Fabrication and characterization of multilayer transparent wood of different species

-

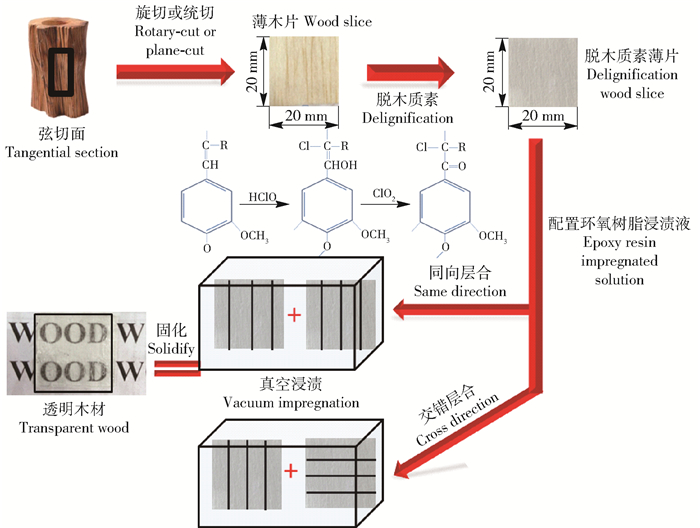

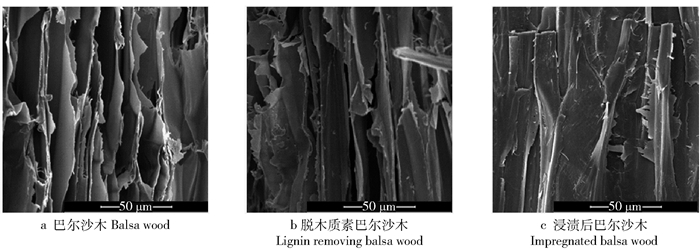

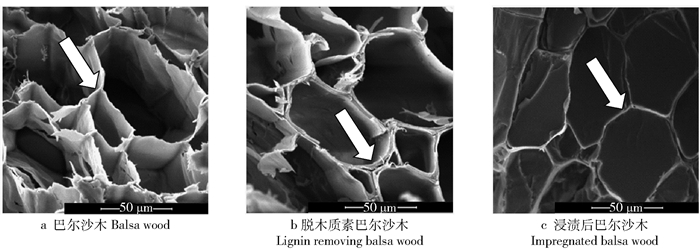

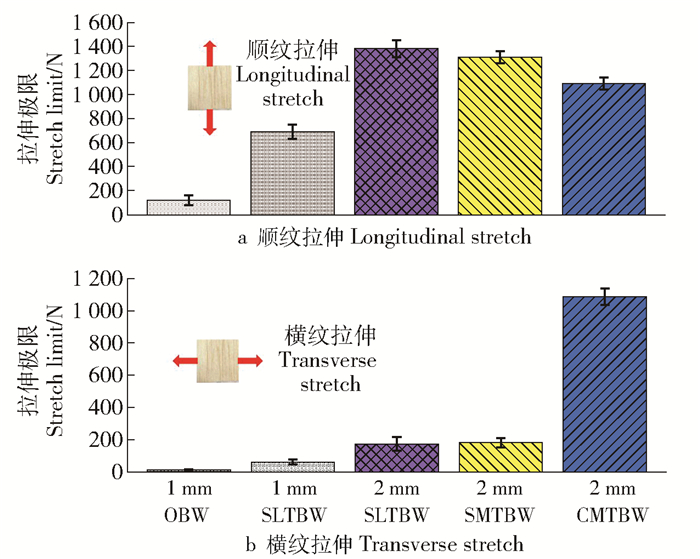

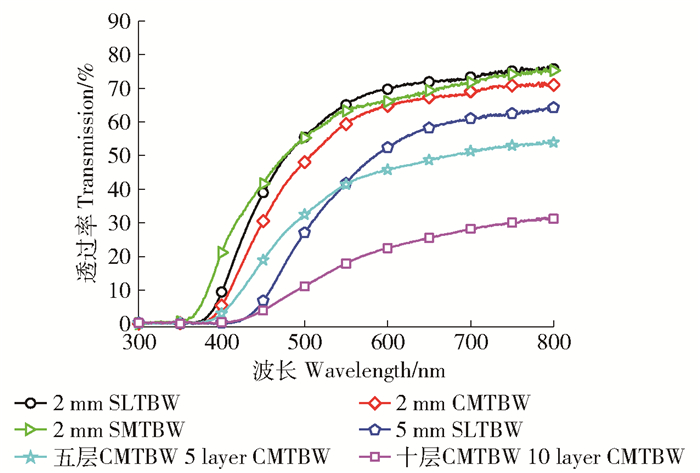

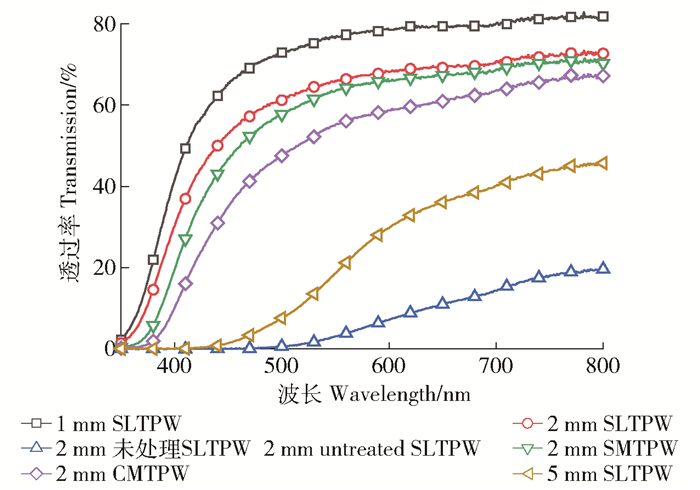

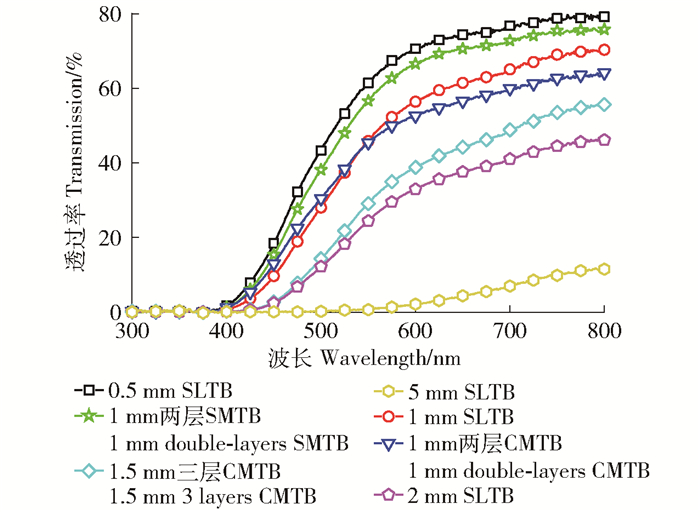

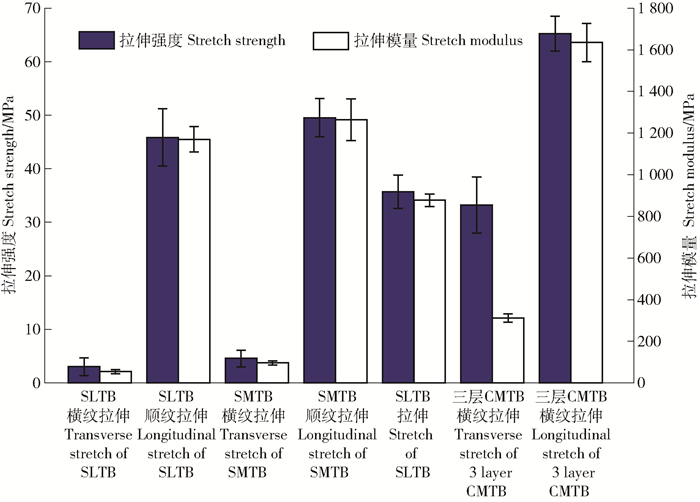

摘要:目的多层透明木材是真空下层压的透明木材。在保持良好透过率的情况下,这种方法将会极大降低透明木材的各向异性。方法本研究选取了3种密度不同但较为常见的树种——0.21 g/cm3的巴尔沙木、0.33 g/cm3的泡桐木和0.49 g/cm3的白椴木为模板制作透明木材,测试其透过率和拉伸性能。并采用层合多层薄木片的方法,制作了最大厚度达10 mm的透明木材。层合时采用同向层合和交错层合两种不同的层合方式,对比了相同厚度的单层木片与多层木片的透过率,以及横纹和顺纹方向的力学性能。结果树种不同,制备透明木材的工艺也不同。巴尔沙木密度最小,内部含有较多的孔隙,较易脱木质素和浸渍树脂。泡桐木中抽提成份较多,达8.9%,因此首先需要去除抽提物,打开闭塞的纹孔,提高渗透性。白椴木密度较大,脱木质素较困难,但拉伸性能最好。除了树种的影响外,厚度对透明木材的透过率影响也很大,木片越厚木质素越难去除,因此透过率也就越低。而采用层合的方法有效降低了去除木质素的难度。对比两种层合方式,同向层合制作的透明木材透过率与单层透明木片相似,而异向层合时透过率低于单层透明木片。但异向层合对消除透明木材横纹与顺纹方向的力学性能差异有明显的效果。结论本研究拓宽了制备透明木材树种的选择范围,并使制备高厚度低成本的透明木材成为可能。Abstract:ObjectiveMultilayer transparent wood is laminated transparent woods (the same direction or cross direction) under vacuum. This will greatly reduce the anisotropy of transparent wood.MethodThis study explored the process of making three kinds of tree species with different densities: balsa (0.21 g/cm3), paulownia (0.33 g/cm3) and basswood (0.49 g/cm3), and tested their transmittance and tensile properties. In order to produce a centimeter thick transparent wood, the lamination method was adopted. The mechanical properties and transmission of single layer and multilayer transparent wood with the same thickness were compared.ResultComparing their similarities and differences, balsa wood has the smallest density and contains more space inside, which is easier to remove lignin and impregnate resin. There were many extractive in paulownia (8.9%), hence it needs to be impregnated in sodium hydroxide (NaOH) to removal extractive and open the blocked pits. The density of basswood was 0.49 g/cm3, which caused lignin difficult to remove, but its tensile property was good. Besides the influence of tree species, the thickness had a great influence on transparent wood. The thicker the wood was, the greater the difficulty of removing lignin was. The properties of transparent wood combined with the same direction were closer to the original transparent wood. However, the transmission of transparent wood combined with the cross direction was lower than original transparent wood. But the difference between transverse and longitudinal stretch had been narrowed.ConclusionOur study widens the selection of transparent wood species and makes it possible for transparent wood with high thickness and low cost.

-

Keywords:

- multilayer composite /

- transparent wood /

- delignification /

- transmission /

- stretch property

-

磨削是木材加工中必不可少的重要工序,所用磨具大多为砂带,主要用于工件定厚和表面抛光。砂带磨削具有“冷态磨削”和“弹性磨削”的特点,是一种高精度、高效率、低成本的加工技术。材料去除率和表面粗糙度作为最常用的砂带磨削性能指标,是衡量砂带磨削效率、砂带寿命,以及评定加工质量的重要指标。材料去除率是指磨削过程中砂带在单位时间内去除被磨削材料的质量百分比,该指标直接影响到工件的定厚效果和表面粗糙度。影响砂带材料去除率的主要因素有砂带制造工艺、砂带目数、磨削压力、磨削速度和磨削延续长度。任青剑等[1]进行了300M超高强度钢的切入式磨削实验,发现在微观形貌方面,磨粒间距较大的砂带多是因磨粒磨损而失效,这是磨削效率降低的一个原因,但针对磨削效率降低的其他原因及其影响因素的探究仍然不够深入。Torrance[2]建立了磨料磨损模型,并将该方法应用于磨削过程中磨削力和金属材料去除率之间关系的预测以及磨料劣化的预测中。由于木材种类繁多,各项性质差异较大,此模型在木材磨削领域的应用存在局限性,仍需进一步研究探索。表面粗糙度的影响因素主要是关于木材特性的,包括纹理、密度、含水率等。刘博等[3]研究发现磨削表面质量会受到木材材性和加工工艺等因素的影响。Tian等[4]使用磨削效率测试系统和表面粗糙度测量仪进行磨削实验,分析比较了3种试材磨削效率和表面粗糙度的变化规律以及相关因素对磨削效率和表面粗糙度的影响,结果表明:磨削效率与表面粗糙度的变化趋势是随磨削次数的增加而逐渐降低,且同一树种、相同的磨削次数下,横向磨削时的磨削效率高于纵向磨削时的磨削效率。该实验在较为宏观的层面下进行探讨,缺乏对于砂带与试件表面微观形貌的进一步研究与分析。

砂带在磨削材料过程中将不可避免地产生磨损,且砂带的磨损是多个因素共同作用的结果,如磨削压力、砂带速度、工件材料等,在磨削不同材料或不同的磨削条件下的砂带磨损形式也会有差异。Ferguson等[5]在进行磨料磨损实验时,通过改变磨料磨粒尺寸、磨削压力、滑动速度和滑动距离来评估复合材料的磨损率。Malinov等[6]发现随着磨削压力的增加,Fe-B合金的耐磨性降低,磨损机制从微切割变为微切割和微耕的混合模式。在实际生产中,砂带生产厂家无法提供准确的砂带使用寿命,多依赖熟练工人的经验来判别砂带的使用寿命,这在一定程度上影响企业的生产效率和经济效益。随着人工智能和传感技术的发展,木材加工智能化已成为重要的发展方向,智能化控制一方面是提高机械设备的智能化控制程度,更重要的一方面是使切削(包括磨削)过程和结果可控,也就是根据要求达到相应的材料去除效率和表面加工质量[7]。比如美国将砂带磨削应用于汽车制造业的FMS生产线上,从磨削过程和设备控制两方面共同调控以达到最终的生产过程智能化。美国3M公司发明的微晶复制砂带使磨粒形状细致均匀且统一,使得磨削过程变得更加精密和高效[8]。

有关木材磨削方面的研究基础较为薄弱,而金属磨削理论并不完全适用于木材,对于木材砂带磨损和磨削效率方面的研究则是少之又少,砂带磨损机理也尚不明晰,这严重阻碍了木材加工技术和砂带制造技术向高效智能方向的发展。针对以上问题,本研究对水曲柳试件开展砂带磨削实验,分析砂带磨损机理及磨粒磨损对材料去除率和表面粗糙度的影响,进一步完善木材磨削理论,并为发展适用于木材的砂带磨削技术提供理论支持。

1. 材料和方法

1.1 材 料

水曲柳(Fraxinus mandshurica)材质坚韧致密,富弹性,纹理通直,刨面光滑,胶接、油漆性能较好,具有良好的装饰性能,在建筑、飞机、造船、仪器、运动器材、家具等行业应用广泛,因此本研究选用水曲柳作为实验材料,其气干密度为0.76 g/cm3,含水率为5.41%。制备的试件尺寸为46 mm(长) × 46 mm(宽) × 24 mm(厚);所有试件取自边材,表面平整,无明显缺陷。本研究所选用砂带为60目普通布基疏植砂型砂带(JW342,DEER,韩国)。

1.2 研究方法

1.2.1 砂带磨削实验装置

本研究所使用的实验装置如图1所示。该装置主要由使工作平台作直线往复运动的驱动系统和提供恒定磨削压力的气动装置组成。将砂带展平放置在工作平台上,调节两端的张紧轮,确保砂带张紧固定;将木制试件放置于夹具内,调节夹紧螺母完成试件的装夹;通过立式布置的带直线导轨的气缸(ADNGF-50-40-A,FESTO,德国),为试件提供恒定的磨削压力(约为100 N);随着试件材料不断去除,其厚度也逐渐减小,试件夹具可沿立式滑轨在气缸导杆行程内下移,使试件与砂带表面始终相接触;驱动系统带动工作平台沿水平滑轨作往复直线运动(平均速度约为0.3 m/s),同时智能计数装置完成磨削次数记录。

1.2.2 材料去除率表征及表面形貌分析

在本研究中,材料去除率定义为每磨削1 000次后试件的质量变化率。每磨削一次则磨削长度为50 mm,可将磨削次数累计与磨削长度进行换算。实验过程中,采用精密分析天平(BSA4235,Sartorious,德国)对试件和砂带进行称重,且每次称重前使用高压气枪(额定压力为3.0 MPa)去除试件和砂带表面的磨屑,进而计算相应的材料去除率和砂带的质量变化情况,直至材料去除率降至3%以内,认为此时砂带寿命已达极限,砂带上的磨粒已无法完成对试件材料的有效切除。采用3D轮廓仪(VR5000,KEYENCE,日本)对磨削过程中试件磨削表面和砂带表面进行扫描,再通过专业分析软件(VR Series version 3.2.0.277)测定试件磨削表面以及砂带的表面粗糙度,并使用扫描电子显微(日立S-3400N Ⅱ)对试件的磨削表面形貌进行分析。实验中对水曲柳分别进行顺纹磨削(磨削方向平行于木材纹理方向)和横纹磨削(磨削方向垂直于木材纹理方向)。

2. 结果与讨论

2.1 横纹磨削

横纹磨削时,磨粒的切削方向与木材纤维方向基本垂直,磨粒多呈负前角或小后角,锋利的刃口将木材纤维拦腰截断,木材纤维基本上以剥离的形式去除[9-10]。观察发现图2a中有较多细窄且清晰的单个磨粒磨削痕迹,而图2b、2c中这种磨削痕迹则逐渐减少,直至较宽的磨削痕迹占绝大多数。由于现有的磨粒制备技术及植砂工艺,新砂带上的磨粒等高性不好,如图3a所示,切削刃曲率半径很小且参差不齐,所以磨削初期会在试件表面上留下细窄、清晰的磨削痕迹。

随着磨削次数增加,高度较高的磨粒由于与试件接触深度加大,会首先发生破碎和脱落,这也就是所谓的“初锐阶段”[11]。从图4b中明显看出,初锐阶段大约在磨削次数5 000次以内,砂带上的磨粒在发生脱落和破碎之外,磨粒的磨损也同时发生,此时砂带质量减小的速率较快,只是砂带脱落、破碎和磨损所占比例不同。图5b中对应的砂带表面粗糙度较高,即磨粒高度之间差异较大,所以更易压入试件进行磨削,故此时对应图4a处材料去除率极高。

初锐阶段结束后,在图3b中可观察到砂带表面相同高度磨粒的个数明显增加,主要由于试件与磨粒之间的相互作用使得磨粒尖端钝化为小平面,其等高性变好且高度变矮,材料去除率会随之下降。此时磨粒协同干涉作用逐渐显著,从图2b中可以看出在一条较宽的磨削痕迹中有许多条细小的磨削痕迹,但是并没有非常明显且完整的单个磨粒的磨削痕迹,这是由于前一个磨粒所产生的磨削痕迹会被后续的磨粒进行进一步“加工”,而最终体现出来的磨削痕迹是众多磨粒共同作用的效果,消除了之前单个磨粒的磨削痕迹,使磨削痕迹的界限变得模糊,这种多磨粒干涉效应[12]也是使工件表面变光滑的最关键因素。

随着磨削阶段到达中、后期,从图2c中可以看出磨粒将木纤维从两侧挤出翘起,在试件表面犁出凹痕,只能切除少量材料,故材料去除率呈下降趋势并在一定程度上影响了试件表面的粗糙度。从图5可以看出,磨削中期试件表面的粗糙度是比较高的,但磨削后期由于磨粒钝化更加明显且高度更低,如图3c,砂带表面等高性进一步增加,表面的粗糙度迅速降低,磨粒与试件表面接触深度变浅,试件表面发生弹塑性变形,导致几乎无法去除材料,表面凹痕更浅,故可见图5a在中、后期表面粗糙度明显下降。观察图4b可得磨削中期到后期砂带质量基本是线性减小的,也就说明砂带的磨损、脱落、破碎最终达到一个较为平衡的阶段。

2.2 顺纹磨削

顺纹磨削时,切削方向与木材纤维方向基本平行,磨粒是从木材纤维的端向切入木材[13]。与横纹磨削类似,在初期阶段磨粒顶端的曲率半径较小,切削刃较为锋利,如图6a,砂带上磨粒的等高性较差,易压入木材做有效切削,从图7a中可观察到初期阶段试件表面有多条清晰且完整的磨粒磨削痕迹。

对比图8a与图4a发现,水曲柳横纹磨削时材料去除率整体大于顺纹磨削的材料去除率,且顺纹磨削时材料去除率的下降速率大于横纹的下降速率。这说明砂带在顺纹磨削时更难去除材料,主要由于顺纹磨削过程中,磨粒切入木材时是从木纤维的端头切入,加之磨粒一般为负前角,很难依靠锋利的刃口将木纤维切断,更多的是将其牵扯拉断[14]。从图8b中也可发现此时砂带的磨损速率更快,导致砂带使用寿命也更短。

随磨削次数增加,砂带磨粒高度降低,顶端刃口曲率半径不断增大,在图7b中可以看到许多较宽的磨削痕迹且在凹痕两侧有较多毛刺及翘起的木纤维,故在图9a中可明显观察到试件表面粗糙度增高。在磨削中期,从图6b可看出,砂带上磨粒脱落,破碎所占比例较大,等高性增大,磨粒与试件的接触深度降低且切割纤维能力减弱,在试件表面发生更多的是耕犁现象,木纤维在多次牵拉下被扯断,如图7b左侧示意图。

至磨削后期,观察图7c发现部分磨削痕迹被木屑填埋,翘起的毛刺被抹平,且凹痕大多较浅,故可见图9a中试件表面粗糙度明显下降。如图6c,此时磨粒整体高度下降,磨粒磨损情况严重,大多仅摩擦试件表面,几乎无法切除材料,同时将折断、翘起的木纤维碾平并填充空隙,使得表面粗糙度降低。但是不难从图9b中发现,顺纹磨削时后期砂带的表面粗糙度更大,这也和切削方式和磨粒破碎形式有关,因为在顺纹切削时纤维大多被拉断,所以磨粒更易受拉力造成破碎和脱落,这也是砂带在顺纹和横纹磨削时的一个主要差异[15]。

2.3 材料去除率、表面粗糙度灰色预测模型

在砂带寿命范围内,累计磨削长度与磨削过程中材料去除率、表面粗糙度间有着密切联系,但由于样本量少[16-17],且存在如木材非均质、砂带植砂磨粒分布偶然性等较多未知因素,较难建立磨削长度与材料去除率、表面粗糙的回归模型。20世纪80年代邓聚龙教授创立了一种就数找数的方法,即灰色系统生成法。其研究对象是“部分信息已知,部分信息未知”的“小样本”、“贫信息”不确定性系统,用于解决“小样本”、“贫信息”的不确定性问题,这种方法容错率较高,也易于实现模糊控制[18]。因此本研究采用均值GM(1,1)预测模型建立磨削长度与材料去除率、表面粗糙度间的灰色预测模型,如图10所示。

2.3.1 模型预测

在本次模型中,系列特征序列为材料去除率和表面粗糙度,相关因素序列为磨削长度,模型原始数据及建模步骤如下:

第一步,根据表1、2中数据,建立初始材料去除率序列

X(0)1 、表面粗糙度序列X(0)2 。表 1 横纹磨削模型数据Table 1. Model data of transverse sanding序号

No.磨削长度

Sanding length/m表面粗糙度

Surface roughness/μm材料去除率

Material removal rate/%1 200 41.178 15.11 2 400 39.723 13.48 3 600 40.546 15.71 4 800 51.551 7.27 5 1 000 54.409 12.66 6 1 200 63.536 11.39 7 1 400 60.472 8.35 8 1 600 67.846 9.61 注:为提高所建灰色模型的预测精度,选取数据均在砂带最佳使用寿命范围内。下同。Notes: to improve the precision of the established gray model, the selected data is located in the range of optimal abrasive belt life. Same as below. 表 2 顺纹磨削模型数据Table 2. Model data of longitudinal sanding序号

No.磨削长度

Sanding length/m表面粗糙度

Surface roughness /μm材料去除率

Material removal rate/%1 100 42.572 14.57 2 200 78.737 14.96 3 300 69.976 11.70 4 400 79.229 12.13 5 500 71.151 7.43 6 600 79.812 11.40 7 700 81.305 8.46 8 800 81.221 5.77 9 900 74.79 6.53 10 1 000 78.662 4.86 X(0)1=(X(0)1(1),X(0)1(2),X(0)1(3),⋯,X(0)1(n−1),X(0)1(n))X(0)2=(X(0)2(1),X(0)2(2),X(0)2(3),⋯,X(0)2(n−1),X(0)2(n)) 式中:

X(0)1(n) 代表材料去除率第n个数据的原始数值;X(0)2(n) 代表表面粗糙度第n个数据的原始数值;n表示原始数列的个数,本文横纹磨削时n = 8,顺纹磨削时n = 10。第二步,均值GM(1,1)建模。

(1)对原始数据做一次累加得

X(1)1 和X(1)2 ,原始序列的1-AGO生成;(2)

X(1)(n) 表示原始序列第n个数的一阶累加数值,X(0)(n) 表示原始序列第n个数值,构造数据矩阵B和数据向量Y;B=[−12(X(1)(1)+X(1)(2)1−12(X(1)(2)+X(1)(3)1⋮⋮−12(X(1)(n−1)+X(1)(n)1],Y=[X(0)(2)X(0)(3)⋮X(0)(n)] GM(1,1)模型可表示为

Y=Bu ,即[X(0)(2)X(0)(3)⋮X(0)(n)]=[−12(X(1)(1)+X(1)(2)1−12(X(1)(2)+X(1)(3)1⋮⋮−12(X(1)(n−1)+X(1)(n)1][ˆaˆb] (3)计算待估向量

ˆu ;ˆu=(ˆa,ˆb)T=(BT⋅B)−1BTY 式中:a为发展灰数,表示序列的发展趋势;b为内生控制灰数,表示数据间的变化关系。

(4)建立模型。

dX(1)1dt+a1X(1)=b1 dX(1)2dt+a2X(1)=b2 式中:t表示序号1,2,······,n−1,n的连续变量;a1、b1分别为计算材料去除率预估向量的发展灰数和内生控制灰数;a2、b2分别为计算表面粗糙度预估向量的发展灰数和内生控制灰数。

第三步,模型检验。

从图11a中数据计算得到:横纹磨削过程中,材料去除率平均模拟相对误差为18.362%,表面粗糙度的平均模拟相对误差为5.170%。从图11b中数据计算可得:顺纹磨削过程中,材料去除率平均模拟相对误差为13.491%,表面粗糙度的平均模拟相对误差为4.603%。

2.3.2 结果分析

由图11可知:采用灰色模型均值GM(1,1)的预测平均模拟相对误差都是在20%以内。考虑预测系统本身局限性,以及木质材料的各向异性导致原始数据的随机性较高,本身规律性不是很明显的情况下,这些因素都加大了预测难度,一定程度上影响了模拟预测的准确性。故本模型适用于预测水曲柳磨削过程中,磨削长度分别与材料去除率、表面粗糙度之间关系的预测,对实际生产具有借鉴意义。

3. 结 论

木材磨削过程中材料去除行为会影响木材加工表面质量,其影响因素主要有磨削方向、材料种类以及磨削过程中砂带的磨损情况。本文主要研究了水曲柳在不同磨削方向时的材料去除率和试件、砂带表面粗糙度变化情况,探究了磨粒磨损过程及其与材料去除率之间的关系,得出以下结论:

(1)磨削过程中磨削方向对砂带磨损的影响不同,顺纹磨削对砂带上磨粒的磨损大于横纹磨削。磨粒的磨损对材料去除率有较大的影响,磨粒磨损程度越大,材料去除率越小。当材料去除率降低至3%时,可认为达到砂带使用寿命,应及时更换砂带。

(2)磨削过程中,砂带上磨粒的等高性对材料去除率也有较大影响。等高性越差,材料去除率越高。随磨削次数增加,砂带材料去除能力不断下降,试件表面粗糙度则呈现先增大后减小的趋势。

(3)采用灰色模型均值GM(1,1)的预测平均模拟相对误差都是在20%以内。适用于水曲柳磨削过程中磨削长度分别与材料去除率、表面粗糙度之间关系的预测。

-

图 5 不同巴尔沙木拉伸极限测试

单层原巴尔沙木Single layer original balsa wood (OBW);单层透明巴尔沙木Single layer transparent balsa wood (SLTBW);同向层合透明巴尔沙木Same direction multilayer transparent balsa wood (SMTBW);交错层合透明巴尔沙木Cross direction multilayer transparent balsa wood (CMTBW)。

Figure 5. Stretch limit test of different balsa woods

图 7 单层与多层透明泡桐木透过率曲线

单层透明泡桐木Single layer transparent paulownia wood (SLTPW);同向层合透明泡桐木Same direction multilayer transparent paulownia wood (SMTPW);交错层合透明泡桐木Cross direction multilayer transparent paulownia wood (CMTPW)。

Figure 7. Transmittance curves of single-layer and multi-layer transparent paulownia wood

-

[1] 管宁. "透明木材"[J].国际木业, 2017, 47(5): 17. doi: 10.3969/j.issn.1671-4911.2017.05.008 Guan N. Wooden glass for windows and solar panels[J]. International Wood Industry, 2017, 47(5): 17. doi: 10.3969/j.issn.1671-4911.2017.05.008

[2] 吴燕, 吴佳敏, 唐彩云, 等.透明木材的制备方法: CN106243391A[P]. 2016-12-21. Wu Y, Wu J M, Tang C Y, et al. Production method of transparent timber: CN106243391A[P]. 2016-12-21.

[3] Fink S. Transparent wood: a new approach in the functional study of wood structure[J]. Holzforschung, 1992, 46(5): 403-408. doi: 10.1515/hfsg.1992.46.5.403

[4] Yu Z Y, Yao Y J, Yao J N, et al. Transparent wood containing CsxWO3 nanoparticles for heat-shielding window applications[J]. Journal of Materials Chemistry A, 2017, 5(13): 5963-6330. doi: 10.1039/C7TA90066J

[5] Zhu M W, Li T, Davis C S, et al. Transparent and haze wood composites for highly efficient broadband light management in solar cells[J]. Nano Energy, 2016, 26: 332-339. doi: 10.1016/j.nanoen.2016.05.020

[6] 李坚, 甘文涛, 高丽坤, 等.一种荧光透明磁性木材的制备方法: CN106313221A[P]. 2017-01-11. Li J, Gan W T, Gao L K, et al. Manufacturing method for fluorescent transparent magnetic wood: CN106313221A[P]. 2017-01-11.

[7] Li Y Y, Yu S, Veinot J G C, et al. Luminescent transparent wood[J]. Advanced Optical Materials, 2017, 5(1): 1600834. doi: 10.1002/adom.201600834

[8] Gan W T, Xiao S L, Gao L K, et al. Luminescent and transparent wood composites fabricated by poly (methyl methacrylate) and γ-Fe2O3@YVO4:Eu3+ nanoparticle impregnation[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(5): 3855-3862. doi: 10.1021/acssuschemeng.6b02985

[9] Li Y Y, Fu Q L, Rojas R, et al. Lignin-retaining transparent wood[J]. Chemsuschem, 2017, 10(17): 3445-3451. doi: 10.1002/cssc.201701089

[10] Yaddanapudi H S, Hickerson N, Saini S, et al. Fabrication and characterization of transparent wood for next generation smart building applications[J]. Vacuum, 2017, 146: 649-654. doi: 10.1016/j.vacuum.2017.01.016

[11] Zhu M W, Song J W, Li T, et al. Highly anisotropic, highly transparent wood composites[J]. Advanced Materials, 2016, 28(26): 5181-5187. doi: 10.1002/adma.201600427

[12] Li Y Y, Yang X, Fu Q L, et al. Towards centimeter thick transparent wood through interface manipulation[J]. Journal of Materials Chemistry A, 2018, 6(3): 1094-1101.

[13] 方露, 常亮, 郭文静, 等. HDPE胶合板与脲醛树脂胶合板的性能对比[J].北京林业大学学报, 2014, 36(2): 125-128. http://j.bjfu.edu.cn/article/id/9992 Fang L, Chang L, Guo W J, et al. Performance comparison of HDPE plywood with UF resin plywood[J]. Journal of Beijing Forestry University, 2014, 36(2): 125-128. http://j.bjfu.edu.cn/article/id/9992

[14] Yokoyama T, Kadla J F, Chang H M. Microanalytical method for the characterization of fiber components and morphology of woody plants[J]. Journal of Agricultural and Food Chemistry, 2002, 50(5): 1040-1044. doi: 10.1021/jf011173q

[15] Gan W T, Gao L K, Xiao S L, et al. Transparent magnetic wood composites based on immobilizing Fe3O4 nanoparticles into a delignified wood template[J]. Journal of Materials Science, 2017, 52(6): 3321-3329. doi: 10.1007/s10853-016-0619-8

[16] 袁金霞, 卫威, 黄显南, 等.两种桐木原料及制浆性能研究[J].中国造纸, 2016, 35(7): 83-85. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGZZ201607023.htm Yuan J X, Wei W, Huang X N, et al. Fiber morphology and KP pulping of two paulownia woods[J]. China Pulp & Paper, 2016, 35(7): 83-85. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGZZ201607023.htm

[17] 周益同, 张小丽, 张力平.木质素的结构及其改性现状[J].现代化工, 2010, 30(S2): 63-66. http://www.cnki.com.cn/Article/CJFDTOTAL-XDHG2010S2019.htm Zhou Y T, Zhang X L, Zhang L P. The structure of lignin and its modification status[J]. Modern Chemical Industry, 2010, 30(S2): 63-66. http://www.cnki.com.cn/Article/CJFDTOTAL-XDHG2010S2019.htm

[18] Dolk M, Yan J F, Mccarthy J L. Lignin 25. kinetics of delignification of western hemlock in flow-through reactors under alkaline conditions[J]. Holzforschung, 1989, 43(2): 91-98. doi: 10.1515/hfsg.1989.43.2.91

[19] 吴博士, 张逊, 杨俊, 等.亚氯酸盐预处理杉木细胞壁木质素溶解机理研究[J].林产化学与工业, 2017, 37(3): 38-44. doi: 10.3969/j.issn.0253-2417.2017.03.005 Wu B S, Zhang X, Yang J, et al. Dissolution mechanism of lignin in Chinese-fir cell walls during chlorite pretreatment[J]. Chemistry and Industry of Forest Products, 2017, 37(3): 38-44. doi: 10.3969/j.issn.0253-2417.2017.03.005

[20] 李立, 白雪涛.紫外线辐射对人类皮肤健康的影响[J].国外医学卫生学分册, 2008, 35(4): 198-202. http://www.cnki.com.cn/Article/CJFDTOTAL-GWYX200804002.htm Li L, Bai X T. Effects of ultraviolet radiation on human skin health[J]. Journal of Environmental Hygiene, 2008, 35(4): 198-202. http://www.cnki.com.cn/Article/CJFDTOTAL-GWYX200804002.htm

[21] 陈玉和, 黄文豪, 常德龙, 等.氢氧化钠预处理对木材漂白促进作用的研究[J].林产化学与工业, 2000, 20(1): 52-56. doi: 10.3321/j.issn:0253-2417.2000.01.010 Chen Y H, Huang W H, Chang D L, et al. Study on promoting effects of NaOH pretreatment on wood bleaching[J]. Chemistry and Industry of Forest Products, 2000, 20(1): 52-56. doi: 10.3321/j.issn:0253-2417.2000.01.010

[22] 李坚, 葛明裕.氢氧化钠溶液预处理提高胶结强度机理的研究[J].东北林业大学学报, 1990, 18(1): 80-87. http://www.cnki.com.cn/Article/CJFDTotal-DBLY199001010.htm Li J, Ge M Y. Mechanism of improving gluing strength in making plyood by the pre-treatment with sodium hydrate a tqueous solution[J]. Journal of Northeast Forestry University, 1990, 18(1): 80-87. http://www.cnki.com.cn/Article/CJFDTotal-DBLY199001010.htm

-

期刊类型引用(5)

1. 罗斌,杜瑶,柳浩雨,王钦悦,李春瑜,李黎,刘红光. 定组态砂带粒度对刨花板磨削的影响. 北京林业大学学报. 2024(09): 141-150 .  本站查看

本站查看

2. 施晨阳,赖文峰,文国卫,蒋天雨,朱晓如,吕增伟,张国防. 基于Maxent模型预测水曲柳的潜在适生区. 西北林学院学报. 2022(02): 149-156 .  百度学术

百度学术

3. 罗斌,张健,柳浩雨,李黎,刘红光,李昊. 木质材料磨削理论及技术研究进展. 木材科学与技术. 2022(04): 6-12 .  百度学术

百度学术

4. 杜瑶,田彪,张健,刘红光,罗斌. 中密度纤维板磨削时的砂带磨损研究及寿命评判. 北京林业大学学报. 2021(10): 126-134 .  本站查看

本站查看

5. 卢冬冬,杨铁牛,杨保健,叶榕伟,阳亚,杜华娜. 肉桂打磨方法优化. 农业工程. 2020(01): 73-78 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: