Preliminary study of epoxy/polyester powder coating applied to reed-based particle board

-

摘要:目的 研究芦苇刨花板表面特性及其对于环氧聚酯粉末涂料涂饰效果的影响作用,为芦苇刨花板的粉末涂料涂饰提供理论和技术参考依据。方法 选用环氧聚酯粉末涂料,采用静电喷涂方式涂布于砂光处理的芦苇刨花板基材表面,在130 ℃条件下固化3 min制备了粉末涂料涂饰的饰面芦苇刨花板。在表征涂料固化行为和芦苇刨花板表面性能基础上,研究了砂光处理对板材表面性能与粉末涂料涂饰效果的影响。结果 环氧聚酯粉末涂料平均粒径为31.5 μm,在130 ℃条件下固化良好;砂光处理可以有效除去芦苇刨花板表层的预固化层和劣化物质,随着砂带目数的提高,芦苇刨花板表面的粗糙度和润湿性均有所改善,实验所选的范围内,240目砂光处理的效果最好;随着砂带目数的提高,粉末涂料在基材表面的流动性得到改善,所形成的涂层也更加平整,涂层平均厚度为125.4 μm,漆膜附着力为0级,铅笔硬度可达3H以上。结论 芦苇刨花板基材经过80目、120目、180目、240目砂带逐级砂光处理后与环氧聚酯粉末涂料结合性能良好,外观质量较优,该方法可以用于芦苇刨花板的粉末涂料涂饰。Abstract:Objective In order to provide a basis for the powder coating of reed-based particle board, this study explored the surface characteristics of reed-based particle board and its influence on the finishing effect of epoxy polyester powder coating.Method A kind of epoxy polyester powder coatings had been selected in this article, which was applied to reed-based particle board by electrostatic spraying, and cured at 130 ℃ in 3 min. On the basis of characterizing the curing behavior of coating and the surface properties of reed-based particle board, the effect of sanding treatment on the surface properties of the panel and the finishing properties of powder coatings was studied.Result The particle size of selected powder coatings which could cure at 130 ℃ was 31.5 μm on average. The sanding process could remove the procuring layer and the increasing of sandpaper mesh could improve the roughness and wettability of the reed-based panel. The effect of treatment of sanding mesh 240 was the best within the selected range of the experiment. The average thickness of coating formed by finishing was 125.4 μm. The coating adhesion grade of the powder coating was 0, and the hardness was more than 3 H. With the increase of sand mesh, the leveling property of powder coating on substrate surface was improved.Conclusion Reed-based particle board with the treatment of sanding mesh 80, 120, 180 and 240 has good bonding performance and appearance quality with epoxy polyester powder coating. This method can be used for reed-based particle board powder coating.

-

Keywords:

- reed-based particle board /

- powder coating /

- sanding treatment /

- coating performance

-

芦苇(Phragmites communis)是禾本科多年生草本植物,在我国中南、华东、华北、东北和西北地区均有分布[1],年产量可达250 ~ 300万t[2],其茎秆可以作为生产人造板的原料[1]。虽然芦苇茎秆表皮层具有的含硅蜡质层可以提高板材防水性,但不利于脲醛等的常用醛类胶黏剂的胶合[3],因此目前生产上主要以二苯基甲烷二异氰酸酯(methylene diphenyl diisocyanate,MDI)作为胶黏剂,制造的板材具有绿色环保、无甲醛、无刺激性气味、防潮等优点,在家具、室内装修装饰等领域具有广泛的应用前景[4]。为了提高芦苇刨花板装饰性能,改善表面质量,拓展使用性能,通常采用三聚氰胺浸渍纸饰面的方式对其进行二次加工。然而,芦苇刨花中含有硅质层、蜡质层[1],不利于芦苇刨花板与浸渍纸的复合,且三聚氰胺浸渍胶膜在使用过程中会释放游离甲醛,给从业者和消费者的健康带来威胁[5]。

粉末涂料是以树脂基料和固化剂为成膜物质,并辅以填料、颜料和功能性助剂的100%固体分的粉末形态涂料[6]。它以空气作为分散介质,通过静电喷涂技术分散吸附在基材表面,通过红外、UV或电子束辐射等方式熔融流平并固化成膜,具有节能环保、涂料损失少、涂装工序少、工艺简单、涂膜质量好等优点。瑞士Ciba公司、美国DuPont公司和奥地利Tiger公司等率先开始将粉末涂料应用于木材和纤维板涂饰,并开发了专用粉末涂料[7-13]。这类粉末涂料佐以颜料可以直接应用于人造板表面,粉末喷涂饰面加工的人造板具有外观优良、耐湿耐水、绿色环保的优点,可以直接应用于家具等木制品的生产。近年来,国内外研究者开始在胶合板、竹材、木质刨花板等表面进行粉末涂料的应用研究[14-20],较少涉及粉末涂料在非木基植物人造板上的应用研究,也未系统研究表面加工处理对涂饰性能影响。

芦苇刨花板相比于纤维板和实木,表面较为粗糙,不利于粉末涂料在其表面的流展;同时由于芦苇硅质层、蜡质层的存在,可能会对其粉末涂饰效果产生影响。因此,研究表面处理对芦苇刨花板的性能影响对于芦苇板的粉末涂饰具有重要意义。本研究通过分析芦苇刨花板的界面特征和环氧聚酯粉末涂料的固化行为,研究了板材砂光处理对粉末涂料涂饰效果的影响作用。以期达到丰富芦苇刨花板的装饰手段,拓宽其应用范围的目的。

1. 材料与方法

1.1 材 料

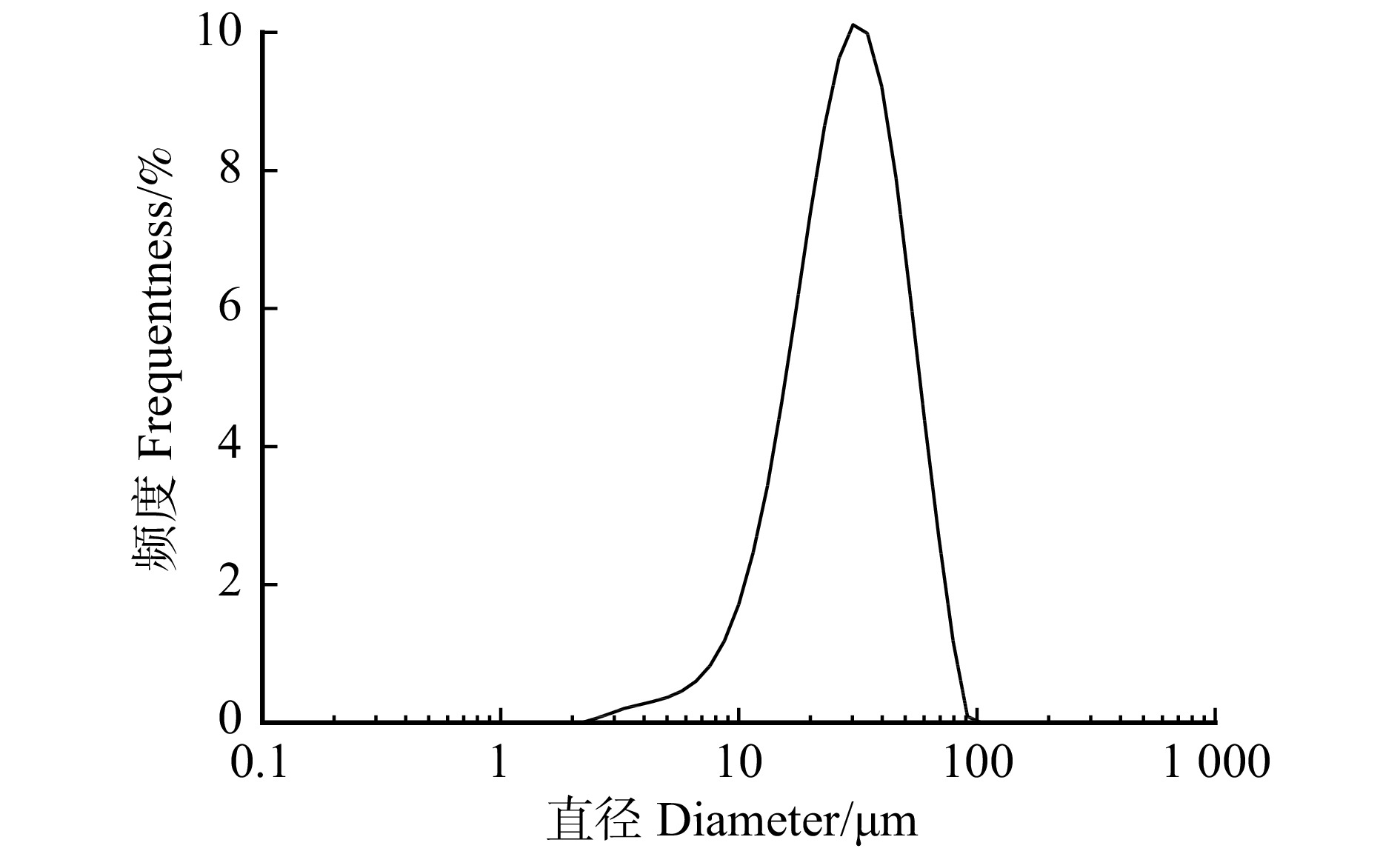

芦苇刨花板,由辽宁盘锦积葭生态板业有限公司生产,密度740 ~ 760 g/m3,含水率10% ~ 12%,试件规格200 mm(长) × 200 mm(宽) × 19 mm(厚)。粉末涂料,由黄山华佳表面科技有限公司提供,主要成分为聚酯树脂和环氧树脂,呈白色,固化条件为130 ℃。粉末涂料颗粒的粒径大小及分布均匀性对粉末喷涂过程中粉末涂料的分散性、带电性、堆积密度以及熔融流动性等都有影响,进而会对形成的涂膜厚度和外观质量产生影响,因此采用激光粒度仪对研究选用的环氧聚酯粉末涂料进行分析。图1显示:该粉末涂料的粒径呈正态分布,主要分布在12 ~ 50 μm之间,中径为26.9 μm,平均粒径为31.5 μm。砂带,品牌型号为鹿牌EA343,目数分别为80、100、120、150、180、240目,购于青岛城阳区翔宇达五金商行。

1.2 研究方法

1.2.1 工艺流程

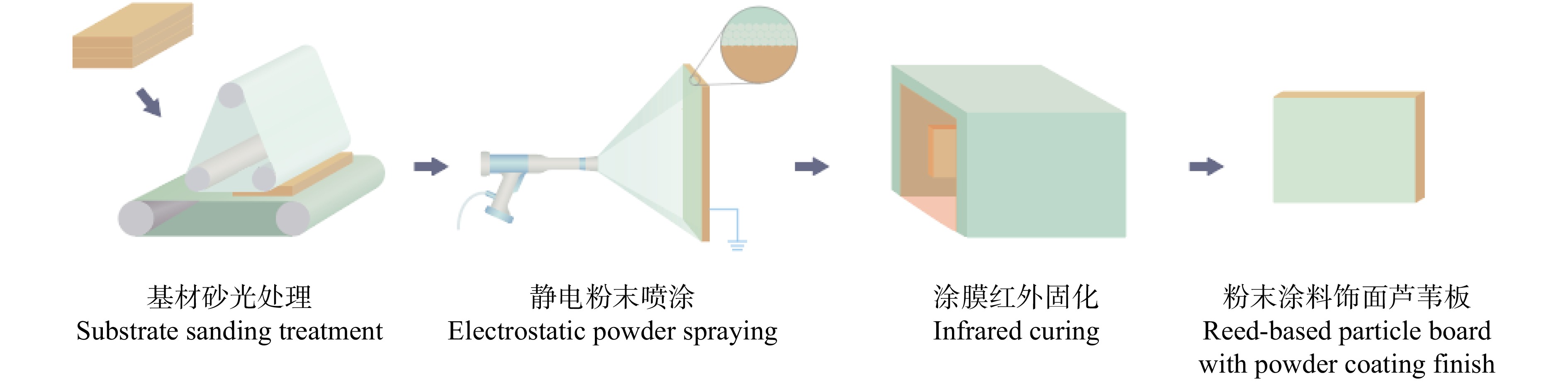

如图2所示:首先将芦苇刨花板裁切成200 mm(长) × 200 mm(宽) × 19 mm(厚)的试件,采用带式砂光机对其表面进行砂光处理,然后将试件送入静电粉体喷房将粉末涂料喷涂在其表面,并立刻将其送入红外线加热炉中进行固化,最终得到粉末涂料涂饰的芦苇刨花板。

1.2.2 基材表面砂光

采用带式砂光机(YMS-2560DA,远铭工业股份有限公司)对芦苇刨花板进行砂光,试件进给速度为10 m/s,砂削速度为15 m/s,试件单面砂削总量0.3 mm,根据表1设计的工艺进行逐级砂光处理。

表 1 砂光处理实验设计Table 1. Experimental design of sanding treatment序号 No. 砂光工序 Sanding process 目数1

Mesh 1目数2

Mesh 2目数3

Mesh 3目数4

Mesh 4对照组

Control group1 80 80 2 80 100 3 80 100 120 4 80 100 120 150 5 80 120 150 180 6 80 120 180 240 1.2.3 粉末静电喷涂

本实验设定静电电压为35 kV,供粉气压为0.05 MPa,将芦苇刨花板试样垂直悬挂于静电粉体喷房的金属挂钩上进行喷涂试验,喷嘴与板材距离为30 cm,上粉量80 g。

1.2.4 涂膜固化工艺

经静电喷涂后的板材送入红外线加热炉(80114962,德国贺利氏产)中进行涂膜固化,固化温度130 ℃,固化时间3 min。

1.2.5 激光粒度测试

利用激光粒度仪(Malvern Mastersizer 2000,英国马尔文仪器有限公司)采用湿法测定粉末涂料粒径。以蒸馏水作为分散介质,用超声法将粉末涂料分散均匀,超声时间为5 min。

1.2.6 差示扫描量热测试

采用差示扫描量热仪(differential scanning calorimeter,DSC)测试粉末涂料的热力学参数。在氮气气氛下对粉末涂料进行30 ~ 300 ℃的等速升温测试, 扫描升温速率分别为5、10、15、20 ℃/min,得到该粉末涂料在不同升温速率下的DSC曲线。对DSC曲线进行分析,采用切线与基线交叉点法计算粉末涂料固化的起始、峰值和终止温度。

1.2.7 板材厚度测试

利用螺旋测微仪测量芦苇刨花板的厚度,每个试件随机选取10点,计算平均值。

1.2.8 表面粗糙度测试

采用表面粗糙度测量仪(TR200,吉泰科仪)根据GB/T12472—2003《产品几何量技术规范(GPS)表面结构 轮廓法木制件表面粗糙度参数及其数值》测定试件的表面粗糙度。选取轮廓算数平均偏差(Ra)、轮廓最大高度(Rz)、轮廓最大峰高(Rp)、轮廓微观不平度的十点高度(RzJIS)和轮廓微观不平度的平均间距(Rs)作为粗糙度特征参数。测试时,每个试件随机取5个点求平均值,沿垂直砂光方向进行采样,选择GAUSS滤波器,取样长度(λc)为2.5 mm,取样误差范围为 ± 80 μm。

1.2.9 接触角测试

利用光学接触角测量仪(SL200B,美国科诺工业有限公司)采用停滴法测定蒸馏水在不同砂光处理前后的芦苇刨花板表面所形成的动态接触角。每次测量使用设备的针头在待测样品的表面滴1滴液滴(约2 μL),采集液滴在试件表面形成的图像,设置拍摄频率为每秒1张,记录接触角随时间变化的曲线。

1.2.10 微观形貌观测

将饰面芦苇刨花板制成5 mm(长) × 5 mm(宽) × 1 mm(厚)试件,制备时从基材部分开始锯切,在涂层附近停止锯切使其自然断裂,从而避免表面涂膜污染截面。在60 ℃真空环境下干燥6 h,并对样品进行喷金处理。用扫描电子显微镜(ZEISS Gemini 300,德国卡尔·蔡司股份公司)进行观察。形貌拍摄时加速电压3.0 kV,样品成像表面到物镜距离为4.9 mm,放大倍数为50倍和500倍。

1.2.11 涂膜主要性能测试

按照GB/T4893.4—2013《家具表面漆膜理化性能试验第4部分:附着力交叉切割测定法》中提供的方法对漆膜附着力进行测试;按照GB/T17657—2013《人造板及其饰面人造板理化性能实验方法》测试漆膜硬度。

2. 结果与分析

2.1 粉末涂料固化动力学分析

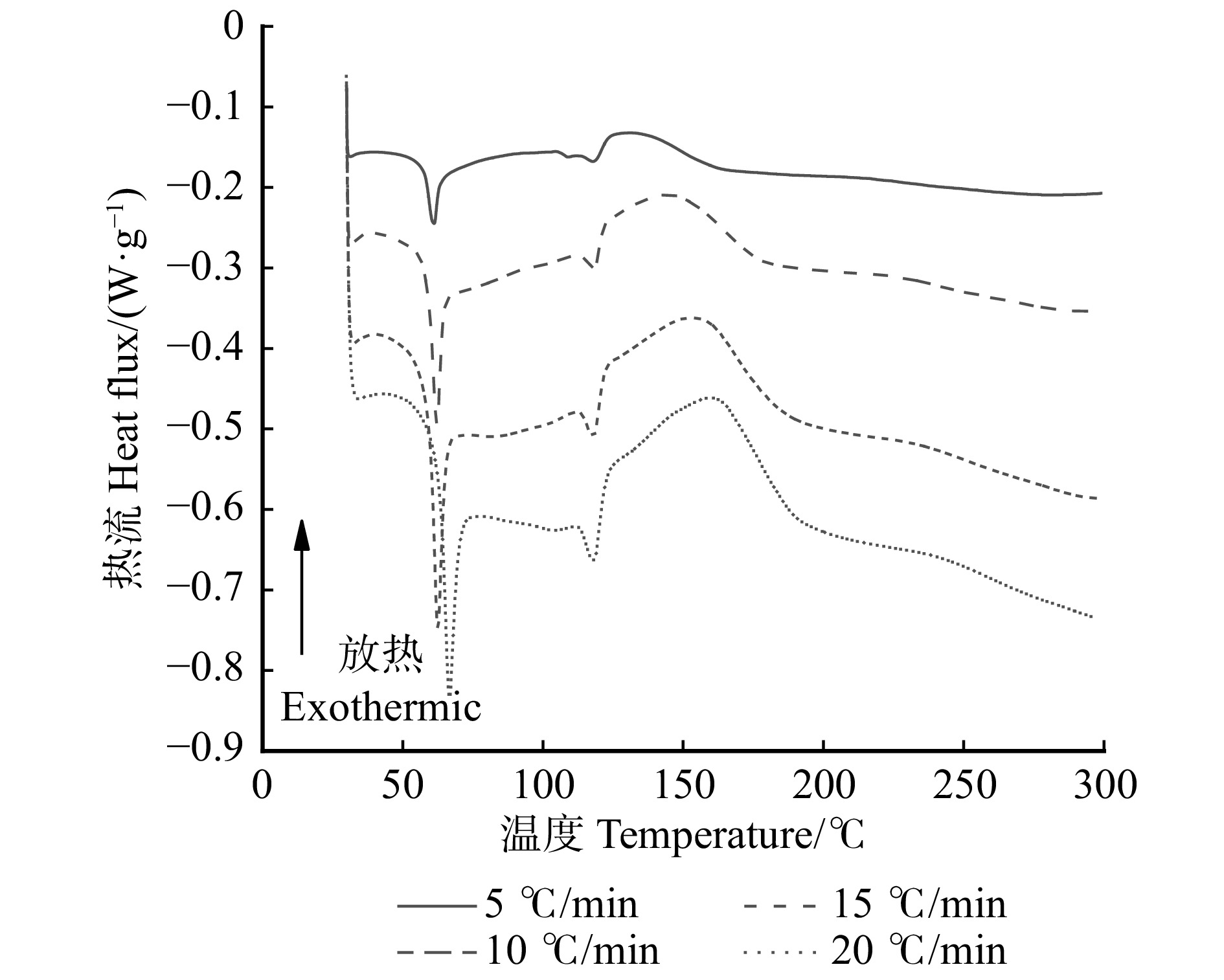

为确定实验所选粉末涂料的固化条件,采用非等温差示扫描量热分析法[21-24]分别对5、10、15、20 ℃/min的升温速率下粉末涂料固化行为进行研究。从图3可以看出:该粉末涂料在不同升温速率下,在60 ~ 70 ℃之间都呈现出一个吸热峰,该吸热峰可能是由水分蒸发造成的;在120 ℃附近的吸热峰是粉末涂料由固态转为熔融态相变所产生的吸热峰。120 ~ 180 ℃之间有一个放热峰,说明该涂料在此温度区间内固化,由于该粉末涂料物质组成比较复杂,两种主要成膜物质的固化温度都在该温度范围内,因此使得放热峰比较宽。

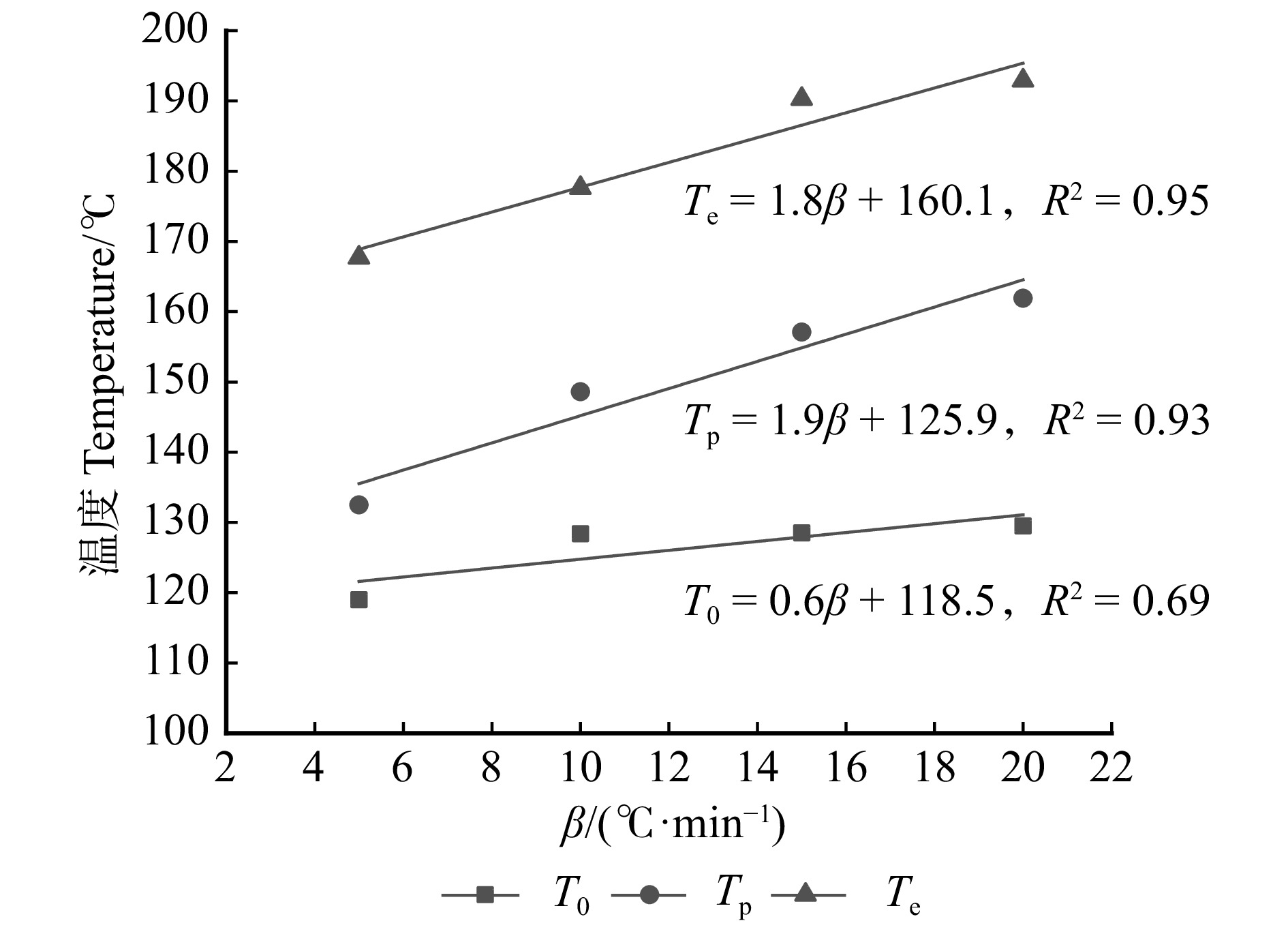

对实验测得的DSC曲线进行分析可以得到涂料固化的起始温度(T0)、峰值温度(Tp)和终止温度(Te)(表2)。结合图3和表2可以看出:升温速率(β)逐步加快,涂料固化的起始温度、峰值温度和终止温度都随之升高。可见升温速率会对涂层固化行为产生影响。在实际生产加工中,人造板基材经过静电喷涂后,会被直接送入已经达到设定固化温度的烘道中进行固化,可以认为此时烘道中的升温速率为0。对表2中粉末涂料固化的起始温度(T0)、峰值温度(Tp)和终止温度(Te)进行线性拟合,可以得到图4,从拟合直线外推至β = 0时,可以得到T0 = 118.5,Tp = 125.9,Te = 160.1,由此推断该粉末涂料理论凝胶温度为118.5 ℃,理论固化温度为125.9 ℃。考虑到实际条件不同于理想状态,因此本研究中芦苇刨花板粉末涂饰的温度设定为130 ℃。

表 2 不同升温速率下固化过程中的特征温度Table 2. Curing temperature at different heating ratesβ/(℃·min−1) T0/℃ Tp/℃ Te/℃ 5 119.0 132.5 167.7 10 128.4 148.6 177.6 15 128.5 157.1 190.3 20 129.5 161.9 192.9 注:β为升温速率,T0为固化起始温度,Tp为固化峰值温度,Te为固化终止温度。Notes: β is the heating rate, T0 is the initial curing temperature, Tp is the peak curing temperature, and Te is the curing termination temperature. 2.2 砂光处理对芦苇板基材表面性能的影响

2.2.1 砂光处理对芦苇刨花板厚度的影响

砂光处理是改善人造板厚度偏差的主要方法[25]。表3为试件6每级砂光后的厚度变化。由表3可知:应用80目砂带砂光可以有效降低板材的厚度偏差,随着砂带目数的逐级升高,板材平均厚度的标准差也随之降低,这进一步说明了砂光处理可以改善芦苇刨花板的厚度不均性。此外,随着砂带目数的提高,砂光磨削量逐步减少,精砂处理(180目和240目)对板材厚度的影响可以忽略不计。

表 4 砂光处理前后的芦苇刨花板表面的粗糙度参数的平均值Table 4. Average roughness of reed-based particle board surface with different sanding treatments砂带目数 Sanding mesh Ra/μm Rz/μm Rp/μm RzJIS/μm Rs/mm 未处理 Untreated 5.71 35.81 9.09 27.93 0.09 80 11.24 69.86 31.46 49.95 0.16 100 10.25 63.71 26.97 45.42 0.15 120 9.55 62.07 26.43 41.82 0.13 150 8.02 52.08 22.31 39.34 0.11 180 7.18 47.48 18.71 39.34 0.10 240 5.84 42.42 14.79 30.01 0.11 表 3 砂光处理对芦苇刨花板厚度的影响Table 3. Effects of sanding treatment on the thickness of reed-based particle boardmm 砂带目数 Sanding mesh 平均厚度 Average thickness 厚度偏差 Thickness deviation 标准差 Standard deviation 未处理 Untreated 19.52 +0.8

−1.30.12 80 19.21 ±0.4 0.05 120 19.03 −0.4

+0.30.04 180 18.88 ±0.3 0.04 240 18.80 −0.2

+0.30.02 2.2.2 砂光处理对芦苇刨花板表面粗糙度的影响

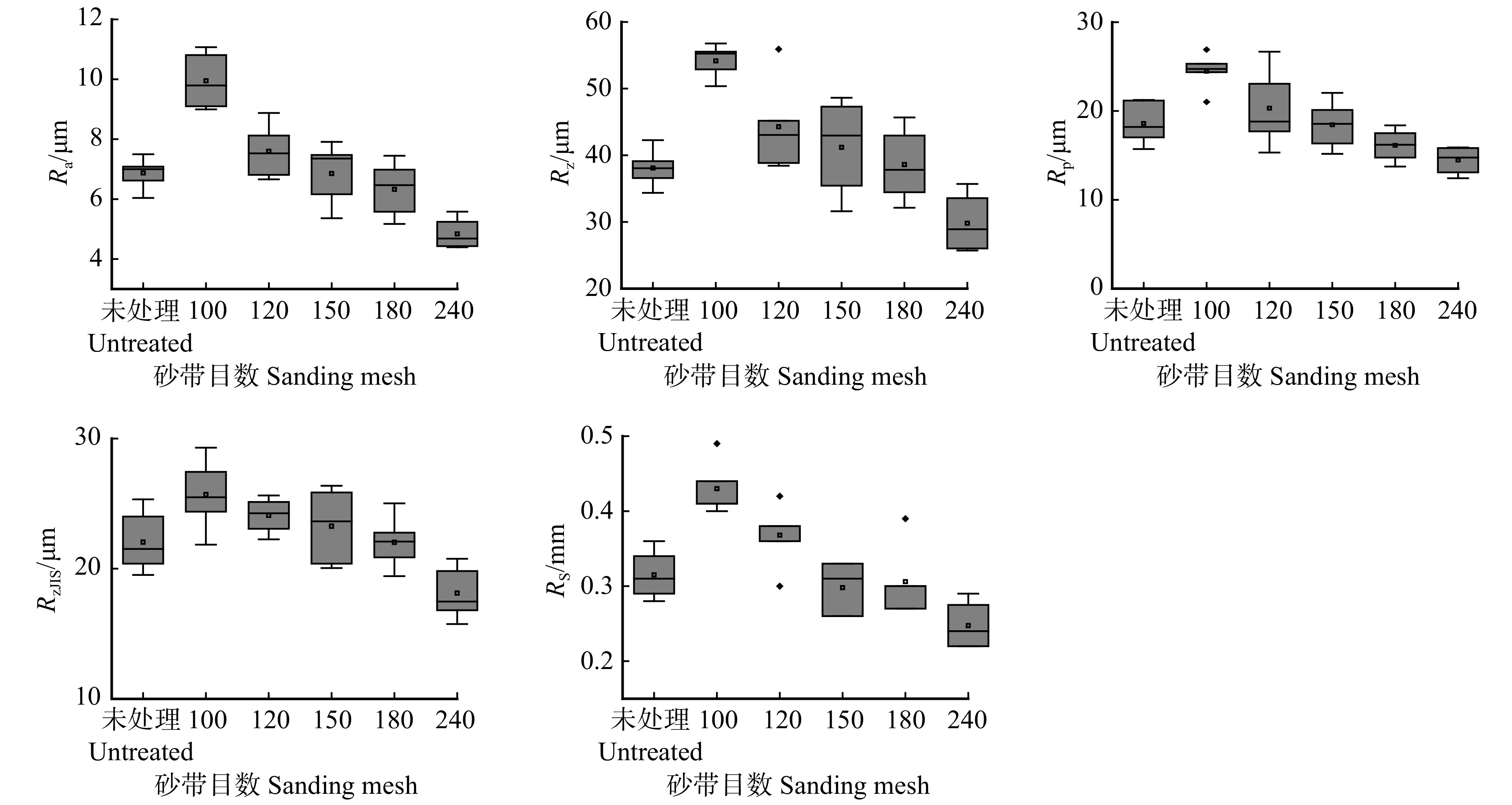

砂光处理会改变芦苇刨花板的表面粗糙度,同时随着砂带目数的增加,芦苇刨花板的表面粗糙度逐步降低。图5显示:未砂光的芦苇刨花板的Ra为5.71 μm,经砂光处理后板材Ra值由80目的11.24 μm降低至240目的5.84 μm;未砂光的芦苇刨花板的Rz为35.81 μm,经逐级砂光处理后由80目的69.86 μm降为240目的42.42 μm;未砂光的芦苇刨花板的Rp为9.09 μm,经逐级砂光处理后由80目的31.39 μm降为240目的14.79 μm;未砂光的芦苇刨花板的RzJIS为27.93 μm,经逐级砂光处理后由80目的49.95 μm降为240目的30.01 μm;未砂光的芦苇刨花板的Rs为0.09 mm,经逐级砂光处理后由80目的0.16 mm降为240目的0.11 mm。未经砂光处理的基材表面最为平滑,各级砂光处理后的板材中,80目处理的板材表面粗糙度最大,240目砂光后的板材表面粗糙度最小。其表面粗糙度各项参数的算数平均值如表4所示。

结合1.1中粉末涂料粒度分布的数据,实验所选粉末涂料尺寸分布在12 ~ 50 μm,中径为26.9 μm,完全可以进入到板材微观轮廓的波峰之间进行填充,240目砂光处理后的板材Rz平均值为42.42 μm,说明至少需要叠加2层粉末涂料才能消除板材表面的微观高度差。

2.2.3 砂光处理对芦苇刨花板表面润湿性的影响

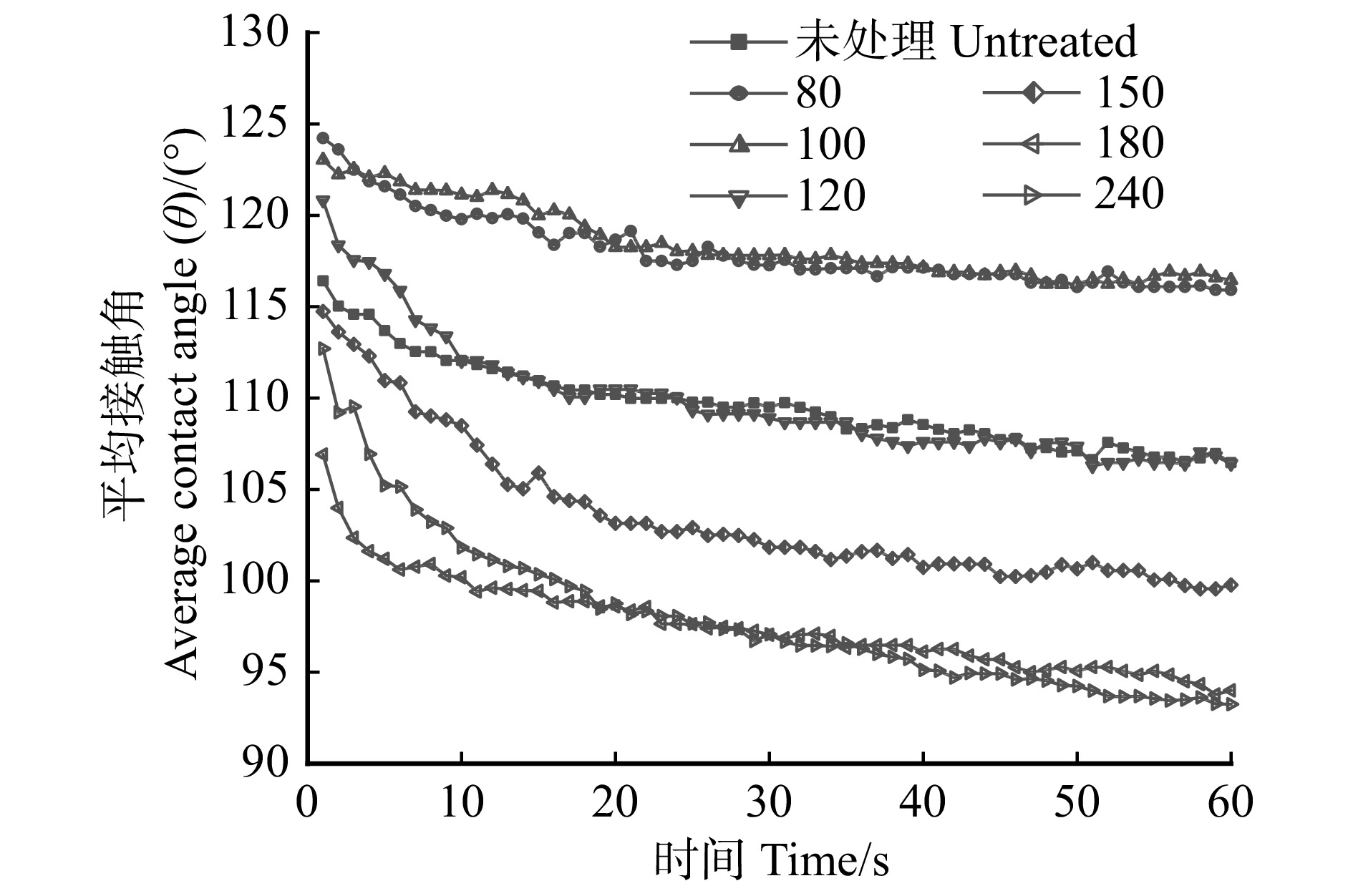

图6展示了不同砂光处理下的芦苇刨花板的动态接触角,由图可知:80目、100目砂光处理后的芦苇刨花板的初始接触角和平衡数值大于未经砂光处理的芦苇刨花板,说明粗砂处理会降低芦苇刨花板表面润湿性;120目砂带处理后的板材动态接触角数值与未经处理的板材近似,说明两者的润湿能力相同;此后随着砂带目数的升高,芦苇刨花板的动态接触角数值逐步降低,并且180目和240目处理后的芦苇刨花板的接触角相近,说明随着砂光精度的提高,芦苇刨花板的表面润湿性会逐步提高,并且在180目之后变化趋势放缓。

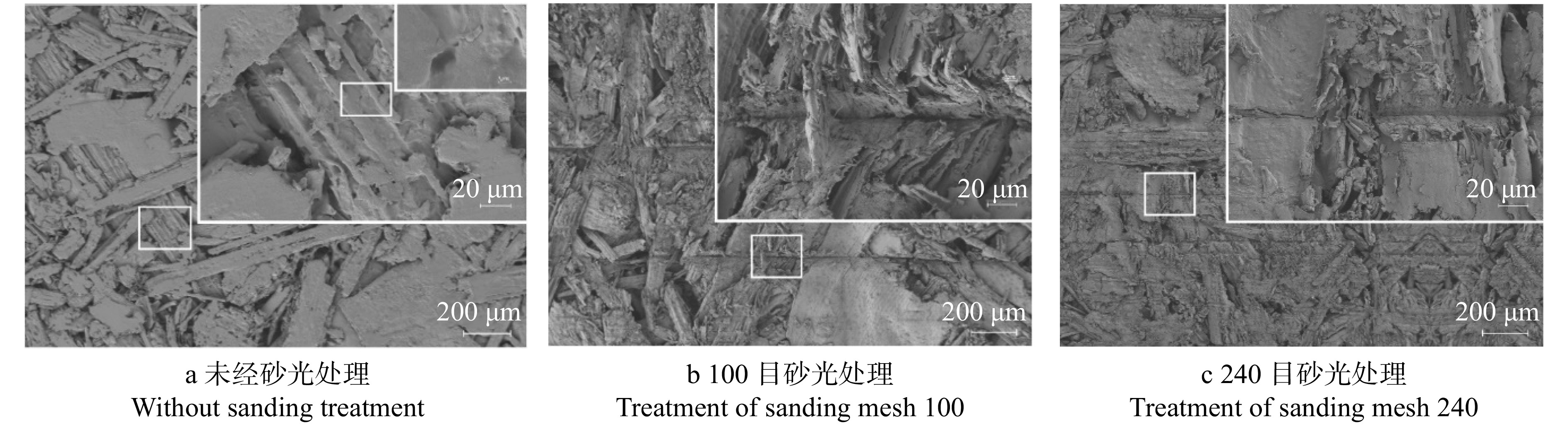

2.2.4 砂光处理对芦苇刨花板表面微观形貌的影响

砂光处理后的芦苇刨花板表面颜色变浅,光泽度降低,这是由于砂光除去了板材表面的预固化层和陈放过程中环境等因子的作用而产生的劣化物质[26],同时表面粗糙度的增加也会降低板材对光线的反射能力,因此使砂光后的板材光泽度降低。

图7a表明:热压后的芦苇刨花板存在不同尺度的芦苇刨花和凝固的胶液,刨花表面被胶液包裹。芦苇刨花相互交叉堆叠,在板材表面形成空隙,部分刨花径切面朝外,其维管束组织在板材表面呈现为槽状。从图7b、7c中可以看到:不同于未经砂光处理的芦苇刨花板,砂光处理后可以在板材表面看到砂带磨粒在板材表面摩擦和刻划留下的凹痕,即“耕犁”[27],以及磨削过程中形成的未完全断裂的切屑。相比于未经砂光的板材,砂光处理后的板材表面暴露出更多的芦苇秸秆纤维,证明砂光除去了板材表面的预固化层和钝化层,使原本被胶液包裹的芦苇秸秆刨花暴露出来,并且对芦苇原有的结构产生了进一步的破坏。此外,随着砂带磨粒粒径的减小,板材表面的孔隙减少,尺度也有所减小,这说明随着砂光程度的加深,板材的预固化层被除去,内层密度较高的部分暴露出来,成为新的表面。对比图7b和7c可以看出:240目砂带磨削处理后的板材表面微观平整度更好,“耕犁”的宽度、间距、深度都比100目砂带处理的板材更小,磨削留下的切屑也更小。因此可以推断,随着砂带目数(粒度)的增加,芦苇刨花板的表面粗糙度将会降低。

2.3 砂光处理对涂膜表面质量的影响

2.3.1 涂膜表面平整度

涂饰加工对芦苇刨花板表面粗糙度要求较高,因此选用100 ~ 240目砂光处理的芦苇刨花板进行粉末涂料涂饰加工,并对其表面平整度进行表征和分析。由图8可知:随着砂光精度的提高,饰面板的表面平整度逐步提升,未经砂光的饰面芦苇板涂层的Ra和Rp与150目砂光处理的饰面板接近,Rz、RzJIS和Rs与180目处理后的饰面板接近。240目砂光处理的饰面板表面平整度最优。

从表5可以看出:未砂光的饰面芦苇刨花板的Ra为6.87 μm,经砂光处理后板材Ra值由100目的9.95 μm降低至240目的4.84 μm;未砂光的芦苇刨花板的Rz为38.03 μm,经逐级砂光处理后由100目的54.16 μm降为240目的29.80 μm;未砂光的芦苇刨花板的Rp为18.59 μm,经逐级砂光处理后由100目的24.47 μm降为240目的14.46 μm;未砂光的芦苇刨花板的RzJIS为22.05 μm,经逐级砂光处理后由100目的25.69 μm降为240目的18.13 μm;未砂光的芦苇刨花板的Rs为0.32 mm,经逐级砂光处理后由80目的0.43 mm降为240目的0.25 mm。随着砂光精度的提高,粉末涂料在基材表面的流平性变好。对比2.2.2中的数据可以看出涂饰后的芦苇刨花板的各项粗糙度参数均低于未涂饰的,说明粉末涂料对芦苇刨花板的缝隙和波谷有较好的填充效果。

表 5 基材表面粗糙度对芦苇刨花板的涂膜表面平整度的影响Table 5. Average value of film surface flatness parameters of reed scrap board after different sanding treatments砂带目数 Sanding mesh Ra/μm Rz/μm Rp/μm RzJIS/μm Rs/mm 未处理 Untreated 6.87 38.08 18.59 22.05 0.32 100 9.95 54.16 24.47 25.69 0.43 120 7.60 44.28 20.32 24.10 0.37 150 6.85 41.19 18.45 23.26 0.30 180 6.33 38.61 16.13 22.04 0.31 240 4.84 29.80 14.46 18.13 0.25 2.3.2 涂膜性能分析

从表6可以看出:粉末涂料在芦苇刨花板基材上所形成的涂膜的附着力达到零级,硬度在3H以上,涂膜无漏底,表面无开裂、鼓泡等缺陷,涂膜表面有轻微的针孔,这可能是在加热固化的过程中,板材中的水分和气体逸出所产生的;Ra值在9 ~ 10 μm之间的板材饰面有轻微的缩孔,说明涂膜在基材表面流动性差,这是基材粗糙度过大和润湿性差导致的。

表 6 涂层性能分析Table 6. Coating performance analysis砂带目数 Sanding mesh 附着力等级

Bonding strength铅笔硬度

Pencil hardness涂膜外观质量 Appearance quality 针孔 Pinhole 缩孔 Shrinkage cavity 开裂 Cracking 鼓泡 Blister 未处理 Untreated 0 3H 轻微 Slight 无 No 无 No 无 No 100 0 3H 轻微 Slight 轻微 Slight 无 No 无 No 120 0 3H 轻微 Slight 轻微 Slight 无 No 无 No 150 0 3H 轻微 Slight 无 No 无 No 无 No 180 0 3H 轻微 Slight 无 No 无 No 无 No 240 0 3H 轻微 Slight 无 No 无 No 无 No 2.3.3 涂膜微观形貌分析

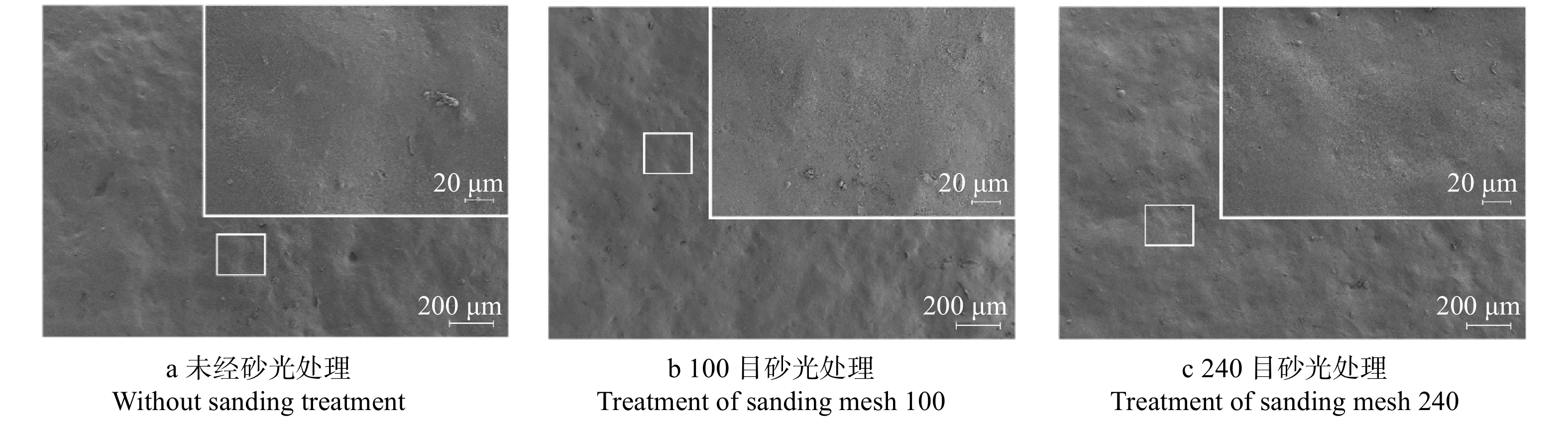

选取未经砂光、100目、240目砂光处理后粉末涂饰的芦苇刨花板,在电子显微镜下观察其表面微观形貌级涂膜固化情况。从图9可以看出:3种处理方法得到的芦苇刨花板的涂膜表面都较为均一、细腻,说明粉末涂料反应充分,固化良好;相比于100目处理的试件,未经砂光和240目砂光处理的试件表面涂膜更为平整,说明涂膜在表面粗糙度低的试件上流平性能好。

为进一步研究涂膜与基材的结合情况,使用电子显微镜拍摄240目砂光后涂饰试件截面的SEM(图10),由图10可知:在箭头所指处可以观察到芦苇刨花被粉末涂料包裹和涂膜渗入基材的沟壑中所形成的“锚状”结构,说明两者之间存在机械结合,因此形成的涂膜表现出较优的结合能力;涂膜内部整体均匀、细致,未见粉末颗粒,说明涂膜内部固化良好。涂膜平均厚度为125.4 μm,表明静电喷涂可以使芦苇刨花板表面堆积3 ~ 4层粉末涂料。因此,该粉末涂料饰面可以消除基材表面波峰和波谷的高度差,进而达到改善板材表面平整度的目的。此外,从图10中可见漆膜断面存在孔洞,这可能是在红外固化阶段,芦苇刨花板基材受热导致内部水分蒸发或其他气体逸出所形成的,由此可以推测粉末涂料涂饰的涂层质量与基材含水率有关,可作为后续研究的重点。

3. 结 论

(1)砂光处理可以有效除去芦苇刨花板表面的预固化层和污染物,降低芦苇刨花板的厚度偏差,是人造板涂饰的必要工序;随着砂带目数的提高,芦苇刨花板表面的粗糙度逐步降低,润湿性逐步提高,240目砂带砂光得到的芦苇刨花板表面粗糙度较低,润湿性较好。

(2)实验选用的粉末涂料粒度分布在12 ~ 50 μm之间,中径为26.9 μm,涂料颗粒可以进入基材表面的波峰之间,熔融流平,提高表面质量。涂料在130 ℃、3 min的条件下,环氧树脂和聚酯树脂发生了交联固化反应。

(3)应用环氧聚酯粉末涂料涂饰的芦苇刨花板可以有效提高板材表面性能。涂饰所形成的涂层外观质量良好、表面平滑、内部密实,漆膜附着力等级为0级,硬度为3H,平均涂膜厚度为125.4 μm。砂光精度影响涂料的流平性和涂膜平整度,240目砂光处理得到的板材涂膜更为平滑。

-

表 1 砂光处理实验设计

Table 1 Experimental design of sanding treatment

序号 No. 砂光工序 Sanding process 目数1

Mesh 1目数2

Mesh 2目数3

Mesh 3目数4

Mesh 4对照组

Control group1 80 80 2 80 100 3 80 100 120 4 80 100 120 150 5 80 120 150 180 6 80 120 180 240 表 2 不同升温速率下固化过程中的特征温度

Table 2 Curing temperature at different heating rates

β/(℃·min−1) T0/℃ Tp/℃ Te/℃ 5 119.0 132.5 167.7 10 128.4 148.6 177.6 15 128.5 157.1 190.3 20 129.5 161.9 192.9 注:β为升温速率,T0为固化起始温度,Tp为固化峰值温度,Te为固化终止温度。Notes: β is the heating rate, T0 is the initial curing temperature, Tp is the peak curing temperature, and Te is the curing termination temperature. 表 4 砂光处理前后的芦苇刨花板表面的粗糙度参数的平均值

Table 4 Average roughness of reed-based particle board surface with different sanding treatments

砂带目数 Sanding mesh Ra/μm Rz/μm Rp/μm RzJIS/μm Rs/mm 未处理 Untreated 5.71 35.81 9.09 27.93 0.09 80 11.24 69.86 31.46 49.95 0.16 100 10.25 63.71 26.97 45.42 0.15 120 9.55 62.07 26.43 41.82 0.13 150 8.02 52.08 22.31 39.34 0.11 180 7.18 47.48 18.71 39.34 0.10 240 5.84 42.42 14.79 30.01 0.11 表 3 砂光处理对芦苇刨花板厚度的影响

Table 3 Effects of sanding treatment on the thickness of reed-based particle board

mm 砂带目数 Sanding mesh 平均厚度 Average thickness 厚度偏差 Thickness deviation 标准差 Standard deviation 未处理 Untreated 19.52 +0.8

−1.30.12 80 19.21 ±0.4 0.05 120 19.03 −0.4

+0.30.04 180 18.88 ±0.3 0.04 240 18.80 −0.2

+0.30.02 表 5 基材表面粗糙度对芦苇刨花板的涂膜表面平整度的影响

Table 5 Average value of film surface flatness parameters of reed scrap board after different sanding treatments

砂带目数 Sanding mesh Ra/μm Rz/μm Rp/μm RzJIS/μm Rs/mm 未处理 Untreated 6.87 38.08 18.59 22.05 0.32 100 9.95 54.16 24.47 25.69 0.43 120 7.60 44.28 20.32 24.10 0.37 150 6.85 41.19 18.45 23.26 0.30 180 6.33 38.61 16.13 22.04 0.31 240 4.84 29.80 14.46 18.13 0.25 表 6 涂层性能分析

Table 6 Coating performance analysis

砂带目数 Sanding mesh 附着力等级

Bonding strength铅笔硬度

Pencil hardness涂膜外观质量 Appearance quality 针孔 Pinhole 缩孔 Shrinkage cavity 开裂 Cracking 鼓泡 Blister 未处理 Untreated 0 3H 轻微 Slight 无 No 无 No 无 No 100 0 3H 轻微 Slight 轻微 Slight 无 No 无 No 120 0 3H 轻微 Slight 轻微 Slight 无 No 无 No 150 0 3H 轻微 Slight 无 No 无 No 无 No 180 0 3H 轻微 Slight 无 No 无 No 无 No 240 0 3H 轻微 Slight 无 No 无 No 无 No -

[1] 向仕龙, 蒋远舟. 非木材植物人造板[M]. 北京: 中国林业出版社, 2008: 195−211. Xiang S L, Jiang Y Z, et al. Non-wood planet based-panel[M]. Beijing: China Forestry Publishing House, 2008: 195−211.

[2] 詹怀宇, 付时雨, 李海龙. 我国非木材纤维制浆的发展概况与技术进步(之二)蔗渣、芦苇和棉秆[J]. 中华纸业, 2011, 32(10): 6−9. doi: 10.3969/j.issn.1007-9211.2011.10.001 Zhan H Y, Fu S Y, Li H L. The development overview and technical progress for non-wood fiber pulping of bagasse, reed and cotton stalk[J]. China Pulp & Paper Industry, 2011, 32(10): 6−9. doi: 10.3969/j.issn.1007-9211.2011.10.001

[3] 樊晓敏, 于志明, 孙玉慧. 异氰酸酯胶芦苇碎料板生产工艺研究[J]. 安徽农业科学, 2011, 39(23): 14429−14431. doi: 10.3969/j.issn.0517-6611.2011.23.199 Fan X M, Yu Z M, Sun Y H. Study on the manufacturing technology of reed flakeboard bonded with MDI resin[J]. Journal of Anhui Agricultural Sciences, 2011, 39(23): 14429−14431. doi: 10.3969/j.issn.0517-6611.2011.23.199

[4] 刘云霞, 刘洪海. 非木材植物人造板的发展与应用现状及展望[J]. 林业机械与木工设备, 2020, 48(12): 8−11, 20. doi: 10.3969/j.issn.2095-2953.2020.12.002 Liu Y X, Liu H H. Development and application and prospects of non-wood plant-based panel[J]. Forestry Machinery & Woodworking Equipment, 2020, 48(12): 8−11, 20. doi: 10.3969/j.issn.2095-2953.2020.12.002

[5] 徐建峰, 龙玲, 刘如. 人造板饰面装饰纸无醛化研究现状[J]. 木材科学与技术, 2021, 35(2): 1−5. doi: 10.12326/j.2096-9694.2021005 Xu J F, Long L, Liu R. Research status review of formaldehyde-free decorative paper for wood-based panels[J]. Chinese Journal of Wood Science and Technology, 2021, 35(2): 1−5. doi: 10.12326/j.2096-9694.2021005

[6] 许伟坤, 王慧丽, 董亿政, 等. 低温固化粉末涂料的研究进展[J]. 涂料工业, 2021, 35(2): 1−5. doi: 10.12020/j.issn.0253-4312.2021.2.1 Xu W K, Wang H L, Dong Y Z, et al. Research progress in low-temperature curing powder coatings[J]. Paint & Coatings Industry, 2021, 35(2): 1−5. doi: 10.12020/j.issn.0253-4312.2021.2.1

[7] 张文标, 肖海湖, 吴利军, 等. 木基材料透明粉末涂饰的研究进展[J]. 林业科技开发, 2013, 27(6): 5−8. doi: 10.3969/j.issn.1000-8101.2013.06.002 Zhang W B, Xiao H H, Wu L J, et al. Research progress of transparent powder finishing for wood-based materials[J]. China Forestry Science and Technology, 2013, 27(6): 5−8. doi: 10.3969/j.issn.1000-8101.2013.06.002

[8] Romer J. Coating MDF furniture with powder: the first industrial series production[C]//Janvier. Powder coating Europe congress. Nüremberg: European Society for Coating Technology, 2002: 15−17.

[9] John B. Powder on MDF: a process analysis: to provide continued growth for powder coatings, suppliers are rapidly expanding the functional range of powders beyond traditional metal-product finishing into nonmetallic substrates such as wood[J]. Industrial Paint & Powder, 2004, 80(9): 16−21.

[10] Schmidt T. Powder coating medium-density fiberboard: a new approach to success[J]. Powder Coating, 2004(7): 16−24.

[11] Zhang W B, Li W Z, Men Q S. The current application situation and development countermeasure in powder coating of wood-based panel surface decoration[C]//Zhou X Y, Mei C T, Jin J W, et al. The 7th pacific rim bio-based composites symposium proceeding: Vol Ⅱ. Nanjing: Science & Technique Literature Press, 2004: 392−396.

[12] Hardesty J H. Electrically conductive MDF surface: U. S. Patent 7 090 897[P]. 2006−08−15.

[13] Jocham C, Schmidt T W, Wuzella G, et al. Adhesion improvement of powder coating on medium density fibreboard (MDF) by thermal pre-treatment[J]. Journal of Adhesion Science and Technology, 2011, 25(15): 1937−1946. doi: 10.1163/016942410X537189

[14] 张秀青, 李雪涛, 张文标, 等. 刨花板表面粉末涂饰初探[J]. 林业科技开发, 2014, 28(6): 114−116. doi: 10.13360/j.issn.1000-8101.2014.06.028 Zhang X Q, Li X T, Zhang W B, et al. Preliminary study on the surface powder coating of particleboard[J]. Journal of Forestry Engineering, 2014, 28(6): 114−116. doi: 10.13360/j.issn.1000-8101.2014.06.028

[15] 李雪涛, 肖海湖, 张文标, 等. 竹地板表面粉末涂料喷涂工艺研究[J]. 竹子研究汇刊, 2015, 34(4): 35−41. Li X T, Xiao H H, Zhang W B, et al. Powder coating process and coating performance of bamboo flooring surface[J]. Journal of Bamboo Research, 2015, 34(4): 35−41.

[16] 李雪涛, 张文标, 张晓春, 等. OSB表面环氧聚酯粉末涂饰探究[J]. 杭州化工, 2015, 45(4): 14−17, 32. doi: 10.13752/j.issn.1007-2217.2015.04.005 Li X T, Zhang W B, Zhang X C, et al. Study on the surface epoxy polyester powder coating of OSB[J]. Hangzhou Chemical Industry, 2015, 45(4): 14−17, 32. doi: 10.13752/j.issn.1007-2217.2015.04.005

[17] 李雪涛, 张文标, 李文珠, 等. 榉木板材静电粉末喷涂基材表面处理方法研究[J]. 杭州化工, 2016, 46(4): 23−27. doi: 10.13752/j.issn.1007-2217.2016.04.007 Li X T, Zhang W B, Li W Z, et al. Study on surface treatment of beech wood by electrostatic powder spraying[J]. Hangzhou Chemical Industry, 2016, 46(4): 23−27. doi: 10.13752/j.issn.1007-2217.2016.04.007

[18] Ayrilmis N. Surface properties of oriented strand board coated by electrostatic dry powder spray deposition technique[J]. BioResources, 2020, 15(1): 1521−1530.

[19] Eustace B. Powder coating system for MDF panels: U.S. Patent Application 12/271, 164[P]. 2009−09−03.

[20] Badila M, Jocham C, Zhang W B, et al. Powder coating of veneered particle board surfaces by hot pressing[J]. Progress in Organic Coatings, 2014, 77(10): 1547−1553. doi: 10.1016/j.porgcoat.2013.09.018

[21] 李文渊. 低温固化环氧粉末涂料及MDF粉末静电喷涂工艺研究[D]. 广州: 广东工业大学, 2015. Li W Y. Study on low temperature curing epoxy powder coatings and the MDF electrostatic spraying process[D]. Guangzhou: Guangdong University of Technology, 2015.

[22] 肖海湖, 张文标, 刘际平, 等. 木基材用低温透明粉末涂料的固化动力学研究[J]. 林业机械与木工设备, 2014, 42(7): 23−26. doi: 10.3969/j.issn.2095-2953.2014.07.005 Xiao H H, Zhang W B, Liu J P, et al. Study on the curing kinetics of low-temperature transparent powder coating[J]. Forestry Machinery & Woodworking Equipment, 2014, 42(7): 23−26. doi: 10.3969/j.issn.2095-2953.2014.07.005

[23] 王慧丽, 袁辉强, 董亿政, 等. 中密度板(MDF)用聚酯/环氧粉末涂料的制备与应用[J]. 涂料工业, 2021, 51(3): 61−66. doi: 10.12020/j.issn.0253-4312.2021.3.61 Wang H L, Yuan H Q, Dong Y Z, et al. Preparation and application of polyester/epoxy powder coatings for medium-density fiberboard (MDF)[J]. Paint & Coatings Industry, 2021, 51(3): 61−66. doi: 10.12020/j.issn.0253-4312.2021.3.61

[24] 吴正慧, 巴旭民, 王爱成. 中密度纤维板(MDF)粉末涂料低温固化技术研究[J]. 涂料工业, 2022, 52(2): 55−59. doi: 10.12020/j.issn.0253-4312.2022.2.55 Wu Z H, Ba X M, Wang A C. Study on low temperature curing technology of powder coatings for medium density fiberboard (MDF)[J]. Paint & Coatings Industry, 2022, 52(2): 55−59. doi: 10.12020/j.issn.0253-4312.2022.2.55

[25] 周定国. 人造板工艺学[M]. 第2版. 北京: 中国林业出版社, 2011: 248−252. Zhou D G. Wood-based panel processing[M]. 2nd ed. Beijing: China Forestry Publishing House, 2011: 248−252.

[26] 李坚, 赵学增, 韩士杰, 等. 砂磨提高胶结强度的机理[J]. 东北林业大学学报, 1987, 15(4): 66−72. doi: 10.13759/j.cnki.dlxb.1987.04.010 Li J, Zhao X Z, Han S J, et al. Mechanism of improving cementation strength by sand grinding[J]. Journal of Northeast Forestry University, 1987, 15(4): 66−72. doi: 10.13759/j.cnki.dlxb.1987.04.010

[27] 李黎. 木材切削原理与刀具[M]. 第2版. 北京: 中国林业出版社, 2012. Li L. Wood cutting theory and tools[M]. 2nd ed. Beijing: China Forestry Publishing House, 2012.

-

期刊类型引用(1)

1. 虞夏霓,刘偲,陈步先,包新德,关鑫,林金国. 砂光处理对翅荚木表面特性影响研究. 林产工业. 2024(06): 14-19 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: