Three-dimensional optical deformation measurement of laminated veneer lumber and the finite element simulation analysis of the pallets

-

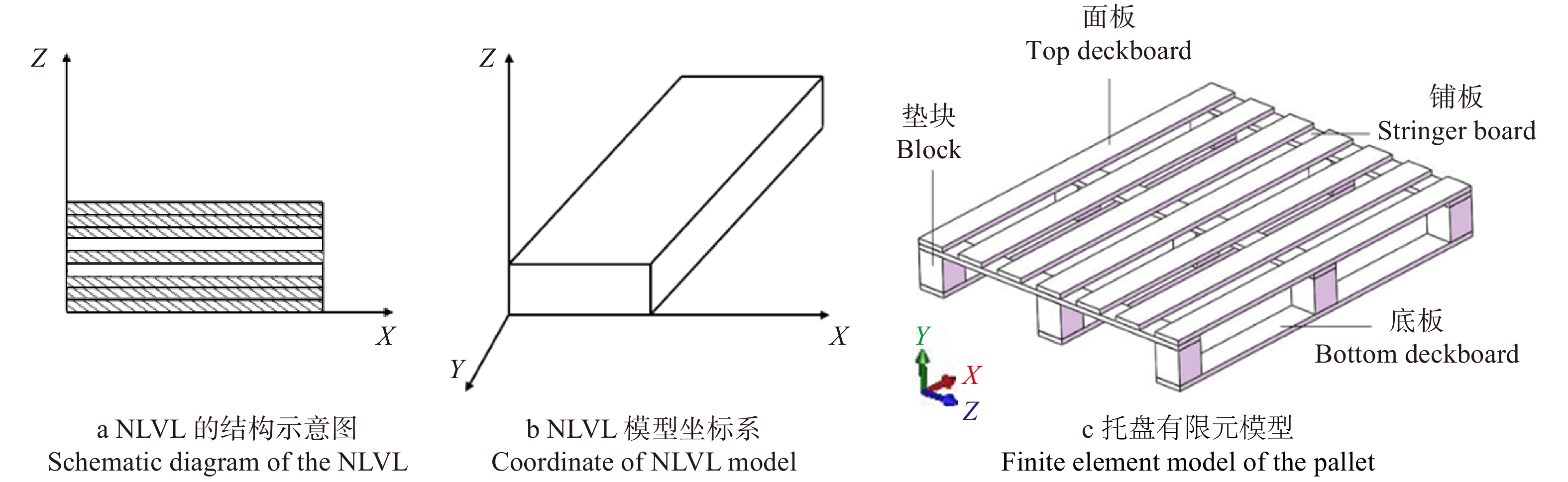

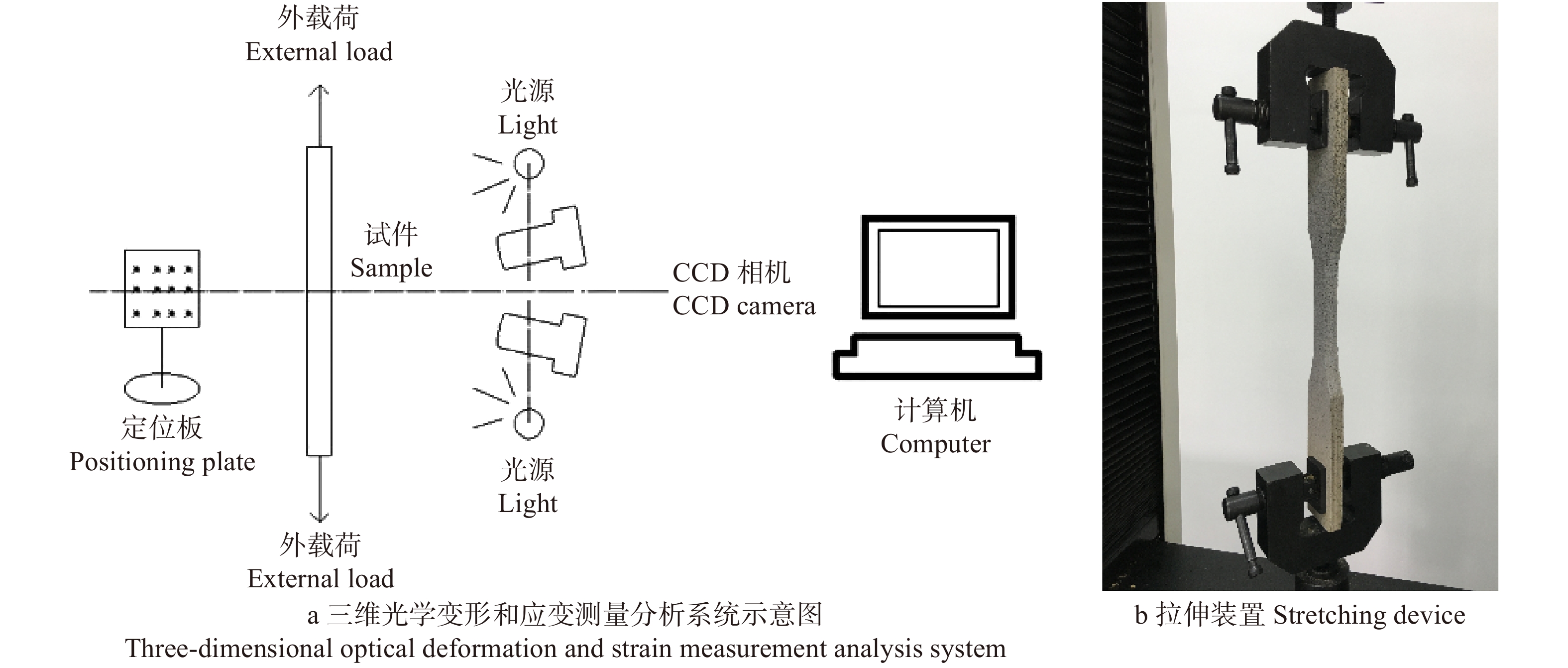

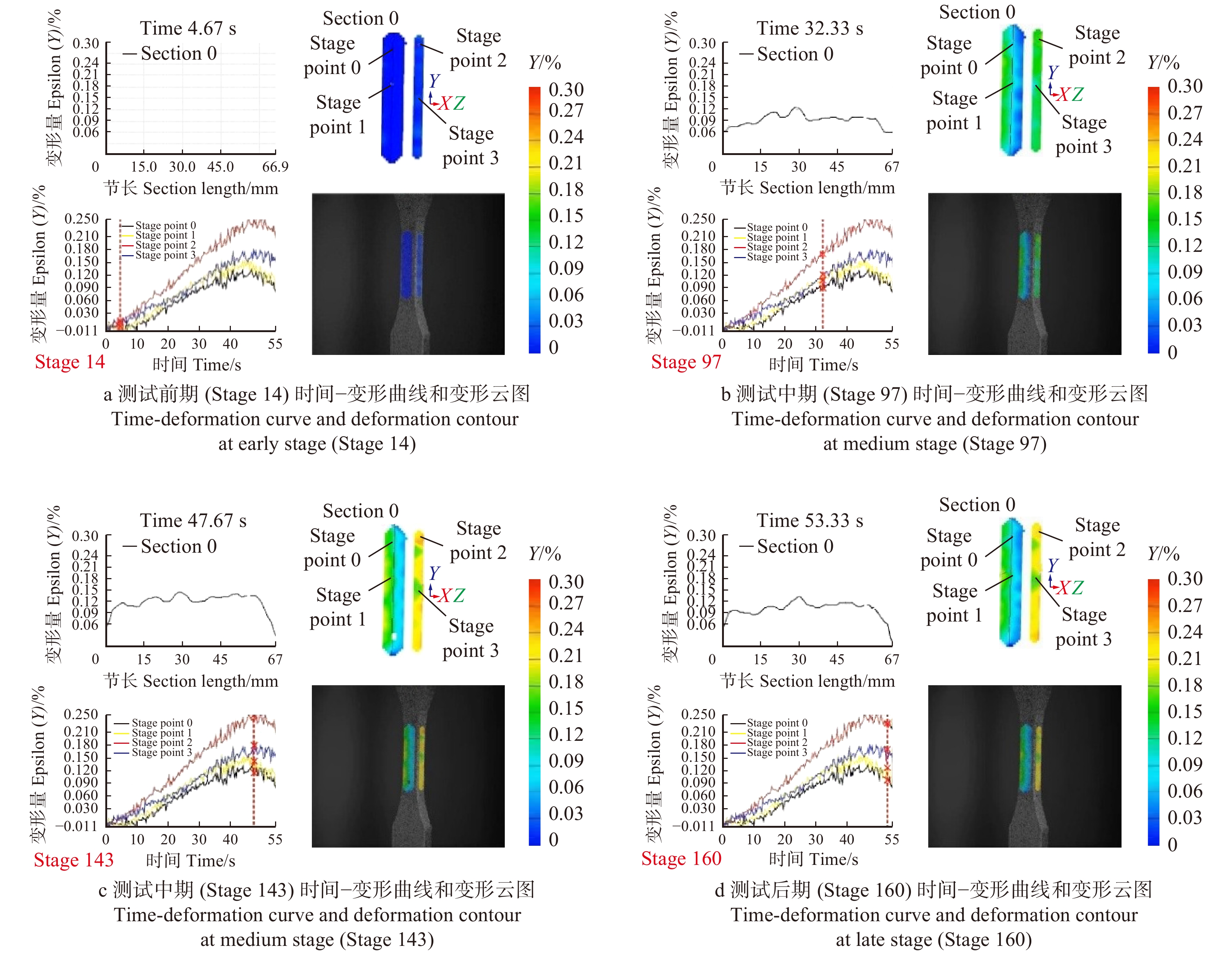

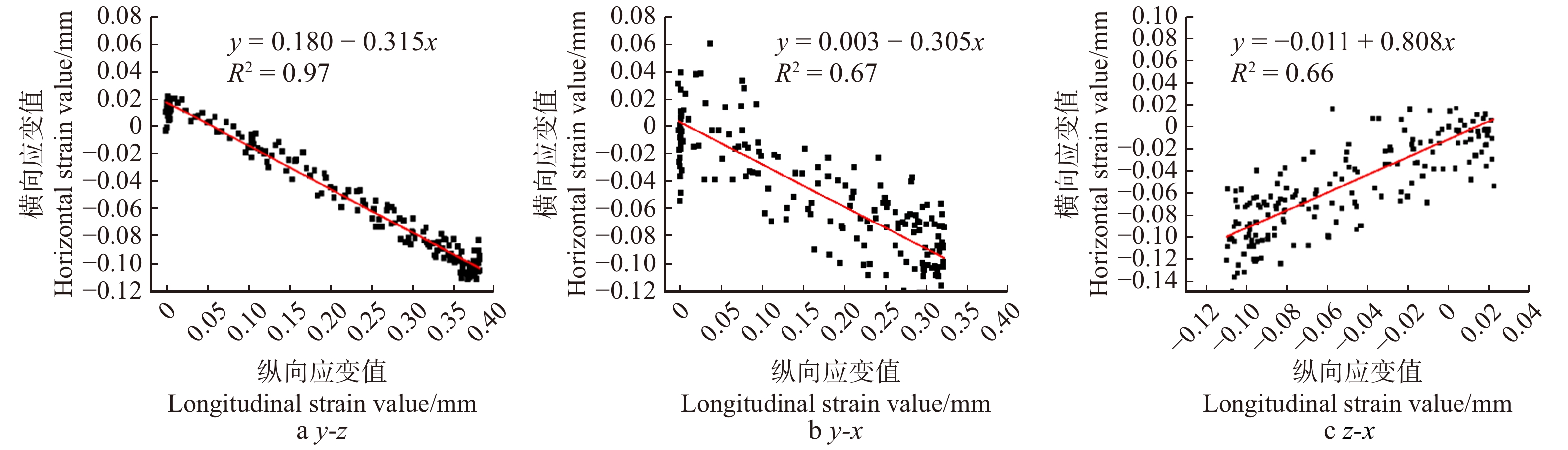

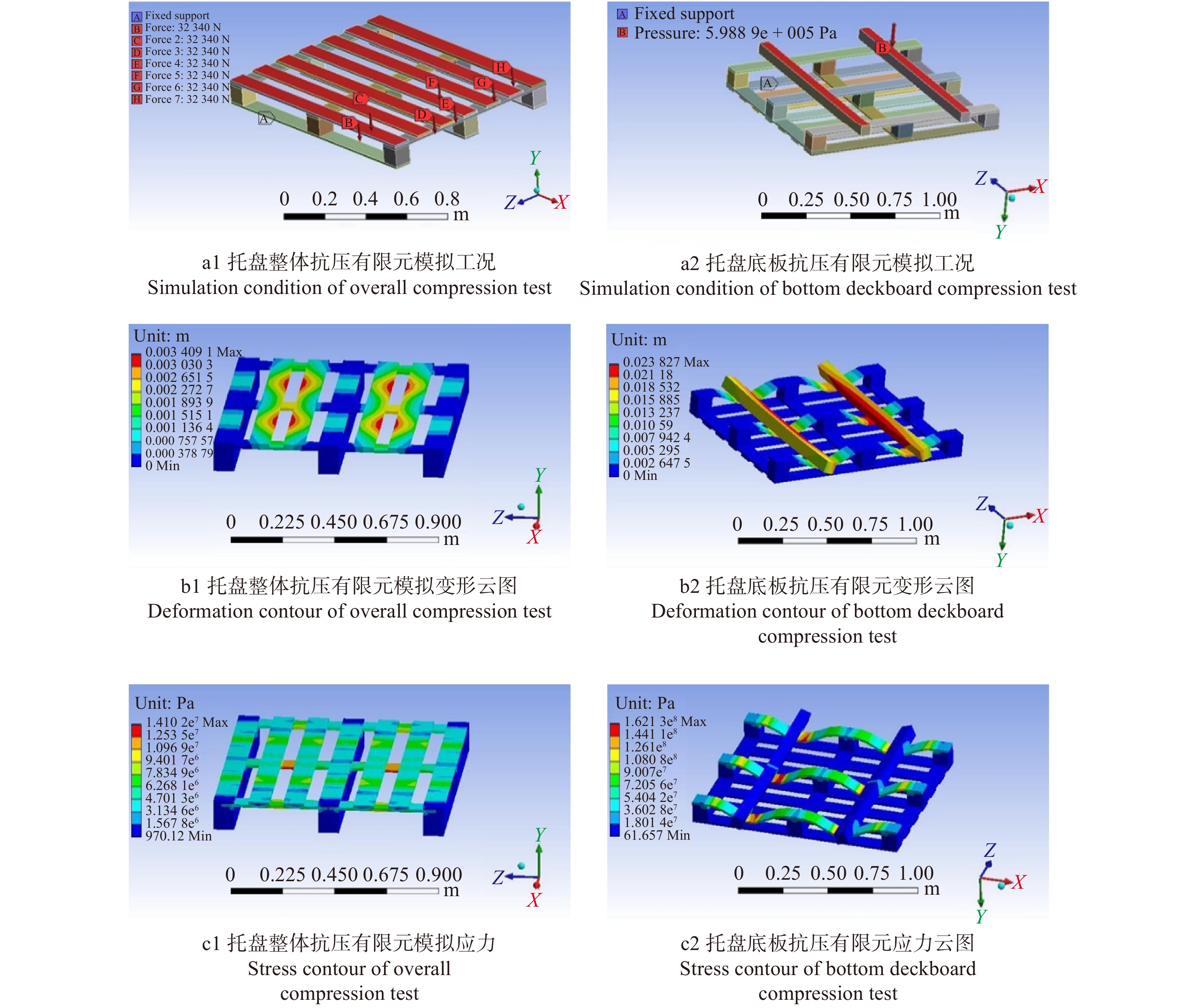

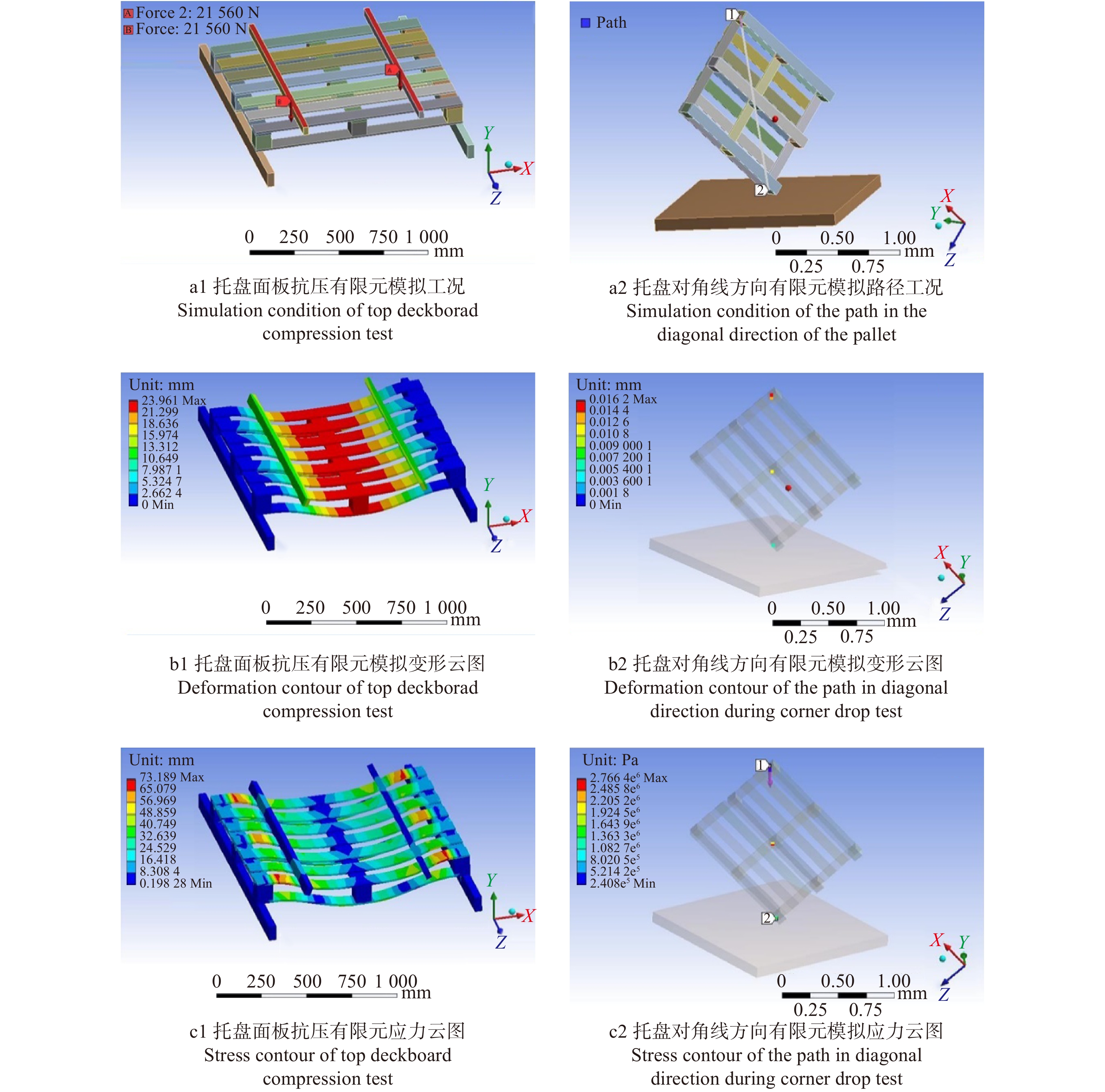

摘要:目的单板层积材应用广泛,但其性能测试多采用破坏性实验方法,存在检测效率低且会造成资源浪费的不足。本研究对一种新型层积板材及其制得的托盘进行无损检测,旨在为木质层积材及制品性能的高效、精确检测提供理论参考和技术支撑。方法将三维光学检测法与有限元仿真分析相结合,首先采用数字散斑法测量并计算获得新型层积板材的弹性常数(包括弹性模量,泊松比,剪切模量);然后导入有限元仿真分析中,分别选取layer单元和solid 185单元对板材模型进行网格划分和静力模拟,优化其仿真模拟参数;参照国际标准ISO 8611—2011 对新型层积板材托盘性能进行检测,利用Solidworks建立及装配托盘模型,在ANSYS workbench软件中对托盘整体结构进行整体抗压、底板抗压、面板抗压和角跌落等仿真模拟,并与实验测试结果进行对比分析。结果三维光学法获得的弹性参数可以应用于新型层积板材及其制品的有限元仿真分析中,ANSYS有限元仿真结果可靠;将新型层积材作为整体结构,选用solid 185单元的仿真模拟结果与实际测试情况最为接近;新型层积材托盘静力仿真分析中托盘的最大变形与实验结果相近,4种工况仿真分析结果与实测结果相同。结论三维光学检测法结合有限元仿真分析可以对木质层积材及其制品的受力、变形和破坏情况进行无损检测,可达到高效和节能的目的。Abstract:ObjectiveThe laminated veneer lumber has been widely used, but its mechanical properties were mostly conducted using destructive methods, which possesses drawbacks like low efficiency and wasting of resources. In this study, a new laminated veneer lumber (NLVL) and the NLVL-made pallets were nondestructively tested, aiming at providing theoretical reference and technical support for detecting the properties of the laminated veneer lumber and its products efficiently and accurately.MethodThe three-dimensional optical deformation measurement with the finite element analysis method was combined, the elastic constants of the NLVL were firstly measured and calculated by three-dimensional optical deformation test, including the elastic modulus, poisson’s ratio, shear modulus, which were used as basic parameters for the static simulation. The layer element and solid 185 element were selected respectively for mesh generation and static simulation of the laminated wood model, and the simulation parameters were optimized. The performance of the NLVL-made pallets was tested according to the international standard ISO 8611−2011. The pallet model was built and assembled using Solidworks, and the overall structure of the pallet was simulated under four working conditions including pressure resistance, bottom runner, surface strength and corner drop in ANSYS workbench software, and the simulation results were compared with the experimental test results.ResultThe study showed that the data gained from three-dimensional optical deformation measurement can be used as parameters in the finite element simulation analysis of the NLVL and its products, the simulation results were close to that of the experimental test. The results were mostly matched when the NLVL was considered as unit and the solid 185 was selected during the simulating analyses. In the static simulation analysis of the NLVL-made pallets, the maximum deformation of the tray was close to the experimental results. The simulation results of the four working conditions were the same as the measured resultsConclusionThis nondestructive method which combined the three-dimensional optical with finite element simulation can be used to analyze the stress, deformation and failure of wooden laminates and their products, therefore, it is possible to achieve the goal of energy saving and high efficiency.

-

胡杨(Populus euphratica)是最古老的杨属植物,是唯一能够在极端干旱区自然成林的高大乔木种[1-2]。天然的胡杨林具有沿河岸呈条带状分布的特点[3],由于胡杨对于荒漠河岸林生态系统维持的重要性,前人对胡杨的适应性已经开展了很多研究。研究表明,水文因子是制约胡杨种群分布和发育的最关键因子[4-6],洪水漫溢后湿润低盐的河漫滩环境是胡杨通过种子更新的最理想场所[7]。水文条件改变带来的干旱区土壤盐渍化问题是影响胡杨种群分布的一个重要因素[8-9]。由于安全生境的缺失,目前胡杨无法通过有性繁殖的方式形成有效的更新[5, 10-12]。

根系的生长是胡杨幼苗能否定植和实现有效更新的关键,近年来越来越多的研究从根系角度对胡杨的生长策略进行分析。在环境条件改变的情况下,植物根系的空间分布、形态特征会表现出相应的适应策略,以更高效地获取资源[13-14]。吕爽等人[15]研究了胡杨幼苗根系对水分因子的响应特征,发现胡杨幼苗一定程度上可以通过地上地下生长权衡来适应干旱环境,良好的水分条件可以促进胡杨幼苗侧根的扩展。Ye等人[16]对干旱胁迫下胡杨实生苗根系特征的研究表明,深根系、大根冠比和鱼尾状根构型是胡杨当年实生苗适应河漫滩环境的重要特征,这与Wang等人[17]的观点类似,胡杨幼苗是通过根系性状和生物量分配的塑性响应来适应一定地下水位条件的。

以往的研究多采用单因素控制条件对胡杨根系进行研究,多因素交互作用,特别是将种间关系和根−土壤水分关系结合的研究更为缺乏。而植物种间关系及其对环境胁迫梯度响应的研究,对胁迫环境下植被的恢复有重要的指导意义[18]。有研究表明,比根面积除了受到土壤水分的影响,来自邻体植物的竞争也对比根面积有重要的影响[19]。除了土壤环境,在干旱区种内种间相互作用也是影响种群动态的重要因素[20-21]。在荒漠河岸林中,胡杨常常和多枝柽柳(Tamarix ramosissima)幼苗在河滩上聚集分布[22]。一些研究发现了胡杨幼苗与多枝柽柳竞争能力的差异[23],但是目前尚未引起足够重视。因此,本研究以胡杨作为研究对象,设置胡杨−胡杨和胡杨−柽柳两种伴生模式,研究胡杨当年生幼苗根系形态特征对多枝柽柳以及土壤水盐变化的响应,旨在为胡杨林的保护、更新和复壮提供理论依据。拟解决以下几个问题:(1)胡杨幼苗根系生长对水盐交互作用的响应;(2)异种伴生者存在条件下,胡杨当年生实生幼苗根系的竞争适应策略;(3)种间竞争存在条件下,胡杨幼苗根系对水盐条件的塑性响应变化。

1. 材料和方法

1.1 实验设计

实验在内蒙古自治区国营额济纳旗林场的日光温室内进行。使用的胡杨种子和多枝柽柳种子采自额济纳旗胡杨林国家自然保护区(41°30′ ~ 42°07′N、101°03′ ~ 101°17′E),均为上一年风干冷藏保存。土壤取自林场苗圃,筛除石子、植物根系等杂质后,经过暴晒,装入口径25 cm,深度达60 cm的塑料软花盆。将花盆里的土浇透之后,平整土面,播入经过清水浸泡的胡杨种子。实验设置了两种伴生模式,既胡杨−胡杨(P-P)组和胡杨−柽柳(P-T)组。后者在胡杨种子萌发、幼苗扎根后,播入多枝柽柳种子。在胡杨幼苗生长了40 d时进行间苗,去除长势不佳的弱苗、畸形苗,胡杨−胡杨组保留10株长势一致、在花盆中均匀分布的幼苗,胡杨−柽柳组各保留5株胡杨和5株柽柳幼苗。间苗后开始对水盐进行控制。

实验对两个伴生模式设置了相同的3个水分梯度(W)和3个盐分梯度(S),水分梯度为低水、中水、高水,分别以W1、W2、W3进行表示,实验控制期间对应的最低质量含水量约为5%、10%、15%,其中中水处理为胡杨人工育苗常用的水分管理模式。盐分处理以加入NaCl水溶液的形式进行,盐分梯度为低盐(0 g/盆)、中盐(1.8 g/盆)和高盐(3.6 g/盆),分别以S1、S2、S3表示。为避免幼苗因离子毒害致死,盐分分为5次施入。水盐两两进行交互,即所有实验处理为以下9种:低水低盐(W1S1)、低水中盐(W1S2)、低水高盐(W1S3)、中水低盐(W2S1)、中水中盐(W2S2)、中水高盐(W2S3)、高水低盐(W3S1)、高水中盐(W3S2)、高水高盐(W3S3)。每个处理4个重复。

1.2 根系性状测定方法

胡杨幼苗经过100 d(一个生长季)的生长后进行破坏性取样。用加压水柱冲洗附在根系上的土壤,以获取完整的根系,并在水中小心地进行单株苗的分离,去除根系上缠绕的杂质。随后将根系置于盛水的透明根盘中,用镊子小心将根系摊开至舒展状态,使其尽可能不重叠,用扫描仪(Epson Perfection V700)进行扫描后,用WinRhizo对扫描的图片进行分析,以获得根系各形态指标,根系分析的径级设置在0.5 mm级别。将扫描后的根系放在纸袋中,在80 ℃下烘干至恒质量,用万分之一天平称得生物量。

需要说明的是,生长的后期,胡杨−柽柳组陆续出现胡杨幼苗地上部分死亡的情形(以叶片全部脱落为准),但幼苗根系还具有活性,形态和生物量积累情况能够反映其生长过程,因此在本实验中,死亡的胡杨幼苗根系数据并入同一处理组进行分析。

1.3 指标计算

根据WinRhizo的分析结果,计算根系的比根长和比根面积及径级在0.5 mm以下的根系数量特征。

比根长 = 总根长(cm)/根生物量(g);

比根面积 = 总根表面积(cm2)/根生物量(g);

根长占比 = 0.5 mm以下根系长度/总根长;

根表面积占比 = 0.5 mm以下根系表面积/总根表面积;

根体积占比 = 0.5 mm以下根系体积/总根体积;

根尖占比 = 0.5 mm以下根尖数/总根尖数。

1.4 数据分析

用Spss 17.0对数据进行分析,对各指标进行水分、盐分和伴生类型进行多因素方差分析,对同一水分梯度下不同盐分梯度间,以及同一盐分梯度不同水分梯度间的幼苗根系特征进行单因素方差分析(one-way ANOVA),采用Duncan法来判定差异显著性。同一处理下,两个不同伴生组采用t检验判定显著性。用sigmaplot 12.5作图。

2. 结果和分析

2.1 水分、盐分和伴生模式对胡杨幼苗根系生长的影响

三因素方差分析(表1)结果表明,水分、盐分和伴生模式对胡杨幼苗根系有显著的影响(P < 0.05),其中水分和伴生模式对总根长、根表面积、基径等多个指标的影响达到极显著(P < 0.001),且水分和伴生模式的交互作用对总根长、总根体积、根表面积和分支数也有显著的影响(P < 0.05)。盐分对总根体积、根尖数和基径有显著的影响(P < 0.05),水盐的交互对幼苗基径、比根长、比根面积影响显著(P < 0.05),但对其他指标影响未达到显著。以上结果表明,当年生胡杨幼苗的根系生长受水分和种间竞争的影响较盐分大。

表 1 水分、盐分及伴生模式对胡杨幼苗根系的影响(三因素方差分析)Table 1. Effects of water, salinity conditions and neighbor patterns on seedling roots of Populus euphratica (three-way ANOVA)因子及因子间交互作用

Factor and interaction among factorsdf 总根长

Total root

length根表面积

Root surface

area总根体积

Total root

volume根尖数

Root tip number基径

Basal diameter比根长

Specific root

length比根面积

Specific root

areaW 2 38.078*** 40.891*** 38.977*** 27.309*** 65.906*** 2.097 4.116* S 2 1.532 2.128 3.438* 3.257* 3.527* 2.833 5.419** N 1 182.288*** 227.118*** 239.979*** 97.963*** 277.821*** 44.807*** 31.885*** W × S 4 0.782 0.709 0.751 0.844 3.255* 5.163*** 4.929*** W × N 2 4.693* 7.819*** 11.472*** 1.071 2.863 1.470 1.003 S × N 2 2.442 2.578 2.420 2.016 0.782 0.266 0.627 W × S × N 4 1.551 1.109 0.610 2.752* 1.878 2.860* 1.201 注:W为水分;S为盐分;N为伴生模式。表中数值为F检验值,“*”表示P < 0.05,“**”表示P < 0.01,“***”表示P < 0.001。下同。Notes: W, water condition; S, salinity condition; N, neighbor pattern. Data are F testing values. “*” means P < 0.05, “**” means P < 0.01 and “***” means P < 0.001. The same below. 进一步分析两种伴生模式下水盐对幼苗根系形态的影响(表2),结果表明水分对总根长、根表面积等各个指标的影响均达到极显著(P < 0.001)。单一盐分对胡杨−胡杨组幼苗根系形态指标没有显著影响(P > 0.05),但对胡杨−柽柳组的总根长、根表面积、总根体积和根尖数的影响均达到极显著(P < 0.001),该结果表明多枝柽柳伴生下,胡杨幼苗根系形态对盐分的响应更为敏感。水盐交互作用较弱,仅对胡杨−胡杨组幼苗基径和胡杨−柽柳组幼苗根尖数有显著的影响(P < 0.05)。

表 2 不同伴生模式下水盐条件对胡杨幼苗根系形态的影响Table 2. Effects of water and salinity conditions on root morphology of P. euphratica seedlings in group P-P and P-T因子及因子

间交互作用

Factor and interaction between factorsdf 总根长

Total root length根表面积

Root surface area总根体积

Total root volume根尖数

Root tip number基径

Basal diameterP-P P-T P-P P-T P-P P-T P-P P-T P-P P-T W 2 21.566*** 22.685*** 24.951*** 22.401*** 26.058*** 19.628*** 12.405*** 20.860*** 35.513*** 31.782*** S 2 0.392 9.185*** 1.03 10.154*** 1.987 11.240*** 0.063 10.540*** 1.113 2.547 W×S 4 1.095 1.533 0.822 1.43 0.631 1.177 1.468 2.931* 4.291** 1.43 注:P-P为胡杨−胡杨组;P-T为胡杨−柽柳组。Notes: P-P, Populus euphratica seedlings neighbored by P. euphratica seedlings; P-T, P. euphratica seedlings neighbored by T. ramosissima seedlings. 2.2 胡杨幼苗根系的径级分布特征

由表3可知,当年生胡杨幼苗的绝大部分根系直径在0.5 mm以下,除胡杨−柽柳组的个别处理,该径级根长占比达到90%以上,根表面积占比超过65%,所有处理中根尖径级低于0.5 mm的比例均超过99%。而根径在0.5 mm以下的根体积占总根体积的比例除个别处理外均低于30%,表明胡杨幼苗的主根体积在总根体积中占比较大。在胡杨−胡杨组,除中水中盐(W2S2)处理根体积占比显著小于低水中盐(W1S2)组,各个指标不同水分和盐分条件下没有显著差异。胡杨−柽柳组在W1和W3条件下,幼苗根系表现出随盐胁迫程度增加,0.5 mm以下根长、根表面积、根体积占比增加的趋势。

表 3 径级为0.5 mm以下的根系占比Table 3. Root proportion of P. euphratica with diameter under 0.5 mm% 指标 Index 胡杨-胡杨组

Group P. euphratica-P. euphratica (group P-P)胡杨-柽柳组

Group P. euphratica-Tamarix ramosissima (group P-T)W1 W2 W3 W1 W2 W3 根长占比

Proportion of root lengthS1 94.84 ± 0.45Aa 93.37 ± 1.12Aa 93.11 ± 1.16Aa 89.89 ± 1.95Bb 94.18 ± 1.08Aa 94.74 ± 0.34Aa S2 93.93 ± 0.98Aa 94.77 ± 0.59Aa 95.27 ± 0.14Aa 92.89 ± 0.73Bab 95.09 ± 0.85Aa 95.08 ± 0.45Aa S3 94.24 ± 0.57Aa 93.82 ± 0.43Aa 94.64 ± 0.62Aa 95.13 ± 0.82Aa 87.92 ± 2.83Bb 95.27 ± 0.62Aa 根表面积占比

Proportion of root surface areaS1 68.50 ± 1.97Aa 66.69 ± 3.40Aa 65.46 ± 3.40Aa 57.32 ± 5.01Ab 67.66 ± 4.07Aa 67.74 ± 1.20Ab S2 68.56 ± 3.03Aa 66.85 ± 2.50Aa 70.89 ± 1.37Aa 65.01 ± 2.29Ab 71.05 ± 3.99Aa 71.64 ± 1.58Aab S3 66.29 ± 2.03Aa 65.69 ± 1.77Aa 71.20 ± 1.88Aa 78.03 ± 2.63Aa 59.40 ± 4.81Ba 73.84 ± 2.40Aa 根体积占比

Proportion of root volumeS1 22.53 ± 1.60Aa 23.33 ± 2.88Aa 20.50 ± 2.51Aa 22.15 ± 3.72Ab 26.99 ± 5.03Aa 22.40 ± 1.19Ab S2 26.22 ± 2.74Aa 19.65 ± 1.67Ba 23.03 ± 1.71ABa 27.38 ± 2.76Ab 31.89 ± 5.57Aa 28.53 ± 1.60Aab S3 21.37 ± 2.38Aa 21.22 ± 1.92Aa 24.92 ± 1.88Aa 49.38 ± 4.39Aa 28.23 ± 3.36Ba 32.70 ± 3.28Ba 根尖占比

Proportion of root tipS1 99.91 ± 0.04Aa 99.83 ± 0.03Aa 99.83 ± 0.03Aa 99.84 ± 0.04Ba 99.91 ± 0.01ABa 99.94 ± 0.01Aa S2 99.83 ± 0.17Aa 99.87 ± 0.03Aa 99.90 ± 0.02Aa 99.89 ± 0.02Aa 99.92 ± 0.01Aa 99.93 ± 0.01Aa S3 99.88 ± 0.03Aa 99.84 ± 0.02Aa 99.83 ± 0.03Aa 99.89 ± 0.02Aa 99.84 ± 0.06Aa 99.92 ± 0.02Aa 注:W1、W2、W3分别为低水、中水、高水;S1、S2、S3分别为低盐、中盐、高盐。不同小写字母(a、b)代表同一水分梯度(W)下各盐分梯度(S1、S2、S3)间有显著性差异,不同大写字母(A、B)代表同一盐分梯度(S)下不同水分梯度(W1、W2、W3)间有显著性差异,P < 0.05。Notes: W1, W2, W3 represent water condition at low, medium and high level, respectively. S1, S2, S3 represent salinity condition at low, medium and high level, respectively. Different lowercase letters (a, b) indicate significant differences among salinity conditions under the same water condition. Different uppercase letters (A, B) indicate significant differences among water conditions under the same salinity condition. 2.3 胡杨幼苗根系的形态特征

在各个水盐梯度下,胡杨−柽柳组胡杨幼苗基径均显著小于相应处理的胡杨−胡杨组幼苗(P < 0.01)(图1)。盐分及水盐交互作用对胡杨−柽柳组幼苗的基径影响均不显著(P > 0.05);对胡杨−胡杨组,单一盐分影响不显著(P > 0.05),但水盐交互作用的影响达到极显著(P < 0.01)(表2、图1)。在各水分梯度下,胡杨−胡杨组幼苗基径对盐分变化的响应不同,低水条件下基径对盐分无响应;中水条件下,高盐处理显著增加幼苗基径(P < 0.05);高水条件下,随盐分梯度升高,幼苗基径降低。所有处理中,胡杨−胡杨组高水低盐的幼苗基径达到最大,为(3.84 ± 0.18)mm。高盐条件下,胡杨−胡杨组各水分梯度间幼苗基径无显著差异,胡杨−柽柳组高水梯度下幼苗基径显著大于低水梯度下的幼苗基径(P < 0.05)。两种伴生模式下幼苗基径在低盐、中盐条件下,高水处理均显著高于对应盐分处理低水、中水条件下的幼苗基径(P < 0.05)。

![]() 图 1 水盐条件对两种伴生模式下当年生胡杨幼苗基径的影响不同小写字母(a、b)代表同一水分梯度(W)下各盐分梯度(S)间有显著性差异,不同大写字母(A、B)代表同一盐分梯度(S)下不同水分梯度(W)间有显著性差异,P < 0.05。*代表胡杨−胡杨组和胡杨−柽柳组间有显著性差异,P < 0.05,“**”、“***”分别代表P < 0.01和P < 0.001。Different lowercase letters (a, b) indicate significant differences among salinity conditions (S) under the same water condition(W). Different uppercase letters indicate significant differences among water conditions (W) under the same salinity condition (S). “*” means significant difference between group P-P and group P-T under the same water and salinity condition at P < 0.05 level, “**” means P < 0.01 and “***” means P < 0.001. The same below.Figure 1. Effects of water and salinity conditions on basal diameter of annual P. euphratica seedlings of group P-P and P-T

图 1 水盐条件对两种伴生模式下当年生胡杨幼苗基径的影响不同小写字母(a、b)代表同一水分梯度(W)下各盐分梯度(S)间有显著性差异,不同大写字母(A、B)代表同一盐分梯度(S)下不同水分梯度(W)间有显著性差异,P < 0.05。*代表胡杨−胡杨组和胡杨−柽柳组间有显著性差异,P < 0.05,“**”、“***”分别代表P < 0.01和P < 0.001。Different lowercase letters (a, b) indicate significant differences among salinity conditions (S) under the same water condition(W). Different uppercase letters indicate significant differences among water conditions (W) under the same salinity condition (S). “*” means significant difference between group P-P and group P-T under the same water and salinity condition at P < 0.05 level, “**” means P < 0.01 and “***” means P < 0.001. The same below.Figure 1. Effects of water and salinity conditions on basal diameter of annual P. euphratica seedlings of group P-P and P-T胡杨−胡杨组幼苗的总根表面积对盐分变化无明显响应(P > 0.05),而胡杨−柽柳组随盐胁迫程度增加,总根表面积减小(P < 0.05)。同一盐分条件下,两种伴生模式低水和中水处理的幼苗总根表面积之间没有差异,高水条件下幼苗的总根表面积显著高于其他两个水分梯度(P < 0.05)(表2、图2)。

总根体积的变化趋势和总根表面积类似,盐分对胡杨−胡杨组幼苗总根体积无显著影响(P > 0.05),而对胡杨−柽柳组幼苗总根体积影响显著(P < 0.001)。胡杨−柽柳组总根体积表现出随盐胁迫程度升高而下降的趋势,但在各个水分条件下均未达到显著(P > 0.05)。相同盐分条件下,两个伴生模式下低水和中水处理间均无差异,高水处理显著高于低水、中水处理(P < 0.05)(表2、图3)。

2.4 胡杨幼苗根系的功能性状

比根长和比根面积可以作为表征植物根系吸收能力的形态指标。一些研究者认为,比根面积比根生物量更能表征植物资源获取能力[19]。和胡杨组相比,胡杨−柽柳组趋向于有更大的比根面积和比根长(图4、5)。在低水、中水分条件下,两个伴生模式下比根面积和比根长对盐分变化没表现出明显的变化趋势;高水条件下,随盐分增大,胡杨−胡杨组和胡杨−柽柳组比根面积和比根长均增大。低盐条件下,胡杨−胡杨组比根面积和比根长随水分增加而减小,但中盐、高盐条件下,中水、高水处理的幼苗比根长和比根面积与低水处理相比没有显著性差异。对胡杨−柽柳组,低盐、中盐条件下,水分升高对比根面积影响不明显,高盐条件下,中水梯度比根长和比根面积显著低于低水和高水梯度(P < 0.05)。

2.5 两种伴生模式下胡杨幼苗根性状间相关性

两种伴生模式下,胡杨幼苗根系性状之间相关性基本一致。比根长和根生物量、平均直径呈显著负相关(P < 0.05),总根长与根尖数、分支数、总根体积呈极显著相关(P < 0.01)。在胡杨−胡杨组,平均直径和总根长呈显著负相关(P < 0.05),与总根体积呈显著正相关(P < 0.05),而在胡杨−柽柳组,平均直径与总根长、总根体积关系较弱(P > 0.05)。比根长在胡杨−胡杨组,与根表面积、总根体积关系不显著(P > 0.05),但在胡杨−柽柳组,与根表面积、总根体积呈极显著负相关(P < 0.01)。此外,胡杨−柽柳组比根面积与除比根长之外的各个指标呈极显著负相关(P < 0.01),而胡杨−胡杨组比根面积与总根长、根表面积、总根体积、根尖数、分支数关系不显著(P > 0.05)。

3. 讨论与结论

水分、盐分胁迫下胡杨幼苗的生长特性已经有较多的研究报道,受到干旱胁迫的条件下,胡杨幼苗株高、生物量积累、光合作用等受到抑制[24-26]。盐胁迫下胡杨幼苗的成活率和生长下降[27],光合作用受阻,根系生长和根尖数、根木质部的吸水效率显著受到抑制,幼苗株高、基径、各器官生物量和总生物量均显著降低[28-29]。但是水盐交互下当年生胡杨幼苗的生长特征研究得还比较少,种间关系对胡杨幼苗的影响也一直未受到重视。本研究采用了3个梯度的水分和盐分进行两两交互,研究两种伴生模式下胡杨幼苗根系生长对土壤水盐环境的响应,发现水分、盐分和伴生模式及其之间的交互作用对当年生胡杨实生幼苗根系的生长起到重要的影响。特别是水分和伴生模式对胡杨幼苗根系生长的影响更为关键。

3.1 水盐交互对胡杨−胡杨组幼苗根系生长的影响

水分对胡杨根系各个指标影响显著,而单一盐分对幼苗的总根长、根表面积、总根体积、基径影响均不显著,水盐交互仅对基径有显著的影响(表1、2),表明在水盐对根系生长的影响中,水分占据绝对的主导地位。这是由于胡杨幼苗对盐分有一定的耐受性[30],一些研究也表明了低盐环境能够刺激胡杨产生不定根[31]。在极端干旱区,水分才是胡杨根系生长的限制性因子。本研究中,随水分梯度升高,胡杨−胡杨组幼苗总根长、基径、根体积等指标增大,表明水分促进胡杨根系的生长,较好的水分利于当年生胡杨幼苗根系的扩展和增粗生长。

在不同水分梯度下,胡杨幼苗基径对盐分的响应有所不同(图1 ~ 3)。在低水的条件下各盐分梯度间的幼苗基径没有差异,中水的条件下,随盐胁迫程度增加而增大,在高水条件下随盐胁迫增加而降低(图1)。这种现象可能是由于低水条件下,幼苗根系生长主要受水分的限制,盐分不是限制幼苗的主要因素;中水条件下,水盐的交互对胡杨幼苗影响较大,主根增粗可能是幼苗增强抗逆性、提高适合度的形态策略;高水条件下,水分限制作用减弱,盐分成为影响胡杨幼苗根系生长的主要因素。

相关性分析表明,胡杨−胡杨组幼苗平均直径和总根长显著负相关,而和总根体积呈显著正相关(表4),结合幼苗径级分布,表明胡杨幼苗具有明显主根的特征(表3)。反映了在无异种竞争者存在的环境下,胡杨幼苗的根系扩展是通过产生大量吸收根来实现的。根系径级分布特征显示根径0.5 mm以下的根系长度占到总长的90%以上,根表面积占总根表面积65%以上,根尖占比超过99%,根体积仅占总根体积20%左右(表2),各指标不随水盐的变化而变化,表明了胡杨根系形态具有一定的保守性。在一定水盐条件范围内,生长状态不同的根系可以保持一定的根系径级数量分布特征,起固着作用的主根和主要发挥吸收功能的根系比例较为稳定,反映了胡杨幼苗对盐旱胁迫具有较强的适应性。这和Ye等人[16]的研究结果一致,根形态变化对干旱胁迫下幼苗根深增加的作用较小,幼苗根系对水分的响应可能更多反映在根系构型的变化上。

表 4 胡杨−胡杨组幼苗指标间相关性Table 4. Correlations between root traits of seedlings in group P-P指标 Index AD TRL RSA TRV Tips Forks BB SRL SRA AD 1 TRL − 0.246* 1 RSA 0.040 0.971** 1 TRV 0.208* 0.869** 0.961** 1 Tips − 0.434** 0.883** 0.789** 0.638** 1 Forks 0.194 0.954** 0.944** 0.859** 0.819** 1 BB 0.166 0.671** 0.736** 0.783** 0.552** 0.632** 1 SRL − 0.516** 0.139 0.034 0.104 0.181 0.136 − 0.472** 1 SRA − 0.247* 0.081 0.039 0.034 0.034 0.101 − 0.500** 0.939** 1 注:AD为平均直径;TRL为总根长;RSA为根表面积;TRV为总根体积;Tips为根尖数;Forks为分支数;BB为根生物量;SRL为比根长;SRA为比根面积。*代表显著相关,P < 0.05,**代表极显著相关,P < 0.01。下同。Notes: AD, average diameter; TRL, total root length; RSA, root surface area; TRV, total root volume; Tips, root tip number; Forks, fork number; BB, belowground biomass; SRL, specific root length; SRA, specific root area. * means correlation is significant at P < 0.05 level; ** means correlation is extremely significant at P < 0.01 level. The same below. 3.2 多枝柽柳对不同水盐条件下胡杨幼苗根系生长的影响

有研究表明,根系竞争在植物种间竞争中具有外显性,无论地上部分竞争存在与否,根系竞争的存在都具有明显的竞争效应[32]。本研究结果表明,胡杨根系的生长受到伴生多枝柽柳的强烈抑制,在任何一个水盐梯度上,两种伴生模式下胡杨幼苗在总根长、总根体积、总根表面积都有极显著的差异(P < 0.01)(图1 ~ 3),表明种间竞争对胡杨根系伸长生长、生物量积累有显著的负效应。

在多枝柽柳的伴生下,当年生胡杨幼苗根系对水盐的响应方式发生改变,表现为幼苗总根长、总根体积、根表面积和根尖数对盐的响应更敏感(表2)。径级分布特征也显示,胡杨−柽柳组幼苗根径低于0.5 mm的根系根长、根表面积和根体积占比对水盐变化响应敏感(表3、图2 ~ 3),仅基径对盐分变化无响应(表2、图1)。本研究结果表明,种间竞争对胡杨幼苗根系形态产生的影响比土壤水盐环境更为显著。多枝柽柳伴生的条件下,根系生长在获取资源和防御之间进行权衡,而造成根系形态调整[33],这可能是胡杨幼苗应对种间竞争提高适合度的策略。

然而幼苗对土壤盐分变化响应敏感,也表明了胡杨幼苗抗逆性减弱。胡杨幼苗在面对来自多枝柽柳的种间竞争时,比根长、比根面积增大。较大的比根长和比根面积表明,单位质量的根系有较大的总根长和根表面积,因此对应较高的水分和养分吸收效率。但结合本实验幼苗正常发育受阻的结果,多枝柽柳竞争下胡杨幼苗比根长、比根面积增大,也表明了幼苗木质化过程受到抑制。研究表明,根系营养状况对比根长有重要的影响,营养状况较好的幼苗倾向有更低的比根长[34]。胡杨−胡杨组的幼苗比根长与根表面积、总根体积无显著相关性,而胡杨−柽柳组的比根长和根表面积、总根体积呈极显著负相关(表4、5)。表明较大的比根长可能是柽柳的竞争导致胡杨幼苗根直径减小,根系强度降低的结果[35-36],即种间竞争使胡杨幼苗根系木质化程度降低,而木质化程度与胡杨当年生幼苗越冬存活息息相关[37]。根系的适应性是影响胡杨幼苗定居和生长的首要因素[7],本研究结果表明,种间竞争可能使野外的胡杨通过实生苗进行更新变得更加困难。

表 5 胡杨−柽柳组幼苗指标间相关性Table 5. Correlations between seedling root indices in group P-T指标 Index AD TRL RSA TRV Tips Forks BB SRL SRA AD 1 TRL 0.184 1 RSA 0.085 0.989** 1 TRV 0.031 0.953** 0.986** 1 Tips − 0.232* 0.974** 0.956** 0.912** 1 Forks 0.196 0.984** 0.965** 0.922** 0.959** 1 BB 0.000 0.895** 0.921** 0.930** 0.881** 0.897** 1 SRL − 0.710** − 0.194 − 0.281** − 0.369** − 0.172 − 0.177 − 0.401** 1 SRA − 0.512** − 0.298** − 0.363** − 0.431** − 0.302** − 0.289** − 0.503** 0.938** 1 目前对种间关系的研究普遍认为,干旱区植物趋向于通过根系生态位的分离来减少竞争,实现互惠共存[18, 38],即支持“环境梯度胁迫假说”[39]。但本研究发现,在不同的环境梯度下,多枝柽柳与胡杨当年生幼苗的种间竞争对胡杨根系的生长产生了强烈的负效应,表现出胡杨幼苗受到多枝柽柳幼苗的竞争排斥,但是种间竞争影响胡杨幼苗根系生长的机制目前还不清楚。很多研究都表明植物的根系具有识别同种和异种根系的能力,并会对此产生不同的响应[40],胡杨根系生长受限是由于种间竞争导致胡杨对限制性资源的获取减少(竞争性抑制),还是由于多枝柽柳根系的化感作用[41],本实验没有进行探究,两者互作的地下生态过程还需要进一步的研究。

-

表 1 新型单板层积材所制木质托盘的参数

Table 1 Parameters of the NLVL-made pallet

名称 Name 数量 Number 尺寸 Dimension 面板 Top deckboard 7 1 200 mm × 90 mm × 13 mm 纵板 Stringer board 3 1 000 mm × 90 mm × 13 mm 底板 Bottom deckboard 3 1 200 mm × 90 mm × 13 mm 垫块 Block 9 90 mm × 90 mm × 87 mm 表 2 新型层积材NLVL和杨木材料的弹性常数

Table 2 Elastic constants of the NLVL and poplar wood

试样 Sample 泊松比 Poisson’s ratio 弹性模量 Elastic modulus/Pa 剪切模量 Shear modulus/Pa y-x z-x y-z x y z y-x z-x y-z NLVL 0.305 0.331 0.315 1.23e10 7.97e9 5.44e9 2.95e9 3.41e9 4.68e9 杨木 Poplar 0.660 0.660 0.400 5.35e9 1.04e9 1.21e9 4.66e8 6.2e8 9.4e7 注:NLVL的z-x平面的泊松比数据引自文献[18]。杨木的弹性常数数据引自文献[19]。Notes: Poisson’s ratio of the NLVL on z-x plane was cited from reference [18]. Elastic modulus of the poplar was cited from reference [19]. 表 3 NLVL板材在最大破坏应力(1 056 N)时的变形量

Table 3 Deformations of NLVL at maximum damage stress of 1 056 N

测试条件 Test condition 变形量 Deformation/mm 静力测试 Static experiment 8.90 Solid 185单元模型 Solid 185 unit 7.69 Layer 46单元模型 Layer 46 unit 32.16 表 4 NLNL托盘的整体抗压、底板抗压、面板抗压实验测试结果

Table 4 Experimental results of compression test of NLVL-made pallet

抗压测试

Compression testing载荷

Load条件

Condition变形量 Deformation/mm 阶段1

Stage 1阶段1

Stage 1力卸载30分钟后

30 min after unload整体 Overall 3P ISO标准 ISO standard < 4 < 4 < 3 实验结果 Experimental result 3.27 3.40 1.10 底板 Bottom deckboard 2P ISO标准 ISO standard < 30 < 30 < 6 实验结果 Experimental result 27.42 26.66 1.05 面板 Top deckboard 2P ISO标准 ISO standard < 30 < 30 < 6 实验结果 Experimental result 29.65 28.30 1.40 注:ISO标准为ISO 8611—2011标准; P为托盘的设计载荷,1 100 kg。Notes: ISO means ISO 8611-2011 standard; P means the design load of pallet, 1 100 kg. -

[1] 于文吉, 张亚慧. 结构用单板类人造板的应用及发展[J]. 木材工业, 2016, 30(2):48−50. doi: 10.3969/j.issn.1001-8654.2016.02.013 Yu W J, Zhang Y H. Application and development of veneer-based structural panels[J]. China Wood Industry, 2016, 30(2): 48−50. doi: 10.3969/j.issn.1001-8654.2016.02.013

[2] 潘景龙, 祝恩淳. 木结构设计原理[M]. 北京: 中国建筑工业出版社, 2009. Pan J L, Zhu E C. Design priciples of timber structures[M]. Beijing: China Architecture and Building Press, 2009.

[3] 陈剑平, 张建辉. 国内外单板层积材应用现状[J]. 林业机械与木工设备, 2012, 40(8):12−13. doi: 10.3969/j.issn.2095-2953.2012.08.005 Chen J P, Zhag J H. Application situation of LVL at home and abroad[J]. Forestry Machinery & Woodworking Equipment, 2012, 40(8): 12−13. doi: 10.3969/j.issn.2095-2953.2012.08.005

[4] 张训亚, 殷亚方, 姜笑梅. 两种无损检测法评估人工林杉木抗弯性质[J]. 建筑材料学报, 2010, 13(6):836−840. doi: 10.3969/j.issn.1007-9629.2010.06.027 Zhanng X Y, Yin Y F, Jiang X M. Evalution of bending properties of Chinese fir plantation by two nondestructive testing methods[J]. Journal of Building Materials, 2010, 13(6): 836−840. doi: 10.3969/j.issn.1007-9629.2010.06.027

[5] 张顺庆, 高晨家, 张龙. 数字图像相关技术在应力应变测量中的发展与最新应用[J]. 影像科学与光化学, 2017, 35(2):193−198. doi: 10.7517/j.issn.1674-0475.2017.02.193 Zhang S Q, Gao C J, Zhang L. The development and latest applications of digital image correlation in stress and strain measurement[J]. Imaging Science and Photochemistry, 2017, 35(2): 193−198. doi: 10.7517/j.issn.1674-0475.2017.02.193

[6] Chen H, Chen G, Ye D, et al. 3D deformation measurement by digital speckle correlation method and stereo vision[C]// International Symposium on Advanced Optical Manufacturing and Testing Technologies: Optical Test and Measurement Technology and Equipment. International Society for Optics and Photonics, Chengdu: Proc. SPIE 6723, 2007. https://doi.org/10.1117/12.783189

[7] 石立万, 王端宜, 吴文亮, 等. 基于数字图像处理的沥青混合料骨架研究[J]. 建筑材料学报, 2016, 19(4):767−772. doi: 10.3969/j.issn.1007-9629.2016.04.028 Shi L W, Wang D Y, Wu W L, et al. Study of asphalt mixture skeleton based on digital image processing[J]. Journal of Building Materials, 2016, 19(4): 767−772. doi: 10.3969/j.issn.1007-9629.2016.04.028

[8] 孙艳玲, 赵东, 高继河. 数字散斑相关方法在木材断裂力学上的应用分析[J]. 北京林业大学学报, 2009, 31(增刊1):206−209. Sun Y L, Zhao D, Gao J H. Application of digital speckle correlation method in wood fracture mechanics[J]. Beijing Forestry University, 2009, 31(Suppl.1): 206−209.

[9] 刘嘉新, 周伟, 李超. 基于有限元的原木横切面应力波振动特性的研究[J]. 林业工程学报, 2018, 3(6):19−24. Liu J X, Zhou W, Li C. Stress wave vibration characterization of cross section of log using finite element method[J]. Journal of Forestry Engineering, 2018, 3(6): 19−24.

[10] 李雪梅. 基于有限元法木材力学性能模拟及优化设计研究[D]. 呼和浩特: 内蒙古农业大学, 2009. Li X M. Research on mechanical property simulation of timber with finite element method and optimization of timber[D]. Huhhot: Inner Mongolia Agriculture University, 2009.

[11] Meng M, Le H R, Rizvi M J, et al. 3D FEA modelling of laminated composites in bending and their failure mechanisms[J]. Composite Structures, 2015, 119: 693−708. doi: 10.1016/j.compstruct.2014.09.048

[12] Wang A S D, Crossman F W. Some new results on edge effect in symmetric composite laminates[J]. Journal of Composite Materials, 1977, 11(1): 92−106. doi: 10.1177/002199837701100110

[13] Tang S, Levy A. A boundary layer theory. (part ii): extension of laminated finite strip[J]. Journal of Composite Materials, 1975, 9(1): 42−52. doi: 10.1177/002199837500900105

[14] Masood S H, Song W Q. Development of new metal/polymer materials for rapid tooling using Fused deposition modelling[J]. Materials & Design, 2004, 25(7): 587−594.

[15] Masood S H, Rizvi S H. An investigation of pallet design using alternative materials for cold room applications[J]. International Journal of Advanced Manufacturing Technology, 2006, 29(1−2): 1−8. doi: 10.1007/s00170-004-2485-9

[16] 李霞镇, 徐明, 蔡芸, 等. 电测法测试结构用重组竹弹性常数的研究[J]. 安徽农业大学学报, 2015, 42(5):756−760. Li X Z, Xu M, Cai Y, et al. Determination of elastic constants of recombinant bamboo for structural material using an electrical measurement method[J]. Journal of Anhui Agricultural University, 2015, 42(5): 756−760.

[17] 康柳, 储德淼, 赵美霞, 等. 托盘用人造板弹性模量与强度的相关关系[J]. 包装工程, 2016, 37(21):110−114. Kang L, Chu D M, Zhao M X, et al. Relationship between MOE and MOR of wood composite panel used in trays[J]. Packaging Engineering, 2016, 37(21): 110−114.

[18] 黄先宝, 卫佩行, 王泉中. 高频热压杨木单板层积材纵向弹性模量和泊松比的测定与分析[J]. 包装工程, 2013, 34(5):1−4. Huang X B, Wei P X, Wang Q Z. Measurement and analysis of longitudinal elastic modulus and Poisson’s ratio of high frequency hot pressing poplar laminated veneer lumber[J]. Packaging Engineering, 2013, 34(5): 1−4.

[19] 荣向吴. 木材的弹性与粘弹性[D]. 合肥: 安徽农业大学, 2008. Rong X W. Wood elasticity and viscoelastic[D]. Hefei: Anhui Agricultural University, 2008.

[20] 钟永, 邢新婷, 任海青, 等. 结构用单板层积材的斜纹承压力学性能[J]. 建筑材料学报, 2014, 17(1):115−119. doi: 10.3969/j.issn.1007-9629.2014.01.021 Zhong Y, Xing X T, Ren H Q, et al. Properties of structural laminated veneer lumber in compression at an angle to grain[J]. Journal of Building Materials, 2014, 17(1): 115−119. doi: 10.3969/j.issn.1007-9629.2014.01.021

[21] 张宏健, 陈琦, 文天国, 等. 机械应力式人造板质量在线无损检测技术的研发和应用[J]. 林产工业, 2007(6):33−35. doi: 10.3969/j.issn.1001-5299.2007.06.009 Zhang H J, Chen Q, Wen T G, et al. Development and application of the mechanical stress type on-line non-destructive testing system for wood-based panel[J]. China Forest Products Industry, 2007(6): 33−35. doi: 10.3969/j.issn.1001-5299.2007.06.009

-

期刊类型引用(3)

1. 梅诗意,李瑜,李士帅,朱怡宁,何金春,孟鑫淼,高颖. 寒冷地区多层轻型木结构墙体热湿性能试验研究. 北京林业大学学报. 2022(06): 135-145 .  本站查看

本站查看

2. 代倩,胡家航,姬晓迪,郭明辉. 建筑用集成材制造技术的环境效能影响. 林业工程学报. 2018(04): 46-50 .  百度学术

百度学术

3. 杨俊霞,邹惠芬. 木结构建筑节能技术研究. 西部皮革. 2018(08): 48 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: