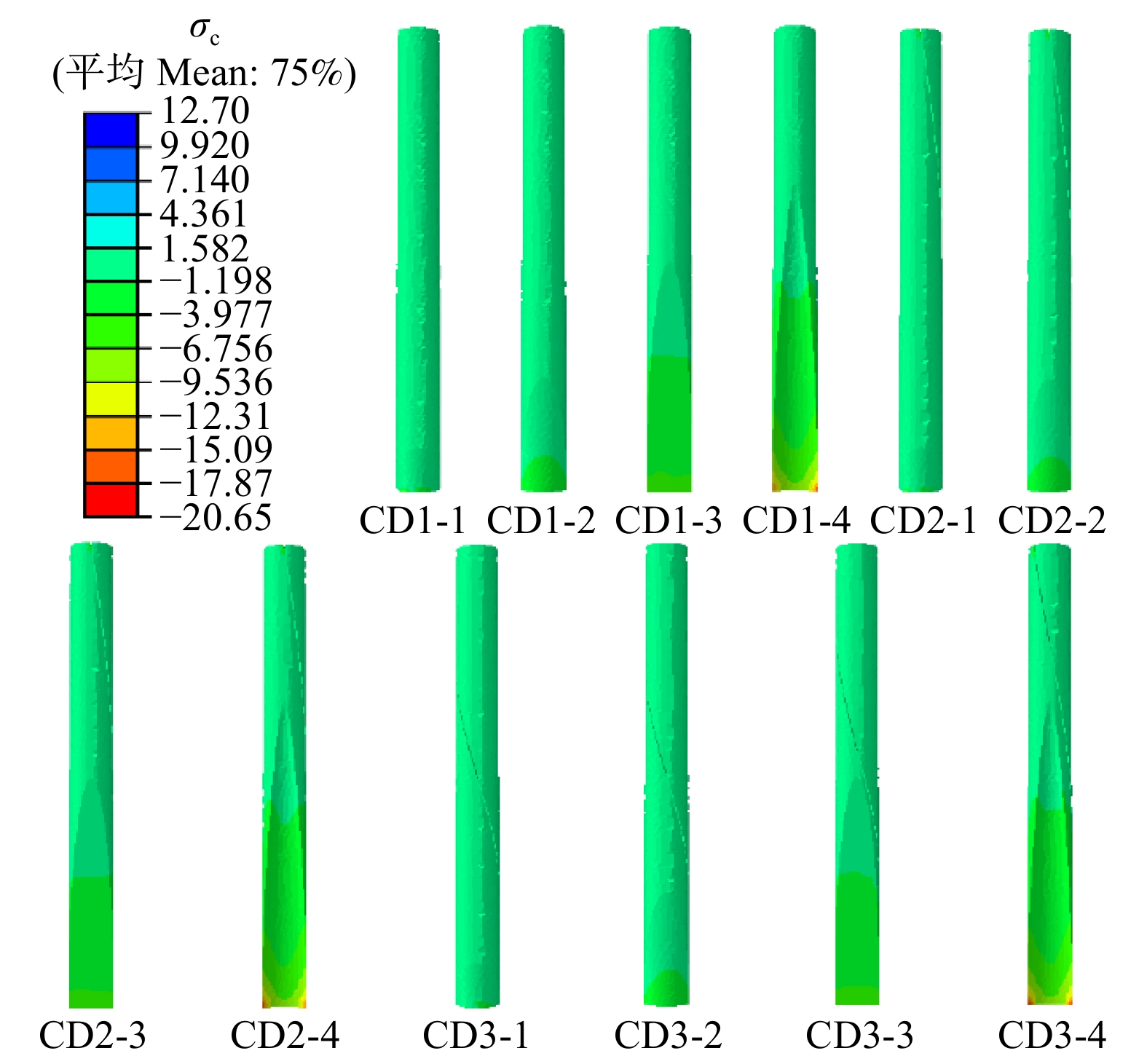

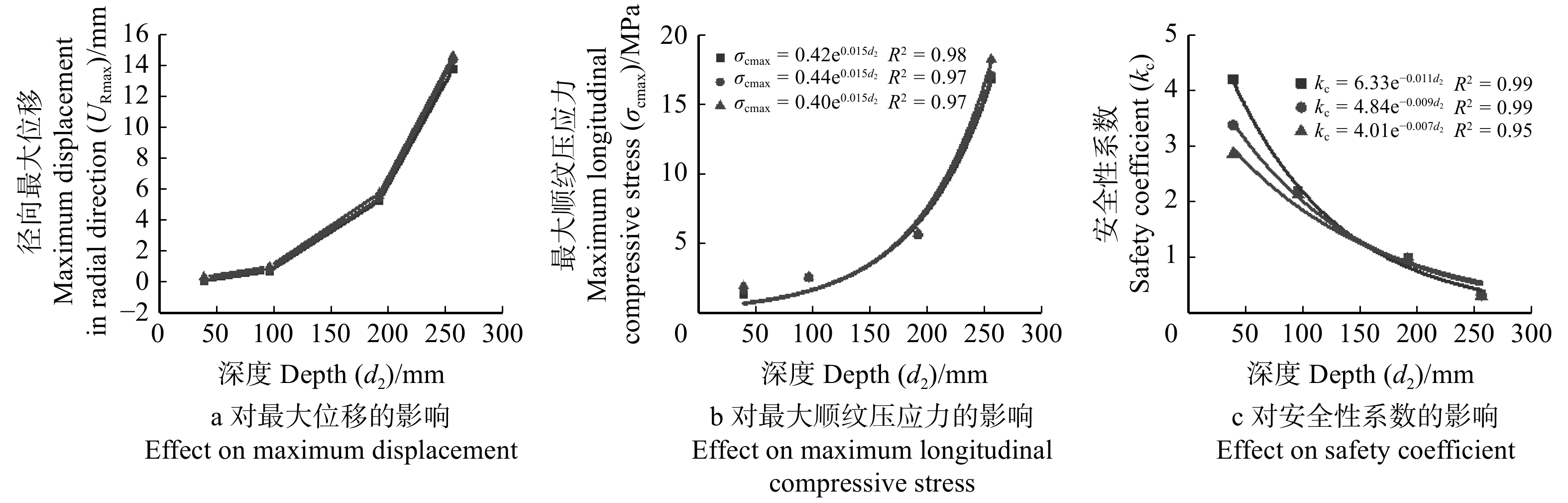

摘要:目的 墙体木柱作为木结构古建筑最重要的承重构件之一,容易出现裂纹、腐朽等缺陷,而各类缺陷会影响墙体木柱顺纹压应力的分布,导致其承载力降低,进而影响其安全性,直接威胁整个建筑的稳定性。因此,研究不同类型的缺陷对古建筑墙体木柱安全性影响是很有必要的。方法 首先建立了墙体木柱裂纹缺陷、腐朽缺陷以及复合缺陷几何模型,并定义了墙体木柱的受压安全性系数kc,然后使用Abaqus有限元软件分别模拟分析了裂纹缺陷模型、单侧腐朽缺陷模型、环形腐朽缺陷模型和复合缺陷模型最大顺纹压应力的大小和位置,探究了不同尺寸的缺陷对墙体木柱安全性的影响,并进行了实例验证。结果 单侧腐朽缺陷以及复合缺陷会使墙体木柱在径向上出现较大偏移,对木柱的稳定性产生较大影响,而裂纹缺陷和环形腐朽缺陷在径向、顺纹方向和切向上偏移较小;裂纹缺陷、单侧腐朽缺陷、环形腐朽缺陷和复合缺陷都对墙体木柱最大顺纹压应力和安全性有较大影响,最大顺纹压应力总是出现在有效截面面积最小处,且均随各缺陷程度的增大呈指数增加,而安全性系数呈指数下降,同时复合缺陷对墙体木柱安全性的影响要大于单一缺陷对墙体木柱的安全性影响。半露明柱与暗柱在腐朽深度相同时,安全性相差不大,在腐朽面积相同时,半露明柱的安全性要远低于暗柱。结论 裂纹缺陷和腐朽缺陷会降低墙体木柱的安全性,而有限元数值模拟能够计算出墙体木柱的顺纹压应力最大值,进而量化墙体木柱的安全性,其结果可以为墙体木柱的修缮提供依据。Abstract:Objective As one of the most important load-bearing components of wooden structure ancient buildings, the wall wood columns are prone to occur the defects such as cracks and decay. All kinds of defects will affect the distribution of longitudinal compressive stress of wall wood columns, leading to a reduction in its bearing capacity, which then affects its safety and directly threatens the stability of the whole building. Therefore, it is necessary to study the influence of different types of defects on the safety of wall wood columns of ancient buildings.Method Firstly, in this paper, the geometric models of wall wood columns with crack, decay defects and composite defects were established, and the compression safety factor kc of wall wood column was defined. Then, the magnitude and location of the maximum longitudinal compressive stress were simulated and analyzed using Abaqus finite element software for the crack defect model, the unilateral decay defect model, the ring decay defect model and the composite defect model, respectively. The influence of defects of different sizes on the safety of wall wood columns was investigated and verified by an example.Result The unilateral decay defects and composite defects caused large deflections in the radial direction of the wall wood columns, which had a greater influence on the stability of wood columns, while wall wood columns with crack defects and ring decay defects had smaller deflections in the radial direction, longitudinal direction and tangent direction. Crack defects, unilateral decay defects, ring decay defects and composite defects had a significant influence on the maximum longitudinal compressive stress and the safety of wall wood columns. The maximum longitudinal compressive stress always occurred at the minimum effective sectional area. The longitudinal compressive stress in wall wood columns increased exponentially with the increase of defect degree and the safety factor decreased exponentially with the increase of defect degree, while the impact of composite defects on the safety of wall wood columns was greater than that of a single defect on the wall wood column safety impact. The difference in safety between semi-exposed columns and concealed columns was not much when the decay depth was same, and the safety of semi-exposed columns was much lower than that of concealed columns when the decay area was same.Conclusion The crack defects and decay defects can reduce the safety of wall wood columns, and the finite element numerical simulation can calculate the maximum longitudinal compressive stress of wall wood columns, and then quantify the safety of wall wood columns, and the results can provide a basis for the repair of wall wood columns.

-

Keywords:

- wall wood column /

- defect /

- numerical simulation /

- safety

-

《北京林业大学学报》(原名《北京林学院学报》)创刊于1979年,由教育部主管、北京林业大学主办,国内外公开发行。历任主编分别为我国6位著名林学家汪振儒、沈国舫、关毓秀、王九龄、贺庆棠、尹伟伦。

《北京林业大学学报》是中文核心期刊、中国科技核心期刊、中国科学引文数据库统计源期刊、中国科技论文统计源期刊。荣获第二届国家期刊奖提名奖、第三届国家期刊奖百种重点期刊、中国精品科技期刊、中国高校精品科技期刊、中国国际影响力优秀学术期刊、“中国科技论文在线优秀期刊”一等奖等。

连续收录《北京林业大学学报》的著名检索期刊和数据库有:美国《化学文摘》(CA)、俄罗斯《文摘杂志》(AJ)、英国国际农业与生物学数据库(CABI)、英国《动物学记录》(ZR)、中国科学引文数据库(CSCD)、中国科技论文统计与引文分析数据库(CSTPCD)、《中国学术期刊文摘》《中国生物学文摘》、中国林业科技文献数据库等。

《北京林业大学学报》是中国最有代表性的林业科学期刊之一,主要刊登代表中国林业科学研究前沿创新水平的稿件。期刊定位为“立足中国,面向世界”的全国性林业科学期刊。面向国内外作者广泛征稿,对校内外稿件的质量要求一视同仁。

为保持学科特色,《北京林业大学学报》重点报道以林木遗传育种学、森林培育学、森林经理学、森林生态学、树木生理学、森林土壤学、森林植物学、森林保护学、自然保护区学、园林植物与观赏园艺、风景园林、水土保持与荒漠化防治、森林工程、木材科学与技术、林产化学加工工程、其他学科在林学上的应用等方面的论文。

《北京林业大学学报》现拥有以北京林业大学、中国林业科学研究院、中国科学院、国内其他综合性大学、农林院校、工科院校以及国外有关科研机构和大学等单位的研究人员为主的作者队伍。近年来随着期刊学术水平和影响因子的不断提高,投稿量显著增加,其中校外作者的投稿量占总收稿量的2/3左右。在此,我们对所有给《北京林业大学学报》赐稿的作者表示衷心的感谢!

《北京林业大学学报》自2015年起由原来的双月刊改为单月刊,大16开本,每月月底出版。每期定价50元。各地邮局发行,邮发代号:82−304。国内统一刊号:CN 11−1932/S。如当地邮局订阅不便或错过征订时间,也可直接汇款向本刊编辑部订阅。

地址:北京市海淀区清华东路35号《北京林业大学学报》编辑部

邮编:100083 发行电话:010−62338397 联系人:刘大林

发行电子信箱:liudalin@bjfu.edu.cn

网址:http://j.bjfu.edu.cn,http://journal.bjfu.edu.cn

-

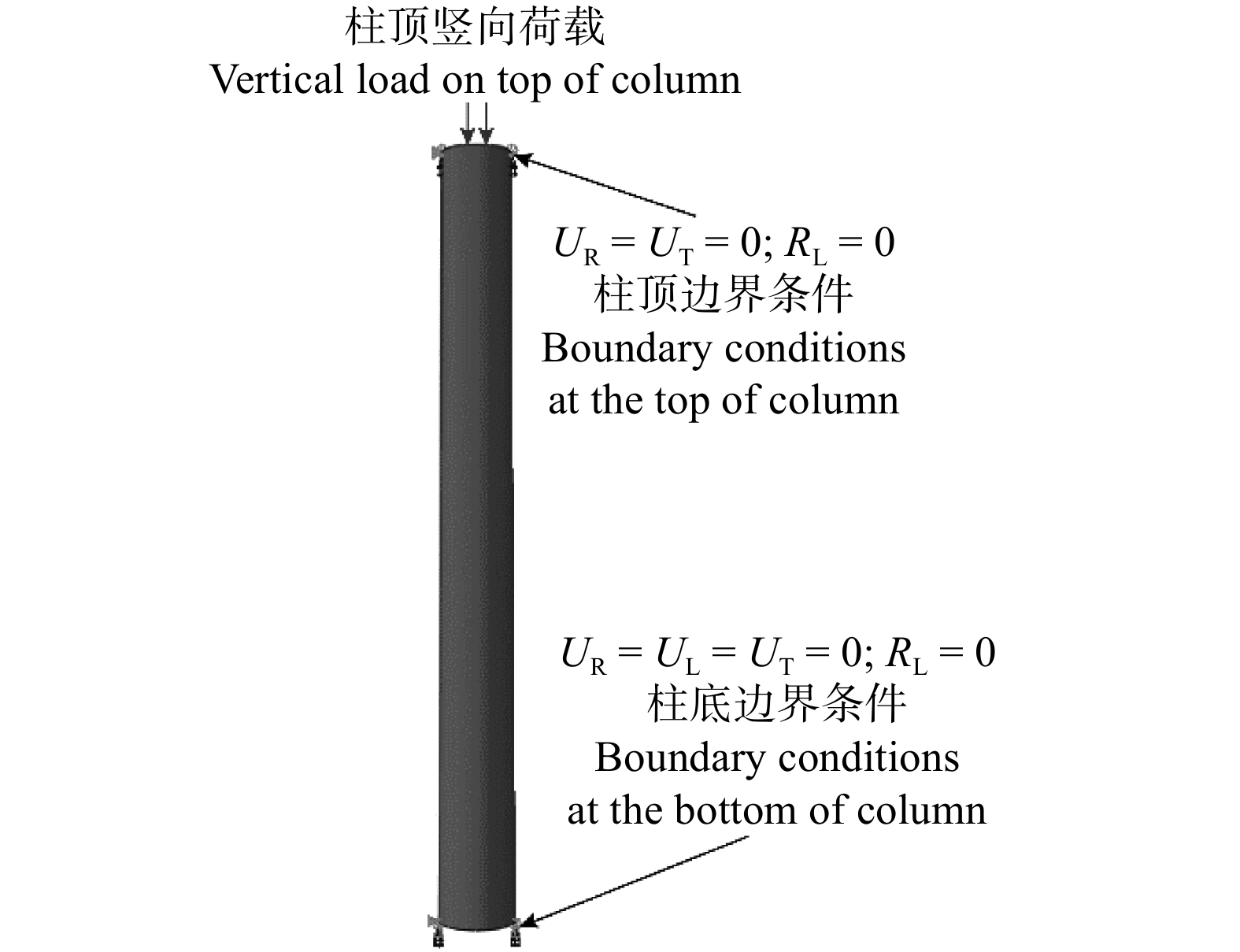

图 6 墙体木柱模型施加荷载与设定边界条件示意图

UR 为径向位移,UL 为顺纹方向位移,UT 为弦向位移,RL 是顺纹方向的转动。UR is radial displacement. UL is longitudial displacement, UT is tangential displacement, RL is rotation in longitudinal direction.

Figure 6. Schematic diagram of applying load and setting boundary conditions of wall wood column model

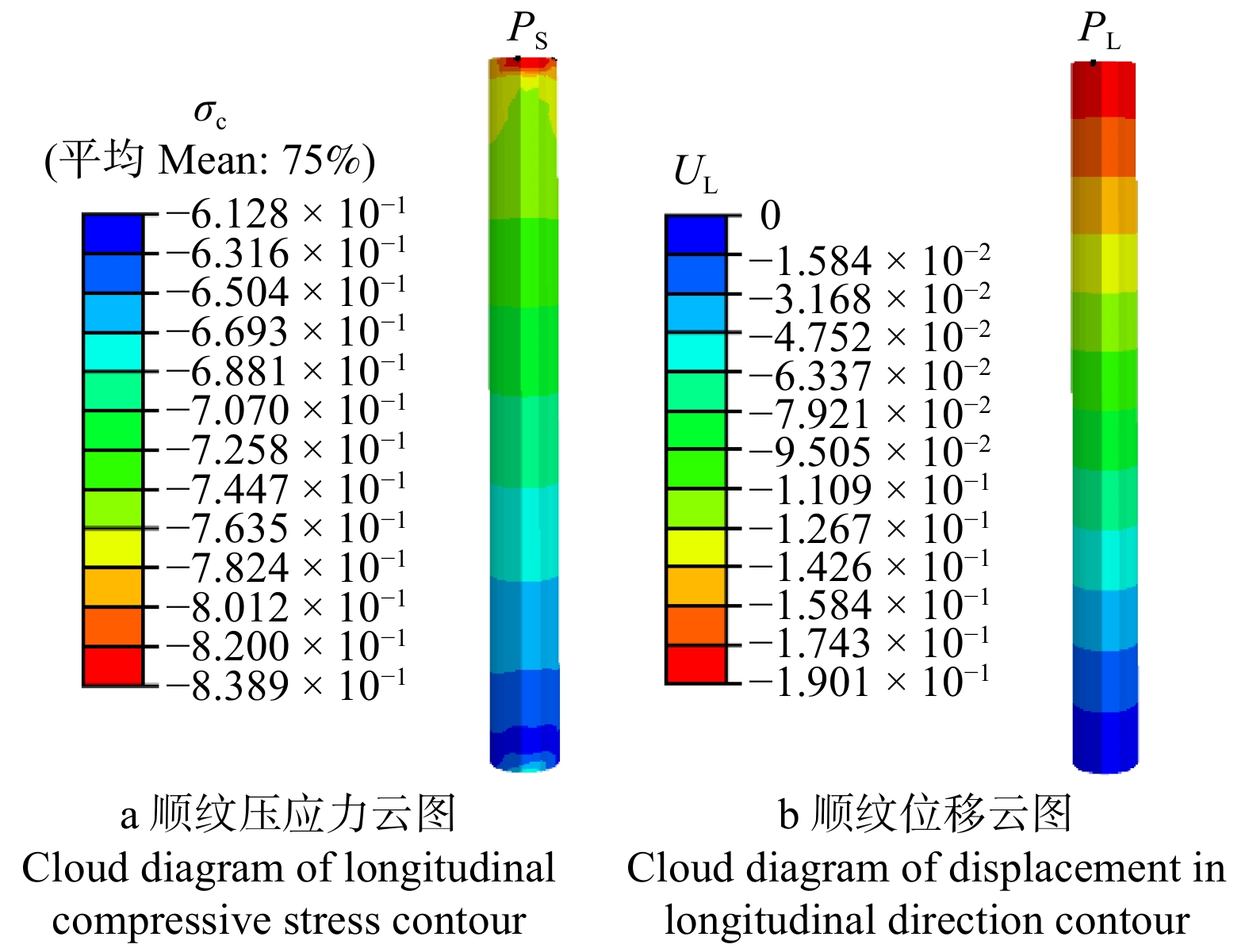

图 8 完好墙体木柱模型数值计算结果

σc 表示顺纹压应力,MPa;PS表示最大压应力位置。UL 表示顺纹方向位移,mm;PL 表示最大顺纹位移位置。σc is longitudinal compressive stress, MPa;PS is the position of maximum compressive stress. UL is the displacement in longitudinal direction, mm. PL is the position of maximum displacement in longitudinal direction.

Figure 8. Numerical calculation results of intact wall wood column model

图 18 某古建筑墙体木柱数值计算结果

UR 表示径向位移,mm;PR 表示最大径向位移位置;σc 表示顺纹压应力,MPa;PS表示最大压应力位置。UR is the displacement in radial direction, mm. PR is the position of maximum displacement in radial direction;σc is the longitudinal compressive stress, MPa. PS is the position of maximum compressive stress.

Figure 18. Numerical calculation results of wall wood column of an ancient building

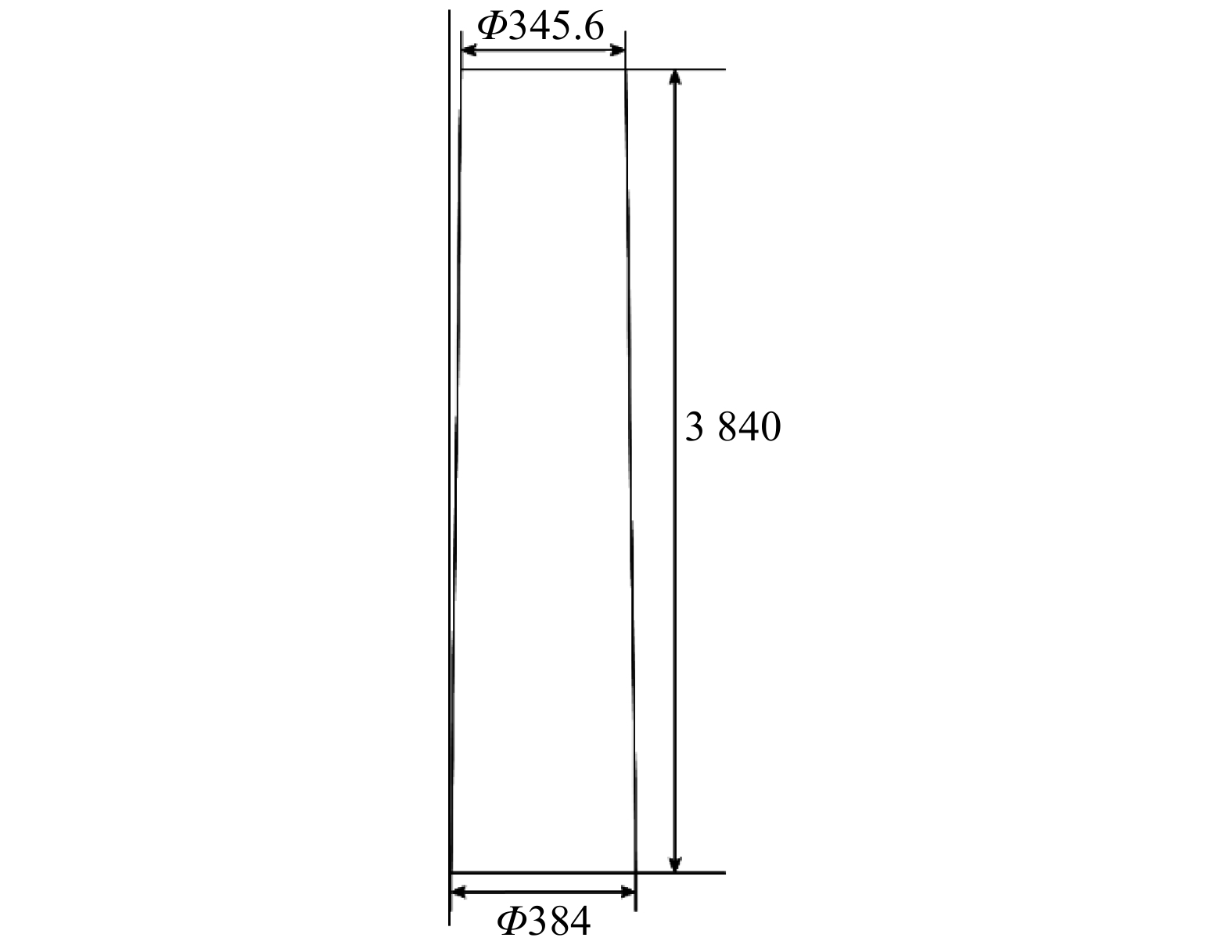

表 1 清式带斗拱建筑檐柱尺寸

Table 1 Dimensions of eave columns of Qing style buildings with bucket arches

等级

Grade尺寸

Size檐柱径

Eave column

diameter/mm檐柱高

Eave column

height/mm一等材

First grade material6.0 1 152 11 520 二等材

Second grade material5.5 1 056 10 560 三等材

Third grade material5.0 960 9 600 四等材

Fourth grade material4.5 864 8 640 五等材

Fifth grade material4.0 768 7 680 六等材

Sixth grade material3.5 672 6 720 七等材

Seventh grade material3.0 576 5 760 八等材

Eighth grade material2.5 480 4 800 九等材

Ninth grade material2.0 384 3 840 十等材

Tenth grade material1.5 288 2 880 十一等材

Eleventh grade material1.0 192 1 920 注:数据引自文献[11],尺寸的单位为寸。Notes: data is cited from reference [11],dimensions are in inches. 表 2 裂纹缺陷模型几何参数

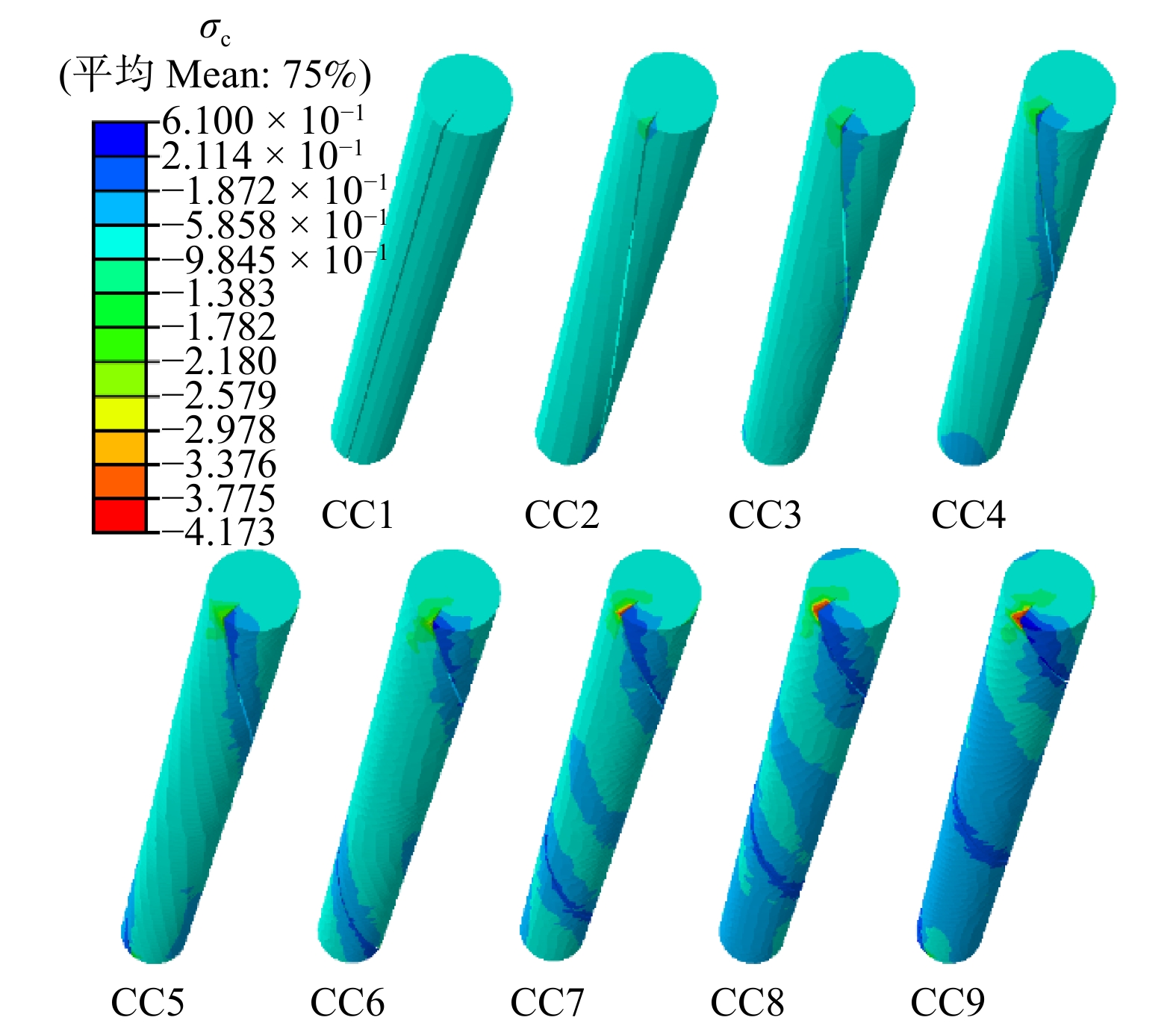

Table 2 Geometric parameters of crack defect models

模型编号

Model No.裂纹斜度

Crack slope (θ)/(°)裂纹深度

Crack depth (d1)/mm裂纹宽度

Crack width (w)/mm裂纹高度

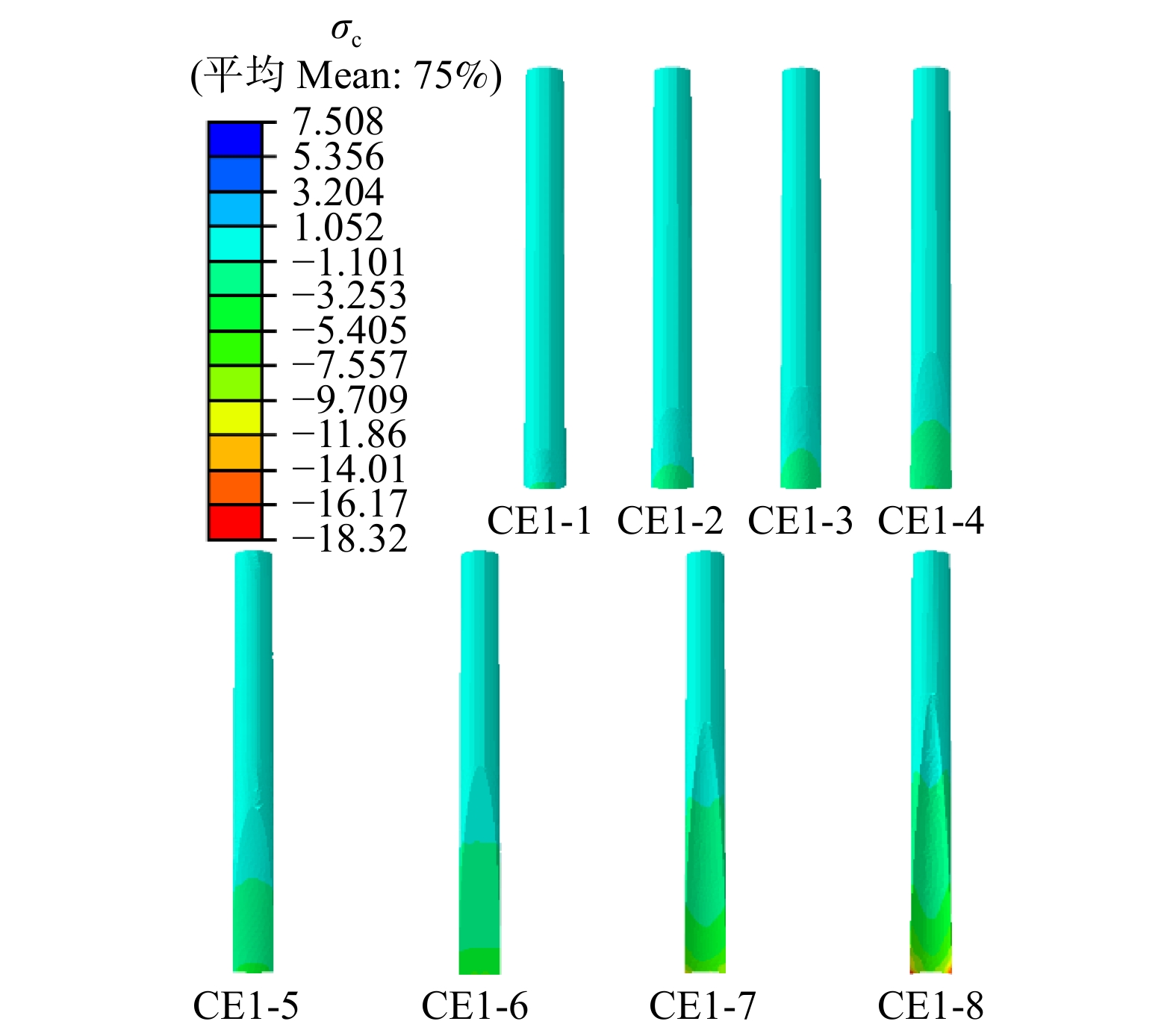

Crack height (l)/mmC0 0 0 0 0 CC1 0 100 10 3 840 CC2 4.5 100 10 3 840 CC3 8.9 100 10 3 840 CC4 13.3 100 10 3 840 CC5 17.4 100 10 3 840 CC6 21.4 100 10 3 840 CC7 25.2 100 10 3 840 CC8 28.8 100 10 3 840 CC9 32.1 100 10 3 840 表 3 腐朽缺陷模型几何参数

Table 3 Geometric parameters of decay defect models

模型编号

Model No.腐朽深度

Decay depth

(d2)/mm腐朽高度

Decay height

(h)/mm腐朽面积占比

Proportion of

decay area (η)/%C0 0 0 0 CE1-1 38.4 384 5 CE1-2 76.8 768 14 CE1-3 96.0 960 20 CE1-4 128.0 1 280 29 CE1-5 153.6 1 536 37 CE1-6 192.0 1 920 50 CE1-7 230.4 2 304 63 CE1-8 256.0 2 560 71 CE2-1 4.8 48 5 CE2-2 19.2 192 20 CE2-3 38.4 384 36 CE2-4 48.0 480 44 CE2-5 57.6 576 50 CE2-6 64.0 640 56 CE2-7 76.8 768 64 CE2-8 96.0 960 75 表 4 复合缺陷模型几何参数

Table 4 Geometric parameters of composite defect model

模型编号

Model No.裂纹斜度

Crack slope

(θ)/(°)裂纹深度

Crack depth

(d1)/mm裂纹宽度

Crack width

(w)/mm裂纹高度

Crack height

(l)/mm腐朽深度

Decay depth

(d2)/mm腐朽高度

Decay height

(h)/mm腐朽面积占比

Proportion of

dacay area (η)/%CD1-1 0 100 10 3 840 38.4 384 5 CD1-2 0 100 10 3 840 96.0 960 20 CD1-3 0 100 10 3 840 192.0 1 920 50 CD1-4 0 100 10 3 840 256.0 2 560 71 CD2-1 8.9 100 10 3 840 38.4 384 5 CD2-2 8.9 100 10 3 840 96.0 960 20 CD2-3 8.9 100 10 3 840 192.0 1 920 50 CD2-4 8.9 100 10 3 840 256.0 2 560 71 CD3-1 17.4 100 10 3 840 38.4 384 5 CD3-2 17.4 100 10 3 840 96.0 960 20 CD3-3 17.4 100 10 3 840 192.0 1 920 50 CD3-4 17.4 100 10 3 840 256.0 2 560 71 表 5 顺纹抗压强度设计值折减系数

Table 5 Reduction coefficient for design value of longitudinal compressive strength

表 6 落叶松木材材性参数

Table 6 Wood property parameters of larch

EL/MPa ER/MPa ET/MPa μLR μLT μRT GLR/MPa GLT/MPa GRT/MPa 14 190 1 419 709.5 0.03 0.02 0.43 1 064.25 851.4 255.42 注:表6引自参考文献[21]和[22]。EL为木柱顺纹方向弹性模量;ER为径向弹性模量;ET为弦向弹性模量;μLR为径面的泊松比;μLT为弦面的泊松比;μRT为端面的泊松比;GLR为径面内的剪切模量;GLT为弦面内的剪切模量;GRT为端面内的剪切模量。Notes: Tab. 6 is cited from reference [21]

and [22]. EL is the longitudinal elastic modulus of wood column; ER is radial elastic modulus; ET is tangential elastic modulus; μLR is the Poisson’s ratio of radial plane; μLT is the Poisson’s ratio of tangential plane; μRT is Poisson’s ratio of end plane; GLR is shear modulus of radial plane; GLT is shear modulus of tangential plane; GRT is shear modulus of end plane.表 7 裂纹缺陷模型数值模拟结果

Table 7 Numerical simulation results ofcrack defect models

模型

编号

Model

No.顺纹最大

位移

Maximum

displacement

in longitudinal

direction

(ULmax)/mm径向最大

位移

Maximum

displacement

in radial

direction

(URmax)/mm弦向最大

位移

Maximum

displacement

in tangent

direction

(UTmax)/mm最大顺纹

压应力

Maximum

longitudinal

compressive

stress

(σcmax)/MPa安全性

系数

Safety

coefficient

(kc)C0 0.19 0 0 0.84 7.43 CC1 0.19 0.03 0 0.86 7.24 CC2 0.20 0.09 0.08 1.19 5.24 CC3 0.21 0.21 0.10 1.67 3.74 CC4 0.22 0.29 0.13 2.02 3.09 CC5 0.22 0.32 0.22 2.25 2.77 CC6 0.24 0.36 0.24 2.49 2.51 CC7 0.26 0.44 0.26 3.76 1.66 CC8 0.27 0.50 0.27 3.91 1.60 CC9 0.28 0.51 0.28 4.17 1.50 表 8 单侧腐朽模型数值模拟结果

Table 8 Numerical simulation results ofunilateral decay models

模型编号

Model No.ULmax/mm URmax/mm UTmax/mm σcmax/MPa kc C0 0.19 0 0 0.84 7.43 CE1-1 0.20 0.09 0 1.45 4.30 CE1-2 0.22 0.41 0 2.20 2.84 CE1-3 0.23 0.71 0 2.79 2.24 CE1-4 0.29 1.51 0 3.80 1.64 CE1-5 0.37 2.55 0 4.18 1.49 CE1-6 0.57 5.12 0 6.13 1.02 CE1-7 0.94 9.49 0.01 11.40 0.55 CE1-8 1.28 13.53 0.02 18.32 0.34 表 9 环形腐朽模型数值模拟结果

Table 9 Numerical simulation results ofannular decay models

模型编号

Model No.ULmax/mm URmax/mm UTmax/mm σcmax/MPa kc C0 0.19 0 0 0.84 7.43 CE2-1 0.19 0 0 0.86 7.26 CE2-2 0.19 0 0 1.37 4.55 CE2-3 0.20 0 0 1.37 4.55 CE2-4 0.20 0 0 1.64 3.80 CE2-5 0.20 0 0 1.87 3.34 CE2-6 0.21 0 0 1.98 3.15 CE2-7 0.22 0 0 2.42 2.58 CE2-8 0.24 0 0 3.21 1.94 表 10 复合缺陷模型数值模拟结果

Table 10 Numerical simulation results ofcomposite defect models

模型编号

Model No.ULmax/mm URmax/mm UTmax/mm σcmax/MPa kc CD1-1 0.19 0.06 0 1.48 4.22 CD1-2 0.24 0.68 0 2.84 2.20 CD1-3 0.58 5.24 0 6.36 0.98 CD1-4 1.30 13.77 0.02 19.03 0.33 CD2-1 0.21 0.13 0.21 1.84 3.39 CD2-2 0.25 0.77 0.22 2.85 2.19 CD2-3 0.60 5.41 0.22 6.42 0.97 CD2-4 1.35 14.35 0.22 19.38 0.32 CD3-1 0.22 0.31 0.32 2.18 2.86 CD3-2 0.27 0.97 0.34 2.92 2.14 CD3-3 0.63 5.76 0.36 6.46 0.97 CD3-4 1.38 14.61 0.37 20.65 0.30 -

[1] 郭开龙, 张厚江, 管成, 等. 木构件局部敲击信号的时域分析与研究[J]. 林业机械与木工设备, 2019, 47(2):42−46. doi: 10.3969/j.issn.2095-2953.2019.02.009 Guo K L, Zhang H J, Guan C, et al. Time domain analysis and research on local coin-tap signals of wood members[J]. Forestry Machinery & Working Equipment, 2019, 47(2): 42−46. doi: 10.3969/j.issn.2095-2953.2019.02.009

[2] 张典, 于永柱, 管成, 等. 故宫养心殿墙体木柱缺陷状况无损检测研究[J]. 北京林业大学学报, 2021, 43(5):127−139. doi: 10.12171/j.1000-1522.20210028 Zhang D, Yu Y Z, Guan C, et al. A non-destructive test study of the defect status of wooden columns in the walls of the Forbidden City[J]. Journal of Beijing Forestry University, 2021, 43(5): 127−139. doi: 10.12171/j.1000-1522.20210028

[3] 汤红永, 张伟平, 顾祥林, 等. 纵向开裂木柱轴压性能试验研究[C]//中国工程建设标准化协会建筑物鉴定与加固委员会. 全国建筑物鉴定与加固改造第九届学术交流会议论文集. 厦门: 福州大学, 2008. Tang H Y, Zhang W P, Gu X L, et al. Axial compression performance of timber column with longitudinal crack[C]//Committee of Assessment and Strengthening of Buildings, China Association for Engineering Construction Standardization. Papers of the 9th National Conference on Building Appraisal and Reinforcement and Reconstruction. Xiamen: Fuzhou University, 2008.

[4] 朱忠漫. 干缩裂缝对历史建筑木构件受力性能影响的试验研究[D]. 南京: 东南大学, 2015. Zhu Z M. A test study on the effect of dry shrink cracks on the force properties of wood components in historical buildings [D]. Nanjing: Southeastern University, 2015.

[5] 谷雨, 邱洪兴, 王靖翔. 腐朽对木柱承载力影响的数值模拟[J]. 淮海工学院学报(自然科学版), 2015, 24(增刊1):60−63. Gu Y, Qiu H X, Wang J X. Numerical simulation of wooden columns ’ bearing capacity with rot[J]. Journal of Huaihai Institute of Technology (Natural Sciences Edition), 2015, 24(Suppl.1): 60−63.

[6] 王玄. 损伤木柱的力学性能退化研究[D]. 西安: 西安建筑科技大学, 2017. Wang X. Analysis on the degradation of mechanical properties of damaged timber columns [D]. Xi ’an: Xi ’an University of Architecture and Technology, 2017.

[7] 郭宇航, 周淑容, 崔佳, 等. 木节对轴心受压胶合木柱稳定承载力的影响[J]. 土木建筑与环境工程, 2017, 39(3):44−49. Guo Y H, Zhou S R, Cui J, et al. Effect of knot on stability of glulam column under axial compressive loading[J]. Journal of Civil and Environmental Engineering, 2017, 39(3): 44−49.

[8] 常鹏, 胡娅春, 王军舰, 等. 累积变形影响下的半刚性节点古建木柱正截面压应力及承载力解析解[J]. 北京交通大学学报, 2018, 42(4):44−50. doi: 10.11860/j.issn.1673-0291.2018.04.006 Chang P, Hu Y C, Wang J J, et al. Normal section’s compression stress and bearing capacity analytical solution of ancient wood column semi-rigid connection joints influenced by cumulative deformation[J]. Journal of Beijing Jiaotong University, 2018, 42(4): 44−50. doi: 10.11860/j.issn.1673-0291.2018.04.006

[9] 欧自娜, 张厚江, 管成. 古建筑七架梁缺陷安全性影响数值模拟研究[J]. 北京林业大学学报, 2020, 42(4):44−50. Ou Z N, Zhang H J, Guan C. Numerical simulation of the safety influence of defects on Qijia-beams of ancient timber building[J]. Journal of Beijing Forestry University, 2020, 42(4): 44−50.

[10] 马炳坚. 中国古建筑木作营造技术[M]. 北京: 科学出版社, 1991. Ma B J. Wood construction technology of Chinese ancient architecture [M]. Beijing: Science Press, 1991.

[11] 梁思成. 清式营造则例[M]. 北京: 中国建筑工业出版社, 1934. Liang S C. Qing structural regulations [M]. Beijing: China Architecture & Building Press, 1934.

[12] 北京市文物局. 古建筑结构安全性鉴定技术规范 第1部分木结构: DB11/T 1190.1—2015 [S]. 北京: 北京市质量技术监督局, 2015. Beijing Municipal Administration of Cultural Heritage. Technical code for appraiser of structural safety of ancient building ( Part 1): timber structure: DB11/T 1190.1—2015 [S]. Beijing: Beijing Quality Technology Control Office, 2015.

[13] 中国木材标准化技术委员会. 木材缺陷图谱: GB/T 18000—1999 [S]. 北京: 国家质量技术监督局, 1999. China Wood Standardization Technical Committee. Wood defect atlas: GB/T 18000−1999 [S]. Beijing: State Bureau of Quality and Technical Supervision, 1999.

[14] 杨忠, 江泽慧, 费本华. 木材初期腐朽研究综述[J]. 林业科学, 2006, 42(3):99−103. doi: 10.3321/j.issn:1001-7488.2006.03.019 Yang Z, Jiang Z H, Fei B H. A summary of the early decay of wood[J]. Scientia Silvae Sinicae, 2006, 42(3): 99−103. doi: 10.3321/j.issn:1001-7488.2006.03.019

[15] Wilcox W W. Review of literature on the effects of early stages of decay on wood strength[J]. Wood and Fiber, 1978, 9(4): 252−257.

[16] Kennedy R W. Strength retention in wood decayed to small weight losses[J]. Forest Products Journal, 1958, 8(10): 308−314.

[17] Mizumoto S. The effect of decay caused by Gloeophyllum trabeum on the strength properties of Japanese red pine sap-wood[J]. Journal of the Ceramic Society of Japan, 1966, 48(1): 7−11.

[18] Toole E R. Reduction in crushing strength and weight associated with decay by rot fungi[J]. Wood Science, 1971, 3(3): 172−178.

[19] 中华人民共和国建设部. 木结构设计标准: GB50005—2017[S]. 北京: 中国建筑工业出版社, 2017. Ministry of Development of the People’s Republic of China. Code for design of timber structures: GB50005−2017[S]. Beijing: China Architecture & Building Press, 2017.

[20] 中华人民共和国建设部. 古建筑木结构维护与加固技术规范: GB 50165—2020[S]. 北京: 中国建筑工业出版社, 2020. Ministry of Development of the People ’s Republic of China. Technical code for maintenance and strengthening of ancient timber buildings: GB50165−2020[S]. Beijing: China Architecture & Building Press, 2020.

[21] 成俊卿. 木材学[M]. 北京: 中国林业出版社, 1985. Cheng J Q. Wood science [M]. Beijing: China Forestry Publishing House, 1985.

[22] 龙卫国, 杨学兵. 木结构设计手册 [M]. 北京: 中国建筑工业出版社, 2005. Long W G, Yang X B. Manual for design of timber structure [M]. Beijing: China Architecture & Building Press, 2005.

[23] 刘大可. 古建筑屋面荷载编汇(上)[J]. 古建园林技术, 2001(3):58−64. Liu D K. Assembly of roof loads in ancient buildings (section 1)[J]. Traditional Chinese Architecture and Gardens, 2001(3): 58−64.

[24] 中国工程建设标准化协会. 建筑结构荷载规范: GB 50009—2012[S]. 北京: 中国建筑工业出版社, 2012. China Association for Engineering Construction Standardization. Load code for the design of building structures: GB 50009−2012[S]. Beijing: China Architecture & Building Press, 2012.

下载:

下载: