Abrasive belt wear mechanism of sanding Manchurian ash

-

摘要:目的砂带磨削是木材加工行业的一项重要工艺。分析砂带磨削过程中的砂带磨损机理及其对材料去除率、磨削表面质量的影响,旨在进一步完善木材切削理论,推动新型砂带研发制造。方法本研究以水曲柳为实验材料,通过测定磨削过程中的试件质量变化和表面形貌,就砂带磨损对试件材料去除率和表面粗糙度的影响进行分析,结合试件材料去除率、磨削过程中砂带的质量变化和表面形貌探究砂带的磨损机理,并采用灰色模型预测磨削长度与材料去除率、磨削表面粗糙度之间的定量关系。结果横纹磨削时,材料去除率整体大于顺纹磨削的材料去除率。整体而言,材料去除率与砂带质量随磨削次数的增加而不断减小,试件表面粗糙度呈先增大后减小的趋势。磨削过程中,砂带磨粒出现磨损、破碎以及脱落的现象,造成砂带质量不断减小,磨粒等高性逐渐增加。顺纹方向磨削对砂带磨粒的磨损大于横纹方向磨削。磨粒磨损程度越大,材料去除率越小。当材料去除率降低至3%时,可认为已基本达到砂带使用寿命。结论磨削过程中,等高性越差,材料去除率越高。随磨削次数增加,砂带材料去除能力不断下降,试件表面粗糙度则呈先增大后减小的趋势。均值GM(1,1)灰色预测模型的平均模拟相对误差都在20%以内,适用于水曲柳砂带磨削过程中磨削长度与材料去除率、表面粗糙度之间的预测。Abstract:ObjectiveSanding is a high-precision and efficient wood material processing technology. The study analyzed the wear mechanism of the abrasive belt during the sanding process and explored the effects of abrasive belt wear on the material removal rate and the sanded surface quality. And the aim is to further improve the basic theory of wood cutting and the development of advanced belt manufacturing technology, so as to realize the intelligence and automation of wood processing.MethodIn this research, Manchurian ash (Fraxinus mandshurica) was used as experimental material. In order to analyze the effect of abrasive belt wear on material removal rate and surface roughness, the mass change and the surface morphology of the test piece were measured experimentally. The wear mechanism of the abrasive belt was explored by calculating the material removal rate and measuring the surface topography of the abrasive belt. In addition, the grey model was used to predict the quantitative relationship between sanding length and material removal rate, and also surface roughness.ResultDuring transverse sanding process, the material removal rate was less than that of longitudinal sanding. Overall, the material removal rate and the quality of abrasive belt decreased with the increase of sanding times, and the surface roughness of the workpiece increased first and then decreased. During the sanding process, abrasive grains of abrasive worn, broken and peeled off, which resulted in the mass of abrasive belt decreasing and the height of abrasive grains tending to be the same.ConclusionIn the sanding process, the abrasive wear caused by transverse sanding is greater than that caused by longitudinal sanding, and the material removal rate decreases with the increase of abrasive wear. When the material removal rate is reduced to 3%, it can be considered to end the service of the abrasive belt, which means the abrasive belt should be replaced in time. In the sanding process, the worse the contour of abrasive particles is, the higher the material removal rate is. With the increase of sanding times, the removal capacity of abrasive belt material decreases. The relative error of predictive average simulation using grey model mean GM (1,1) is within 20%, so it is suitable for predicting the relationship between sanding length and material removal rate, and also surface roughness in the process of sanding Manchurian ash.

-

Keywords:

- sanding /

- abrasive wear /

- material removal rate /

- surface roughness /

- grey prediction model

-

磨削是木材加工中必不可少的重要工序,所用磨具大多为砂带,主要用于工件定厚和表面抛光。砂带磨削具有“冷态磨削”和“弹性磨削”的特点,是一种高精度、高效率、低成本的加工技术。材料去除率和表面粗糙度作为最常用的砂带磨削性能指标,是衡量砂带磨削效率、砂带寿命,以及评定加工质量的重要指标。材料去除率是指磨削过程中砂带在单位时间内去除被磨削材料的质量百分比,该指标直接影响到工件的定厚效果和表面粗糙度。影响砂带材料去除率的主要因素有砂带制造工艺、砂带目数、磨削压力、磨削速度和磨削延续长度。任青剑等[1]进行了300M超高强度钢的切入式磨削实验,发现在微观形貌方面,磨粒间距较大的砂带多是因磨粒磨损而失效,这是磨削效率降低的一个原因,但针对磨削效率降低的其他原因及其影响因素的探究仍然不够深入。Torrance[2]建立了磨料磨损模型,并将该方法应用于磨削过程中磨削力和金属材料去除率之间关系的预测以及磨料劣化的预测中。由于木材种类繁多,各项性质差异较大,此模型在木材磨削领域的应用存在局限性,仍需进一步研究探索。表面粗糙度的影响因素主要是关于木材特性的,包括纹理、密度、含水率等。刘博等[3]研究发现磨削表面质量会受到木材材性和加工工艺等因素的影响。Tian等[4]使用磨削效率测试系统和表面粗糙度测量仪进行磨削实验,分析比较了3种试材磨削效率和表面粗糙度的变化规律以及相关因素对磨削效率和表面粗糙度的影响,结果表明:磨削效率与表面粗糙度的变化趋势是随磨削次数的增加而逐渐降低,且同一树种、相同的磨削次数下,横向磨削时的磨削效率高于纵向磨削时的磨削效率。该实验在较为宏观的层面下进行探讨,缺乏对于砂带与试件表面微观形貌的进一步研究与分析。

砂带在磨削材料过程中将不可避免地产生磨损,且砂带的磨损是多个因素共同作用的结果,如磨削压力、砂带速度、工件材料等,在磨削不同材料或不同的磨削条件下的砂带磨损形式也会有差异。Ferguson等[5]在进行磨料磨损实验时,通过改变磨料磨粒尺寸、磨削压力、滑动速度和滑动距离来评估复合材料的磨损率。Malinov等[6]发现随着磨削压力的增加,Fe-B合金的耐磨性降低,磨损机制从微切割变为微切割和微耕的混合模式。在实际生产中,砂带生产厂家无法提供准确的砂带使用寿命,多依赖熟练工人的经验来判别砂带的使用寿命,这在一定程度上影响企业的生产效率和经济效益。随着人工智能和传感技术的发展,木材加工智能化已成为重要的发展方向,智能化控制一方面是提高机械设备的智能化控制程度,更重要的一方面是使切削(包括磨削)过程和结果可控,也就是根据要求达到相应的材料去除效率和表面加工质量[7]。比如美国将砂带磨削应用于汽车制造业的FMS生产线上,从磨削过程和设备控制两方面共同调控以达到最终的生产过程智能化。美国3M公司发明的微晶复制砂带使磨粒形状细致均匀且统一,使得磨削过程变得更加精密和高效[8]。

有关木材磨削方面的研究基础较为薄弱,而金属磨削理论并不完全适用于木材,对于木材砂带磨损和磨削效率方面的研究则是少之又少,砂带磨损机理也尚不明晰,这严重阻碍了木材加工技术和砂带制造技术向高效智能方向的发展。针对以上问题,本研究对水曲柳试件开展砂带磨削实验,分析砂带磨损机理及磨粒磨损对材料去除率和表面粗糙度的影响,进一步完善木材磨削理论,并为发展适用于木材的砂带磨削技术提供理论支持。

1. 材料和方法

1.1 材 料

水曲柳(Fraxinus mandshurica)材质坚韧致密,富弹性,纹理通直,刨面光滑,胶接、油漆性能较好,具有良好的装饰性能,在建筑、飞机、造船、仪器、运动器材、家具等行业应用广泛,因此本研究选用水曲柳作为实验材料,其气干密度为0.76 g/cm3,含水率为5.41%。制备的试件尺寸为46 mm(长) × 46 mm(宽) × 24 mm(厚);所有试件取自边材,表面平整,无明显缺陷。本研究所选用砂带为60目普通布基疏植砂型砂带(JW342,DEER,韩国)。

1.2 研究方法

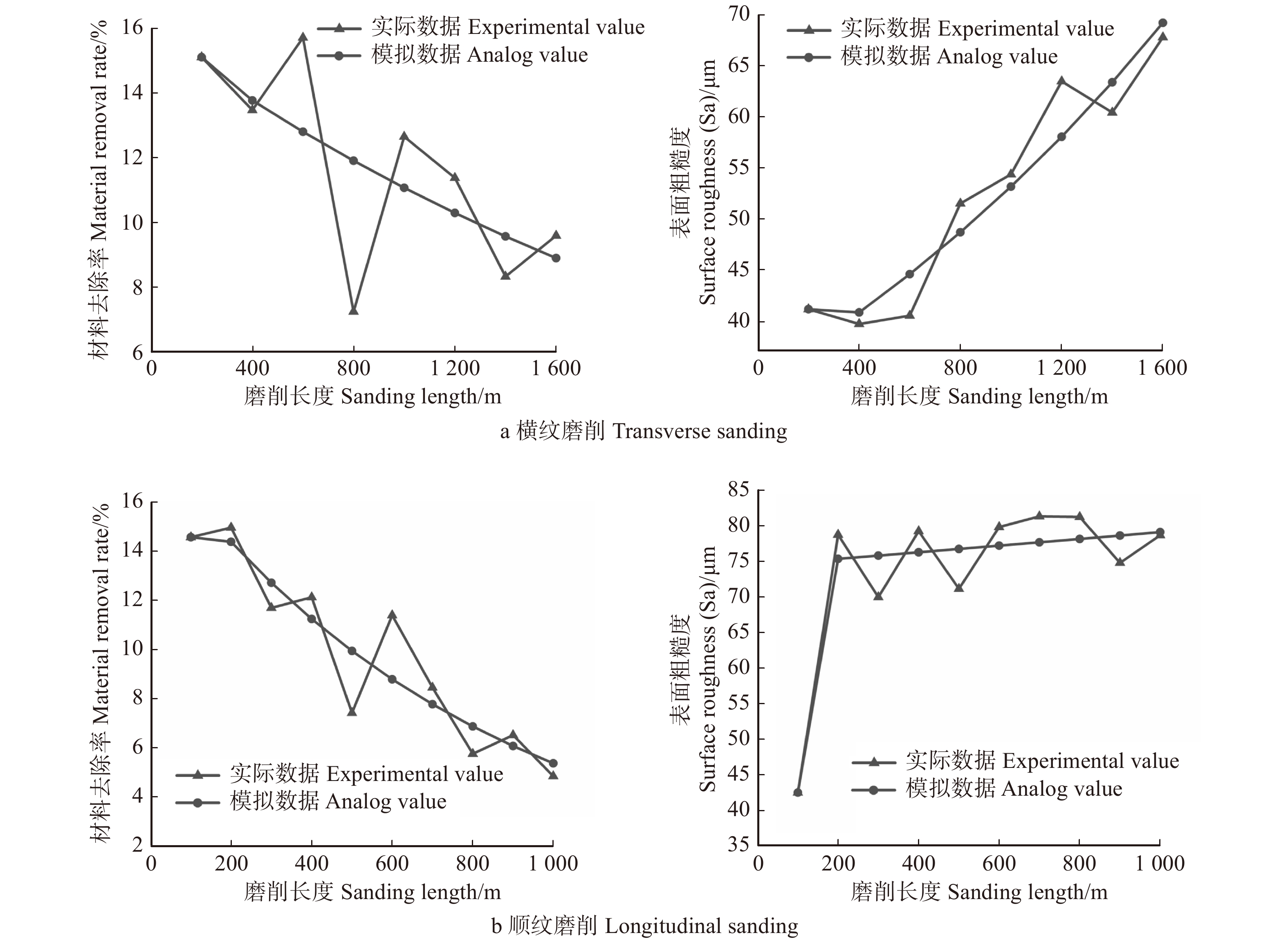

1.2.1 砂带磨削实验装置

本研究所使用的实验装置如图1所示。该装置主要由使工作平台作直线往复运动的驱动系统和提供恒定磨削压力的气动装置组成。将砂带展平放置在工作平台上,调节两端的张紧轮,确保砂带张紧固定;将木制试件放置于夹具内,调节夹紧螺母完成试件的装夹;通过立式布置的带直线导轨的气缸(ADNGF-50-40-A,FESTO,德国),为试件提供恒定的磨削压力(约为100 N);随着试件材料不断去除,其厚度也逐渐减小,试件夹具可沿立式滑轨在气缸导杆行程内下移,使试件与砂带表面始终相接触;驱动系统带动工作平台沿水平滑轨作往复直线运动(平均速度约为0.3 m/s),同时智能计数装置完成磨削次数记录。

1.2.2 材料去除率表征及表面形貌分析

在本研究中,材料去除率定义为每磨削1 000次后试件的质量变化率。每磨削一次则磨削长度为50 mm,可将磨削次数累计与磨削长度进行换算。实验过程中,采用精密分析天平(BSA4235,Sartorious,德国)对试件和砂带进行称重,且每次称重前使用高压气枪(额定压力为3.0 MPa)去除试件和砂带表面的磨屑,进而计算相应的材料去除率和砂带的质量变化情况,直至材料去除率降至3%以内,认为此时砂带寿命已达极限,砂带上的磨粒已无法完成对试件材料的有效切除。采用3D轮廓仪(VR5000,KEYENCE,日本)对磨削过程中试件磨削表面和砂带表面进行扫描,再通过专业分析软件(VR Series version 3.2.0.277)测定试件磨削表面以及砂带的表面粗糙度,并使用扫描电子显微(日立S-3400N Ⅱ)对试件的磨削表面形貌进行分析。实验中对水曲柳分别进行顺纹磨削(磨削方向平行于木材纹理方向)和横纹磨削(磨削方向垂直于木材纹理方向)。

2. 结果与讨论

2.1 横纹磨削

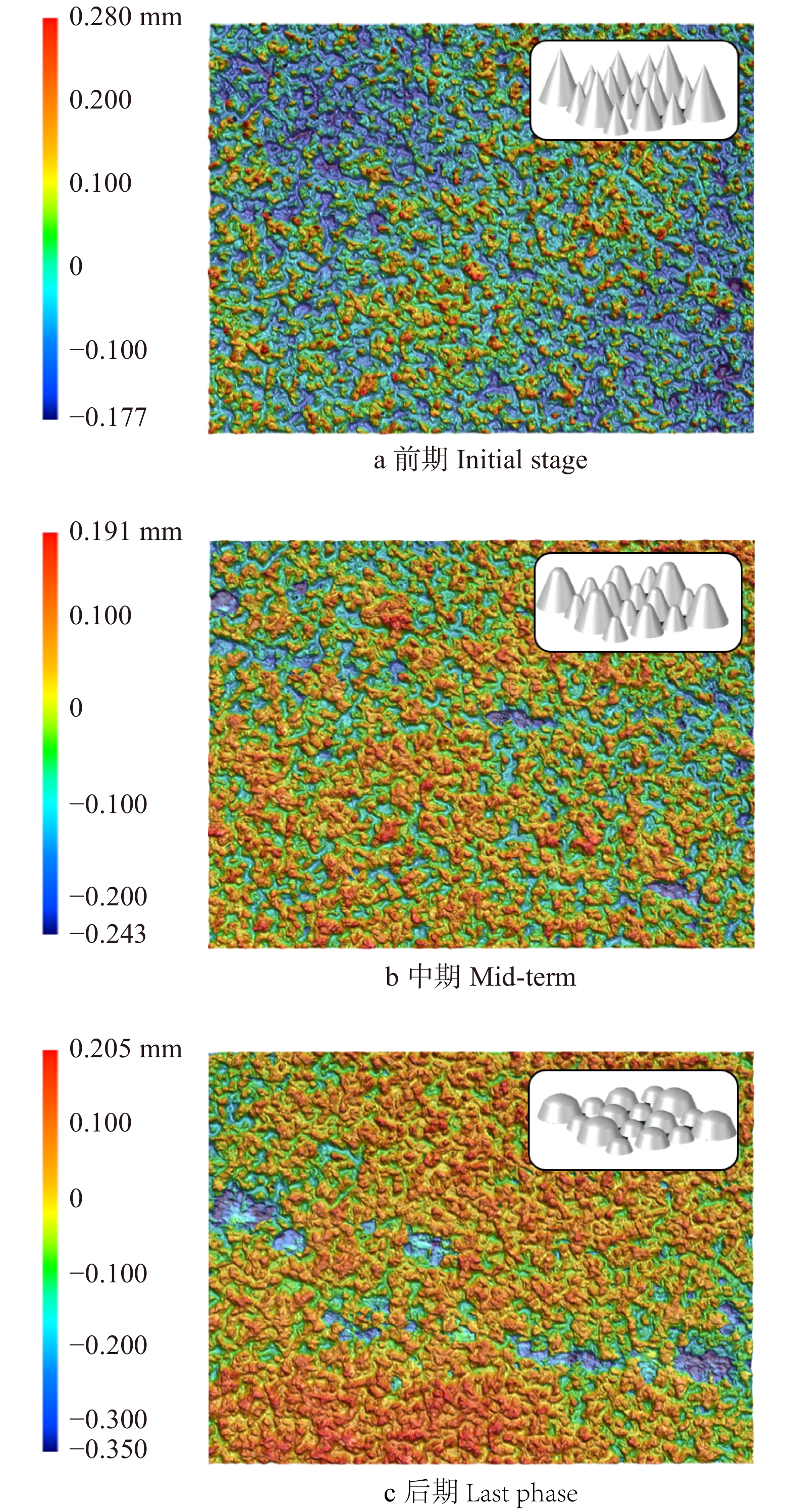

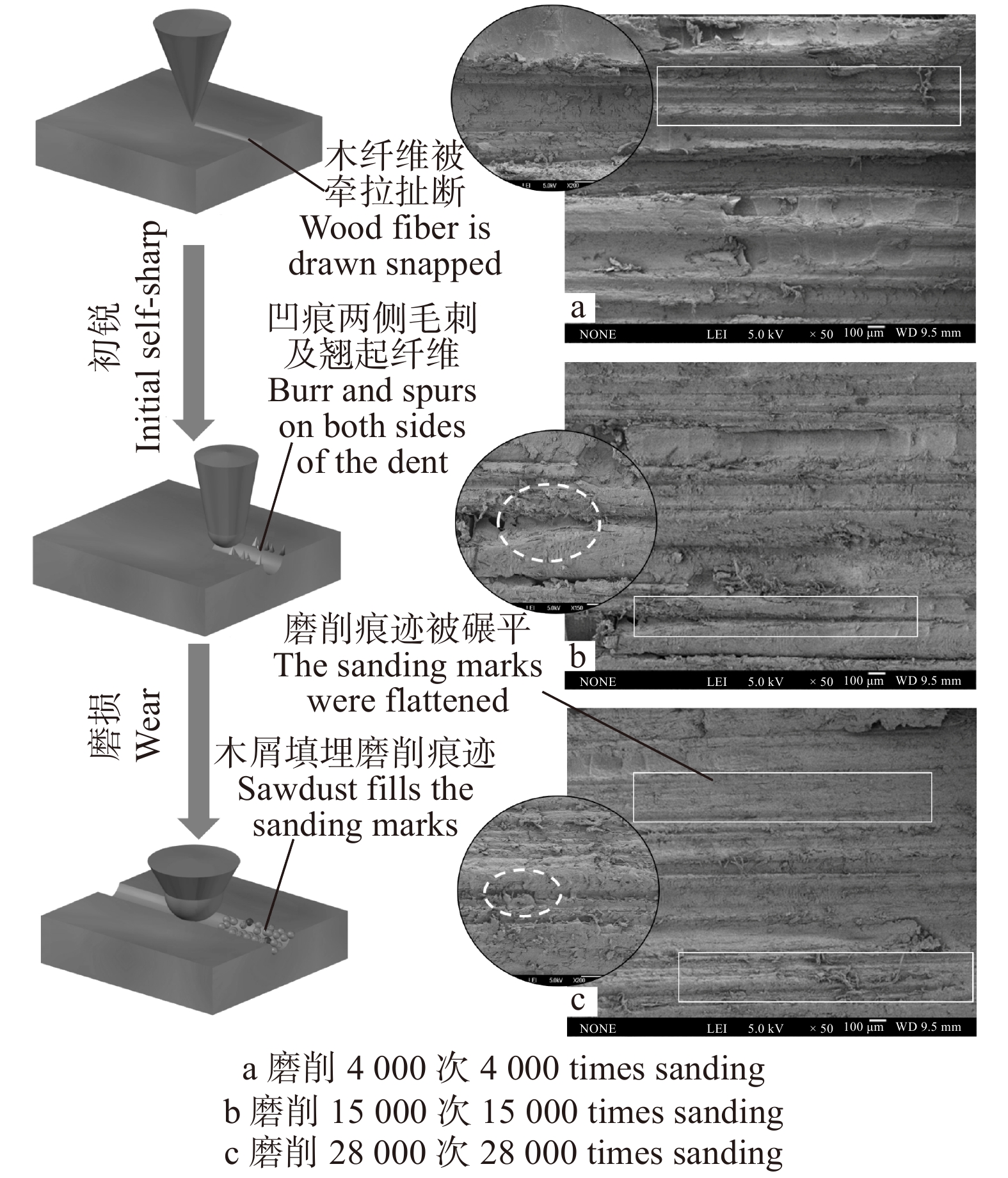

横纹磨削时,磨粒的切削方向与木材纤维方向基本垂直,磨粒多呈负前角或小后角,锋利的刃口将木材纤维拦腰截断,木材纤维基本上以剥离的形式去除[9-10]。观察发现图2a中有较多细窄且清晰的单个磨粒磨削痕迹,而图2b、2c中这种磨削痕迹则逐渐减少,直至较宽的磨削痕迹占绝大多数。由于现有的磨粒制备技术及植砂工艺,新砂带上的磨粒等高性不好,如图3a所示,切削刃曲率半径很小且参差不齐,所以磨削初期会在试件表面上留下细窄、清晰的磨削痕迹。

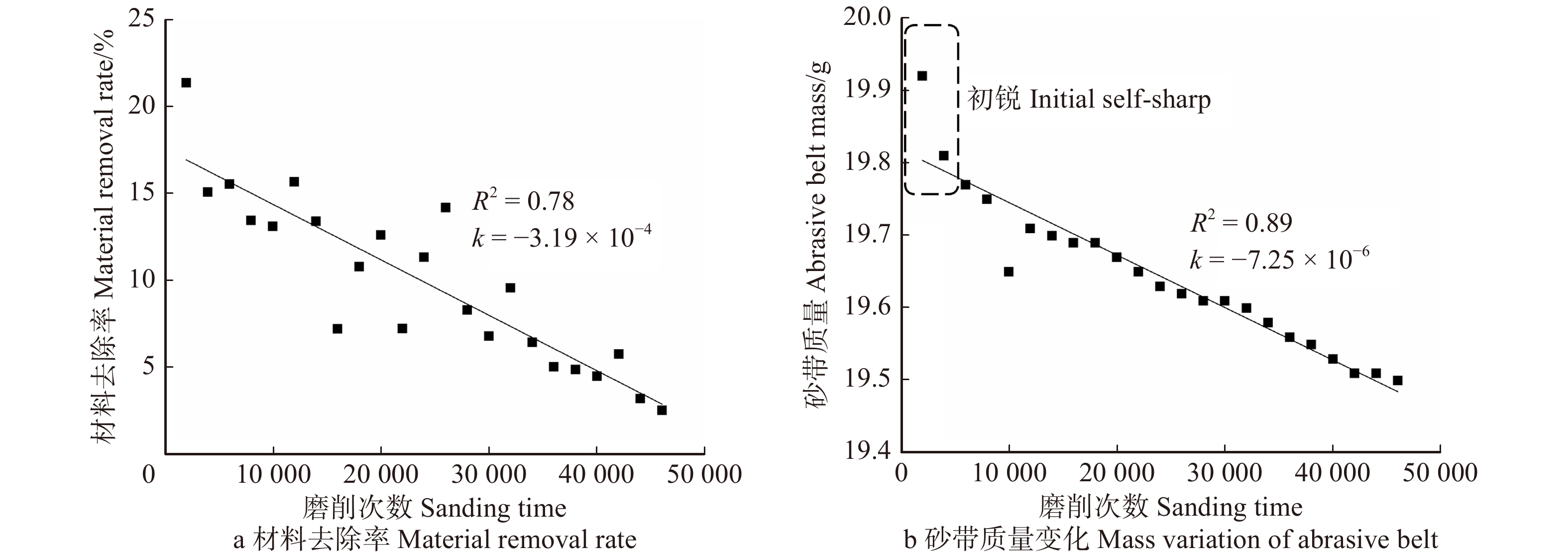

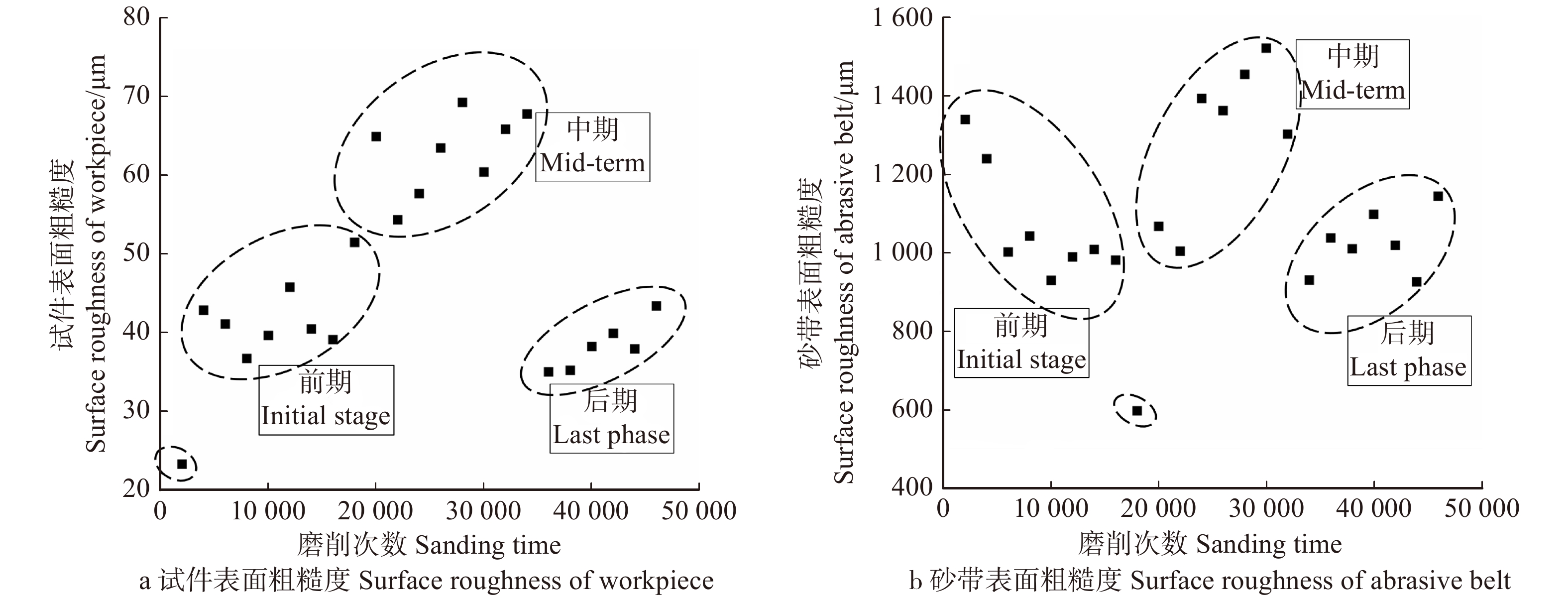

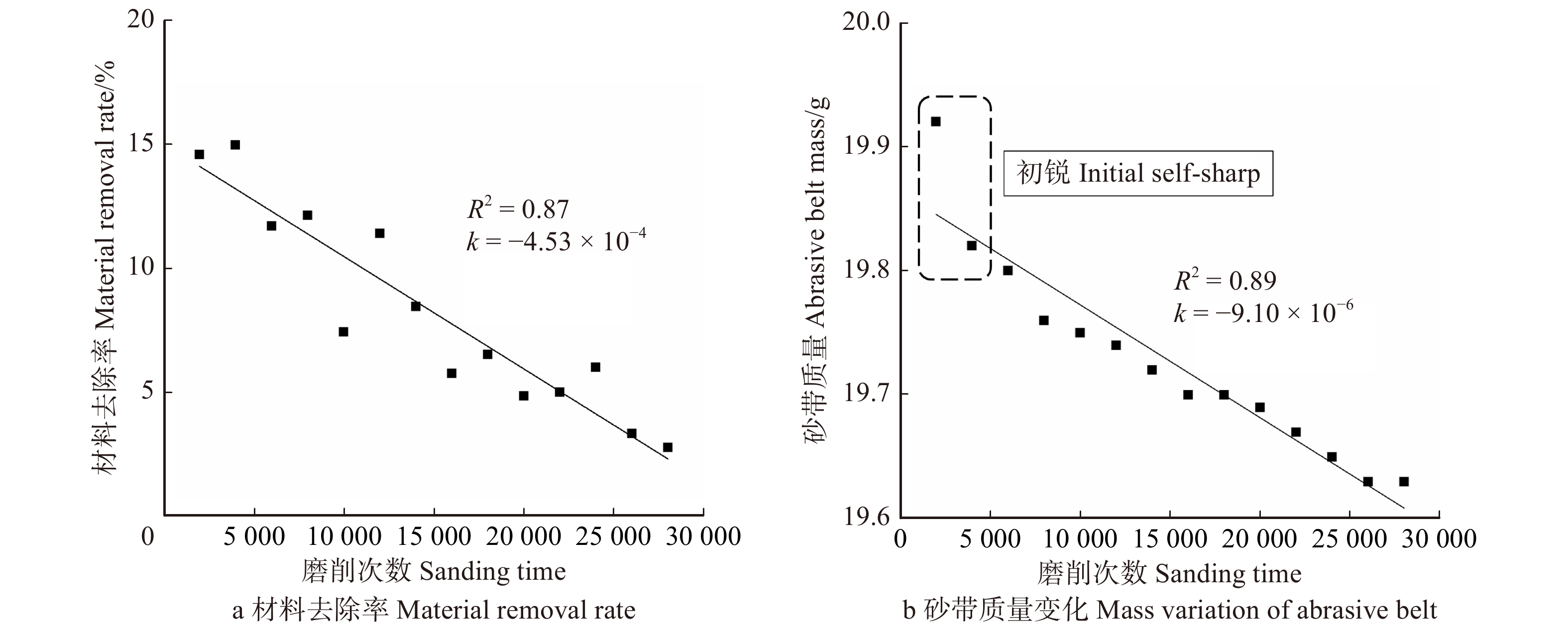

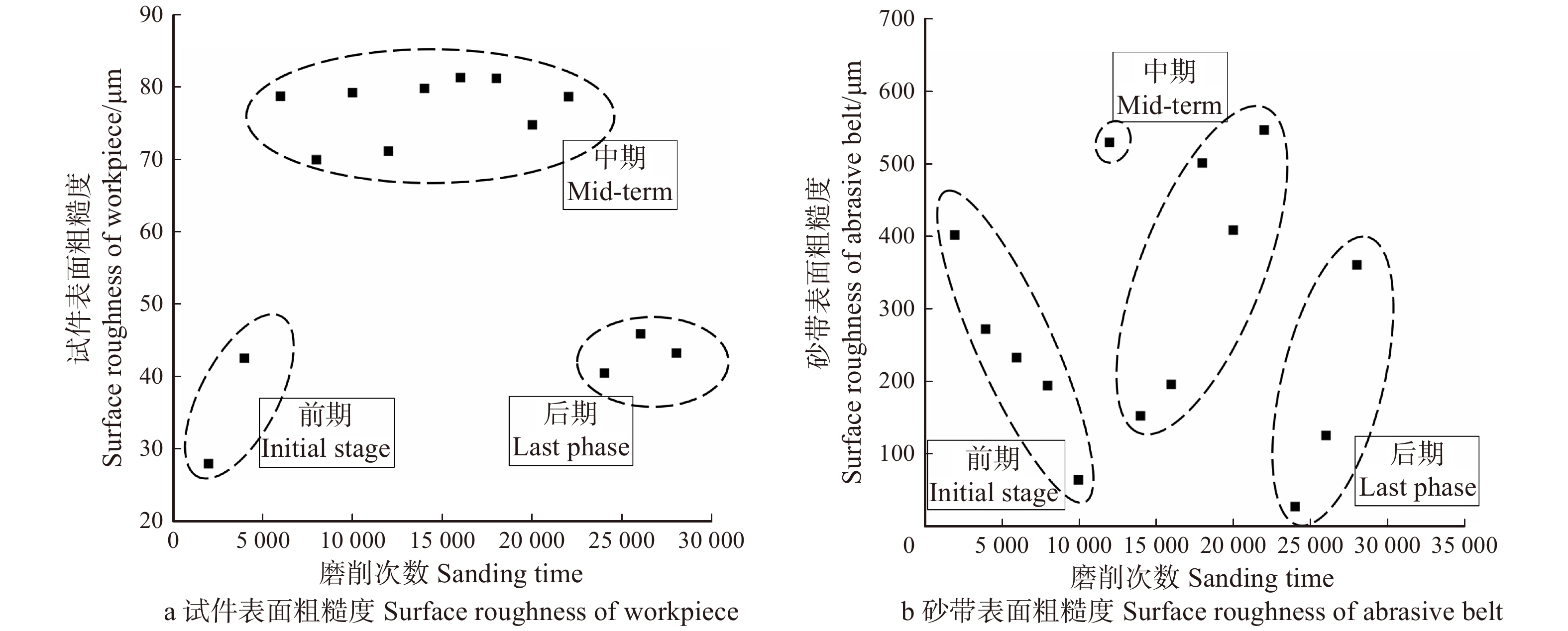

随着磨削次数增加,高度较高的磨粒由于与试件接触深度加大,会首先发生破碎和脱落,这也就是所谓的“初锐阶段”[11]。从图4b中明显看出,初锐阶段大约在磨削次数5 000次以内,砂带上的磨粒在发生脱落和破碎之外,磨粒的磨损也同时发生,此时砂带质量减小的速率较快,只是砂带脱落、破碎和磨损所占比例不同。图5b中对应的砂带表面粗糙度较高,即磨粒高度之间差异较大,所以更易压入试件进行磨削,故此时对应图4a处材料去除率极高。

初锐阶段结束后,在图3b中可观察到砂带表面相同高度磨粒的个数明显增加,主要由于试件与磨粒之间的相互作用使得磨粒尖端钝化为小平面,其等高性变好且高度变矮,材料去除率会随之下降。此时磨粒协同干涉作用逐渐显著,从图2b中可以看出在一条较宽的磨削痕迹中有许多条细小的磨削痕迹,但是并没有非常明显且完整的单个磨粒的磨削痕迹,这是由于前一个磨粒所产生的磨削痕迹会被后续的磨粒进行进一步“加工”,而最终体现出来的磨削痕迹是众多磨粒共同作用的效果,消除了之前单个磨粒的磨削痕迹,使磨削痕迹的界限变得模糊,这种多磨粒干涉效应[12]也是使工件表面变光滑的最关键因素。

随着磨削阶段到达中、后期,从图2c中可以看出磨粒将木纤维从两侧挤出翘起,在试件表面犁出凹痕,只能切除少量材料,故材料去除率呈下降趋势并在一定程度上影响了试件表面的粗糙度。从图5可以看出,磨削中期试件表面的粗糙度是比较高的,但磨削后期由于磨粒钝化更加明显且高度更低,如图3c,砂带表面等高性进一步增加,表面的粗糙度迅速降低,磨粒与试件表面接触深度变浅,试件表面发生弹塑性变形,导致几乎无法去除材料,表面凹痕更浅,故可见图5a在中、后期表面粗糙度明显下降。观察图4b可得磨削中期到后期砂带质量基本是线性减小的,也就说明砂带的磨损、脱落、破碎最终达到一个较为平衡的阶段。

2.2 顺纹磨削

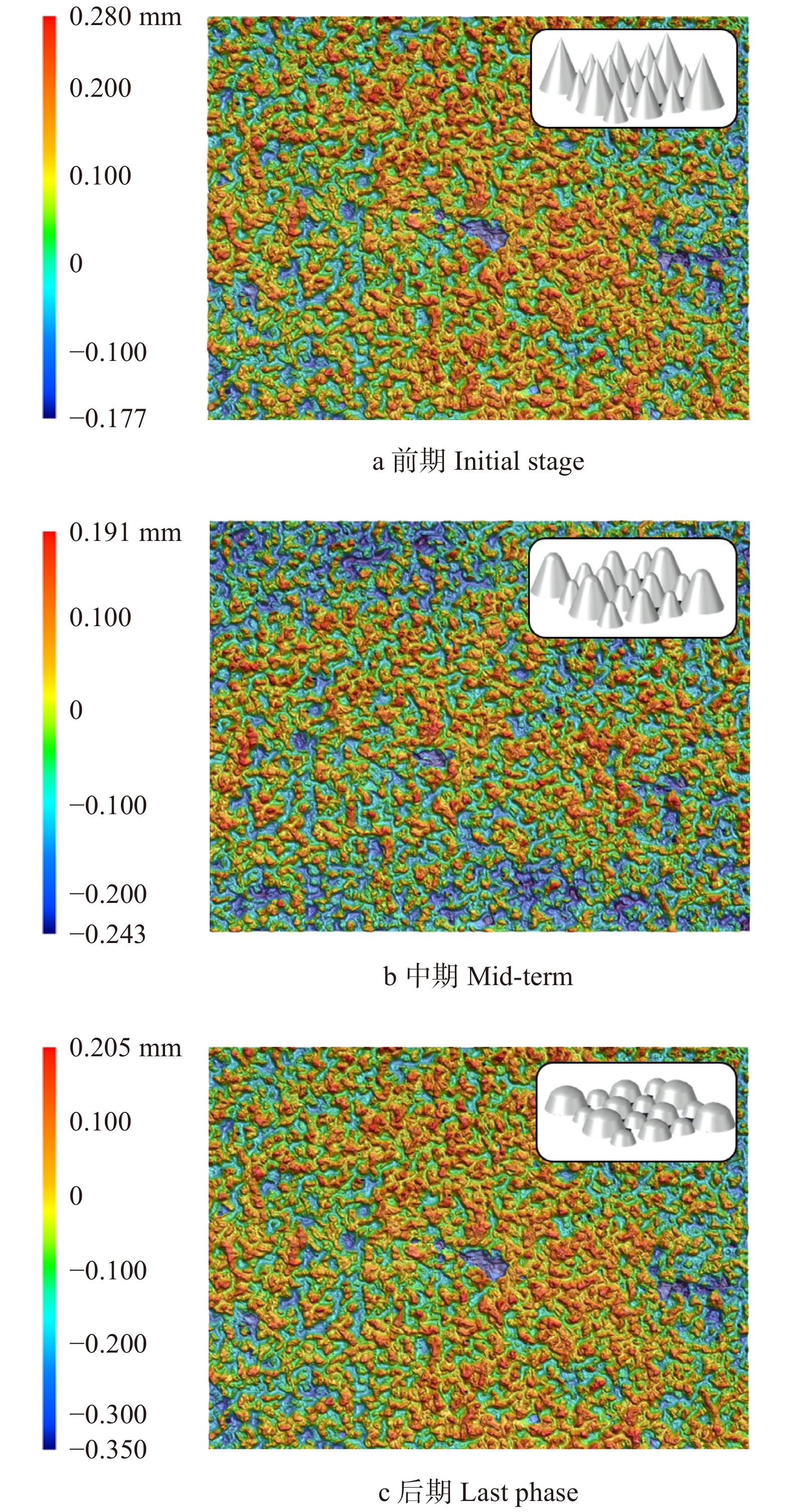

顺纹磨削时,切削方向与木材纤维方向基本平行,磨粒是从木材纤维的端向切入木材[13]。与横纹磨削类似,在初期阶段磨粒顶端的曲率半径较小,切削刃较为锋利,如图6a,砂带上磨粒的等高性较差,易压入木材做有效切削,从图7a中可观察到初期阶段试件表面有多条清晰且完整的磨粒磨削痕迹。

对比图8a与图4a发现,水曲柳横纹磨削时材料去除率整体大于顺纹磨削的材料去除率,且顺纹磨削时材料去除率的下降速率大于横纹的下降速率。这说明砂带在顺纹磨削时更难去除材料,主要由于顺纹磨削过程中,磨粒切入木材时是从木纤维的端头切入,加之磨粒一般为负前角,很难依靠锋利的刃口将木纤维切断,更多的是将其牵扯拉断[14]。从图8b中也可发现此时砂带的磨损速率更快,导致砂带使用寿命也更短。

随磨削次数增加,砂带磨粒高度降低,顶端刃口曲率半径不断增大,在图7b中可以看到许多较宽的磨削痕迹且在凹痕两侧有较多毛刺及翘起的木纤维,故在图9a中可明显观察到试件表面粗糙度增高。在磨削中期,从图6b可看出,砂带上磨粒脱落,破碎所占比例较大,等高性增大,磨粒与试件的接触深度降低且切割纤维能力减弱,在试件表面发生更多的是耕犁现象,木纤维在多次牵拉下被扯断,如图7b左侧示意图。

至磨削后期,观察图7c发现部分磨削痕迹被木屑填埋,翘起的毛刺被抹平,且凹痕大多较浅,故可见图9a中试件表面粗糙度明显下降。如图6c,此时磨粒整体高度下降,磨粒磨损情况严重,大多仅摩擦试件表面,几乎无法切除材料,同时将折断、翘起的木纤维碾平并填充空隙,使得表面粗糙度降低。但是不难从图9b中发现,顺纹磨削时后期砂带的表面粗糙度更大,这也和切削方式和磨粒破碎形式有关,因为在顺纹切削时纤维大多被拉断,所以磨粒更易受拉力造成破碎和脱落,这也是砂带在顺纹和横纹磨削时的一个主要差异[15]。

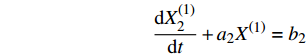

2.3 材料去除率、表面粗糙度灰色预测模型

在砂带寿命范围内,累计磨削长度与磨削过程中材料去除率、表面粗糙度间有着密切联系,但由于样本量少[16-17],且存在如木材非均质、砂带植砂磨粒分布偶然性等较多未知因素,较难建立磨削长度与材料去除率、表面粗糙的回归模型。20世纪80年代邓聚龙教授创立了一种就数找数的方法,即灰色系统生成法。其研究对象是“部分信息已知,部分信息未知”的“小样本”、“贫信息”不确定性系统,用于解决“小样本”、“贫信息”的不确定性问题,这种方法容错率较高,也易于实现模糊控制[18]。因此本研究采用均值GM(1,1)预测模型建立磨削长度与材料去除率、表面粗糙度间的灰色预测模型,如图10所示。

2.3.1 模型预测

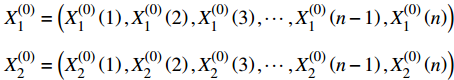

在本次模型中,系列特征序列为材料去除率和表面粗糙度,相关因素序列为磨削长度,模型原始数据及建模步骤如下:

第一步,根据表1、2中数据,建立初始材料去除率序列

X(0)1 、表面粗糙度序列X(0)2 。表 1 横纹磨削模型数据Table 1. Model data of transverse sanding序号

No.磨削长度

Sanding length/m表面粗糙度

Surface roughness/μm材料去除率

Material removal rate/%1 200 41.178 15.11 2 400 39.723 13.48 3 600 40.546 15.71 4 800 51.551 7.27 5 1 000 54.409 12.66 6 1 200 63.536 11.39 7 1 400 60.472 8.35 8 1 600 67.846 9.61 注:为提高所建灰色模型的预测精度,选取数据均在砂带最佳使用寿命范围内。下同。Notes: to improve the precision of the established gray model, the selected data is located in the range of optimal abrasive belt life. Same as below. 表 2 顺纹磨削模型数据Table 2. Model data of longitudinal sanding序号

No.磨削长度

Sanding length/m表面粗糙度

Surface roughness /μm材料去除率

Material removal rate/%1 100 42.572 14.57 2 200 78.737 14.96 3 300 69.976 11.70 4 400 79.229 12.13 5 500 71.151 7.43 6 600 79.812 11.40 7 700 81.305 8.46 8 800 81.221 5.77 9 900 74.79 6.53 10 1 000 78.662 4.86 X(0)1=(X(0)1(1),X(0)1(2),X(0)1(3),⋯,X(0)1(n−1),X(0)1(n))X(0)2=(X(0)2(1),X(0)2(2),X(0)2(3),⋯,X(0)2(n−1),X(0)2(n)) 式中:

X(0)1(n) 代表材料去除率第n个数据的原始数值;X(0)2(n) 代表表面粗糙度第n个数据的原始数值;n表示原始数列的个数,本文横纹磨削时n = 8,顺纹磨削时n = 10。第二步,均值GM(1,1)建模。

(1)对原始数据做一次累加得

X(1)1 和X(1)2 ,原始序列的1-AGO生成;(2)

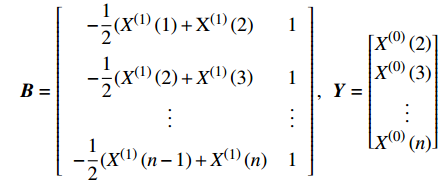

X(1)(n) 表示原始序列第n个数的一阶累加数值,X(0)(n) 表示原始序列第n个数值,构造数据矩阵B和数据向量Y;B=[−12(X(1)(1)+X(1)(2)1−12(X(1)(2)+X(1)(3)1⋮⋮−12(X(1)(n−1)+X(1)(n)1],Y=[X(0)(2)X(0)(3)⋮X(0)(n)] GM(1,1)模型可表示为

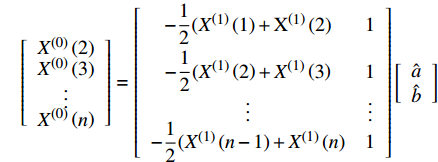

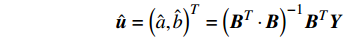

Y=Bu ,即[X(0)(2)X(0)(3)⋮X(0)(n)]=[−12(X(1)(1)+X(1)(2)1−12(X(1)(2)+X(1)(3)1⋮⋮−12(X(1)(n−1)+X(1)(n)1][ˆaˆb] (3)计算待估向量

ˆu ;ˆu=(ˆa,ˆb)T=(BT⋅B)−1BTY 式中:a为发展灰数,表示序列的发展趋势;b为内生控制灰数,表示数据间的变化关系。

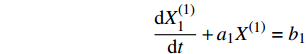

(4)建立模型。

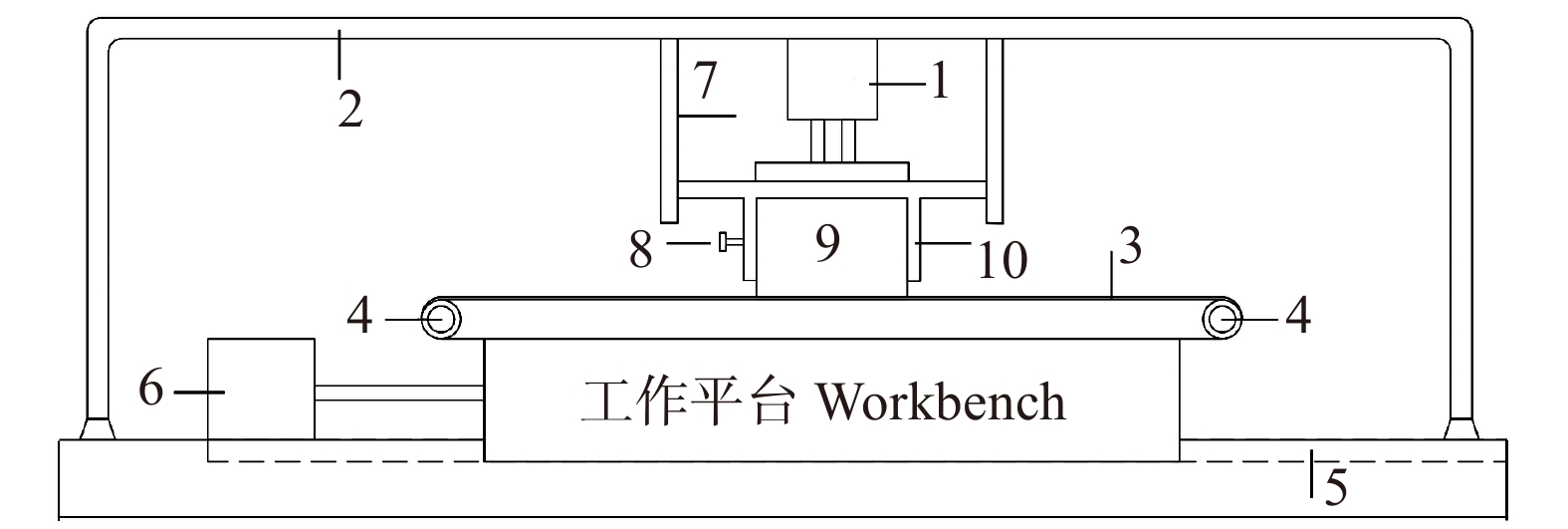

dX(1)1dt+a1X(1)=b1 dX(1)2dt+a2X(1)=b2 式中:t表示序号1,2,······,n−1,n的连续变量;a1、b1分别为计算材料去除率预估向量的发展灰数和内生控制灰数;a2、b2分别为计算表面粗糙度预估向量的发展灰数和内生控制灰数。

第三步,模型检验。

从图11a中数据计算得到:横纹磨削过程中,材料去除率平均模拟相对误差为18.362%,表面粗糙度的平均模拟相对误差为5.170%。从图11b中数据计算可得:顺纹磨削过程中,材料去除率平均模拟相对误差为13.491%,表面粗糙度的平均模拟相对误差为4.603%。

2.3.2 结果分析

由图11可知:采用灰色模型均值GM(1,1)的预测平均模拟相对误差都是在20%以内。考虑预测系统本身局限性,以及木质材料的各向异性导致原始数据的随机性较高,本身规律性不是很明显的情况下,这些因素都加大了预测难度,一定程度上影响了模拟预测的准确性。故本模型适用于预测水曲柳磨削过程中,磨削长度分别与材料去除率、表面粗糙度之间关系的预测,对实际生产具有借鉴意义。

3. 结 论

木材磨削过程中材料去除行为会影响木材加工表面质量,其影响因素主要有磨削方向、材料种类以及磨削过程中砂带的磨损情况。本文主要研究了水曲柳在不同磨削方向时的材料去除率和试件、砂带表面粗糙度变化情况,探究了磨粒磨损过程及其与材料去除率之间的关系,得出以下结论:

(1)磨削过程中磨削方向对砂带磨损的影响不同,顺纹磨削对砂带上磨粒的磨损大于横纹磨削。磨粒的磨损对材料去除率有较大的影响,磨粒磨损程度越大,材料去除率越小。当材料去除率降低至3%时,可认为达到砂带使用寿命,应及时更换砂带。

(2)磨削过程中,砂带上磨粒的等高性对材料去除率也有较大影响。等高性越差,材料去除率越高。随磨削次数增加,砂带材料去除能力不断下降,试件表面粗糙度则呈现先增大后减小的趋势。

(3)采用灰色模型均值GM(1,1)的预测平均模拟相对误差都是在20%以内。适用于水曲柳磨削过程中磨削长度分别与材料去除率、表面粗糙度之间关系的预测。

-

表 1 横纹磨削模型数据

Table 1 Model data of transverse sanding

序号

No.磨削长度

Sanding length/m表面粗糙度

Surface roughness/μm材料去除率

Material removal rate/%1 200 41.178 15.11 2 400 39.723 13.48 3 600 40.546 15.71 4 800 51.551 7.27 5 1 000 54.409 12.66 6 1 200 63.536 11.39 7 1 400 60.472 8.35 8 1 600 67.846 9.61 注:为提高所建灰色模型的预测精度,选取数据均在砂带最佳使用寿命范围内。下同。Notes: to improve the precision of the established gray model, the selected data is located in the range of optimal abrasive belt life. Same as below. 表 2 顺纹磨削模型数据

Table 2 Model data of longitudinal sanding

序号

No.磨削长度

Sanding length/m表面粗糙度

Surface roughness /μm材料去除率

Material removal rate/%1 100 42.572 14.57 2 200 78.737 14.96 3 300 69.976 11.70 4 400 79.229 12.13 5 500 71.151 7.43 6 600 79.812 11.40 7 700 81.305 8.46 8 800 81.221 5.77 9 900 74.79 6.53 10 1 000 78.662 4.86 -

[1] 任青剑, 万宏强, 王斐. 300M超高强度钢的切入式磨削加工性[J]. 兵工自动化, 2017, 36(9):61−65. Ren Q J, Wan H Q, Wang F. Plunge grinding machining performance of 300M ultra high strength steel[J]. Ordnance Industry Automation, 2017, 36(9): 61−65.

[2] Torrance A A. The effect of grit size and asperity blunting on abrasive wear[J]. Wear, 2002, 253: 813−819. doi: 10.1016/S0043-1648(02)00103-5

[3] 刘博, 李黎, 杨永福. 木材与中密度纤维板的磨削力研究[J]. 北京林业大学学报, 2009, 31(增刊 1):197−201. Liu B, Li L, Yang Y F. Sanding force of wood and medium density fiberboard[J]. Journal of Beijing Forestry University, 2009, 31(Suppl. 1): 197−201.

[4] Tian M, Li L. Study on influencing factors of sanding efficiency of abrasive belts in wood materials sanding[J]. Wood Research, 2014, 59(5): 835−842.

[5] Ferguson D C, Kolecki J C, Siebert M W, et al. Evidence for Martian electrostatic charging and abrasive wheel wear from the wheel abrasion experiment on the Pathfinder Sojourner Rover[J]. Journal of Geophysical Research, 1999, 104(4): 8747−8789.

[6] Malinov L S, Malysheva I E, Klimov E S, et al. Effect of particular combinations of quenching, tempering and carburization on abrasive wear of low-carbon manganese steels with metastable austenite[J]. Materials Science Forum, 2019, 945: 574−578. doi: 10.4028/www.scientific.net/MSF.945

[7] Guo X L, Zhu Z L, Ekevad M, et al. The cutting performance of Al2O3 and Si3N4 ceramic cutting tools in the milling plywood[J]. Advances in Applied Ceramics, 2018, 117(1): 16−22. doi: 10.1080/17436753.2017.1368946

[8] Yuan C Q, Guo Z W, Tao W, et al. Effects of different grain sized sands on wear behaviours of NBR/ casting copper alloys[J]. Wear, 2017, 384−385: 185−191. doi: 10.1016/j.wear.2017.02.019

[9] Ding W F, Zhu Y J, Zhang L C, et al. Stress characteristics and fracture wear of wear of brazed CBN grains in monolayer grinding wheels[J]. Wear, 2015, 332−333: 800−809. doi: 10.1016/j.wear.2014.12.008

[10] Eder S J, Cihak-Bayr U, Pauschitz A. Nanotribological simulations of multi-grit polishing and grinding[J]. Wear, 2015, 340−341: 25−30. doi: 10.1016/j.wear.2015.03.006

[11] 罗斌, 李黎, 刘红光. 木材磨削力和影响磨削力的因素[J]. 木材加工机械, 2012(1):6−10. doi: 10.3969/j.issn.1001-036X.2012.01.002 Luo B, Li L, Liu H G. Wood sanding force and the factors of sanding force[J]. Wood Processing Machinery, 2012(1): 6−10. doi: 10.3969/j.issn.1001-036X.2012.01.002

[12] 时萌蒙, 雷亚芳, 肖建平, 等. 几种木材与人造板带式磨削的加工质量[J]. 木材加工机械, 2016(3):41−45. Shi M M, Lei Y F, Xiao J P, et al. Abrasive belt grinding quality of several solid wood and wood-based board[J]. Wood Processing Machinery, 2016(3): 41−45.

[13] 罗斌.木质材料砂带磨削磨削力及磨削参数优化研究[D]. 北京: 北京林业大学, 2015. Luo B. Study on sanding force and optimal sanding parameters in the belt sanding process of wood materials[D]. Beijing: Beijing Forestry University, 2015.

[14] 刘博.木材及中密度纤维板磨削力的研究[D]. 北京: 北京林业大学, 2008. Liu B. Study on sanding force of wood and medium density fiberboard[D]. Beijing: Beijing Forestry University, 2008.

[15] Poulachon G, Moisan A, Jawahir I S. Tool-wear mechanisms in hard turning with polycrystalline cubic boron nitride tools[J]. Wear, 2001, 250: 576−586. doi: 10.1016/S0043-1648(01)00609-3

[16] 杨华龙, 刘金霞, 郑斌. 灰色预测GM(1, 1)模型的改进及应用[J]. 数学的实践与认识, 2011, 41(23):39−46. Yang H L, Liu J X, Zheng B. Improvement and application of grey prediction GM(1, 1) model[J]. Mathematics in Practice and Theory, 2011, 41(23): 39−46.

[17] 孔雪, 王丽, 冯益华. 灰色预测GM(1, 1) 模型应用现状与展望[J]. 齐鲁工业大学学报, 2018, 32(6):49−53. Kong X, Wang L, Feng Y H. Review and prospects of the application status of GM(1, 1)[J]. Journal of Qilu University of Technology, 2018, 32(6): 49−53.

[18] 谢乃明, 刘思峰. 离散GM(1, 1)模型与灰色预测模型建模机理[J]. 系统工程理论与实践, 2005(1):93−99. doi: 10.3321/j.issn:1000-6788.2005.01.014 Xie N M, Liu S F. Discrete GM(1, 1) and mechanism of grey forecasting model[J]. Systems Engineering:Theory & Practice, 2005(1): 93−99. doi: 10.3321/j.issn:1000-6788.2005.01.014

-

期刊类型引用(5)

1. 罗斌,杜瑶,柳浩雨,王钦悦,李春瑜,李黎,刘红光. 定组态砂带粒度对刨花板磨削的影响. 北京林业大学学报. 2024(09): 141-150 .  本站查看

本站查看

2. 施晨阳,赖文峰,文国卫,蒋天雨,朱晓如,吕增伟,张国防. 基于Maxent模型预测水曲柳的潜在适生区. 西北林学院学报. 2022(02): 149-156 .  百度学术

百度学术

3. 罗斌,张健,柳浩雨,李黎,刘红光,李昊. 木质材料磨削理论及技术研究进展. 木材科学与技术. 2022(04): 6-12 .  百度学术

百度学术

4. 杜瑶,田彪,张健,刘红光,罗斌. 中密度纤维板磨削时的砂带磨损研究及寿命评判. 北京林业大学学报. 2021(10): 126-134 .  本站查看

本站查看

5. 卢冬冬,杨铁牛,杨保健,叶榕伟,阳亚,杜华娜. 肉桂打磨方法优化. 农业工程. 2020(01): 73-78 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: