Computerized tomography of defects in Pinus massoniana and its image interpretation

-

摘要:目的

通过解译计算机断层扫描(CT)图像获取马尾松原木的缺陷类型、空间分布和形态特征,以实现目标缺陷的三维重建,为CT技术在木质材料中的应用提供技术支撑。

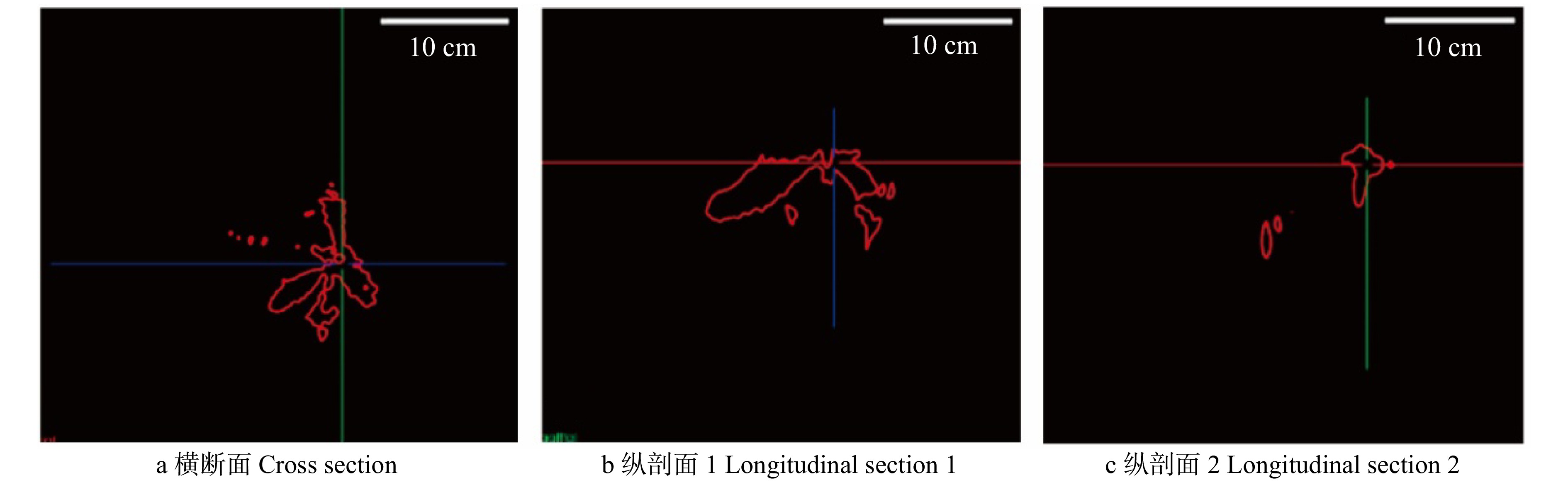

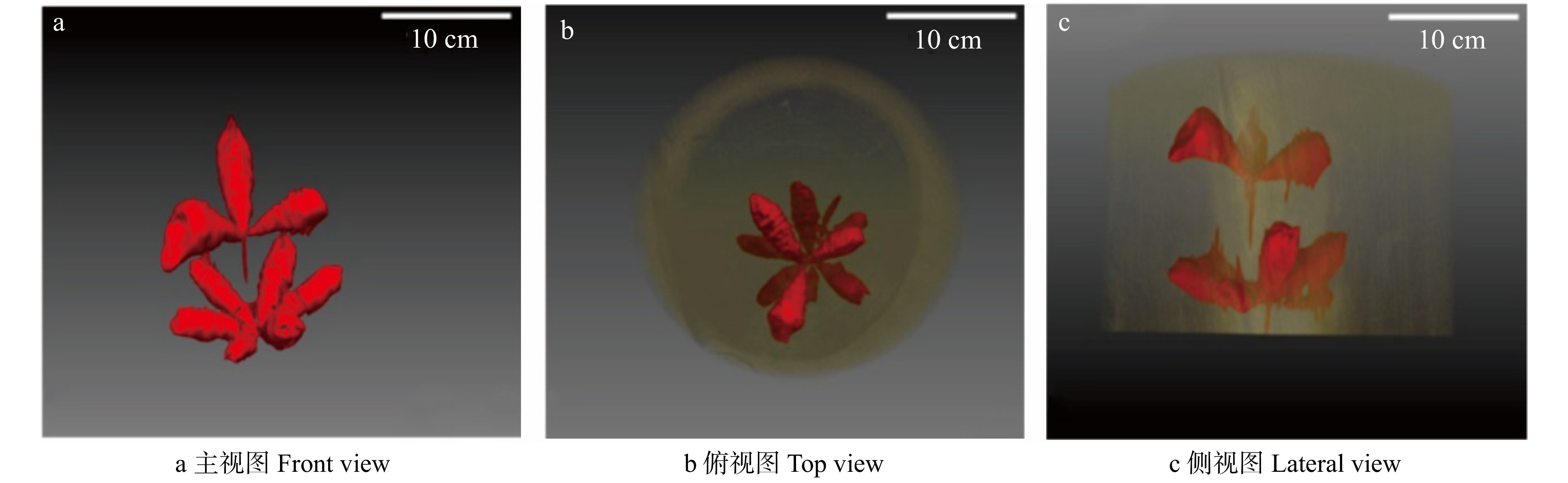

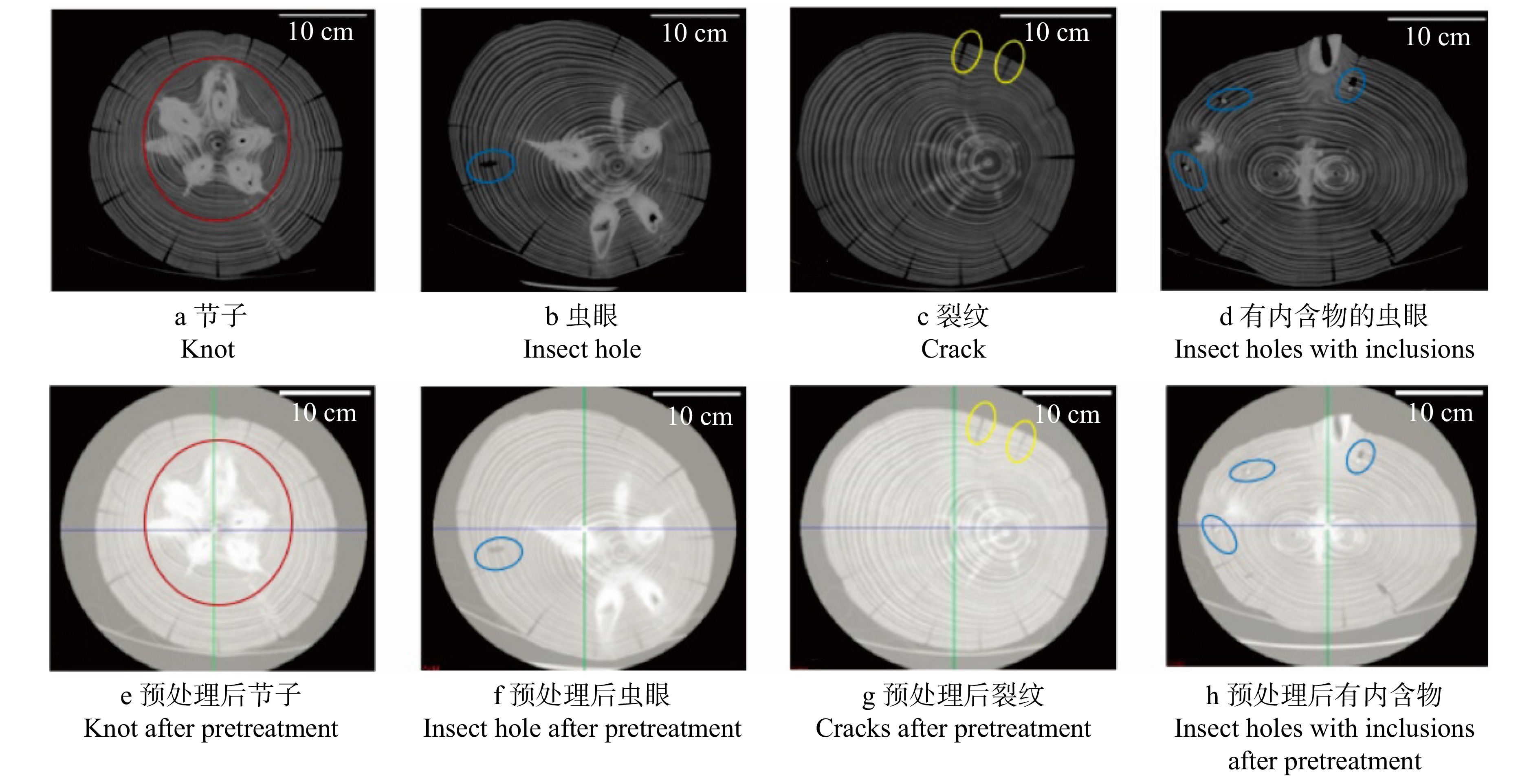

方法设置合理的扫描参数快速完成马尾松原木扫描。针对CT扫描获取的马尾松原木缺陷图像,采用曲率各向异性扩散滤波去除噪声,选取合理阈值进行阈值分割,实现裂纹、虫眼的分割;采用参数形变模型算法,实现节子的分割。利用Mimics软件,通过三维区域生长法建立裂纹、虫眼的三维模型;基于MITK Workbench软件,通过VTK三维可视化面绘制中的移动立方体算法建立节子的三维模型。

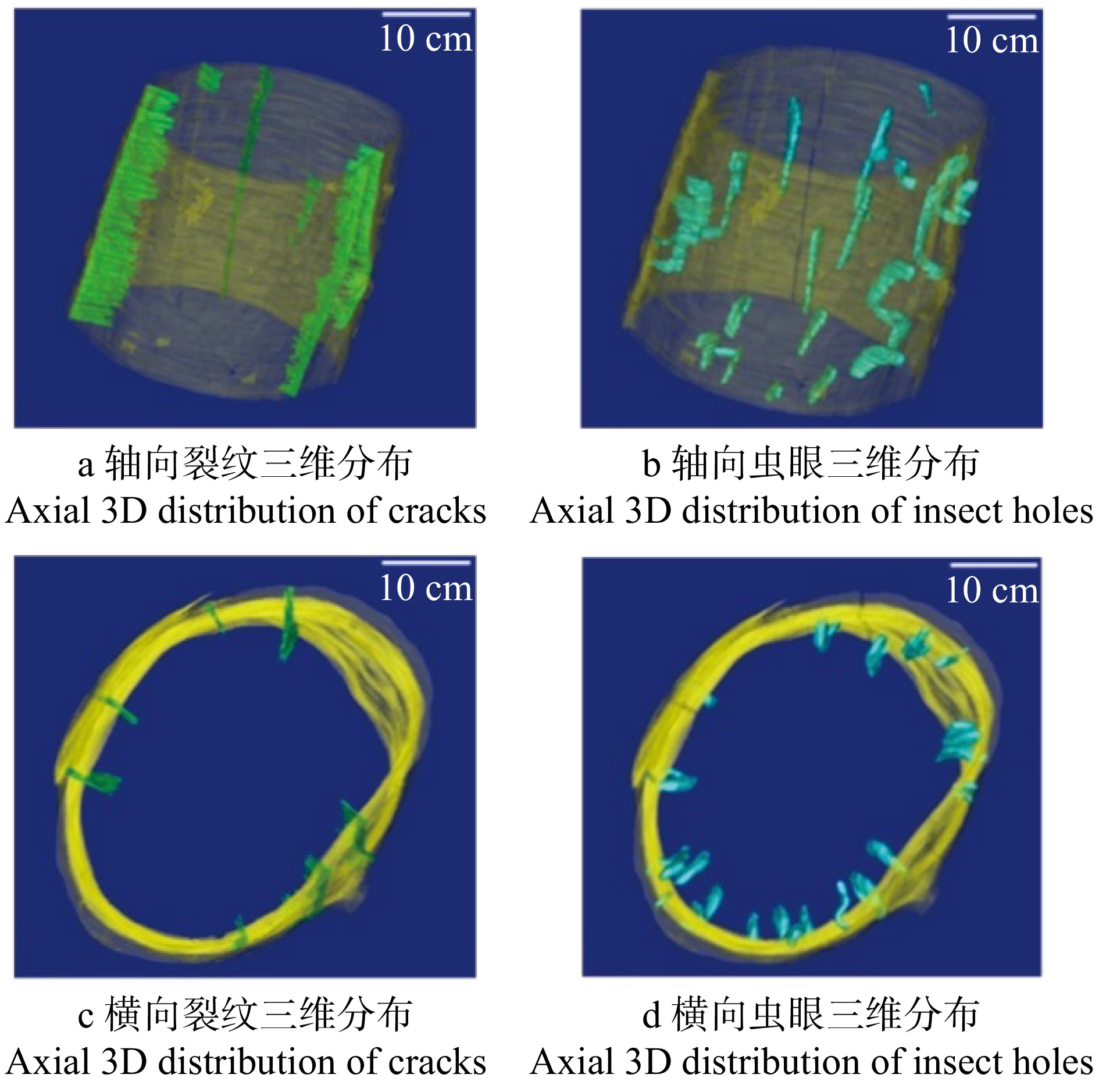

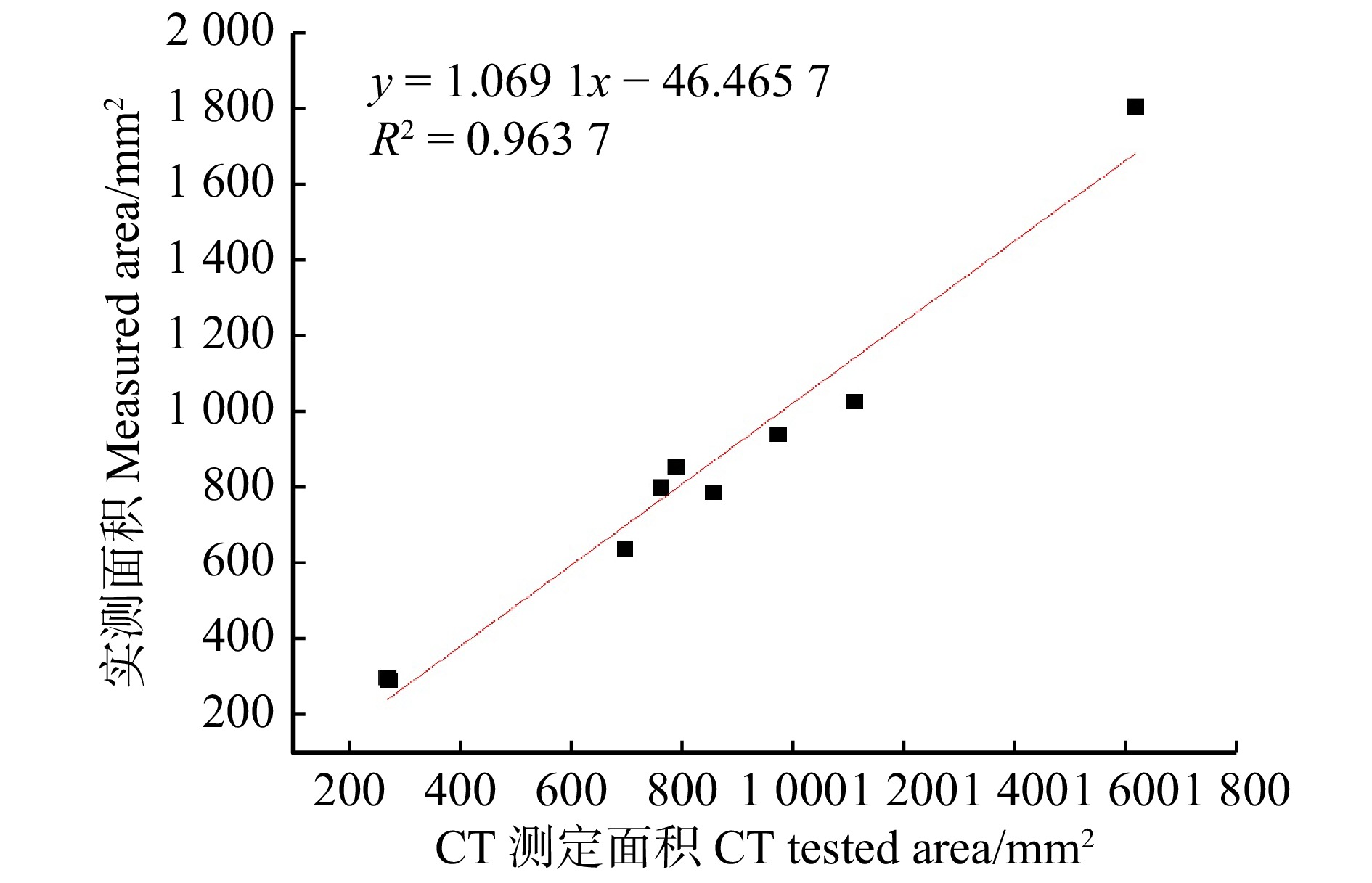

结果阈值分割法、参数形变模型法能快速准确地识别原木内部缺陷并提取缺陷特征信息,具有较高的识别效率和精度,相对误差较小,在3.63% ~ 10.36%范围内波动。三维区域生长法和移动立方体算法实现了原木内部裂纹、虫眼和节子的三维重建,能够快速获取缺陷的空间分布、结构特征,并量化特征信息。

结论本研究提出的分析方法适用于不同缺陷的图像分割和三维可视化,可以获取缺陷在马尾松原木中的空间分布位置与特征参数,缺陷检测准确率高。研究结果为木材保护和木材利用的改进提供了技术支撑。

Abstract:ObjectiveIn order to realize the three-dimensional reconstruction of targeted defects and provide technical support for the application of CT technology in wood materials, the defect types, spatial distribution and morphological characteristics of Pinus massoniana log were interpreted based on computerized tomography (CT) images.

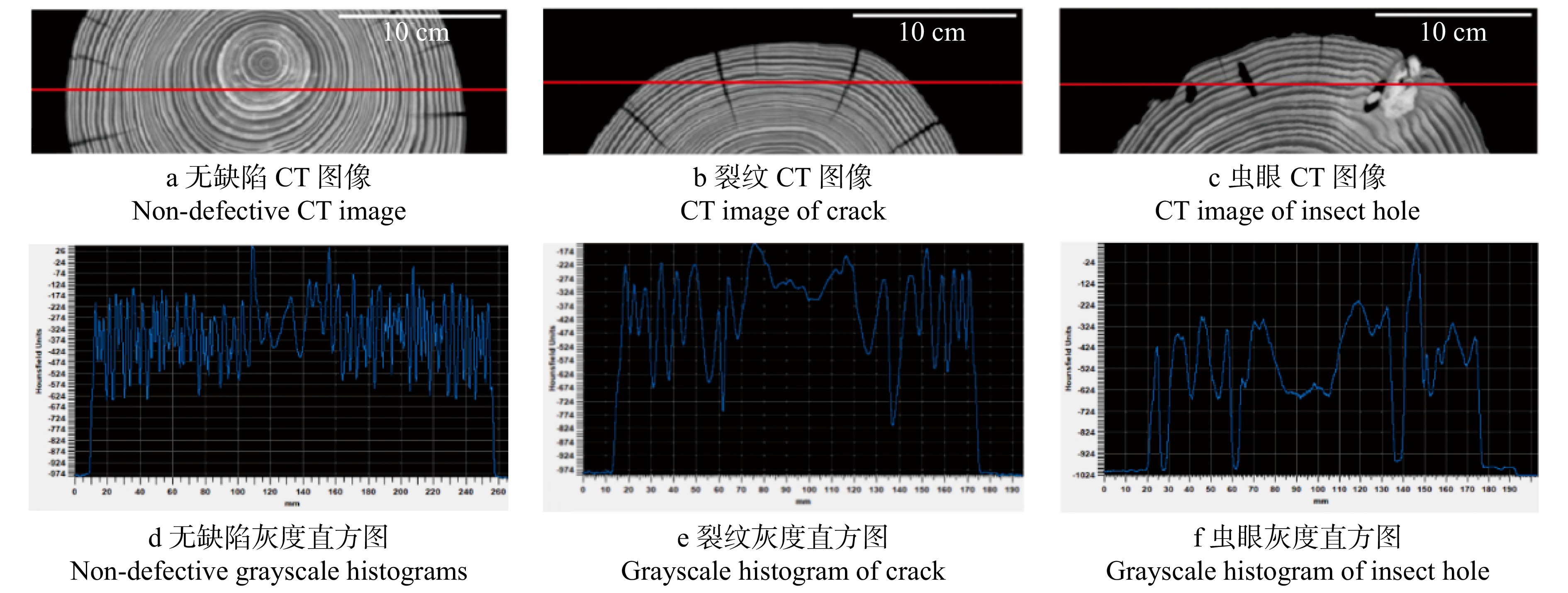

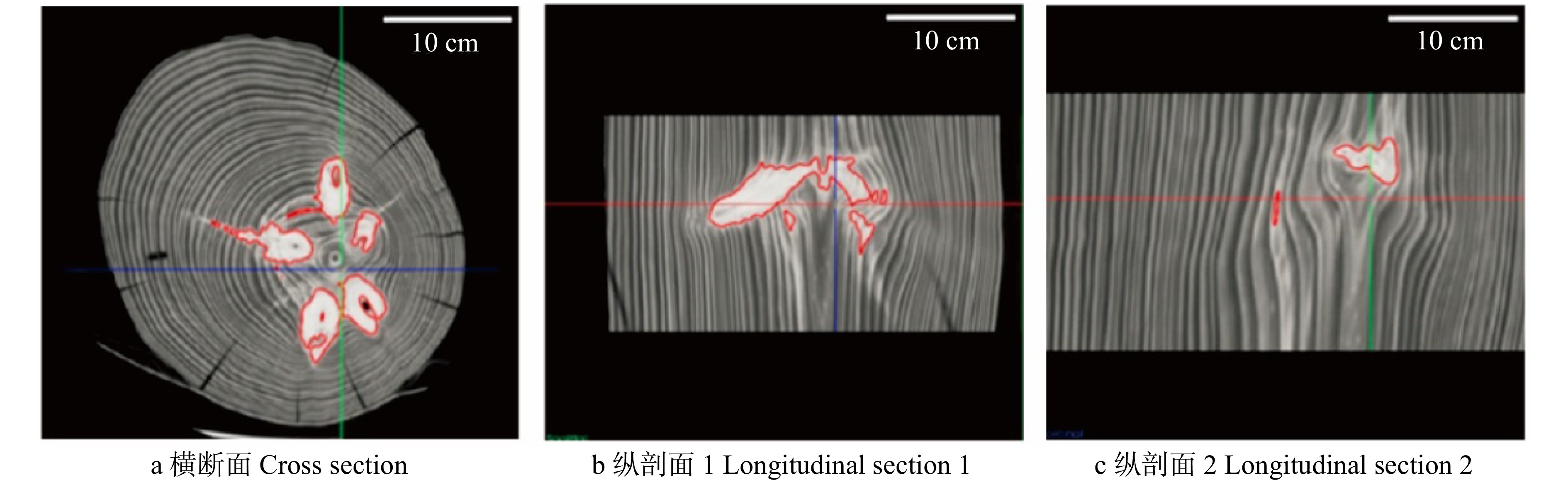

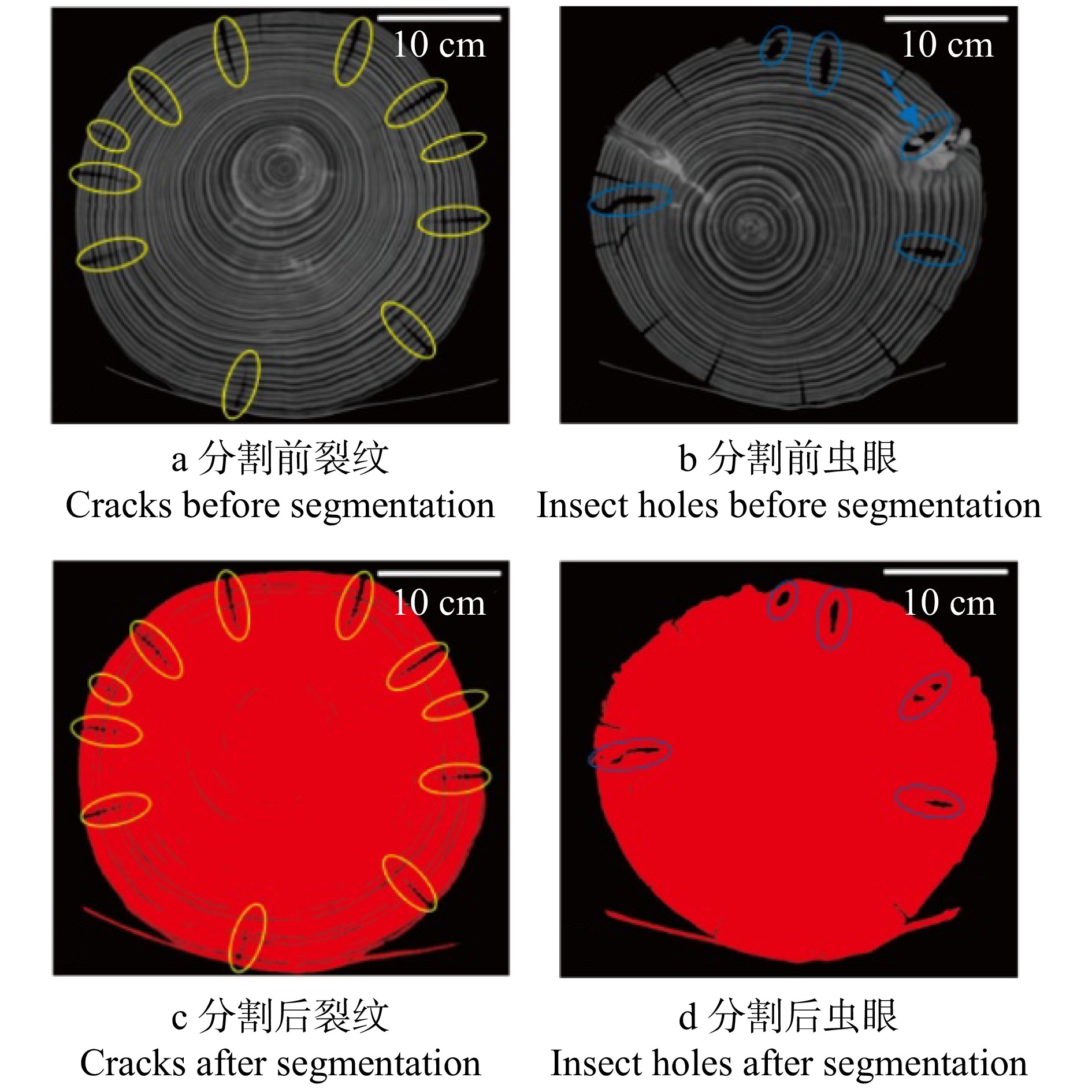

MethodReasonable parameters were set to quickly complete the scanning of P. massoniana logs. For CT image of the defects in P. massoniana log, the curvature anisotropic diffusion filtering was used to reduce noise. The threshold segmentation was applied to realize the segmentation of crack and insect hole by selecting reasonable thresholds, and the parametric deformation modeling algorithm was used to realize the segmentation of knots. Using Mimics software, the three-dimensional model of crack and insect hole was established by 3D area growth method. Based on MITK Workbench software, the 3D model of knots was established using the moving cube algorithm in 3D visualization surface rendering of VTK.

ResultThe threshold segmentation method and parameter deformation modeling method can quickly and accurately identify the internal defects of logs and extract the defect feature information, which had high identification efficiency and accuracy. The relative error was small, fluctuating within the range of 3.63%−10.36%. The three-dimensional reconstruction of internal cracks, insect holes and knot was realized by three-dimensional region growth method and the moving cube algorithm, which can quickly obtain the spatial distribution, structural characteristics and quantify the feature information of defects.

ConclusionAn image segmentation and three-dimensional visualization method suitable for different defects is proposed, the spatial distribution location and characteristic parameters of the defects in P. massoniana logs are obtained, and the accuracy of defect detection is high. The research results can provide technical support for wood protection and utilization improvement.

-

Keywords:

- defect /

- tomography /

- knot /

- image segmentation /

- three dimensional /

- visualization /

- algorithms

-

-

表 1 马尾松原木各部位平均CT值

Table 1 Average CT values of different parts in P. massoniana log

序号 No. CT值 CT value 心材 Heartwood 边材 Sapwood 节子 Knot 1 −229.53 −351.20 157.10 2 −391.25 −369.50 165.00 3 −358.15 −391.10 172.60 4 −320.60 −373.75 174.42 均值 Average value −324.88 −371.38 167.28 表 2 马尾松原木中裂纹体积参数值

Table 2 Volumetric parameter values of cracks in P. massoniana log

序号

No.裂纹体积

Volume of crack/cm3原木体积

Volume of log/cm3裂纹占原木体积百分比

Percentage of cracks in volume of log/%1-1 1.78 6 143.05 0.03 1-2 2.98 6 143.05 0.05 1-3 1.65 6 143.05 0.03 1-4 2.07 6 143.05 0.03 1-5 1.18 6 143.05 0.02 2-1 2.81 9 783.06 0.03 2-2 6.49 9 783.06 0.06 2-3 2.02 9 783.06 0.02 2-4 1.28 9 783.06 0.01 表 3 马尾松原木中虫眼体积参数值

Table 3 Volumetric parameter values of insect holes in P. massoniana log

序号

No.虫眼体积

Volume of insect hole/cm3原木体积

Volume of log/cm3虫眼占原木体积百分比

Percentage of insect holes in volume of log/%1-1 1.98 6 143.05 0.03 1-2 1.17 6 143.05 0.02 1-3 1.07 6 143.05 0.02 1-4 4.31 6 143.05 0.07 1-5 1.37 6 143.05 0.02 1-6 1.96 6 143.05 0.03 1-7 0.78 6 143.05 0.01 1-8 1.57 6 143.05 0.03 2-1 1.02 9 783.06 0.01 2-2 2.33 9 783.06 0.02 2-3 1.76 9 783.06 0.02 2-4 1.66 9 783.06 0.02 2-5 0.80 9 783.06 0.01 2-6 2.77 9 783.06 0.03 2-8 0.80 9 783.06 0.01 表 4 马尾松原木中节子体积参数值

Table 4 Volumetric parameter values of knots in P. massoniana log

序号

No.节子数量

Knot number节子体积

Knot volume/cm3原木体积

Log volume/cm3节子占原木体积百分比

Percentage of knots in volume of log/%1 7 310.00 8 055.75 3.84 2 6 212.10 5 857.49 3.62 3 9 266.44 9 201.68 2.89 4 4 361.64 1 0173.00 3.55 5 5 148.70 6 304.89 2.35 表 5 节子、裂纹和虫眼的CT测定与实测面积比较

Table 5 Comparison of the measured area of knots, cracks and insect holes with the area tested by CT

类型

Type试样编号

Specimen No.横截面半径

Cross-sectional radius/mm横截面面积

Cross-sectional area/mm2实测面积

Measured area/mm2CT测定面积

Area tested by CT/mm2相对误差

Relative error/%节子

Knot4-1 85.37 22 884.17 788(3.44%) 857.51(3.75%) 8.82 4-2 108.71 37 109.63 1 029(2.77%) 1 113.42(3.00%) 8.20 4-3 108.71 37 109.63 941(2.54%) 975.13(2.63%) 3.63 裂纹

Carck5-1 71.30 15 962.79 802(5.02%) 763.12(4.54%) −4.85 5-2 83.50 21 892.87 857(3.91%) 790.62(3.61%) −7.75 5-3 62.00 12 070.16 292(2.42%) 274.51(2.27%) −5.99 5-4 61.75 11 973.02 300(2.51%) 271.14(2.26%) −9.62 虫眼

Insect hole6-1 87.25 23 903.45 1 805(7.55%) 1 617.98(6.77%) −10.36 6-2 57.00 10 201.86 639(6.26%) 698.71(6.08%) 9.34 注:括号内数值为缺陷面积在横截面面积中的占比。Note: values inside the parentheses are the proportion of defect area to the cross-sectional area. -

[1] Kaiser S, Kaiser M S. Comparison of wood and knot on wear behaviour of pine timber[J]. Research on Engineering Structures and Materials, 2020, 6(1): 35−44.

[2] Kunesh R H, Johnson J W. Effect of single knots on tensile strength of 2-by 8- inch douglas-fir dimension lumber[J]. Forest Products Journal, 1972, 22: 32−37.

[3] Mäkinen H. Effect of stand density on the branch development of silver birch (Betula pendula Roth) in central Finland[J]. Trees, 2002, 16: 346−353. doi: 10.1007/s00468-002-0162-x

[4] 钟丽辉, 程昱之, 孙永科, 等. 木材缺陷识别方法综述[J]. 农业技术与装备, 2020, 371(11): 151−152. doi: 10.3969/j.issn.1673-887X.2020.11.071 Zhong L H, Cheng Y Z, Sun Y K, et al. Review of wood defect identification method[J]. Agricultural Technology & Equipment, 2020, 371(11): 151−152. doi: 10.3969/j.issn.1673-887X.2020.11.071

[5] 张瑞峰, 夏坡坡. 基于CNN的典型木材缺陷图像识别研究[J]. 现代化农业, 2019(1): 37−40. doi: 10.3969/j.issn.1001-0254.2019.01.021 Zhang R F, Xia P P. Research on image recognition of typical wood defects based on CNN[J]. Modernizing Agriculture, 2019(1): 37−40. doi: 10.3969/j.issn.1001-0254.2019.01.021

[6] Ling J X, Xie Y H. Research on wood defects classification based on deep learning[J]. Wood Research, 2022, 67(1): 147−156. doi: 10.37763/wr.1336-4561/67.1.147156

[7] Wang B G, Yang C M, Ding Y C, et al. Detection of wood surface defects based on improved YOLOv3 algorithm[J]. BioRecsources, 2021, 16(4): 6766−6780. doi: 10.15376/biores.16.4.6766-6780

[8] 王正, 江莺, 严飞, 等. 基于YOLOv7的木材缺陷检测模型Wood-Net的研究[J]. 林业工程学报, 2024, 9(1): 132−140. Wang Z, Jiang Y, Yan F, et al. Research on wood defect detection model Wood-Net based on YOLOv7[J]. Journal of Forestry Engineering, 2024, 9(1): 132−140.

[9] 赵鹏, 赵匀, 陈广胜. 基于3D扫描技术的木材缺陷定量化分析[J]. 农业工程学报, 2017, 33(7): 171−176. doi: 10.11975/j.issn.1002-6819.2017.07.022 Zhao P, Zhao Y, Chen G S. Quantitative analysis of wood defect based on 3D scanning technique[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(7): 171−176. doi: 10.11975/j.issn.1002-6819.2017.07.022

[10] 何潇. 原木心边材密度与含水率的计算机断层扫描检测研究[D]. 哈尔滨: 东北林业大学, 2015. He X. Study on the log heartwood and sapwood density and moisture content detection based on computed tomography[D]. Harbin: Northeast Forestry University, 2015.

[11] 高明宇, 倪海明, 张博洋, 等. 一种基于 GoogLeNet 卷积神经网络的木节缺陷识别方法[J]. 森林工程, 2021, 37(4): 66−70. doi: 10.3969/j.issn.1006-8023.2021.04.009 Gao M Y, Ni H M, Zhang B Y, et al. A method for recognizing wood knots defects based on GoogLeNet convolutional neural network[J]. Forest Engineering, 2021, 37(4): 66−70. doi: 10.3969/j.issn.1006-8023.2021.04.009

[12] Longuetaud F, Mothe F, Kerautret F, et al. Automatic knot detection and measurements from X-ray CT images of wood: a review and validation of an improved algorithm on softwood samples[J]. Computers and Electronics in Agriculture, 2012, 85: 77−89. doi: 10.1016/j.compag.2012.03.013

[13] 陈偲, 沈肇雨, 王正, 等. 正交胶合木平面剪切的开裂形貌及其破坏模式探究[J]. 林产工业, 2022, 59(6): 7−13. Chen S, Shen Z Y, Wang Z, et al. Study on plane shear cracking morphology and failure mechanism of cross laminated timber[J]. China Forest Products Industry, 2022, 59(6): 7−13.

[14] 王卿平, 刘杏娥, 张桂兰, 等. 基于X射线CT技术快速检测不同含水率状态下的毛竹密度[J]. 光谱学与光谱分析, 2016, 36(6): 1899−1903. Wang Q P, Liu X E, Zhang G L, et al. Rapidly detection for moso bamboo density under different moisture condition based on X-CT technology[J]. Spectroscopy and Spectral Analysis, 2016, 36(6): 1899−1903.

[15] 王亚磊, 赵茂程, 王正. 木材动态弹性模量测量中节子对于应力波传播的影响[J]. 西北林学院学报, 2014, 29(3): 183−187. doi: 10.3969/j.issn.1001-7461.2014.03.37 Wang Y L, Zhao M C, Wang Z. Influence of wood knots on the stress wave propagation in the dynamic measurement of elastic modulus[J]. Journal of Northwest Forestry University, 2014, 29(3): 183−187. doi: 10.3969/j.issn.1001-7461.2014.03.37

-

期刊类型引用(3)

1. 李辉,林沂,孟祥爽,史振伟,蔡万园. 基于地基激光雷达的栾树分形特征分析. 山东农业大学学报(自然科学版). 2022(03): 475-483 .  百度学术

百度学术

2. 何东健,熊虹婷,芦忠忠,刘建敏. 基于多视角立体视觉的拔节期玉米水分胁迫预测模型. 农业机械学报. 2020(06): 248-257 .  百度学术

百度学术

3. 郭彩玲,刘刚. 基于颜色取样的苹果树枝干点云数据提取方法. 农业机械学报. 2019(10): 189-196 .  百度学术

百度学术

其他类型引用(7)

下载:

下载: