Quantitative identification of surface defects in wood paneling based on improved YOLOv5

-

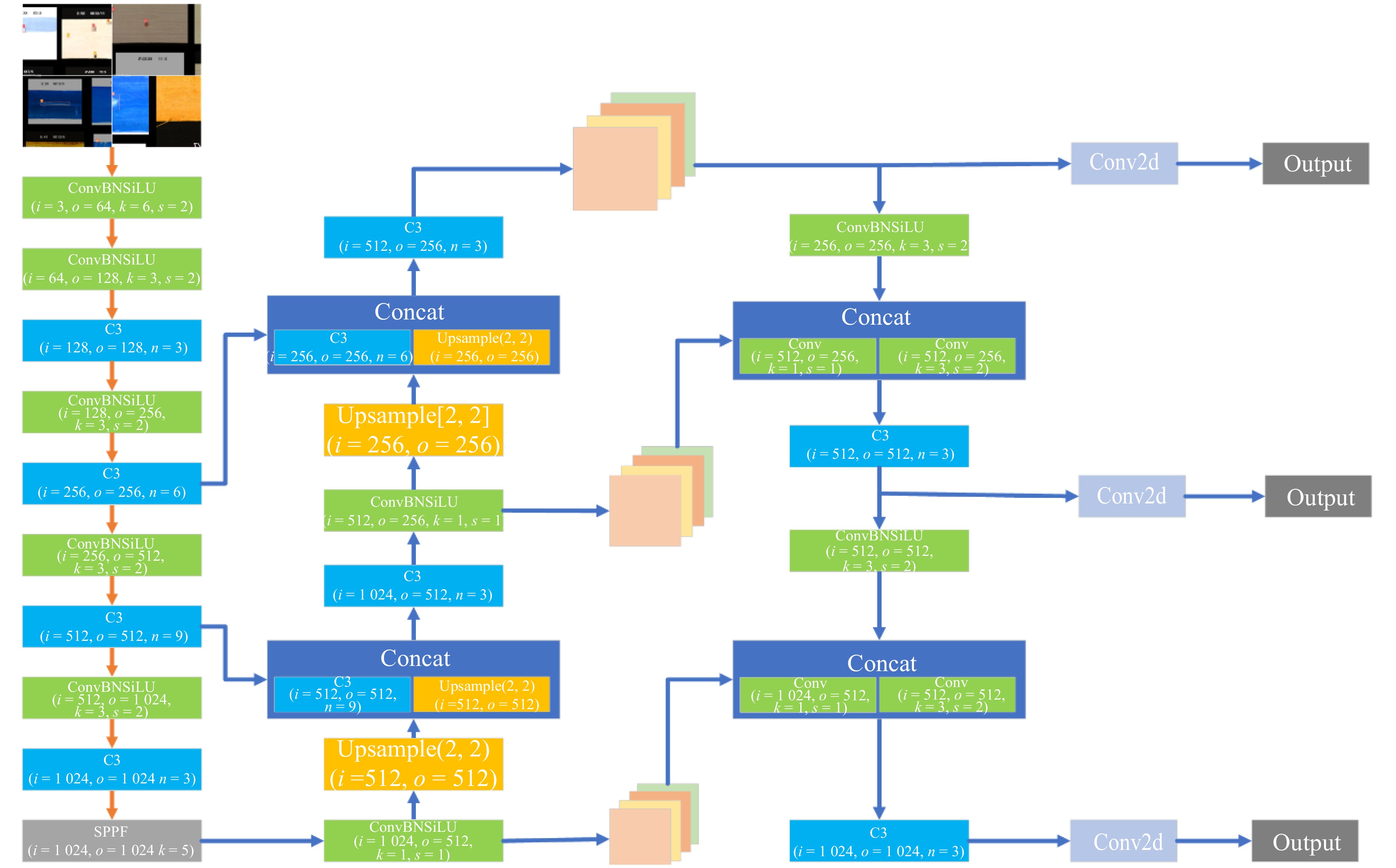

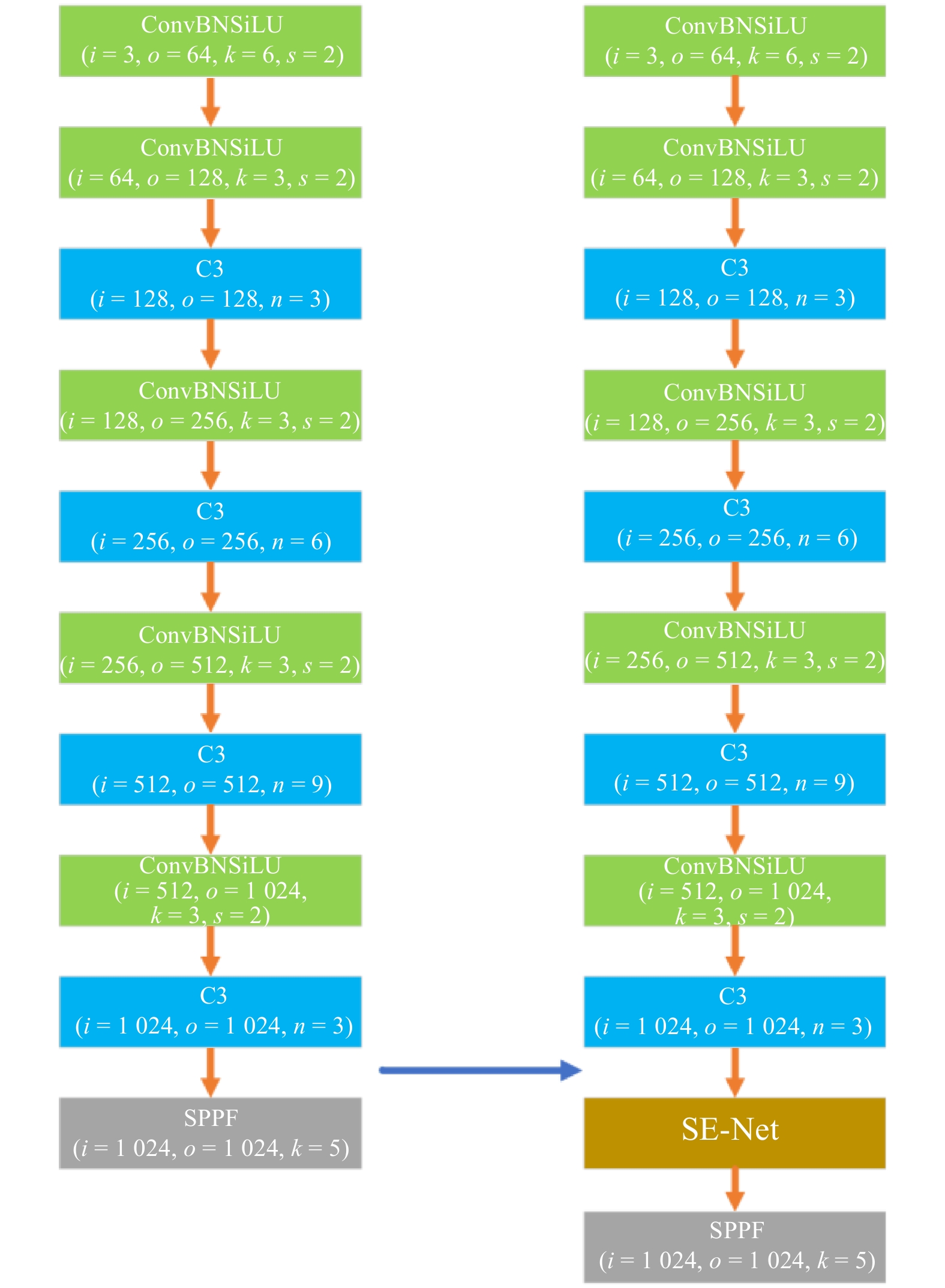

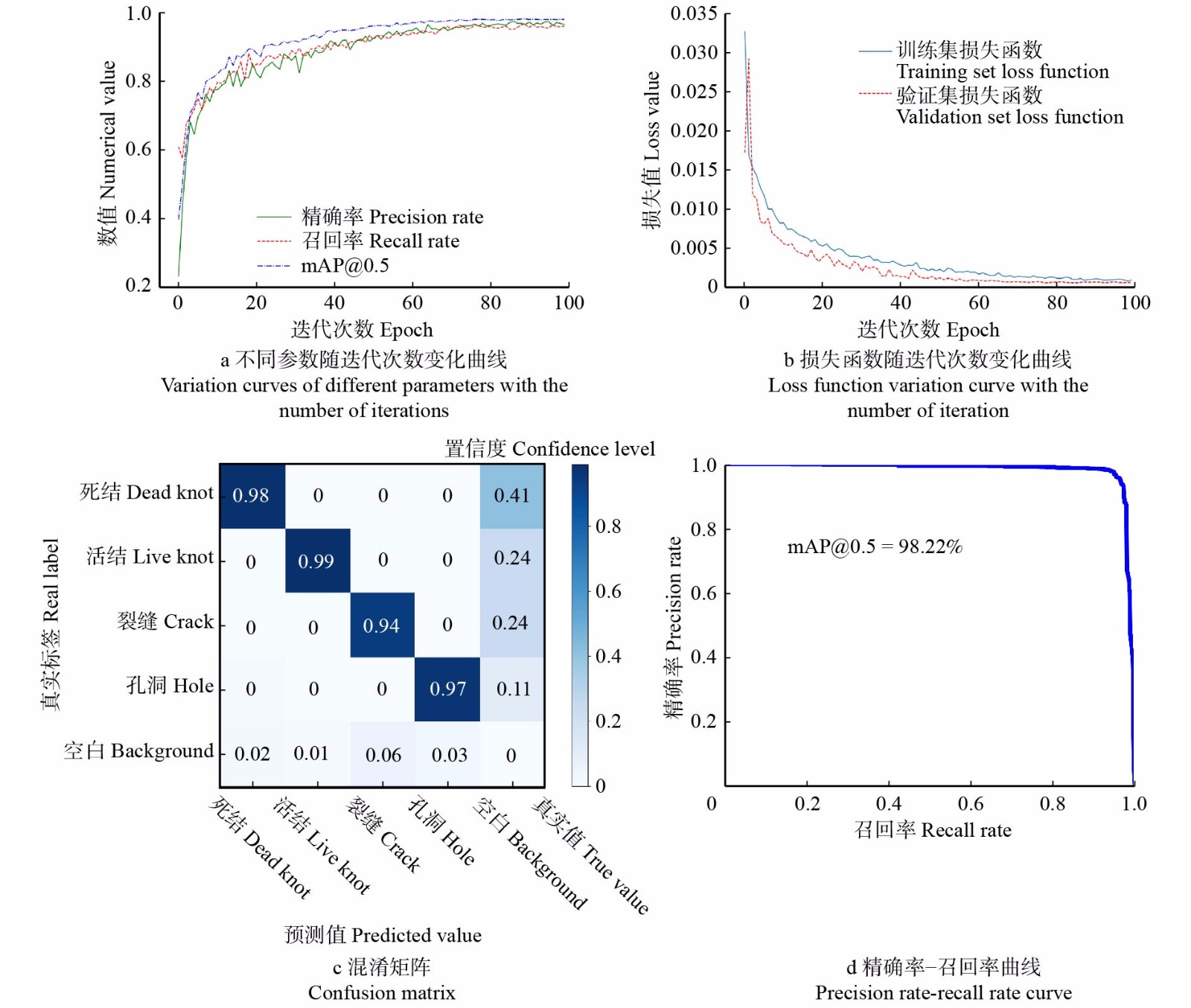

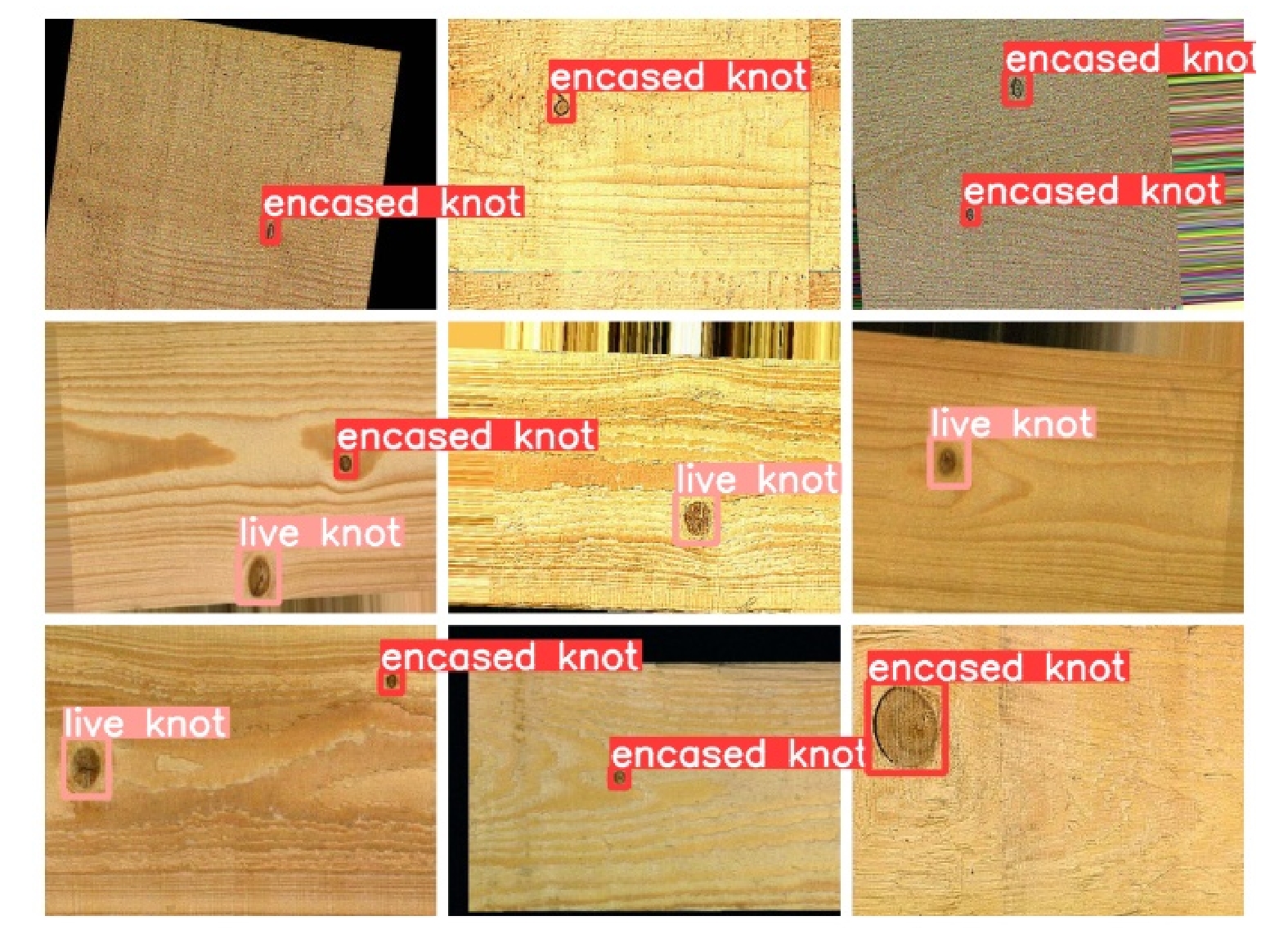

摘要:目的 为解决人工及传统数字图像处理方法对木板材表面缺陷识别效果差、效率低等问题,提高木材利用率。以深度学习模型为基础,构建木板材表面缺陷检测系统,旨在拓展深度学习模型在木板材缺陷检测领域的应用。方法 基于“Wood Defect Database”公开数据集中的839张木板材缺陷图像,使用Imgaug数据增强库对数据集进行扩充;通过在主干特征网络部分引入SE注意力机制,使用focus、FPN + PAN结构构建YOLOv5木板材表面缺陷目标检测框架,进而采用迁移学习思想改进训练方式,将训练过程分为两个阶段(冻结阶段和解冻阶段)。然后将构建的模型与当前主流深度学习目标检测模型进行对比,最后利用混淆矩阵、Loss值变化曲线、模型大小、检测时间以及均值平均精确率等指标评价模型。结果 提出了一种基于YOLOv5模型对木板材表面缺陷中活节、死节、裂缝、孔洞的检测方法。模型对死节、活节、裂缝、孔洞识别结果的均值平均精确率分别约为98.66%、99.06%、98.10%和96.53%,并与当前主流检测模型进行比较,改进的模型具有更好的精确率、召回率和均值平均精确率,分别为97.48%、96.53%和98.22%。模型单幅图像平均检测时间为10.3 ms,最大检测耗时20.5 ms,检测效果与泛化特性较好,模型所占内存仅13.7 MB,易于移植。结论 实验表明改进的YOLOv5模型可用于检测木板材表面主要缺陷。且模型对木板材表面缺陷的识别效果优于其他5种主流检测模型。在维持原有检测精度的基础上,提高了小目标缺陷的识别能力,减少了木板材缺陷漏检的情况,实现了在复杂场景下的快速检测。Abstract:Objective This paper aims to solve the problems of poor recognition and low efficiency of surface defects of wood panel lumber by manual and traditional digital image processing methods, and to improve the utilization rate of wood. Based on the deep learning model, we constructed a wood panel surface defect detection system, aiming to expand the application of deep learning model in the field of wood panel defect detection.Method Based on 839 wood panel defect images in the public dataset “Wood Defect Database”, the dataset was expanded using Imgaug data enhancement library; by introducing SE attention mechanism in the backbone feature network part, the YOLOv5 wood panel surface defect target detection framework was constructed using focus, FPN + PAN structure, and then the transfer learning idea to improve the training method and divide the training process into two phases (freezing phase and unfreezing phase). Then the constructed model was compared with the current mainstream deep learning target detection models, and finally the model was evaluated using confusion matrix, loss value change curve, model size, detection time, and mean average accuracy.Result A detection method based on YOLOv5 model for live knots, dead knots, cracks and holes in wood panel surface defects was proposed. The mean average accuracy of the model for dead knots, live knots, cracks, and hole identification results were about 98.66%, 99.06%, 98.10% and 96.53, respectively, and compared with the current mainstream detection models, the improved model had better accuracy, recall, and mean average accuracy of 97.48%, 96.53% and 98.22%, respectively. The average detection time of the model for a single image was 10.3 ms, and the maximum detection time was 20.5 ms. The detection effect and generalization characteristics were good, and the model only occupied 13.7 MB of memory, making it easy to transplant.Conclusion The experiments indicate that the improved YOLOv5 model can be used to detect the main defects on the surface of wood paneling. The model is better than the other five mainstream inspection models in identifying surface defects. On the basis of maintaining the original detection accuracy, it improves the recognition of small target defects, reduces the situation of missing wood panel defects, and realizes fast detection in complex scenes.

-

Keywords:

- wood plate /

- surface defect /

- YOLOv5 /

- real-time detection /

- deep learning /

- quantitative identification

-

光能利用效率(LUE)是指植被通过光合作用将吸收的单位光合有效辐射转换成干物质的效率[1-2]。它不仅是植物光合作用的重要生态学概念,也是利用遥感参数模型在区域尺度监测植被生产力的关键参数。光能利用率的变化能够对植被有机物的积累过程产生直接影响。光能资源与水肥等资源相比,具有无限制性、瞬时性、不可存储性等特点,因此,在一定时空范围内,植被对光能的截获吸收和利用能力的高低直接决定了生态系统的生产潜力[2]。当前,LUE广泛应用于不同尺度陆地生态系统总初级生产力(GPP)或净初级生产力(NPP)模型估算,和全球碳循环的研究中[3-6]。一些模型的比较研究表明,基于LUE的遥感模型模拟的全球净初级生产力(NPP)的平均值与其他参考模型的平均值有很大差异[7]。模型模拟结果的不确定性主要来自植被光合作用吸收的光合有效辐射和LUE[7]两个方面。此外,由于参数本身的观测和尺度变化带来的不确定性,以及模型的建立和运用范围的扩大,对结果的认识将有很大的不确定性。因此,了解LUE的生理生态基础,对于优化LUE模型和评价模型的可靠性具有重要的意义[8]。目前,对光能利用效率的研究大多集中在农田、草地和森林生态系统中[9-11],对荒漠生态系统LUE的变化特征以及影响因子的调节机理的认识非常有限[9]。因此,不同的时间尺度上环境因子对荒漠生态系统光能利用率的作用强度还需要根据实际的观测数据进一步研究探索。

已有学者研究了不同尺度(叶片、个体、种群)碳循环过程的时间动态及其调控机理,其中LUE作为量化辐射能在群落尺度上的行为参数,已受到广泛关注。研究表明在生长季保证养分充足且没有水分胁迫的条件下,LUE是一个常数[12],同时也有研究证明LUE随着植被生长发育而改变[4,9],不同植被类型的光能利用效率具有明显的时空差异[5,9]。不同时间尺度上,影响LUE的主要环境因子也有差异在不同时间尺度上其环境影响因子也变现的各不相同。在昼夜尺度上,LUE主要受到辐射、温度等[13-14]影响;季节时间尺度上,LUE主要受到LAI、温度、养分元素等[15-16]影响。

由于观测尺度的不同,光能利用效率的计算方法也各不相同。包括叶片尺度上常采用叶片光合作用仪观测法[17-18],群落尺度上常采用生物量收获发和涡度协方差方法[3],生态系统尺度上采用遥感观测法和模型反演法等[5,19]。叶片观测法一般用于控制实验,用于探究植物叶片光合作用光响应的机理过程,LUE用表观量子速率表示。生物量收获法破坏性大且耗费大量的人力物力,一般多用于农作物的研究,其缺点是不能反应短时期(小时或者日尺度)LUE的变化。遥感观测法和模型反演多用于长时间序列的大尺度研究。涡度协方差方法被许多科研工作者用来直接测量大面积生态系统物质和能量通量,而不扰动下垫面。同时,也为研究区域生态系统尺度的光合特征参数提供了途径,为估算GPP提供了一种方法,为提高区域尺度光能利用效率的准确度提供参考。涡度协方差法在时空尺度上可以与卫星遥感尺度转换相关联,使得从冠层尺度到景观水平估算LUE成为可能。

油蒿(Artemisia ordosica)广泛分布于中国西北干旱与半干旱地区,是荒漠灌木生态系统的建群种。现已有大量关于油蒿的光合作用和灌木生态系统碳水耦合的研究[20-21],但是关于油蒿灌木荒漠LUE的季节动态变化及其对环境因子响应的研究相对较少。本文运用涡度协方差方法对宁夏盐池毛乌素沙地油蒿灌木荒漠进行了全年的连续性监测,结合同步观测的气象因子,分析油蒿灌木荒漠光能利用效率在日尺度和季节尺度的变化特征及其对环境因子的响应,了解油蒿灌木荒漠光能资源利用机理,为荒漠生态系统的永续管理和沙区植被恢复提供科学参考依据。

1. 研究区概况

该研究区于宁夏盐池毛乌素沙地生态系统国家定位观测研究站(37°42′31″ N、107°13′47″ E,海拔1 560 m)。位于毛乌素沙地南缘,是黄土高原向鄂尔多斯台地、半干旱区向干旱区、干草原区向荒漠草原区、农区向牧区过渡的重要生态交错带,属于典型中温带大陆性季风气候[22-23]。多年平均空气温度8.1 ℃(1954—2004年),全年无霜期165 d。年均降雨量287 mm,其中62%集中在7—10月之间[20],年平均潜在蒸发散为2 024 mm。该区主要由活动沙丘、半固定沙丘和固定沙丘组成。主要土壤类型为灰钙土,土壤有机质含量在0.5% ~ 0.8%之间,土壤pH值在7.5 ~ 8.5之间,在土壤层1 m深度范围内的土壤总氮含量为0.15 g/kg[21]。研究区主要植被为油蒿灌木。

2. 研究方法

2.1 CO2通量和微气象因子观测

涡度相关观测系统以高度为4.2 m的观测塔为载体,主要观测仪器包括三维超声风速仪(WindMasterTM Pro,Gill Instruments Ltd,Lymington,England)和CO2/H2O闭路红外气体分析仪(IGRA;model LI-7200,LI-COR Biosciences,Lincoln,NE,USA)。

微气象数据测量仪器均设立在4.2 m的通量塔上,辐射数据由净辐射仪(CNR-4,Kipp and Zonen,Delft,the Netherlands)测量,空气温度由空气温湿度传感器(HMP45C,Campbell Scientific Ltd,USA)测量。土壤温度由安装在通量观测塔周围的土壤温度传感器(Campbell-109,Campbell Scientific Ltd,USA)测量,土壤热通量由分布在通量塔周围的5块10 cm深的土壤热通量板(HFP01,Campbell Scientific Ltd,USA)测量,土壤体积含水量分别用10、30、70和120 cm深的土壤温湿度探头(ECH2O-5TE,Decagon Devices,USA)测量,降雨量由翻斗式雨量筒(TE525MM,Campbell Scientific Inc.,USA)测量。涡度协方差系统的数据和微气象数据用CR3000(Campbell Scientific Ltd,USA)数据采集器以10 Hz频率记录,并生成30 min的平均值。

2.2 LAI与养分元素的测定

在通量塔贡献区内设置100 m × 100 m的样地,沿样地东西方向和南北方向每隔20 m设置1条样线,样地内共设置12条样线。每两条样线相交点为叶面积指数测量点,共36个点。2014年4—10月,用LAI-2000冠层分析仪每隔1周对油蒿灌木荒漠的LAI进行一次测定。样地叶面积指数计算公式为LAI = ΣLAIi/36,式中:i为第i个测量点[22]。

2014年4月,选取10个10 m × 10 m小样方,每个小样方分别选取油蒿5株,每隔一周从每株植物上取10片叶子,带回实验室,杀青并烘至恒量,将每株油蒿的取样叶子充分混合研磨,制成供试品。每隔15 d在小样方中用土钻取0 ~ 30 cm层土样,共3次重复,将每层土壤样品均匀混合并带回实验室。自然风干后,用2 mm筛过筛,制成土样进行试验。叶氮含量和土壤全氮含量均采用凯氏定氮法测定[23]。

2.3 数据处理

生态系统净碳交换(NEE)被定义为公式(1)[24]:

NEE=Fc+Fs+Vc (1) 式中:Fc是通量观测塔测得的植被上部CO2交换量,Fs是测得的冠层内部储存通量,Vc是指垂直和水平平流效应的通量。该研究区域有着均匀分布的植被下垫面,因此Vc可忽略不计。对于低矮的冠层Fs接近于0,因此Fs可忽略不计[20]。因此,

NEE=Fc (2) 本研究所用数据从2014年1月1日至2014年12月31日,期间由于仪器故障等造成36.12%数据缺失。通过剔除异常值[25]、旋转二次坐标轴[26]、消除传感器延时影响[27]、频率响应校正[28]等方法来对10 Hz数据进行了校正和质量控制。由于在夜间稳定条件下涡流不明显,导致计算出的NEE值低于夜间实际CO2通量值,因此夜间NEE(NEEnight)数据应通过摩擦风速(u*)控制和筛选,剔除掉u* < 0.18 m/s的数据[22]。经筛选后得到47.7%的有效数据,然后用5倍标准差方法剔除掉异常值。缺失数据按照时长进行插补:不足2 h的数据间隙一般采用线性插值,对于2 h ~ 7 d的数据间隔,使用邻近7 d相同时段的观测平均值,对于大于7 d的数据缺口,采用Michaelis-Menten(3)和Lloyd-Taylor方程(4)通过区分白天和晚上的NEE和Re进行插值[29-30],通过公式(5)计算出生态系统的NEP和GEP:

NEPnight=Re10Q10(Ts−10)/10 (3) NEEday=αPARAmax (4) {\rm{NEP}} = - {\rm{NEE}},\;{\rm{GEP}} = {\rm{NEP}} + {R_{\rm{e}}} (5) 式中:NEPnight为夜间生态系统净交换量,等于夜间生态系统的呼吸值Re(μmol/(m2·s)),Ts为10 cm 深的土壤温度(℃),Re10是Ts = 10 ℃时生态系统的呼吸值(μmol/(m2·s)),Q10是生态系统的呼吸敏感因子(μmol/(m2·s))。NEEday是白天生态系统净交换量(μmol/(m2·s)),α是表观量子效率(μmol/μmol),PAR是光合有效辐射,Amax是最大光合同化速率(μmol/(m2·s)),Rd是白天生态系统平均呼吸速率(μmol/(m2·s))。因为夜间测量出的NEE值就是生态系统夜间的呼吸值(自养呼吸和异养呼吸),因此通过公式(3)将Re与Q10的参数确定出来,根据白天的土壤温度计算出白天的生态系统呼吸值,考虑到植物的光合参数会受到物候和季节变化影响,因此在进行拟合和插补工作时应分别按月进行。gs运用彭曼公式计算得到:

g_{\rm{s}} = \frac{{\lambda E {\text{γ}} {g_{\rm{a}}}}}{{{\rm{\Delta }}\left( {{R_{\rm{n}}} - G} \right) - \lambda E\left( {{\rm{\Delta }} + {\text{γ}} } \right) + \rho {C_{\rm{p}}}{\rm{VPD}}{g_{\rm{a}}}}} (6) 式中:λ为汽化潜热(J/ kg);E为测量的ET值(kg/(m2· s));γ为干湿度常数(kPa/K,通常用0.066 5 kPa/℃表示);∆为饱和蒸气压差和温度之间的斜率关系(kPa/K);ga为空气动力学导度(mm/s);Cp为空气的比热容(J/(kg·K));ρ为干空气密度(kg/m3);VPD是大气饱和水汽压差(kPa);Rn是净辐射(W/m2);G是土壤热通量(W/m2)。

\frac{1}{{{g_a}}} = \frac{u}{{{u^{*2}}}} + 6.2{u^{* - 0.67}} (7) 式中:u为冠层风度;u*为测量风速。

归一化植被指数(NDVI)的计算公式[31]:

{\rm{NDVI}} = \frac{{{{{R}}_{{\rm{NIR}}}} - {R_{{\rm{VIS}}}}}}{{{R_{{\rm{NIR}}}} + {R_{{\rm{VIS}}}}}} (8) 式中:RNIR表示近红外辐射(700 ~ 3 000 nm),RVIS表示可见光辐射(380 ~ 780 nm),本文分别用太阳辐射和光合有效辐射表示RNIR和RVIS。NDVI选用了每天11:00—14:00的辐射数据计算而得[32]。

LUE的估算结果很大程度上取决于GEP和PAR间的线性或非线性(例如直角双曲线方程)关系[33-34]。目前广泛使用的光能利用效率是指太阳辐射利用400 ~ 700 nm波长(PAR,μmol/(m2·s))范围内的光合有效辐射和植物通过吸收光合有效辐射将光能转化成生物量的速率。目前LUE的估算方法很多,但是在生态系统尺度上LUE的定义为:

{\rm{LUE}} = \frac{{{\rm{GEP}}}}{{{\rm{APAR}}}} (9) 式中:GEP为总生态系统生产力(g/(m2·d)),APAR为吸收光合有效辐射(MJ/(m2·d)),本文用散射PAR(PARdif)来代替吸收光合有效辐射[35-37]。

为研究生长季内(5—10月)不同时期LUE的主要影响因子,本文分析了GEP和LUE与环境因子之间的相关性。数据统计与分析使用Matlab2014(Version 7.12.0.,The Math Works,Natick,MA,USA),作图使用OriginPro-2015完成。

3. 结果与分析

3.1 环境因子与LUE的日变化

环境因子与LUE的日变化特征如图1所示。生长季内每日平均Ta的变化范围为11.0 ~ 28.4 ℃,每日平均Ts变化范围为8 ~ 29 ℃,VPD变化范围为0.8 ~ 2.1 kPa。VPD和Ta的最低值出现在08:00,最高值出现在16:00;Ts出现明显滞后现象,最低值出现在上午10:00左右,最高值出现在下午18:00左右;gs有一个单峰,峰值稳定在14:00左右,昼夜平均变化范围为0 ~ 4.2 mm/s。PAR呈现出明显的单峰,其中峰值稳定在14:00左右。GEP呈现出单峰趋势,其中7、8月峰值在12:00左右稳定,其余月份的峰值在10:00—16:00之间稳定,中午11:00的时候达到每日最大值,总体变化趋势表现为7月 > 8月 > 6月 > 9月 > 10月 > 5月;LUE在06:00—14:00逐渐减小,14:00—19:00逐渐增大,在14:00的时候达到每日最低值(0.000 8 ~ 0.002 4 μmol/μmol),整体的变化趋势表现为9月 > 8月 > 7月 > 6月 > 5月 > 10月。

![]() 图 1 环境因子、GEP和LUE昼夜变化趋势Ta.空气温度;Ts.10 cm深土壤温度;VPD.饱和水汽压差;gs.气孔导度;PARtot.总入射光合有效辐射;PARdif.散射光合有效辐射;GEP.生态系统总生产力;LUE.光能利用效率。下同。Ta, air temperature; Ts, soil temperature of 10 cm depth; VPD, vapor pressure deficit; gs, stomatal conductance; PARtot, total incident photosynthetically active radiation; PARdif, diffuset photosynthetically active radiation; GEP, gross ecosystem productivity; LUE, light use efficiency. The same below.Figure 1. Mean diurnal variation in environmental factors and gross ecosystem production(GEP)and light use efficiency

图 1 环境因子、GEP和LUE昼夜变化趋势Ta.空气温度;Ts.10 cm深土壤温度;VPD.饱和水汽压差;gs.气孔导度;PARtot.总入射光合有效辐射;PARdif.散射光合有效辐射;GEP.生态系统总生产力;LUE.光能利用效率。下同。Ta, air temperature; Ts, soil temperature of 10 cm depth; VPD, vapor pressure deficit; gs, stomatal conductance; PARtot, total incident photosynthetically active radiation; PARdif, diffuset photosynthetically active radiation; GEP, gross ecosystem productivity; LUE, light use efficiency. The same below.Figure 1. Mean diurnal variation in environmental factors and gross ecosystem production(GEP)and light use efficiency3.2 环境因子与LUE的季节变化

图2为2014年生长季环境因子和生物因子的季节变化。油蒿灌木的日平均气温变化范围为3.4 ~ 27.6 ℃,日平均土壤温度变化范围为8.5 ~ 28.6 ℃。NDVI的变化范围为0.2 ~ 0.4。PAR从春季到夏季逐渐增加,随后降低,峰值出现在6月9日(56.6 mol/(m2·d))。年降雨总量341.9 mm,观测期降雨具有明显的季节变异,月累计降雨量9月(76.2 mm) > 7月(74.9 mm) > 8月(67.1 mm) > 6月(43.5 mm) > 10月(26.8 mm) > 5月(5.3 mm),在5月前的累计降雨量仅36.6 mm,降雨集中在7、8、9这3个月。VPD季节变化明显,在6月达到最大值,总体表现为夏季高、冬季低,变化范围为0.05 ~ 2.8 kPa。

![]() 图 2 环境和生物因子季节动态变化图NDVI. 归一化植被指数;LAI. 叶面积指数;leaf_N. 叶片N含量;soil_N. 土壤N含量;SWC10、SWC30、SWC70分别表示10、30、70 cm土壤含水量。下同。NDVI, normalized differential vegetation index; LAI, leaf area index. leaf_N, leaf N content; soil_N, soil N content. SWC10, SWC30, SWC70, represent 10, 30, 70 cm soil water content, respectively. The same below.Figure 2. Seasonal dynamics of environmental factors and biological factors

图 2 环境和生物因子季节动态变化图NDVI. 归一化植被指数;LAI. 叶面积指数;leaf_N. 叶片N含量;soil_N. 土壤N含量;SWC10、SWC30、SWC70分别表示10、30、70 cm土壤含水量。下同。NDVI, normalized differential vegetation index; LAI, leaf area index. leaf_N, leaf N content; soil_N, soil N content. SWC10, SWC30, SWC70, represent 10, 30, 70 cm soil water content, respectively. The same below.Figure 2. Seasonal dynamics of environmental factors and biological factorsGEP在7月达到最大值(图3),此时油蒿进入完全展叶期,叶面积指数达到最大,光合速率增加并达到最大,因此在7月生态系统总初级生产力达到最大值。PAR在5月达到最大值,此时油蒿处于展叶期,LAI迅速增大(图2)并随着生长季呈现递增的趋势,由于7月份以后PAR的下降速率比GEP的下降速率大,从而导致LUE在9月份达到最大值0.002 5 g/MJ,月平均LUE介于0.000 9 ~ 0.002 5 g/MJ之间,平均值为0.002 g/MJ(图3)。8月份的总生态系统生产力总值达到最大23.19 g/(m2·d)(图4),对应的LUE月总值在9月份达到最大值0.179 g/MJ,出现这种不对等增长趋势的原因主要是由于辐射的变化所导致的(图4)。

3.3 季节尺度上油蒿GEP和LUE对环境因子的响应

GEP与Ta、Ts和降雨量之间呈现出较好的正相关关系(图5),随着温度的增加,GEP呈现明显的递增趋势,降雨量的增加也会提高GEP的大小,SWC对GEP的变化有着72%的贡献率。随着Nsoil含量的增大,LUE表现出先减小后增大的趋势,在Nsoil达到0.24 g/kg时达到最低,Nsoil对LUE的变化有着90%的贡献率,LUE的变化还随着gs的增大呈现先减小后增大的趋势,gs对LUE的变化有着64%的贡献率,LUE的季节变化主要受到Nsoil和gs的影响。

4. 讨 论

4.1 LUE的日变化以及对环境因子的响应

生长季(5—10月)LUE昼夜变化基本保持一致,呈现出先减小后增大的趋势,在14:00达到最小值,这与呼伦贝尔贝加针茅草甸草原生态系统中的光能利用效率的昼夜变化趋势基本一致[34]。LUE的昼夜变化一般受GEP和PAR昼夜变化的驱动,其中GEP的昼夜变化趋势为先增大后趋于稳定最后变小,而PAR的昼夜变化是先增大后减小的单峰趋势,并在14:00点时PAR达到最大值。光合作用是植物生长和物质积累的基础,其中光是光合作用的主导因子[38],午后高PAR常常限制植物光合作用,从而导致在昼夜尺度上LUE的变化与GEP的变化趋势正好相反。此外,夏季LUE的昼夜变化也受生态系统冠层导度(gs)的影响,夏季植物在中午时遭受高温、高辐射胁迫,此时gs达到最小,引起气孔关闭,空气阻力增加,光合作用受阻导致叶片光合速率降低[39-40],从而降低了生态系统LUE。

4.2 LUE的季节变化以及对环境因子的响应

研究区油蒿灌木荒漠光能利用效率动态随着环境变化和植被本身的生理特征的变化而变得复杂,但是LUE有着显著的季节动态特征。LUE的季节变化呈现出先增加后下降的单峰趋势,在9月份达到最大值0.002 5 g/MJ,10月份达到最低值0.000 9 g/MJ。这与内蒙古荒漠草原的光能利用效率的变化趋势一致,在8月份达到最大值0.355 g/MJ,同时最低值出现在4月份0.219 g/MJ[41]。卫亚星等[42]对青海省稀疏灌木的研究发现LUE介于0.026 ~ 0.049 g/MJ之间,最大值出现在7月份。由于7、8月份是植被的生长旺季,水热条件充足,植被覆盖率最大,此时植被的累积光物质质量也较多,吸收光合有效辐射量最大,LUE达到最大值。

植物冠层光合作用主要受冠层吸收的太阳辐射控制,植被叶片在截获入射太阳光合有效辐射进行光合作用时也具有光保护机制。植被在环境胁迫条件下(如极端高温、水分或养分亏缺、高光强等)通过降低光合作用效率[43]实现光保护过程。氮元素不仅参与植物光合作用而且是维持植物生长的重要元素,与生物圈的演替和发展紧密相关[37],Green等[15]证实了冠层总氮含量与光能利用效率之间存在显著正相关性。在低覆盖率的地表,降雨会增加土壤含水量,改变Ts,通过影响PAR[24,41]从而改变LUE的大小。VPD会通过影响植被叶片的伸展、改变叶片气孔导度从而改变光合速率来影响LUE的变化。在本研究区域内已经被证实VPD会通过影响该生态系统的碳交换过程[44],同时土壤水分的补给不足会限制半干旱草原和灌木生态系统的生产力[44-45],从而导致LUE降低。苏培玺等[46]对荒漠植物梭梭(Haloxylon ammodendron)和沙拐枣(Calligonum mongolicum)的光合作用过程研究发现,在水分条件好时光合速率明显增大,LUE明显提高。

朱文泉等[39]结合遥感数据、气象数据和实测NPP数据,系统的模拟了中国典型植被的最大光能利用效率LUEmax,得到中国灌木类型的最大光能利用效率为0.429 g/MJ。本文估算出的光能利用效率值远远低于前人的研究,可能与荒漠生态系统较小的生产力、较大的辐射值紧密相关。实际光能利用效率与环境条件的关系非常复杂,植被类型、地理位置、气候条件、植被营养状况(叶氮含量)和植被生长阶段都会影响光能利用效率的变化。

5. 结 论

本文通过研究油蒿灌木荒漠光能利用效率的昼夜和季节动态变化,明确了在不同时间尺度上LUE的主要影响因子。

(1) 在日尺度上,LUE呈现出先降低后增加的趋势,在14:00时达到最低值;LUE的日变化主要受gs和PAR的影响。

(2) 在季节尺度上,LUE呈现出先增加后降低的趋势,在9月份达到最大值,LUE的季节变化主要受土壤N含量和gs的影响。

研究还发现,LUE的大小主要取决于GEP与PAR的比值关系,在长时间尺度上通过增加土壤的养分元素,可以提高植被的光合生产能力,从而提高光能利用效率。此外,本研究主要集中在季节和生态系统尺度上,对于毛乌素沙地油蒿灌木荒漠的最大光能利用效率的定量研究还应结合卫星遥感数据与当地多年的地面实测数据相结合进行多时空多尺度的研究。

-

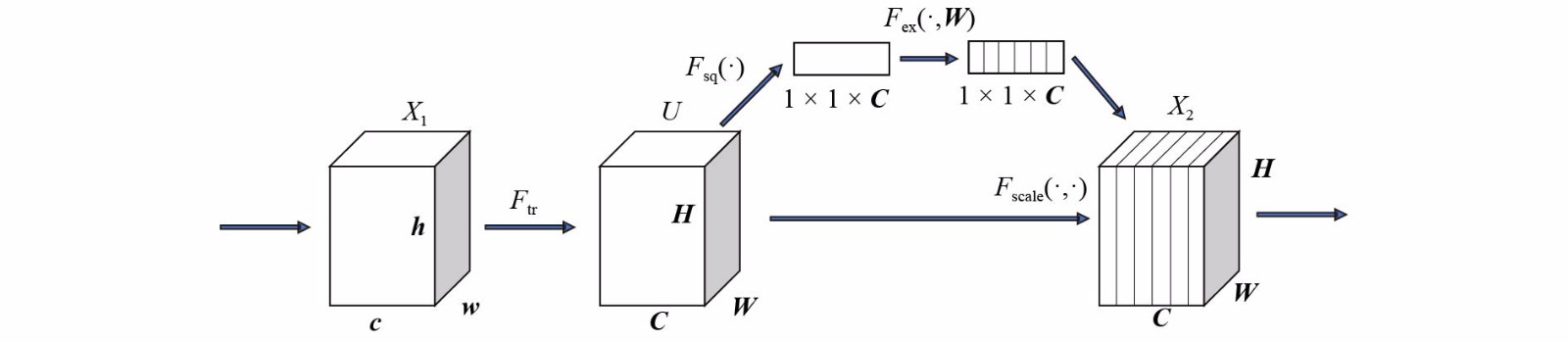

图 3 SE-Net结构示意图

{X}_{1} 指输入,U是主干网络每一层卷积层的输出,c、w、h、C、W、H均为特征向量, {X}_{2} 表示结合了权重之后最终的输出。 {F}_{\mathrm{t}\mathrm{r}} 为卷积操作,运算 {F}_{\mathrm{s}\mathrm{q}} 为挤压操作, {F}_{\mathrm{e}\mathrm{x}} 表示激励操作, {F}_{\mathrm{s}\mathrm{c}\mathrm{a}\mathrm{l}\mathrm{e}} 指代缩放操作。 {X}_{1} refers to input, U refers to the output of each convolution layer of the backbone network, c, w, h, C, W, H are the eigenvector, {X}_{2} represents the final output after combining weights. {F}_{\mathrm{t}\mathrm{r}} is a convolution operation, {F}_{\mathrm{s}\mathrm{q}} is the squeeze operation, {F}_{\mathrm{e}\mathrm{x}} stands for excitation operation, {F}_{\mathrm{s}\mathrm{c}\mathrm{a}\mathrm{l}\mathrm{e}} refers to the scale operation.

Figure 3. SE-Net structure diagram

表 1 数据集标注数量

Table 1 Number of dataset annotations

标签 Label 死节 Dead knot 活节 Live knot 孔洞 Hole 裂缝 Crack 数量 Quantity 3 311 2 117 825 2 269 表 2 实验环境

Table 2 Experimental environment

配置名称 Configuration name 版本参数 Version parameter 系统环境 System environment Ubuntu18.04 中央处理器 Central processing unit AMD Ryzen7 4800H with Radeon Graphics@2.90 GHz 图形处理器 Graphics processing unit NVIDIA GeForce RTX 2060 6 GB 图形处理器加速库 Graphics processing unit acceleration library CUDA tookit10.1,cuDNN7.5.6 随机存取存储器 Random access memory 16 GB 深度学习框架 Deep learning framework Pytorch1.8.0 表 3 改进YOLOv5模型对不同缺陷识别结果对比

Table 3 Comparison of improved YOLOv5 model for different defect identification results

% 标签 Label 精确率 Precision rate 召回率 Recall rate mAP@0.5 mAP@0.5∶0.95 死节 Dead knot 97.35 97.50 98.66 78.74 活节 Live knot 97.92 98.14 99.06 83.19 裂缝 Crack 96.70 91.55 98.10 72.22 孔洞 Hole 95.57 96.73 96.53 80.15 注:mAP@0.5表示在交并比(IoU)设为0.5时,每一个类别下所有图片的均值平均精确率,mAP@0.5∶0.95表示在不同交并比阈值(0.50 ~ 0.95,步长0.05)(0.50、0.55、0.60、0.65、0.70、0.75、0.80、0.85、0.90、0.95)上的均值平均精确率。Notes: mAP@0.5 indicates the average accuracy of all images in each category when the intersection and combination ratio is set to 0.5, mAP@0.5∶0.95 indicates the average accuracy of the mean value on the threshold of different intersection and combination ratios (0.50−0.95, step size 0.05) (0.50, 0.55, 0.60, 0.65, 0.70, 0.75, 0.80, 0.85, 0.90, 0.95). 表 4 不同模型识别结果对比

Table 4 Comparison of recognition results of different models

网络模型

Network model精确率

Precision rate/%召回率

Recall rate/%mAP@0.5/% 检测时间

Detection time/ms模型大小

Model size/MBSSD 81.17 91.60 86.12 91.4 92.1 faster-RCNN 89.16 93.50 81.94 178.6 108.0 YOLOv3 96.89 93.59 96.30 32.7 117.0 YOLOv4 81.90 92.37 86.75 120.2 224.0 YOLOv5 97.14 96.12 98.06 22.1 13.7 改进的YOLOv5

Improved YOLOv597.48 96.53 98.22 10.3 14.1 -

[1] 谢永华. 数字图像处理技术在木材表面缺陷检测中的应用研究[D]. 哈尔滨: 东北林业大学, 2013. Xie Y H. The application and research of digital image processing on wood surface texture inspection[D]. Harbin: Northeast Forestry University, 2013.

[2] Akhyar F, Novamizanti L, Putra T, et al. Lightning YOLOv4 for a surface defect detection system for sawn lumber[C]//Jay K C C, Klara N, Yong R, et al. IEEE 5th International Conference on Multimedia Information Processing and Retrieval (MIPR). New York: IEEE, 2022: 184−189.

[3] 肖雨晴, 杨慧敏, 王柯欣, 等. 卷积神经网络在木材缺陷检测应用中的研究进展[J]. 木材科学与技术, 2021, 35(3): 12−18. doi: 10.12326/j.2096-9694.2020088 Xiao Y Q, Yang H M, Wang K X, et al. Research progress of convolutional neural network in wood defect detection[J]. Wood Science and Technology, 2021, 35(3): 12−18. doi: 10.12326/j.2096-9694.2020088

[4] Xia B, Luo H, Shi S. Improved faster R-CNN based surface defect detection algorithm for plates[J]. Computational Intelligence and Neuroscience, 2022, 2022: 11−22.

[5] Mu H, Zhang M, Qi D, et al. Wood defects recognition based on fuzzy bp neural network[J]. International Journal of Smart Home, 2015, 9: 143−152.

[6] Yang Y, Zhou X, Liu Y, et al. Wood defect detection based on depth extreme learning machine[J]. Applied Sciences, 2020, 10(21): 7488. doi: 10.3390/app10217488

[7] Mu H, Zhang M, Qi D, et al. The application of RBF neural network in the wood defect detection[J]. International Journal of Hybrid Information Technology, 2015, 8(2): 41−50. doi: 10.14257/ijhit.2015.8.2.04

[8] 李超, 刘思佳, 曹军, 等. 基于PSO优选特征的实木板材缺陷的压缩感知分选方法[J]. 北京林业大学学报, 2015, 37(7): 117−122. Li C, Liu S J, Cao J, et al. The method of wood defectrecognition based on PSO feature selection and compressed sensing[J]. Journal of Beijing Forestry University, 2015, 37(7): 117−122.

[9] Chen L C, Pardeshi M S, Lo W T, et al. Edge-glued wooden panel defect detection using deep learning[J]. Wood Science and Technology, 2022, 56(2): 477−507. doi: 10.1007/s00226-021-01316-3

[10] 缪伟志, 陆兆纳, 王俊龙, 等. 基于视觉的火灾检测研究[J]. 森林工程, 2022, 38(1): 86−92. doi: 10.3969/j.issn.1006-8023.2022.01.011 Miao W Z, Lu Z N, Wang J L, et al. Fire detection research based on vision[J]. Forest Engineering, 2022, 38(1): 86−92. doi: 10.3969/j.issn.1006-8023.2022.01.011

[11] 高明宇, 倪海明, 张博洋, 等. 一种基于GoogLeNet卷积神经网络的木节缺陷识别方法[J]. 森林工程, 2021, 37(4): 66−70. doi: 10.3969/j.issn.1006-8023.2021.04.009 Gao M Y, Ni H M, Zhang B Y, et al. A method for recognizing wood knots defects based on GoogLeNet convolutional neural network[J]. Forest Engineering, 2021, 37(4): 66−70. doi: 10.3969/j.issn.1006-8023.2021.04.009

[12] He T, Liu Y, Yu Y, et al. Application of deep convolutional neural network on feature extraction and detection of wood defects[J]. Measurement, 2020, 152: 107357. doi: 10.1016/j.measurement.2019.107357

[13] Urbonas A, Raudonis V, Maskeliūnas R, et al. Automated identification of wood veneer surface defects using faster region-based convolutional neural network with data augmentation and transfer learning[J]. Applied Sciences, 2019, 9(22): 4898. doi: 10.3390/app9224898

[14] Shi J, Li Z, Zhu T, et al. Defect detection of industry wood veneer based on NAS and multi-channel mask R-CNN[J]. Sensors, 2020, 20(16): 4398. doi: 10.3390/s20164398

[15] Sun P A. Wood quality defect detection based on deep learning and multicriteria framework[J]. Mathematical Problems in Engineering, 2022, 2022: 9−16.

[16] Wang L, Yan W Q. Tree leaves detection based on deep learning[C]//Minh N, Wei Q Y, Harvey H. International Symposium on Geometry and Vision. Auckland: Auckland University of Technology (AUT), 2021: 26−38.

[17] 赵睿, 刘辉, 刘沛霖, 等. 基于改进YOLOv5s的安全帽检测算法[J/OL]. 北京航空航天大学学报, 2023[2023−01−12]. https://doi.org/10.13700/j.bh.1001-5965.2021.0595. Zhao R, Liu H, Liu P L, et al. Research on safety helmet detection algorithm based on improved YOLOv5s[J/OL]. Journal of Beijing University of Aeronautics and Astronautics, 2023[2023−01−12]. https://doi.org/10.13700/j.bh.1001-5965.2021.0595.

[18] 李彦甫, 范习健, 杨绪兵, 等. 基于自注意力卷积网络的遥感图像分类[J]. 北京林业大学学报, 2021, 43(10): 81−88. doi: 10.12171/j.1000-1522.20210196 Li Y F, Fan X J, Yang X B, et al. Remote sensing image classification framework based on self-attention convolutional neural network[J]. Journal of Beijing Forestry University, 2021, 43(10): 81−88. doi: 10.12171/j.1000-1522.20210196

[19] 邹梓吟, 盖绍彦, 达飞鹏, 等. 基于注意力机制的遮挡行人检测算法[J]. 光学学报, 2021, 41(15): 157−165. Zou Z Y, Gai S Y, Da F P, et al. Occluded pedestrian detection algorithm basedon attention mechanism[J]. Acta Optica Sinica, 2021, 41(15): 157−165.

[20] Gao M, Wang F, Liu J, et al. Estimation of the convolutional neural network with attention mechanism and transfer learning on wood knot defect classification[J]. Journal of Applied Physics, 2022, 131(23): 233101. doi: 10.1063/5.0087060

[21] Du J. Understanding of object detection based on CNN family and YOLO[J] . Journal of Physics Conference, 2018, 1004: 012029.

[22] Gao M, Song P, Wang F, et al. A novel deep convolutional neural network based on ResNet-18 and transfer learning for detection of wood knot defects[J]. Journal of Sensors, 2021, 2021: 16−27.

下载:

下载: