Influence of micro-grit size of precision-shaped abrasive belt on particleboard sanding

-

摘要:目的

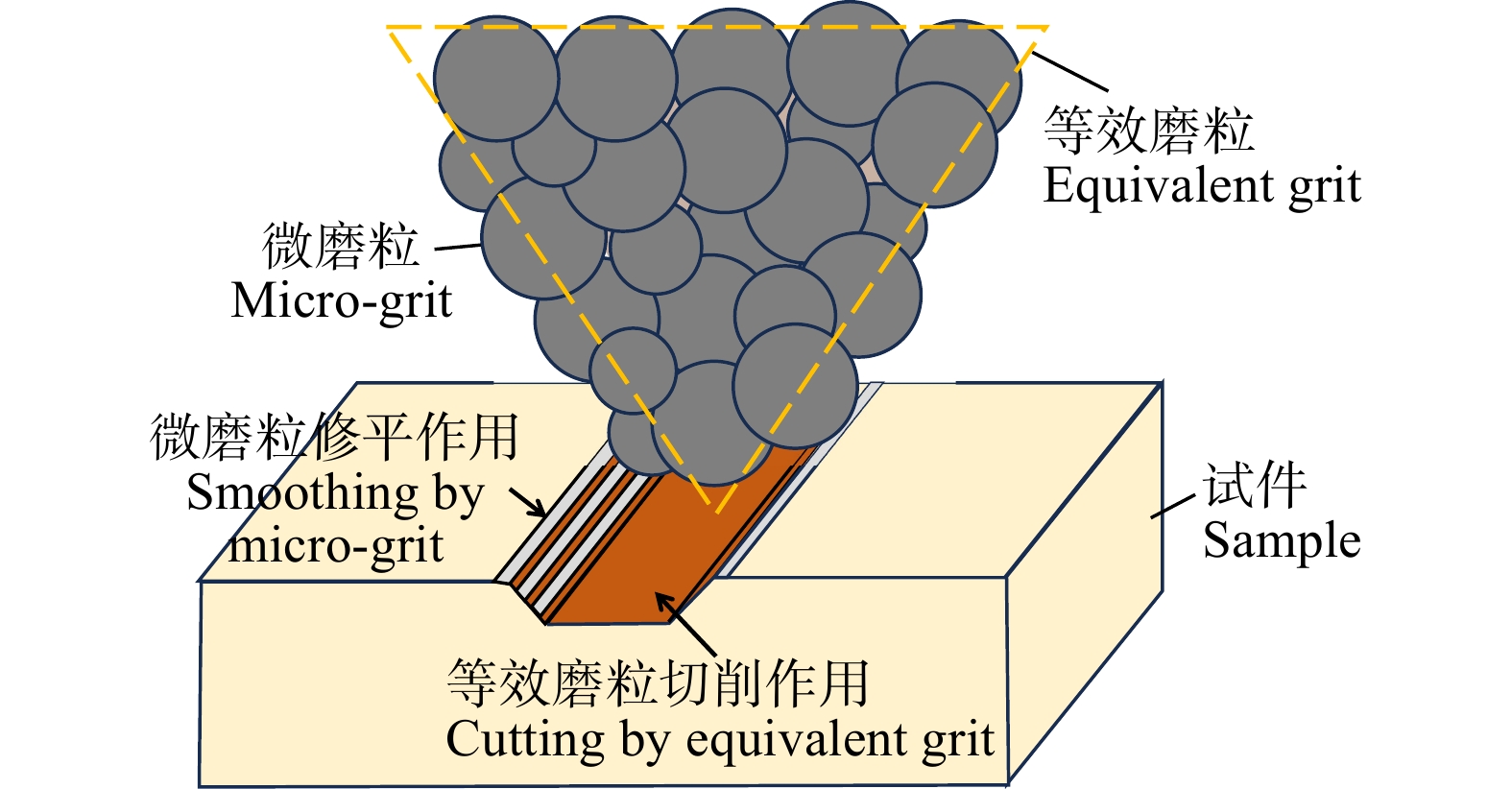

为探究新型定组态砂带的微磨粒粒度对木质材料磨削性能的影响,为定组态砂带的设计和制备提供依据,开展了定组态砂带磨削试验。

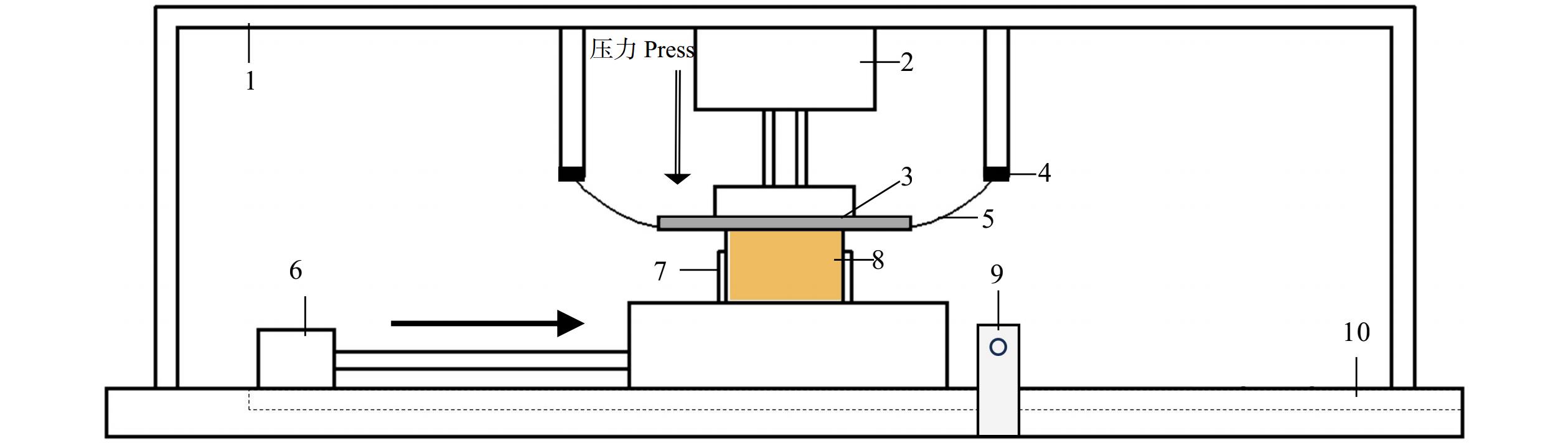

方法本研究制备150目、180目、220目3种不同粒度的定组态砂带(P-150/180/220),与220目的非定组态砂带(O-220)对照,以刨花板为磨削对象,分别开展20万次磨削试验。对比不同微磨粒粒度的定组态砂带在磨削过程中材料去除量、刨花板表面粗糙度、砂带质量的变化,以分析定组态砂带粒度对磨削性能和砂带磨损的影响。

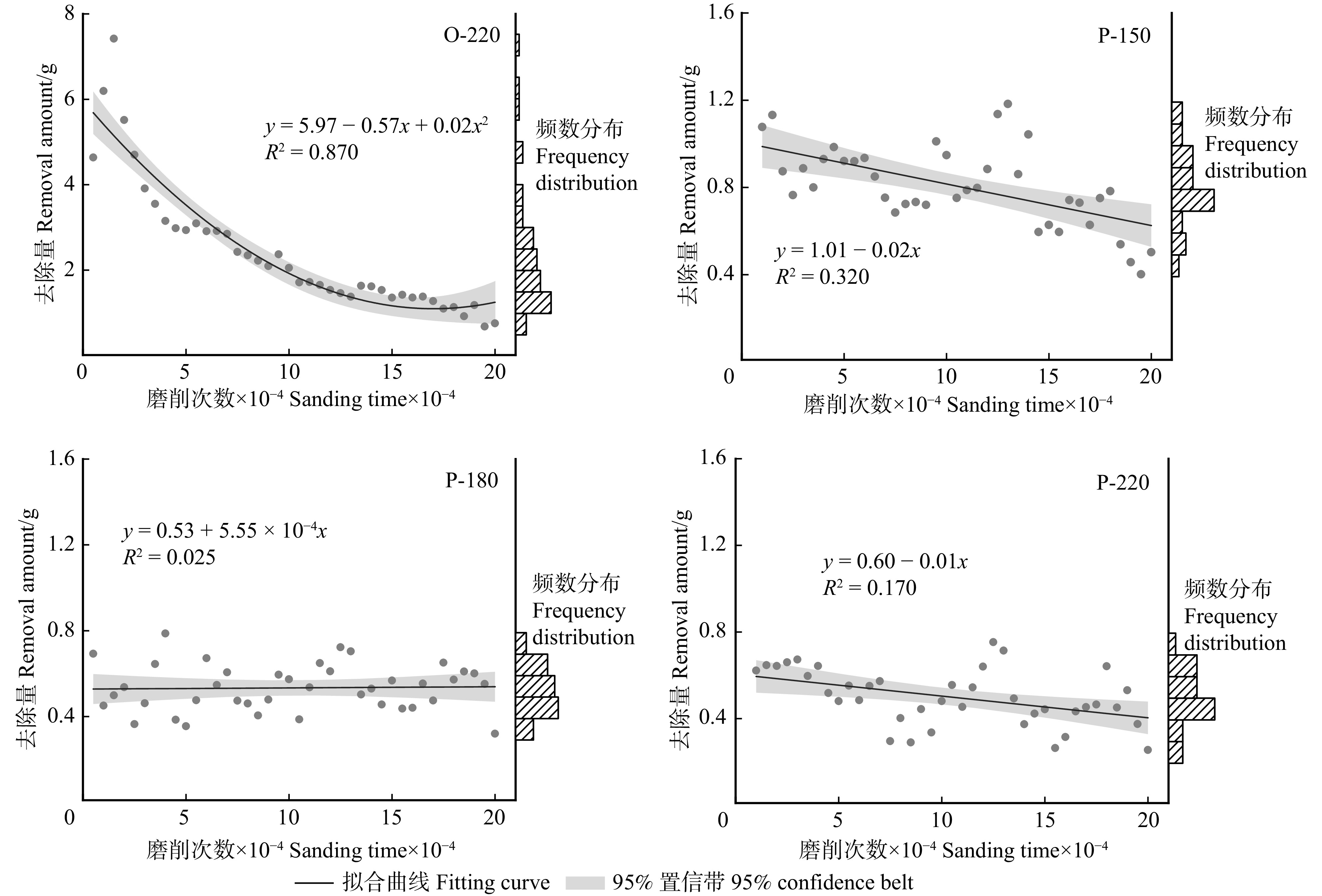

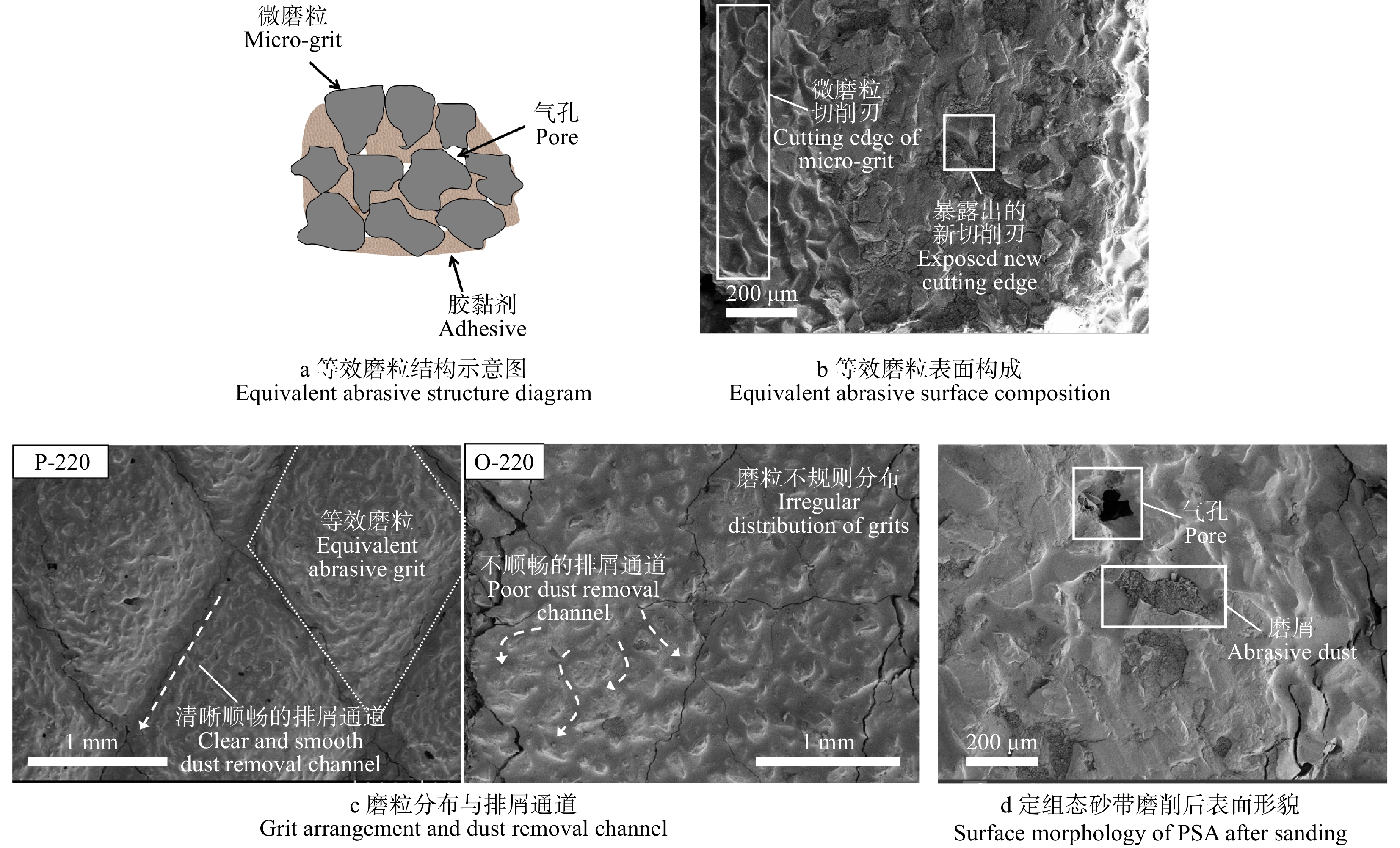

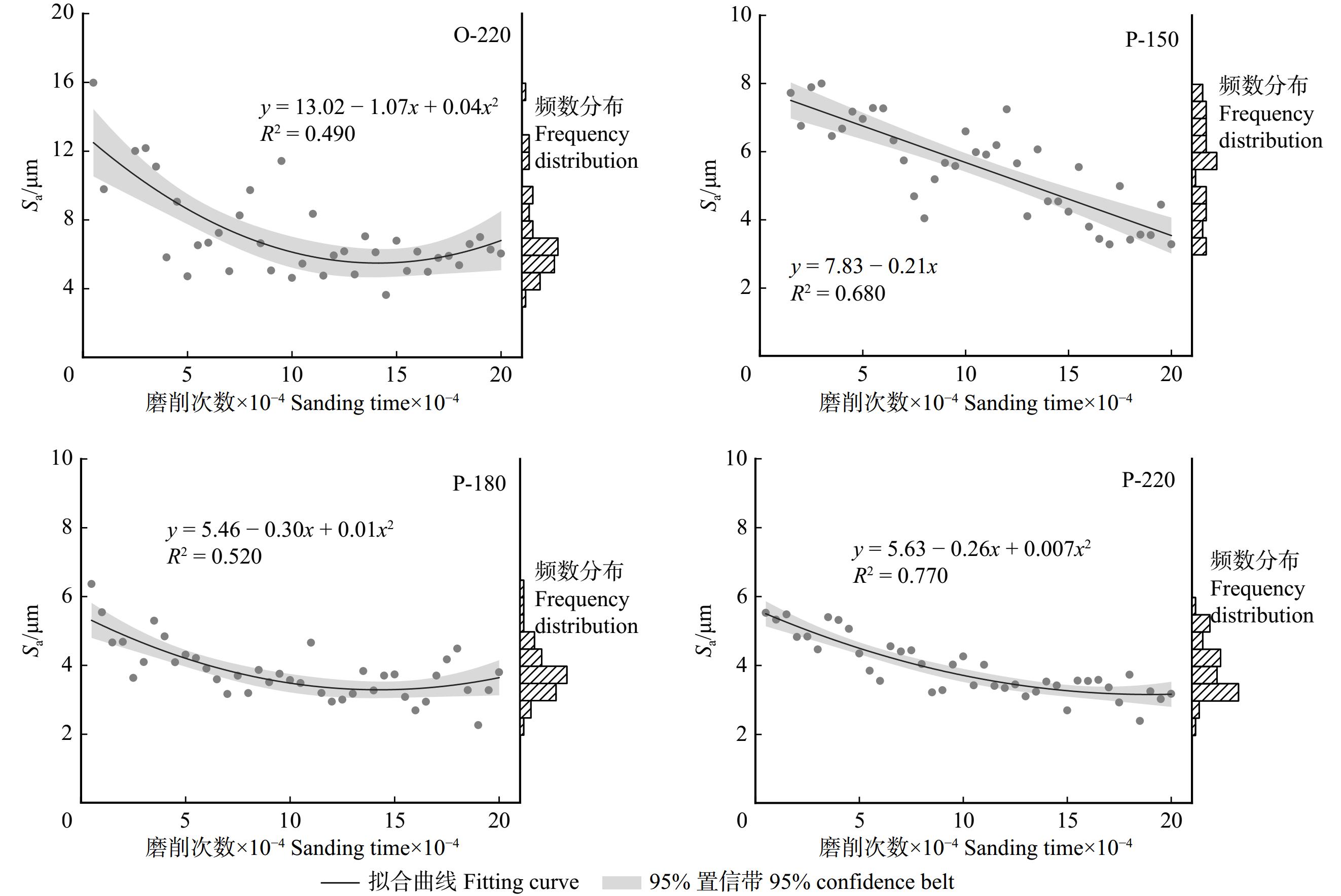

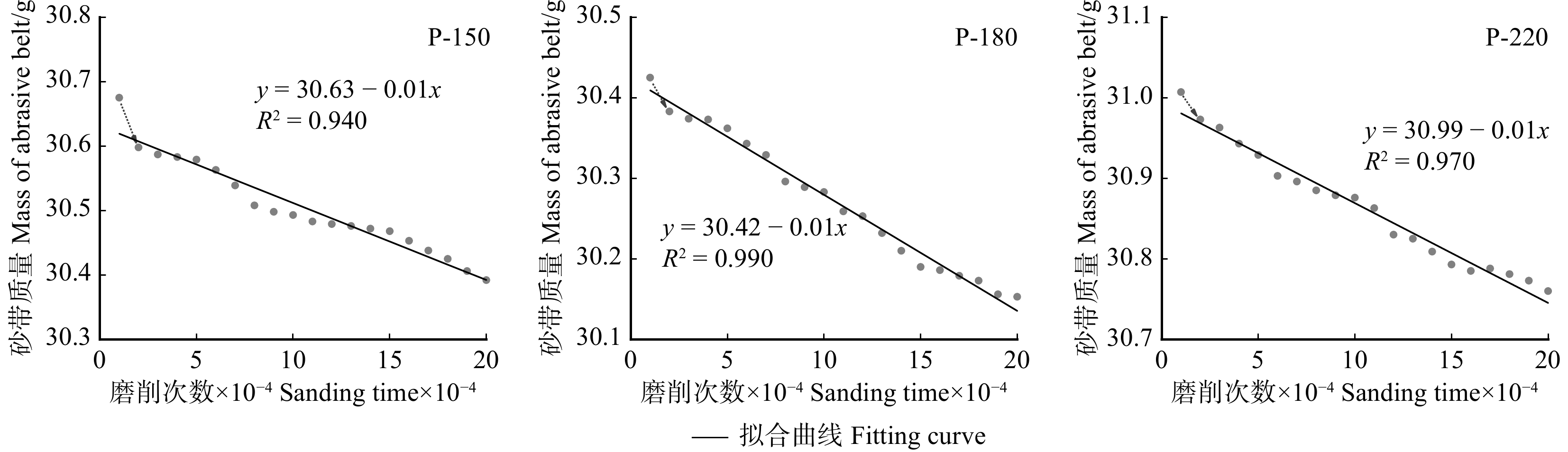

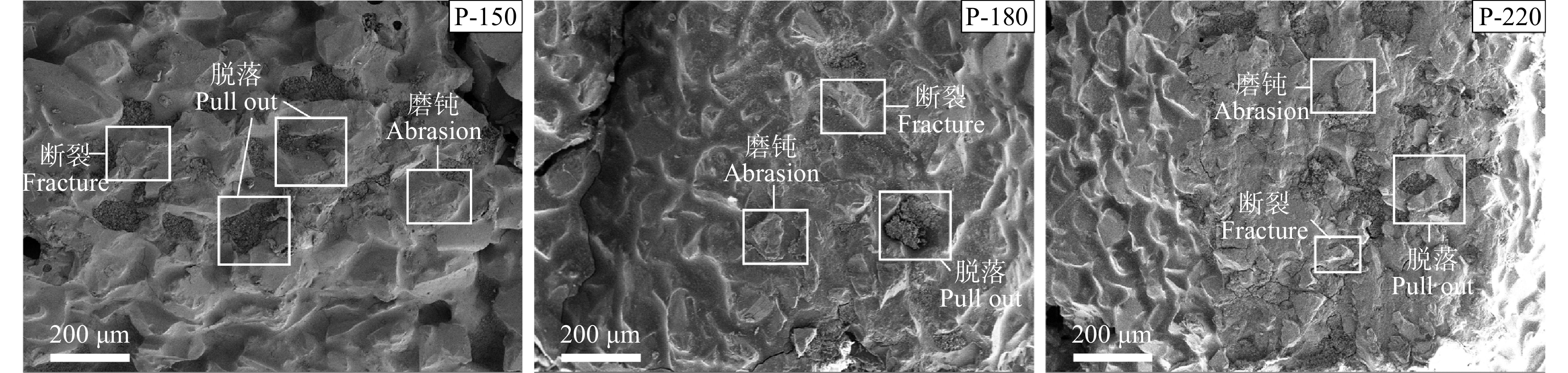

结果(1)定组态砂带的刨花板去除量小于非定组态砂带,但稳定性远优于非定组态砂带;定组态砂带去除量的平均值与微磨粒粒度负相关,而随着磨粒粒度增大,定组态砂带去除量更加稳定。(2)定组态砂带磨削刨花板的表面粗糙度呈先下降后稳定,小范围上下波动的变化趋势;随着磨粒粒度的增大,刨花板表面粗糙度减小且更加稳定。(3)定组态砂带质量在磨削过程呈波浪形周期性下降;P-150砂带质量损失最快,P-180砂带质量下降最稳定;定组态砂带等效磨粒与表面微磨粒间存在补偿作用和协同作用。

结论在等效磨粒形状和尺寸相同的情况下,微磨粒粒度对定组态砂带磨削性能有显著影响,但这种差异在粒度小的微磨粒中表现更加明显。本研究为定组态砂带的设计和生产提供了科学依据和理论支撑,促进了木材加工技术和砂带制造技术向高效智能化方向发展。

Abstract:ObjectiveTo investigate the effects of micro-grit sizes on the sanding performance of wood materials and to provide a basis for the design and preparation of precision-shaped abrasive belts (PSAs), sanding experiments with PSAs were carried out.

MethodIn this study, abrasive belts with grit sizes of 150, 180, and 220 meshs (P-150/180/220) were prepared and compared with ordinary coated abrasive belt (OCA) with a grit size of 220 (O-220). 200 000 sanding tests were conducted respectively using particleboards as sanding samples. The material removal amount, surface roughness of particleboards, and mass changes of abrasive belts were compared to analyze the effect of micro-grit sizes of abrasive belt on sanding performance and wear process.

Result(1) The removal amount of particleboard with PSA was less than that with OCA, but the stability of PSA was much better than that of OCA. There was a negative correlation between the average removal amount of particleboard sanded by PSA and the size of micro-grit. The removal amount of PSA became more stable with the increase of grit size. (2) The surface roughness of particleboard sanded by PSA decreased initially, stabilized and fluctuated within a small range. With the increase of grit size, the surface roughness of particleboard decreased and became more convergent. (3) In the sanding process, the mass of PSA showed a periodic wavy decline. The mass loss of P-150 was the fastest, and the mass decline of P-180 was the most stable. There were compensatory and synergistic effects between the equivalent abrasive particle and surface micro-grit.

ConclusionUnder the condition where the shape and size of equivalent abrasive grits are the same, the micro-grit size significantly affects the sanding performance of PSA, particularly in PSA with smaller micro-grit size. This study provides a scientific basis and theoretical support for the design and production of PSAs, promoting the development of wood processing technology and abrasive belt manufacturing technology toward high efficiency and intelligence.

-

Keywords:

- particle board /

- surface roughness /

- abrasive belt /

- sanding /

- grit size /

- precision-shaped abrasive belt

-

-

图 3 不同粒度砂带磨削刨花板的去除量分布

O-220代表220目非定组态砂带,P-150、P-180、P-220代表微磨粒粒度分别为150目、180目、220目的定组态砂带。下同。O-220 represents an ordinary coated abrasive belt with micro-grit size of 220. P-150, P-180, and P-220 represent precision-shaped abrasive belt with micro-grit size of 150, 180, and 220, respectively. The same below.

Figure 3. Removal amount distribution of particle board sanded with abrasive belts of different grit sizes

表 1 不同粒度砂带磨削刨花板去除量的数据统计

Table 1 Data statistics of the removal amount sanded with abrasive belts of different grit sizes

砂带类型

Abrasive belt type最大值

Max. value/g最小值

Min. value/g均值

Mean/gSD 极差

Range/gO-220 7.420 0.678 2.426 1.520 6.742 P-150 1.183 0.402 0.806 0.186 0.781 P-180 0.787 0.320 0.524 0.109 0.467 P-220 0.753 0.255 0.496 0.129 0.498 表 2 不同粒度砂带磨削刨花板表面粗糙度

Table 2 Sa of particle board sanded with abrasive belts of different grit sizes

砂带类型

Abrasive

belt type最大值

Max.

value/μm最小值

Min.

value/μm均值

Mean/

μm

SD极差

Range/

μmO-220 15.977 3.637 7.107 2.617 12.340 P-150 7.999 3.281 5.521 1.439 4.718 P-180 6.365 2.264 3.818 0.806 4.101 P-220 5.528 2.389 3.911 0.827 3.139 表 3 不同目数定组态砂带磨削过程的质量统计数据

Table 3 Statistical data of mass of PSAs with different grit sizes

砂带类型

Abrasive belt type初始质量

Initial mass/g结束质量

Final mass/g质量损失

Mass loss/gP-150 30.675 30.392 0.283 P-180 30.425 30.153 0.272 P-220 31.007 30.760 0.247 -

[1] 张健. 木质材料磨削表面创成机理研究[D]. 北京: 北京林业大学, 2022. Zhang J. Research on surface creation mechanism in sanding wood materials[D]. Beijing: Beijing Forestry University, 2022.

[2] 王维朗, 潘复生, 陈延君, 等. 砂带磨削技术及材料的研究现状和发展前景[J]. 材料导报, 2006, 20(2): 106−108. Wang W L, Pan F S, Chen Y J, et al. Present research status and development prospect of abrasive belt grinding technique[J]. Materials Reports, 2006, 20(2): 106−108.

[3] 杨雅琦, 汪生莹, 耿金光, 等. 水曲柳磨削的砂带磨损机理研究[J]. 北京林业大学学报, 2019, 41(8): 138−146. Yang Y Q, Wang S Y, Geng J G, et al. Abrasive belt wear mechanism of sanding Manchurian ash[J]. Journal of Beijing Forestry University, 2019, 41(8): 138−146.

[4] Luo B, Li L, Liu H, et al. Effects of sanding parameters on sanding force and normal force in sanding wood-based panels[J]. Holzforschung, 2015, 69(2): 241−245. doi: 10.1515/hf-2014-0012

[5] 李晓旭, 陈永光, 李黎. 木质材料砂带磨削的若干问题[J]. 木材加工机械, 2010, 21(3): 44−48. Li X X, Chen Y G, Li L. Abrasive belt sanding technology of wood-based panel[J]. Wood Processing Machinery, 2010, 21(3): 44−48.

[6] Luo B, Zhang J, Bao X, et al. The effect of granularity on surface roughness and contact angle in wood sanding process[J]. Measurement, 2020, 165: 108133. doi: 10.1016/j.measurement.2020.108133

[7] Nemli G, Akbulut T, Zekovic E. Effects of some sanding factors on the surface roughness of particleboard[J]. Silva Fennica, 2007, 41(2): 373−378.

[8] Vitosyte J, Ukvalbergiene K, Keturakis G. Roughness of sanded wood surface: an impact of wood species, grain direction and grit size of abrasive material[J]. Materials Science-Medziagotyra, 2015, 21(2): 255−259.

[9] Wu X, Niu H, Li X J, et al. Research on GA-BP neural network model of surface roughness in air drum sanding process for poplar[J]. European Journal of Wood and Wood Products, 2022, 80(2): 477−487. doi: 10.1007/s00107-021-01686-2

[10] Gurau L. Testing the processing-induced roughness of sanded wood surfaces separated from wood anatomical structure[J]. Forests, 2022, 13(2): 331. doi: 10.3390/f13020331

[11] Kúdela J, Mrenica L, Javorek. The influence of milling and sanding on wood surface morphology[J]. Acta Facultatis Xylologiae, 2018, 60(1): 71−83.

[12] Laina R, Sanz-Lobera A, Villasante A, et al. Effect of the anatomical structure, wood properties and machining conditions on surface roughness of wood[J]. Maderas-Ciencia Y Tecnologia, 2017, 19(2): 203−212.

[13] Copak A, Jirous-Rajkovic V, Spanic N, et al. The impact of post-manufacture treatments on the surface characteristics important for finishing of OSB and particleboard[J]. Forests, 2021, 12(8): 975. doi: 10.3390/f12080975

[14] Adamcik L, Kminiak R, Schmidtova J. Measurement of the roughness of the sanded surface of beech wood with the profile measurement software of the keyence vhx-7000 microscope[J]. Acta Facultatis Xylologiae Zvolen, 2023, 65(1): 73−85.

[15] Medved S, Krajsek G. The impact of sandpaper grit size on formaldehyde emission from particleboards[J]. Acta Silvae Et Ligni, 2017, 112: 1−6. doi: 10.20315/ASetL.112.1

[16] 罗斌, 张健, 柳浩雨, 等. 木质材料磨削理论及技术研究进展[J]. 木材科学与技术, 2022, 36(4): 6−12. doi: 10.12326/j.2096-9694.2021175 Luo B, Zhang J, Liu H Y, et al. Research status of sanding theory and technology for wood materials[J]. Chinese Journal of Wood Science and Technology, 2022, 36(4): 6−12. doi: 10.12326/j.2096-9694.2021175

[17] Zhang J, Luo B, Li L, et al. Cutting characteristics for sugar maple using single grit with spherical cone and triangular pyramid geometries[J]. Materials, 2019, 12(21): 3621. doi: 10.3390/ma12213621

[18] Du Y, Tian B, Zhang J, et al. Sanding performance and failure progress of precision-shaped abrasive belt during sanding MDF[J]. European Journal of Wood and Wood Products, 2024, 82(2): 461−472. doi: 10.1007/s00107-023-02013-7

[19] ISO/TC 213. Geometrical product specifications (GPS)—surface texture: areal—part 2: terms, definitions and surface texture parameters: ISO 25178-2: 2021 [S]. New York: International Organization for Standardization, 2021.

[20] 杜瑶, 田彪, 张健, 等. 中密度纤维板磨削时的砂带磨损研究及寿命评判[J]. 北京林业大学学报, 2021, 43(10): 126−134. Du Y, Tian B, Zhang J, et al. Research on abrasive belt wear and working life evaluation during sanding medium density fiberboard[J]. Journal of Beijing Forestry University, 2021, 43(10): 126−134.

[21] Zhang J, Yang Y, Luo B, et al. Research on wear characteristics of abrasive belt and the effect on material removal during sanding of medium density fiberboard (MDF)[J]. European Journal of Wood and Wood Products, 2021, 79(6): 1563−1576. doi: 10.1007/s00107-021-01718-x

-

期刊类型引用(1)

1. 徐媛,陈锦玲,陈玉梅,李璐璐,李惠敏,秦新民. 干旱胁迫下花生转录组与miRNA测序及相关基因的表达. 贵州农业科学. 2021(01): 1-9 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: