Acoustic vibration performance of birch veneer-metal copper mesh composites

-

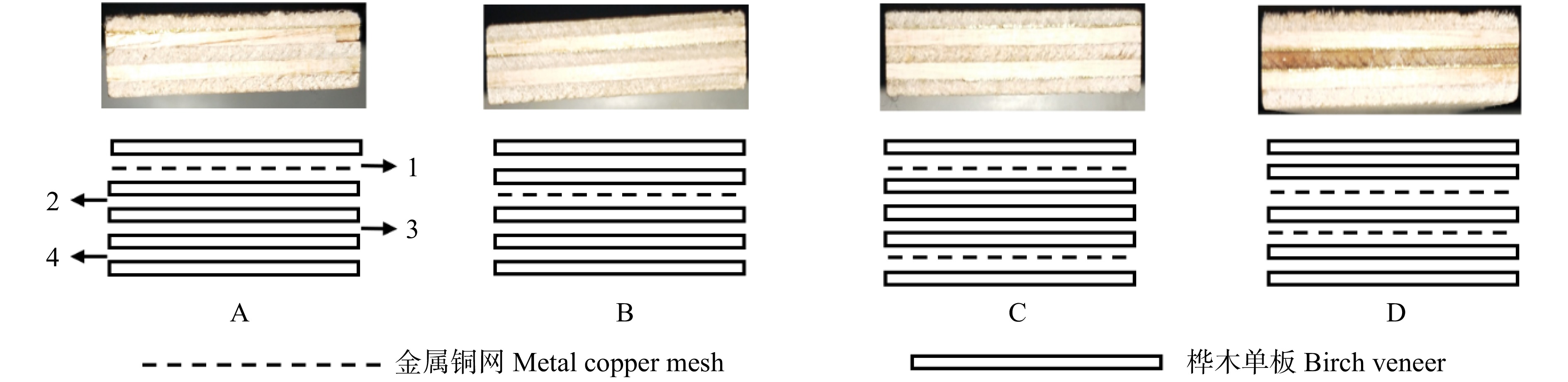

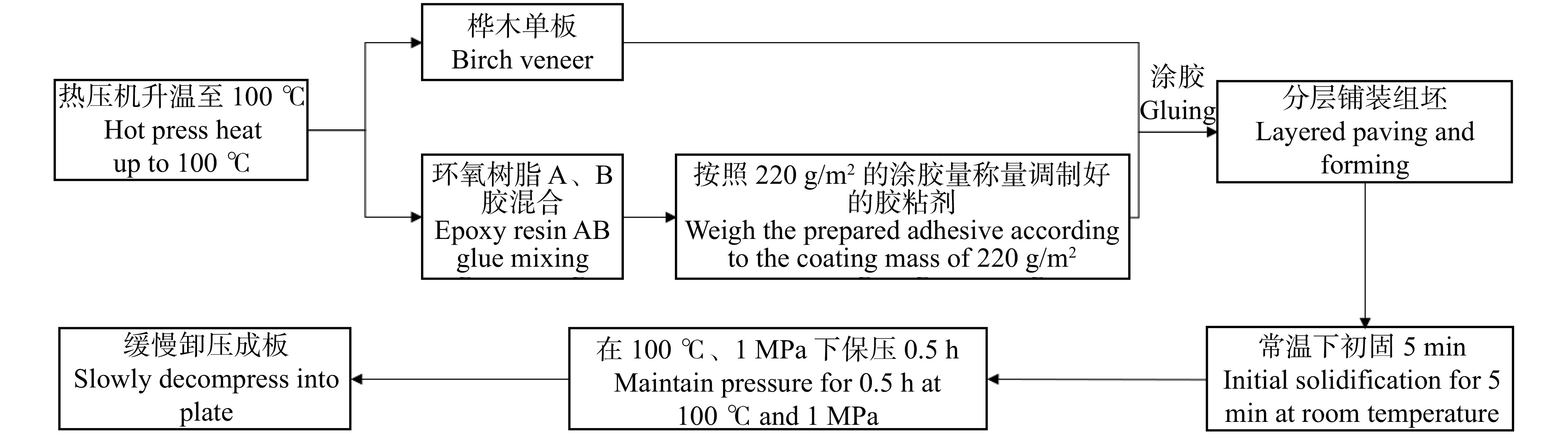

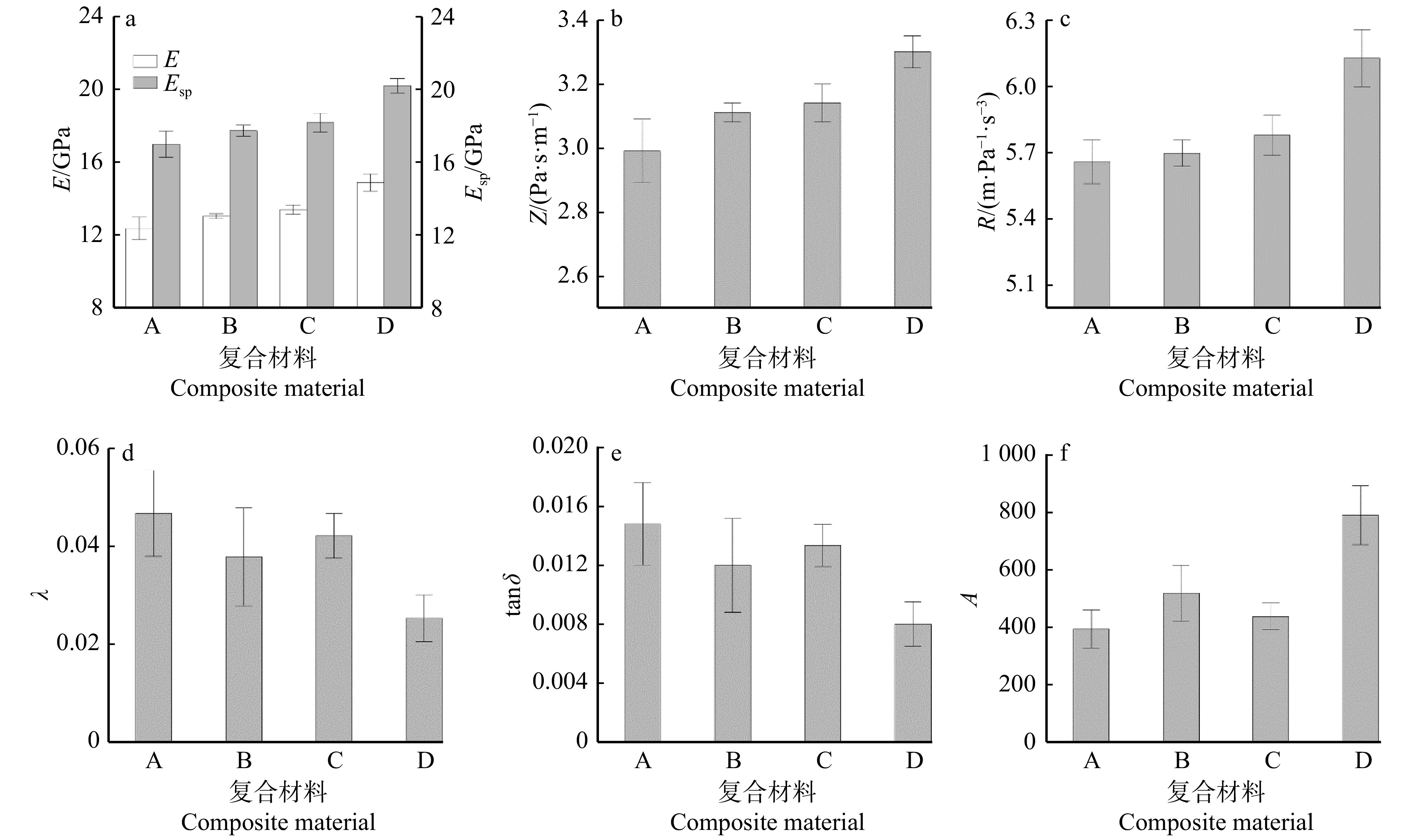

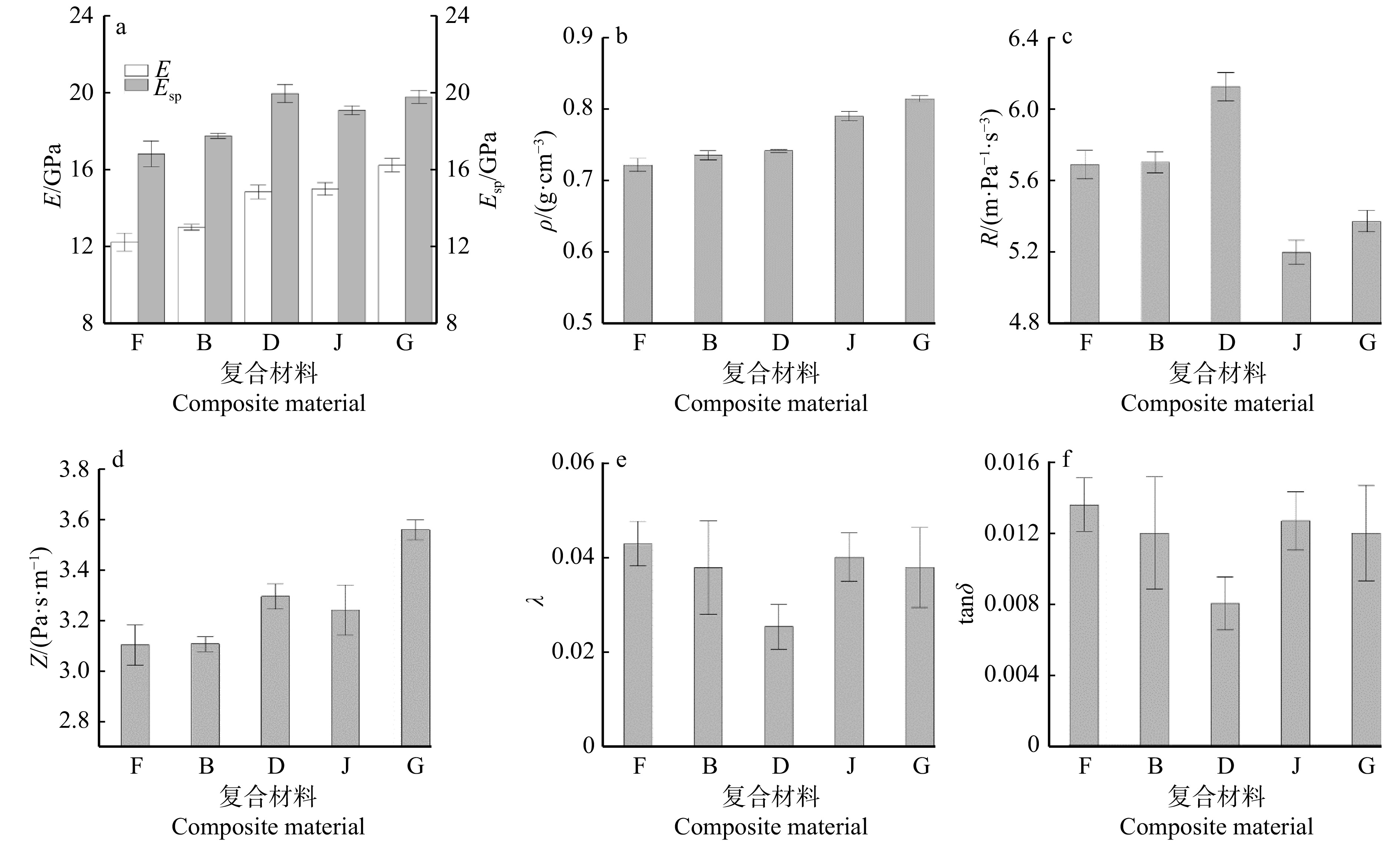

摘要:目的 传统实木乐器音板的选材和用材都十分严格,然而当下我国优质木材资源紧缺,资源需求压力较大,开发可用作乐器音板的复合材料是缓解木材需求压力的有效途径。方法 试验制备了双层、5层桦木单板分别与金属铜网复合的两种厚度复合材料。在分析复合材料尺寸稳定性的基础上,利用双通道快速傅里叶变换频谱分析仪测试其声学振动性能,研究桦木单板铺装方向、金属铜网添加位置与添加层数对声学振动性能的影响,并采用综合评分法比较了复合材料与西加云杉的声学性能。结果 加入金属网后制备的双层、5层桦木单板复合材料的抗湿胀系数最高分别为80.00%与88.09%,胶合界面的增加提升了复合材料的抗湿胀系数。桦木单板铺装方向影响复合材料的EL/ER值,以单板纹理平行铺装的双层单板复合材料EL/ER值为29.09,以单板纹理交错铺装的双层单板复合材料EL/ER值为0.99。加入2层金属铜网的5层复合材料,具有接近西加云杉的振动效率品质和更为优秀的音色,其抗湿涨系数平均值达到87.61%、纵向比动弹性模量达到20.20 GPa、声辐射品质常数达到6.13 m/(Pa·s3)、声阻抗为3.29 Pa·s/m、E/G值达到29.63。结论 通过与西加云杉木材的比较表明,复合材料的声学振动性能基本能达到一般乐器的要求,并且具有良好的尺寸稳定性,是传统实木音板的良好替代材料。Abstract:Objective The selection and use of traditional solid wood musical instrument soundboards are very strict. However, at present, there is a shortage of high-quality wood resources in our country, and the pressure on resource demand is relatively high. The development of composite materials that can be used as musical instrument soundboards is an effective way to alleviate the pressure on wood demand.Method 2-layer and 5-layer birch veneer composite materials with two thicknesses and metal copper meshes were prepared in the experiment. On the basis of analyzing the dimensional stability of composite, the acoustic vibration performance of the composite was tested by the dual channel Fast Fourier Transform Spectrum Analyzer (FFT), and the effects of the direction of birch veneer pavement, the location and number of layers of metal copper mesh on the acoustic vibration performance were studied. The acoustic performance of the composite was compared with that of Sitka spruce by the comprehensive scoring method.Result The highest coefficient of moisture expansion resistance of double layer and five layer birch veneer composites prepared with metal mesh was 80.00% and 88.09%, respectively. The increase of bonding interface improved the coefficient of moisture expansion resistance of the composites. The direction of birch veneer pavement affected the EL/ER value of composite materials. The EL/ER value of double-layer veneer composite materials paved with parallel veneer texture was 29.09, and the EL/ER value of double-layer veneer composite materials paved with interlaced veneer texture was 0.99. The 5-layer composite added with two layers of metal copper mesh had a vibration efficiency quality close to that of Sitka spruce and a better timbre. Its moisture resistance coefficient reached 87.61%, the longitudinal specific dynamic modulus of elasticity reached 20.02 GPa, the sound radiation quality constant reached 6.13 m/(Pa·s3), the sound impedance was 3.29 Pa·s/m, and the E/G value reached 29.63.Conclusion The comparison with Sitka spruce shows that the acoustic vibration performance of the composite material can basically meet the requirements of general musical instruments, and it has good dimensional stability, which is a good substitute for traditional solid wood soundboards.

-

-

表 1 复合材料纵向尺寸膨胀率与抗湿胀系数

Table 1 Longitudinal dimensional expansion rate and moisture expansion coefficient of composites

项目

Item桦木单板

Birch veneer双层单板复合材料

Double-layer veneer composite5层单板复合材料

Five-layer veneer compositeD0 D90 F B D J G 纵向尺寸膨胀率

Longitudinal dimensional expansion rate/%2.10 0.45 0.42 0.27 0.26 0.26 0.24 0.25 抗湿胀系数

Anti swelling coefficient/%78.57 80.00 87.14 87.61 87.61 88.57 88.09 表 2 双层复合材料前5阶共振频率

Table 2 First fifth resonance frequency of double-layer composite

Hz 材料

Material1阶共振频率

1st resonance

frequency (f1)2阶共振频率

2nd resonance

frequency (f2)3阶共振频率

3rd resonance

frequency (f3)4阶共振频率

4th resonance

frequency (f4)5阶共振频率

5th resonance

frequency (f5)D0 380 1 030 2 040 3 230 4 650 D90 160 400 870 1 390 2 120 表 3 双层单板复合材料与西加云杉的声学性能基本参数

Table 3 Average values of basic parameters of acoustic properties of double-layer veneer composites and Sitka spruce

材料

Materialρ/(g·cm−3) R/

(m·Pa−1·s−3)Z/(Pa·s·m−1) Esp/GPa EL/GPa ER/GPa EL/ER λ A tan δ × 103 vL/(m·s−1) vR/(m·s−1) D0 0.67(0.012) 7.60(0.163) 3.46(0.079) 26.51

(0.651)17.75(0.597) 0.61(0.003) 29.09 0.029(0.001) 822.03(17.642) 9.24(0.387) 5 128(71) 457

(13)D90 0.63(0.013) 3.09(0.087) 1.22(0.014) 3.76

(0.023)2.37(0.019) 2.40(0.017) 0.99 0.025(0.007) 379.26(10.734) 8.15(0.235) 1 942(15) 1 966

(21)西加云杉

Sitka spruce0.49 10.11 2.4 24.08 11.8 1.29 9.15 4953 1651 注:ρ为试样的密度;R为纵向试样的声辐射品质常数;Z为纵向试样的声阻抗;Esp为纵向试样的比动弹性模量;EL为纵向试样的动弹性模量;ER为径向试样的动弹性模量;EL/ER为纵向试样与径向试样的动弹性模量之比;λ为纵向试样的对数衰减系数;A为纵向试样的声转换率;tan δ为纵向试样的损耗角正切值;vL为纵向试样的声速;vR为径向试样的声速;()中数值该组数据的标准偏差。Notes: ρ is the density of specimen; R is the sound radiation quality constant of the longitudinal sample; Z is the acoustic impedance of the longitudinal sample; Esp is the specific dynamic elastic modulus of the longitudinal specimen; EL is the dynamic elastic modulus of the longitudinal specimen; ER is the dynamic elastic modulus of radial specimen; EL/ER is the ratio of dynamic elastic modulus of longitudinal specimen and radial specimen; λ Is the logarithmic attenuation coefficient of the longitudinal sample; A is the sound conversion rate of the longitudinal sample; tan δ is the tangent value of the loss angle of the longitudinal sample; vL is the sound velocity of the longitudinal sample; vR is the sound velocity of the radial sample; standard deviation of this group of data for the value in brackets. 表 4 5层复合材料前5阶频率

Table 4 First fifth order frequency of five-layer composite

Hz 材料 Material f1 f2 f3 f4 f5 A 320 880 1 660 2 640 3 720 B 320 870 1 650 2 560 3 570 C 340 920 1 730 2 700 3 760 D 370 1 030 1 940 3 030 4 240 F 310 890 1 670 2 620 3 720 J 330 860 1 540 2 420 3 440 G 350 960 1 800 2 840 4 000 表 5 4项声学性能指标权重

Table 5 Weight factors of 4 acoustic performance indexes

Esp/GPa R/(m·Pa−1·s−3) Z/(Pa·s·m−1) E/G 0.36 0.29 0.25 0.10 表 6 复合材料与西加云杉声学性能指标对比

Table 6 Comparison of acoustic properties between composites and Sitka spruce

材料 Material ρ/(g·cm−3) E/GPa Esp/GPa R/(m·Pa−1·s−3) Z/(Pa·s·m−1) E/G D 0.74 14.86(0.36) 20.02(0.47) 6.13(0.12) 3.29(0.04) 29.63(0.52) 西加云杉 Sitka spruce 0.49 11.80 24.20 10.11 2.16 13.60 注:括号中数值为该组数据的标准偏差。 Note:the values in brackets are the SD of this group of data. -

[1] 刘镇波, 沈隽. 共鸣板用材的振动特性与钢琴的声学品质[M]. 北京: 科学出版社, 2009. Liu Z B, Shen J. Vibration characteristics of acoustics board and acoustic quality of piano[M]. Beijing: Science Press, 2009.

[2] 余德倩, 赵晨鹏, 翟胜丞, 等. 吸湿循环处理对常用乐器用材声学振动性能的影响[J]. 林业工程学报, 2021, 6(5): 61−67. Yu D Q, Zhao C P, Zhai S C, et al. Effect of hygroscopic cycle treatment on acoustic vibration performance of different wood species for musical instruments[J]. Journal of Forestry Engineering, 2021, 6(5): 61−67.

[3] 张晓玮, 王婧如, 王明浩, 等. 中国云杉属树种地理分布格局的主导气候因子[J]. 林业科学, 2020, 56(4): 1−11. doi: 10.11707/j.1001-7488.20200401 Zhang X W, Wang J R, Wang M H, et al. Dominant climatic factors influencing the geographical distribution pattern of Picea in China[J]. Scientia Silvae Sinicae, 2020, 56(4): 1−11. doi: 10.11707/j.1001-7488.20200401

[4] 陈伏生, 易敏, 马际凯, 等. 中国林木种业发展现状与展望[J]. 江西农业大学学报, 2021, 43(3): 488−496. doi: 10.13836/j.jjau.2021054 Chen F S, Yi M, Ma J K, et al. Current status and future prospect of forest seed industry in China[J]. Acta Agriculturae Universitatis Jiangxiensis, 2021, 43(3): 488−496. doi: 10.13836/j.jjau.2021054

[5] 江泽慧, 邓丽萍, 宋荣臻, 等. 木竹材声学振动特性研究进展[J]. 世界林业研究, 2021, 34(2): 1−7. doi: 10.13348/j.cnki.sjlyyj.2021.0011.y Jiang Z H, Deng L P, Song R Z, et al. Research progress on the acoustic vibration performance of wood and bamboo[J]. World Forestry Research, 2021, 34(2): 1−7. doi: 10.13348/j.cnki.sjlyyj.2021.0011.y

[6] 贺福, 杨永岗. 碳纤维增强木材复合材料[J]. 化工新型材料, 2003, 31(10): 9−12. doi: 10.3969/j.issn.1006-3536.2003.10.004 He F, Yang Y G. Carbon fiber reinforced wood composite[J]. New Chemical Materials, 2003, 31(10): 9−12. doi: 10.3969/j.issn.1006-3536.2003.10.004

[7] Phillips S, Lessard L. Application of natural fiber composites to musical instrument top plates[J]. Journal of Composite Materials, 2012, 46(2): 145−154. doi: 10.1177/0021998311410497

[8] Jalili M M, Mousavi S Y, Pirayeshfar A S. Investigating the acoustical properties of carbon fiber-, glass fiber, and hemp fiber-reinforced polyester composites[J]. Polymer Composites, 2015, 35(11): 2103−2111.

[9] 张元梓, 刘乾, 高源, 等. 木质−碳纤维复合材料的制备工艺[J]. 东北林业大学学报, 2019, 47(10): 90−95. doi: 10.3969/j.issn.1000-5382.2019.10.018 Zhang Y Z, Liu Q, Gao Y, et al. Process optimization of wood-carbon fiber composites[J]. Journal of Northeast Forestry University, 2019, 47(10): 90−95. doi: 10.3969/j.issn.1000-5382.2019.10.018

[10] Ono T, Miyakoshi S, Watanabe U. Acoustic characteristics of unidirectionally fiber-reinforced polyurethane foam composites for musical instrument soundboards[J]. Acoustical Science and Technology, 2002, 23(3): 135−142. doi: 10.1250/ast.23.135

[11] Ono T, Isomura D. Acoustic characteristics of carbon fiber-reinforced synthetic wood for musical instrument soundboards[J]. Acoustical Science and Technology, 2004, 25(6): 475−477. doi: 10.1250/ast.25.475

[12] 贺建民, 路伟, 王立峰, 等. 碳纤维增强面板的制备及其力学性能[J]. 森林工程, 2022, 38(3): 63−69. doi: 10.3969/j.issn.1006-8023.2022.03.009 He J M, Lu W, Wang L F, et al. Preparation and mechanical properties of carbon fiber reinforced panel[J]. Forest Engineering, 2022, 38(3): 63−69. doi: 10.3969/j.issn.1006-8023.2022.03.009

[13] Ismail A S, Jawaid M, Naveen J. Void content, tensile, vibration and acoustic properties of kenaf/bamboo fiber reinforced epoxy hybrid composites[J]. Materials, 2019, 12(13): 2094. doi: 10.3390/ma12132094

[14] 郑海军, 顾少华, 李琪微, 等. 基于主成分评价法的竹木旱滑板面板力学性能综合评价[J]. 林业工程学报, 2022, 7(3): 46−52. Zheng H J, Gu S H, Li Q W, et al. Comprehensive evaluation of mechanical properties of bamboo-wood dry skateboard face panels using principal component evaluation method[J]. Journal of Forestry Engineering, 2022, 7(3): 46−52.

[15] 林斌, 苗媛媛, 李瑞, 等. 桦木单板/玻璃纤维复合材料声学振动性能的研究[J]. 北京林业大学学报, 2019, 41(1): 126−133. doi: 10.13332/j.1000-1522.20180317 Lin B, Miao Y Y, Li R, et al. Acoustic vibration properties of birch veneer/glass fiber composites[J]. Journal of Beijing Forestry University, 2019, 41(1): 126−133. doi: 10.13332/j.1000-1522.20180317

[16] Lee S K, Kim M W, Park C J, et al. Effect of fiber orientation on acoustic and vibration response of a carbon fiber/epoxy composite plate natural vibration mode and sound radiation[J]. International Journal of Mechanical Sciences, 2016, 117: 162−173. doi: 10.1016/j.ijmecsci.2016.08.023

[17] Sayyad A S, Ghugal Y M. On the free vibration analysis of laminated composite and sandwich plates: a review of recent literature with some numerical results[J]. Composite, 2015, 129: 177−201.

[18] 赵俊石. 玻璃纤维增强杨木单板复合层板结构与工艺研究[D]. 北京: 中国林业科学研究院, 2013. Zhao J S. Research on reinforced glass fiber poplar veneer composite laminates structure and technology[D]. Beijing: Chinese Academy of Forestry, 2013.

[19] Tang L D, Wu Y B, Yuan L P, et al. The heat insulation and smoke suppression effect of M-Si-phosphocarbonaceous catalyzed by metal salt-doped APP silicon gel in situ build in wood[J]. Journal of Thermal Analysis and Calorimetry, 2021, 146(6): 2353−2364. doi: 10.1007/s10973-020-10530-3

[20] 胡伟航, 沈梦霞, 段超, 等. 基于木材的超级电容器电极材料的研究进展[J]. 中国造纸, 2021, 40(3): 83−94. doi: 10.11980/j.issn.0254-508X.2021.03.012 Hu W H, Shen M X, Duan C, et al. Research progress of wood-based electrode materials for supercapacitors[J]. China Pulp and Paper, 2021, 40(3): 83−94. doi: 10.11980/j.issn.0254-508X.2021.03.012

[21] Han G J, Ma Z G, Zhou B, et al. Cellulose-based Ni-decorated graphene magnetic film for electromagnetic interference shielding[J]. Journal of Colloid and Interface Science, 2021, 583: 571−578. doi: 10.1016/j.jcis.2020.09.072

[22] 梁祥鹏. 多层实木铝箔复合制备功能人造板技术研究[D]. 郑州: 河南农业大学, 2016. Liang X P. Study on preparation technology of multi-poplar veneer/aluminum boil laminated functional boards[D]. Zhengzhou: Henan Agricultural University, 2017.

[23] Duan S W, Zhou W Z, Liu X L, et al. Experimental study on the bending behavior of steel-wood composite beams[J]. Advance in Civil Engineering, 2021: 1315849.

[24] 肖飞, 吴义强, 左迎峰, 等. 竹单板/泡沫铝复合材料的制备及胶合性能评估[J]. 林业工程学报, 2021, 6(3): 35−40. Xiao F, Wu Y Q, Zuo Y F, et al. Preparation and bonding performance evaluation of bamboo veneer/foam aluminum composites[J]. Journal of Forestry Engineering, 2021, 6(3): 35−40.

[25] 中华人民共和国国家林业局. 改性木材尺寸稳定性测定方法: LY/T 2490—2015[S]. 北京: 中国标准出版社, 2015. The SAtate Forestry Administration of the People’s Republic of China. Test method for dimensional stability of modified wood: LY/ T 2490−2015[S]. Beijing: Standards Press of China, 2015.

[26] Ashaari Z, Lee S H, Nabil F L, et al. Physico-mechanical properties of laminates made from Sematan bamboo and saesenduk wood derived from Malaysia’s secondary forest[J]. International Forestry Review, 2017, 19(Suppl. 3): 1−8.

-

期刊类型引用(1)

1. 徐媛,陈锦玲,陈玉梅,李璐璐,李惠敏,秦新民. 干旱胁迫下花生转录组与miRNA测序及相关基因的表达. 贵州农业科学. 2021(01): 1-9 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: