Mixing chamber design of polyurea spray airbrush and simulation analysis based on FLUENT

-

摘要: 为提高聚脲喷涂喷枪的混合效果,基于撞击流理论设计了一种新型聚脲喷涂喷枪的混合室。混合室采用两级撞击混合,分别采用两组T型和两组Y型对撞混合形式。利用SolidWorks设计混合室的结构模型后,利用FLUENT软件,采用冷、热水在混合室内撞击混合、对流传热的方法进行仿真模拟,并且计算了流体在混合室内的微观混合时间。结果表明:合理增加撞击流混合室的混合级数和采用多组T型、Y型对撞混合形式可增益混合效果;撞击流混合室的主要混合区是在撞击区;流体在喷枪内停留的总时间约为5.71 ms,满足具有反应迅速这一特性的材料的混合要求;微观混合时间小于1 ms,混合效果优异。Abstract: In order to improve the mixing effect of polyurea spray airbrush, a novel mixing chamber of polyurea spray airbrush was designed based on impinging streams principle. The mixing chamber adopted two level impingement mix and respectively used two groups of T types and Y types. After the mixing chamber model was designed by the SolidWorks, we used FLUENT to simulate with the methods of convective heat transfer and the impingement mix of the cold and hot water in the mixing chamber and calculated the micromixing time that the fluid stayed in the mixing chamber. The results showed that under rational conditions, the more multiplicity the mixing stages and impingement modes of T types and Y types are, the better mixing effects the impinging streams mixing chamber will be. The main mixing zone of impinging streams mixing chamber is the impinging area. In the spray airbrush, the total staying time of the fluid is about 5.71 ms, which meet the requirements that some materials have the features of quick mixing. The micromixing time is less than 1 ms, so the mixing effect is very good.

-

Keywords:

- polyurea spray /

- mixing chamber /

- impinging streams /

- micromixing /

- simulation

-

撞击流(Impinging streams, IS)的概念首先由Elperin提出,此后Elperin和Tamir进行了一系列的研究,其特点是可显著增强微观混合,明显强化热、质传递,从而提高混合效果,其传质效果较普通混合方法提高2~3个数量级,由于优异的微观混合性能而得到了较广泛的应用[1-2]。撞击流混合器是通过高速流动的流体瞬间激烈的撞击来实现能量的快速消耗,从而降低流体的离析程度,达到快速混合的目的[3]。因此混合器的结构状态对气—固、气—液、液—液等的热、质传递效率有根本的影响,改进和开发新型混合器具有重要意义。

喷涂聚脲弹性体技术是国外近30年来开发的一种新型无溶剂、无污染的绿色环保施工技术,该技术在许多领域发展迅猛。聚脲材料具有强度高、柔韧性好、耐磨、防水、防腐蚀等优点[4-7]。因聚脲材料具有反应迅速,固化时间短这一特性[8],聚脲材料的A、B组份不能提前混合,必须在喷枪的混合室内发生反应后瞬间喷出,故混合室的设计既要达到优异的混合效果又不能堵枪,这也是聚脲喷涂喷枪混合室结构的设计难点。聚脲喷枪混合室的设计基本都采用撞击流理论,目前,聚脲喷涂喷枪混合室普遍采用一级单一T型结构,该结构极易导致聚脲材料的A、B组份在混合室内得不到充分的撞击混合,化学反应不充分,使得涂层质量不佳,产生“橘皮”现象,形成凹凸不平的涂面。针对此不足,本文基于撞击流理论,设计了一种新型聚脲喷涂喷枪混合室,在不堵枪的前提下增益其混合效果。并利用FLUENT软件对混合室内流体的混合情况进行了仿真分析。这对于进一步扩大聚脲弹性体技术的应用范围具有实际意义,同时为进一步改进和开发新型撞击流混合器提供可靠的理论依据。

1. 混合室结构设计

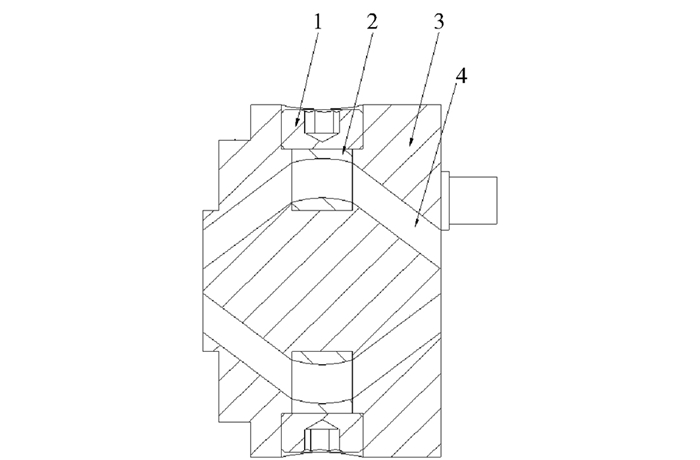

混合室是聚脲材料混合发生化学反应的关键部件,混合室的总体结构如图 1所示,该混合室采用两级撞击混合。第一级混合是由物料入口和第一混合室组成的两组T型对撞混合形式;第二级混合是由物料导流块、物料导流通道、第二混合室和喷头组成的两组Y型对撞混合形式。以下该型混合室简写为2T+2Y。

A、B组份在第一混合室混合的剖视图如图 2所示,喷枪前端垂直于混合室轴线周置4个直径为5 mm的物料入口,形成两组T型结构,A、B组份的4股流体互成90°圆周进入第一混合室内发生撞击混合,为使混合剧烈和化学反应充分,喷枪的第一混合室的空间应尽量紧凑,直径设计为9 mm。

由于混合室必须设计在喷枪内,受到喷枪结构尺寸的限制,故经过一次混合的物料由第一混合室进入第二混合室进行二次撞击混合的结构是混合室结构设计的关键和难点。通过设计物料导流块来连接第一混合室与第二混合室,物料导流块总成的剖视图如图 3所示,它是由物料导流块、4个物料导流通道衔接块和4个螺塞构成。物料导流块内具有4个直径为5 mm的物料导流通道。4个物料导流通道衔接块和物料导流块安装后由螺塞固定、密封,物料导流通道中部形成圆弧结构,此结构的物料导流通道可防止在高压的作用下,物料在导流通道内集聚,造成堵塞、流通不畅,并且可有效减小高压物料对导流通道产生的强烈冲击,从而延长喷枪的使用寿命;同时避免了导流通道内压力损失过大;还综合考虑了制造工艺,使其便于加工制造。

参见图 1和图 3,第二混合室设计在喷头内,采用两组Y型撞击混合形式。为了减少物料在喷枪内的停留时间,并且增加物料斜向撞击混合的强度,第二混合室的尺寸设计应尽可能的小,喷头出口的内径设计为1.5 mm。

2. 混合效果仿真分析

2.1 仿真前处理

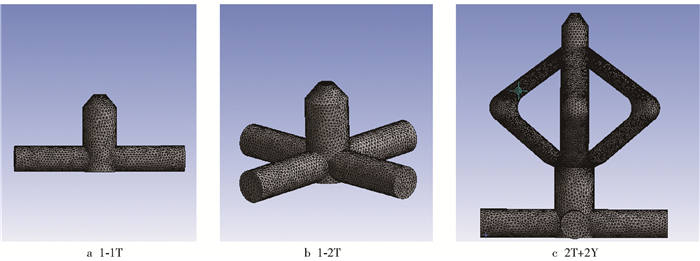

目前,聚脲喷枪混合室一般为一级单一T型结构。为了进行对比分析,本文除了建立了主要设计的2T+2Y型混合室模型,还建立了一级单一T型混合室模型(1-1T)和一级两组T型混合室模型(1-2T),3种模型的网格划分、边界条件等的设定均采用一致性原则。

2.1.1 网格划分

利用SolidWorks软件按1:1比例建立混合室的三维模型,导入ANSYS的前处理软件ICEM对其进行网格划分。此步骤是整个仿真中最重要的步骤,此阶段得到的有限元网格将对仿真分析的准确性和经济性起到决定作用。高质量的网格会明显地提高仿真结果的计算精度和收敛速度。

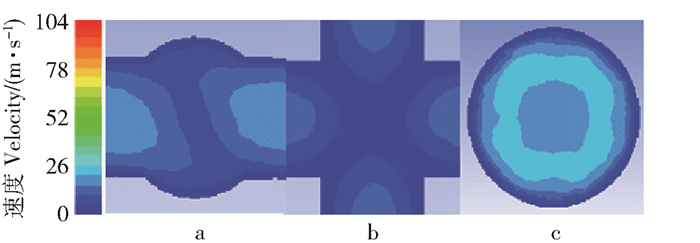

因模型结构较为复杂,故选用非结构化网格。非结构化网格是没有规则拓扑关系的网格,对几何模型有较强的适应性,可对复杂区域进行划分。非结构化网格的划分采用差分方法的网格生成技术,网格类型选择Tetra/Mixed,最后利用Smooth方法自下而上(Bottom-up)地生成高质量的四面体网格。1-1T模型、1-2T模型和2T+2Y模型的网格划分分别如图 4a、b和c所示。

2.1.2 湍流模型选择

湍流模型的合理性选择在仿真中起到极其重要的作用,直接影响仿真结果的精度和真实性。国内外学者分别采用多种形式的湍流模型仿真模拟撞击流流场。其中,李友凤等[9]在对撞击流混合器微观混合性能的研究中采用标准k-ε湍流模型进行仿真模拟;刘海峰等[10]则是采用RNG k-ε湍流模型分析较大尺度的撞击流流场;而Sonia等[11]是用标准k-ε湍流模型和雷诺应力湍流模型(RSM模型)对撞击流流场进行仿真模拟;邹春等[12]采用标准k-ε湍流模型、RNG k-ε湍流模型和雷诺应力湍流模型共同对撞击流流场进行仿真模拟比较,得出在撞击流仿真结果的精度和准确性等方面,RNG k-ε湍流模型要优于标准k-ε湍流模型和雷诺应力湍流模型。RNG k-ε湍流模型通过修正湍流黏性系数,考虑了平均流动中的旋转及旋流流动情况,能更好地处理高应变率及流线弯曲程度较大的流动,可仿真模拟更广范围的湍流流动,更加准确可靠。本研究中混合室三维模型结构应变率高、流线弯曲程度大,故选用RNG k-ε湍流模型,其中湍流动能k(m2/s2)和耗散率ε(W/kg)的运输方程[13]如下:

∂∂t(ρk)+∂∂xi(ρkui)=∂∂xi(αkμeff∂k∂xj)+Gk−ρε (1) ∂∂t(ρε)+∂∂xi(ρεui)=∂∂xj(αεμeff∂ε∂xj)+[C1ε-η(1-η/η0)1+βη3]εkGk-C2εε2k (2) μeff=μ+ρCμk2ε (3) η=k√2ε|∂ui∂xj+∂uj∂xi| (4) 式中:μ为有效湍流黏性系数,单位为kg/(m·s);ui、uj为湍流黏性系数,单位为kg/(m·s),i、j为坐标分量;μeff表示修正湍流黏性系数,考虑了平均流动中的旋转及旋流流动情况,单位为kg/(m·s);η表示湍流与平均流时间尺度的比例,单位为%;ρ为流体密度,单位为kg/m3;Gk为速度梯度导致的湍流动能产生的相,单位为m2/s2;t为时间,单位为s;xi、xj为x轴方向距离,单位为m;Cμ,αk、αε、C1ε、C2ε、η0和β为湍流模型系数,数值均通过空气、水的湍流试验得到的,分别取值0.084、1.139、1.139、1.42、1.68、4.337和0.012。

2.1.3 边界条件设定

入口边界类型定义为PRESSURE-INLET。1-1T模型中,95 ℃流体和5 ℃流体分别通过两个物料入口相对进入,Inlet 1为95 ℃流体的入口,Inlet 2为5 ℃流体的入口;1-2T和2T+2Y模型中,95和5 ℃流体分别通过4个物料入口交叉进入,Inlet 1为95 ℃流体的两个入口,Inlet 2为5 ℃流体的两个入口。出口边界定义为PRESSURE-OUTFLOW,其他面默认为固壁无滑移边界条件,采用标准壁面函数法处理,壁面材料设为钢(Steel),壁面和空气换热系数(Heat transfer coefficient)设为30 W/(m2·K),空气温度(Free stream temperature)设为30 ℃,并启动能量方程。

A、B组份混合体积比为1:1时,得到的化学反应效果最好[14];高压空气辅助雾化喷涂的压力一般为4~6 mPa[15],压力较高的流体在混合室内的湍流强度更剧烈,混合更均匀,故入口压力均选定为6 mPa。两流体黏度均设置在100 mPa·s[16]。仿真模拟中的相关参数和边界条件如表 1所示。

表 1 相关参数和边界条件Table 1. Relevant parameters and boundary conditions流体材料

Fluid material导热系数

Thermal conductivity/(W·m-1·K-1)比热

Specific heat/(J·kg-1·K-1)密度

Density/(kg·m-3)入口1

Inlet 1入口2

Inlet 2出口

Outlet水

Water0.06 4 182 998.2 6 mPa 95 ℃ 6 mPa5 ℃ 一个大气压

One atmospheric pressure2.2 求解与仿真结果分析

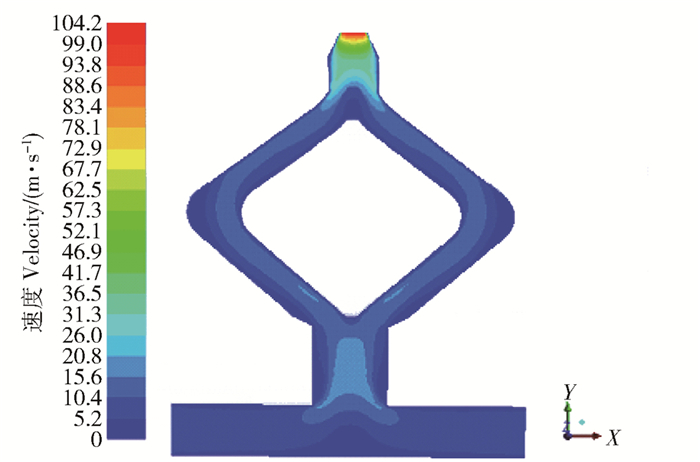

将网格数据导入FLUENT14.5求解器,通过冷、热水在混合室内撞击混合、对流传热的方法,利用有限元后处理模块(Post prep)计算混合室内流体的速度、温度和压力等分布规律,从而研究流体在混合室内的混合效果[17]。在计算区域内,将整个流场分为5个区域:入口区、撞击区、漩涡区、导流区和出口区,其中撞击区包括第一撞击区和第二撞击区,流体的流动状态相对于撞击面对称。

2.2.1 速度仿真结果分析

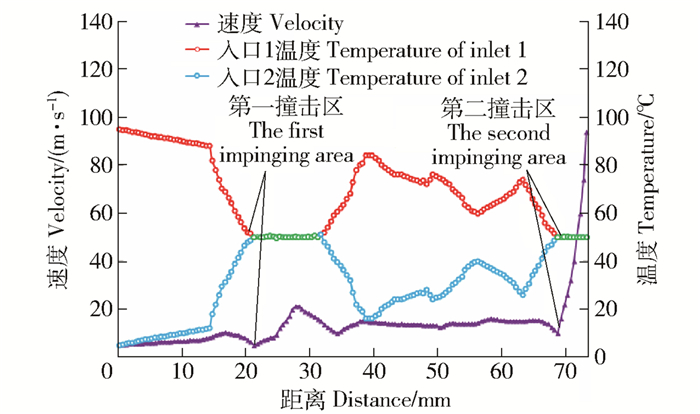

由图 5中流体在2T+2Y模型的纵截面速度分布情况和图 6中流体在2T+2Y模型中的速度沿管道中心轴的沿程变化曲线(读取左纵坐标)表明:在入口区,4股流体从入口向撞击区流动,轴向速度逐渐减小并转化为径向速度;在第一撞击区,径向速度均逐渐减小接近于零;在漩涡区,流体以撞击面为界,分别在撞击面两边形成漩涡,在靠近撞击面处的流体向出口方向流动并形成层流,远离撞击面处的流体向入口方向流动并进一步增大漩涡,从而增加混合效果;在导流区,径向速度一部分转化为轴向速度,流体进入物料导流通道时,由于流体的重新分配,造成流体的挤压、碰撞加剧,流体的速度波动较大且呈降低趋势并形成湍流,进一步增加混合效果;在第二撞击区,流体发生四轴斜向撞击,流体的轴向速度逐渐转化为径向速度,速度波动较大,存在明显的速度衰减,形成第二个漩涡区;在出口区,流体的径向速度逐渐趋于零,而轴向速度逐渐增大并趋于均匀。

图 7a、b和c分别显示了流体在1-1T模型的撞击区、2T+2Y模型的第一、第二撞击区的速度分布情况。对比发现:流体在2T+2Y模型的第一撞击区中心处的速度降低幅度明显比流体在1-1T模型的撞击区中心处的速度降低幅度大,说明流体在2T+2Y模型的第一撞击区的撞击混合更加剧烈;流体在第二撞击区的速度波动也十分明显,再次提高了混合效果。

2.2.2 温度仿真结果分析

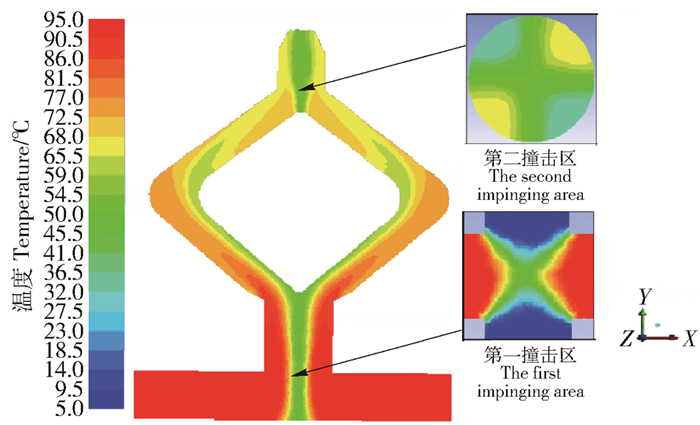

由图 8中流体在2T+2Y模型纵截面和撞击区温度分布情况和图 6中流体在2T+2Y模型中的温度沿管道中心轴的沿程变化曲线(读取右纵坐标)表明:在入口区,两股高温流体和两股低温流体交叉进入;在第一撞击区,4股流体发生剧烈的混合,在撞击区中心处的流体通过混合传热,温度迅速趋于50 ℃,但在撞击区边缘处存在高温流体和低温流体;在漩流区,流体以撞击面为界,分别在撞击面两边形成漩涡,进一步促进混合,在靠近撞击面处的流体向出口方向流动并形成层流,经过撞击区混合后的流体几乎相互不干涉;在导流区,沿壁面分流出高温、低温流体,流体由层流流动转变为湍流流动,流体的温度进一步趋于一致;在第二撞击区,流体再次发生剧烈的撞击混合,在撞击中心处,流体的温度迅速趋于一致达到50 ℃,几乎没有温度波动;在出口区,混合均匀的流体迅速喷出。

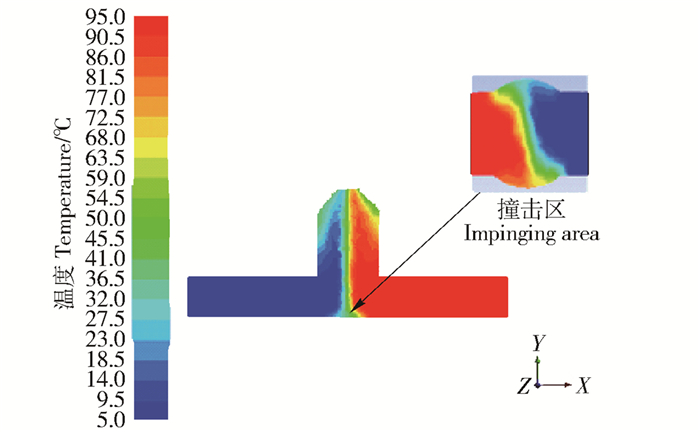

对比图 8中流体在2T+2Y模型纵截面和撞击区的温度分布情况和图 9中流体在1-1T模型纵截面和撞击区的温度分布情况均可直观的看出:温差90 ℃的流体在2T+2Y模型第二撞击区的混合效果完全优于流体在2T+2Y模型第一撞击区的混合效果,同时流体在2T+2Y模型第一撞击区的混合效果明显优于流体在1-1T模型撞击区的混合效果。

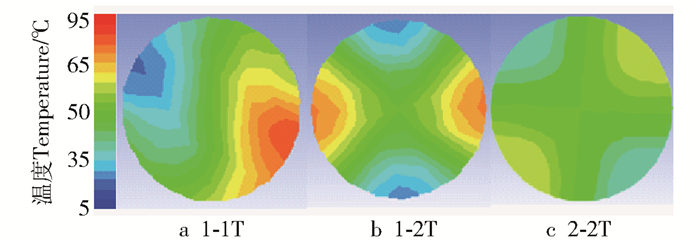

图 10a、b和c分别显示了流体在1-1T、1-2T及2T+2Y模型出口的温度分布情况,经过计算分析发现:流体在1-1T模型出口的温度区间跨越8个梯度,温差高达66 ℃,45~55 ℃流体的流量仅占整个出口流量的28%;流体在1-2T模型出口的温度区间跨越7个梯度,温差为54 ℃,45~55℃流体的流量占整个出口流量的36%;而流体经过2T+2Y模型出口的温度区间仅跨越3个梯度,温差仅为28 ℃,且45~55 ℃流体的流量占到整个出口流量的69%,进而说明改进后的混合室结构对于提高流体的混合效果具有质的飞越。

2.2.3 压力仿真结果分析

由图 11中流体在2T+2Y模型纵截面压力分布可知:流体在第一撞击区和第二撞击区存在剧烈的压力波动,湍流强度剧烈,流体发生剧烈的撞击混合。流体在物料导流通道内的压力分布均匀,均在5.58~5.92 mPa之间,没有较大的压力损失,并且此结构增加了流体的撞击混合强度,故此混合室的结构合理。

2.2.4 湍流强度仿真结果分析

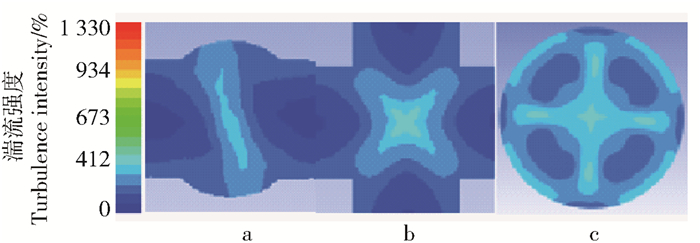

图 12a、b和c分别显示了流体在1-1T模型的撞击区、2T+2Y模型的第一撞击区和第二撞击区的湍流强度分布情况。在撞击区内,湍流强度关于撞击中心线近似对称。撞击中心处是湍流强度最大的区域,也是湍流动能最小的区域。对比图像可得:流体在2T+2Y模型第一、第二撞击区中心处的湍流强度约为流体在1-1T模型撞击区中心处的1.3倍,湍流强度较大区域所占的面积依次增大。撞击区中心处同时也是湍流脉动速度最大的区域,撞击区的脉动特性可促进流体间的混合,强化传递过程。

综上所述,增加多组T型、Y型撞击混合结构及增加多级撞击混合结构可有效提高混合效果。同时可以看出撞击流混合室的混合区域主要集中在撞击区,这与前人的研究结果一致[18-19]。

由仿真模拟计算得到流体的体积流量约为6.65×10-4 m3/s,撞击流混合室体积经SolidWorks计算约为3.77×10-8 m3,由此可得流体在混合室内停留的总时间约为5.71 ms,完全满足聚脲等具有反应迅速,固化时间短这一特性的材料的混合要求。

2.3 微观混合时间的估算

微观混合即指分子尺度上的混合。在空间狭小的混合室内,流体分子之间剧烈的相互撞击、相互渗透。微观混合是促使流体充分混合的决定性因素,不但影响化学反应的转化率和选择性,而且也影响产物的质量。流体在混合室内撞击产生剧烈的微观混合的时间一般不足1 ms,故混合室的结构对于促进流体的微观混合尤为重要。

微观混合时间t越小,意味着到达最大混合均匀状态所需时间越短, 微观混合效果越好。微观混合时间t(s)的数学表达式[20]为:

t=k1(v/ε)1/2 (5) 式中:k1为常数;ν为运动黏度(水的相应值为10-6 m2/s)。

单位质量能量耗散速率(ε, W/kg)与撞击区流体初速度(u, m/s)有如下关系:

ε∝u3 (6) 由此得到:

t=k2u−3/2 (7) 式中:k2为常数,其大小由反应器的类型与特性决定,对于撞击流反应器,k2约为10-2数量级[21]。

由仿真计算结果得出流体在2T+2Y模型的第一混合室和第二混合室内的撞击初始速度u1和u2分别约为5和10 m/s,则流体在第一混合室和第二混合室内的微观混合时间t1和t2分别约为0.89和0.32 ms,可见微观混合时间小于1 ms,并且t2<t1,第二混合室的混合效果优于第一混合室。

3. 结论

1) 经过两级撞击后的流体混合效果完全优于一级混合,合理增加撞击流混合室的混合级数可有效地优化混合效果,并且采用多组T型、Y型对撞混合形式可增益混合效果,这给撞击流混合器的设计提供了理论依据。

2) 撞击流混合室的混合区域主要集中在撞击区,其他区域对混合效果贡献不大,这与前人的研究结果一致。

3) 流体在喷枪内停留的总时间约为5.71 ms,可满足聚脲等具有反应迅速、固化时间短这一特性的材料的混合要求。

4) 流体在物料导流通道内的压力分布均匀,均在5.58~5.92 mPa之间,没有较大的压力损失,并且此结构增加了流体的撞击混合强度,故此混合室结构合理。

5) 第一混合室和第二混合室内的微观混合时间分别约为0.89和0.32 ms,此混合室具有优异的混合效果。

-

表 1 相关参数和边界条件

Table 1 Relevant parameters and boundary conditions

流体材料

Fluid material导热系数

Thermal conductivity/(W·m-1·K-1)比热

Specific heat/(J·kg-1·K-1)密度

Density/(kg·m-3)入口1

Inlet 1入口2

Inlet 2出口

Outlet水

Water0.06 4 182 998.2 6 mPa 95 ℃ 6 mPa5 ℃ 一个大气压

One atmospheric pressure -

[1] 伍沅.撞击流——原理·性质·应用[M].北京:化学工业出版社, 2006: 3-12. WU Y. Impinging streams: principle, nature, applications[M]. Beijing: Chemical Industry Press, 2006: 3-12.

[2] ELPERIN I T. Heat and mass transfer in opposing currents[J]. Energy Physics, 1961, 56(6): 62-68. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b34257247972d14b82b30c56ef64267f

[3] 骆培成, 程易, 汪展文, 等.液—液快速混合设备研究进展[J].化工进展, 2005, 24(12): 1319-1326. doi: 10.3321/j.issn:1000-6613.2005.12.001 LUO P C, CHENG Y, WANG Z W, et al. Research progress of liquid-liquid fast mixing equipment[J]. Chemical Industry and Engineering Progress, 2005, 24 (12): 1319-1326. doi: 10.3321/j.issn:1000-6613.2005.12.001

[4] PRIMEAUX D J. Polyurea spray technology in commercial applications[C]//60 Years of Polyurethanes: International Symposium and Exhibition. Michigan: University of Detroit, 1998: 224-238.

[5] 黄微波, 王宝柱, 陈酒姜, 等.喷涂聚脲弹性体技术的发展[J].中国涂料, 2001, 5(11): 31-37. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zhonggtl200105011 HUANG W B, WANG B Z, CHEN J J, et al. The development of spray polyurea elastomer technology[J]. Coatings of China, 2001, 5(11): 31-37. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zhonggtl200105011

[6] PRIMEAUX D J. A study of polyurea spray elastomer system[J]. High Solid Coatings, 1994, 15: 2-7.

[7] 商汉章, 李运德, 沙金.喷涂聚脲弹性体技术的现状和应用[J].中国涂料, 2008, 23(9): 54-57. doi: 10.3969/j.issn.1006-2556.2008.09.017 SANG H Z, LI Y D, SHA J. Status and use of spraying polyurea elastomer technology[J]. Coatings of China, 2008, 23(9): 54-57. doi: 10.3969/j.issn.1006-2556.2008.09.017

[8] 黄微波, 吕平.绿色材料—喷涂聚脲的技术原理[J].房材与应用, 2000(2): 22-27. doi: 10.3969/j.issn.1673-7237.2000.02.009 HUANG W B, LV P. Technology principle of spray polyurea material[J]. Housing Materials & Applications, 2000(2): 22-27. doi: 10.3969/j.issn.1673-7237.2000.02.009

[9] 李友凤, 叶红齐, 何显达, 等.撞击流混合器微观混合性能的研究[J].高校化学工程学报, 2012, 26(1): 49-55. doi: 10.3969/j.issn.1003-9015.2012.01.009 LI Y F, YE H Q, HE X D, et al. Study on micromixing characteristics of impinging streams mixers[J]. Journal of Chemical Engineering of Chinese Universities, 2012, 26(1): 49-55. doi: 10.3969/j.issn.1003-9015.2012.01.009

[10] 刘海峰, 刘辉, 龚欣, 等.大喷嘴间距对置撞击流径向速度分布[J].华东理工大学学报, 2000, 26(2): 168-171. doi: 10.3969/j.issn.1006-3080.2000.02.014 LIU H F, LIU H, GONG X, et al. Radial velocity of wide spaced impinging streams[J]. Journal of East China University of Science and Technology, 2000, 26(2): 168-171. doi: 10.3969/j.issn.1006-3080.2000.02.014

[11] SONIA B, HATEM M, GEORGES L P, et al. Numerical and experimental study of two turbulent opposed plane jets[J]. Heat and Mass Transfer, 2003, 39(8-9): 675-686. doi: 10.1007/s00231-002-0336-5

[12] 邹春, 刘朝霞, 张立麒, 等.不同湍流模型比较模拟撞击流[J].华中科技大学学报(自然科学版), 2006, 34(9): 72-76. doi: 10.3321/j.issn:1671-4512.2006.09.023 ZOU C, LIU Z X, ZHANG L Q, et al. Comparison among turbulence models for impinging jet flows[J]. Journal of Huazhong University of Science and Technology (Nature Science Edition), 2006, 34(9): 72-76. doi: 10.3321/j.issn:1671-4512.2006.09.023

[13] 胡仁喜. FLUENT14. 5流场分析从入门到精通[M].北京:机械工业出版社, 2014: 205-210. HU R X. FLUENT14. 5 Flow field analysis from entry to master[M]. Beijing: China Machine Press, 2014: 205-210.

[14] 黄微波, 杨宇润, 王宝柱.喷涂聚脲弹性体技术[J].聚氨酯工业, 1999, 14(4): 7-11. http://www.cqvip.com/main/detail.aspx?id=3847209 HUANG W B, YANG Y R, WANG B Z. Spray polyurea elastomer technology[J]. Polyurethane Industry. 1999, 14(4): 7-11. http://www.cqvip.com/main/detail.aspx?id=3847209

[15] 刘登良.物料工艺[M].北京:化学工业出版社, 2009: 1983-1984. LIU D L. Material process[M]. Beijing: Chemical Industry Press, 2009: 1983-1984.

[16] 黄微波.喷涂聚脲弹性体技术—聚脲化学反应原理[J].上海涂料, 2006, 44(4): 29-33. doi: 10.3969/j.issn.1009-1696.2006.04.008 HUANG W B. Spray polyurea elastomer technology: polyurea chemical reaction principle[J]. Shanghai Coating, 2006, 44(4): 29-33. doi: 10.3969/j.issn.1009-1696.2006.04.008

[17] 李成植, 张建伟, 邱金梁.撞击流混合器的出口位置对其混合性能的影响[J].化工机械, 2009, 36(1): 38-41. doi: 10.3969/j.issn.0254-6094.2009.01.010 LI C Z, ZHANG J W, QIU J L. Influence of the exit positions of impinging stream reactors on the their mixing performance[J]. Chemical Engineering and Machinery, 2009, 36(1): 38-41. doi: 10.3969/j.issn.0254-6094.2009.01.010

[18] 杨海健, 张建文, 苗健瑞.管式填料床反应器内的湍流微观混合研究[J].高校化学工程学报, 2006, 20(3): 390-394. doi: 10.3321/j.issn:1003-9015.2006.03.012 YANG H J, ZHANG J W, MIAO J R. Study on turbulent micromixing in a tubular packed bed reactor[J]. Journal of Chemical Engineering of Chinese Universities, 2006, 20(3): 390-394. doi: 10.3321/j.issn:1003-9015.2006.03.012

[19] 伍沅.撞击流性质及其应用[J].化工进展, 2001, 20(11): 8-13. doi: 10.3321/j.issn:1000-6613.2001.11.003 WU Y. Properties and application of impinging stream[J]. Chemical Industry and Engineering Progress, 2001, 20(11): 8-13. doi: 10.3321/j.issn:1000-6613.2001.11.003

[20] ROUSSEAUX J M, MUHR H, PLASARI E. Mixing and micromixing times in the forced vortex region of unbaffled mixing devices[J]. Canadian Journal of Chemical Engineering, 2001, 79(5): 697-707. doi: 10.1002/cjce.5450790501

[21] 李崇, 李志鹏, 高正明, 等.撞击流反应器微观混合性能的研究[J].北京化工大学学报(自然科学版), 2009, 36(6): 1-4. doi: 10.3969/j.issn.1671-4628.2009.06.001 LI C, LI Z P, GAO Z M, et al. Micromixing characteristics of an opposed-jet reactor[J]. Journal of Beijing University of Chemical Technology (Natural Science Edition), 2009, 36(6): 1-4. doi: 10.3969/j.issn.1671-4628.2009.06.001

-

期刊类型引用(4)

1. 杨维红,刘忠,杨博文,刘晓岚. 一种重要的造纸助剂——湿强剂. 天津造纸. 2022(02): 39-45 .  百度学术

百度学术

2. 宁晓,符庆金,王燕云,姚春丽,梁帅博,袁涛,顿旭继. 聚丙烯酰胺环氧氯丙烷-膨润土的二元体系增加湿强度效果及其机理. 东北林业大学学报. 2020(06): 110-114+119 .  百度学术

百度学术

3. 梁帅博,姚春丽,符庆金,刘倩,袁涛. 纸张二元增强体系的研究进展. 中国造纸学报. 2020(02): 89-95 .  百度学术

百度学术

4. 宁晓,姚春丽,管丽娜. 聚酰胺多胺环氧氯丙烷/荧光海藻酸钠体系对二次纤维增湿强的机理. 造纸科学与技术. 2018(03): 46-51+61 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: