Comparison study on characteristic analysis methods of CLT wall-to-floor T connection under shear test

-

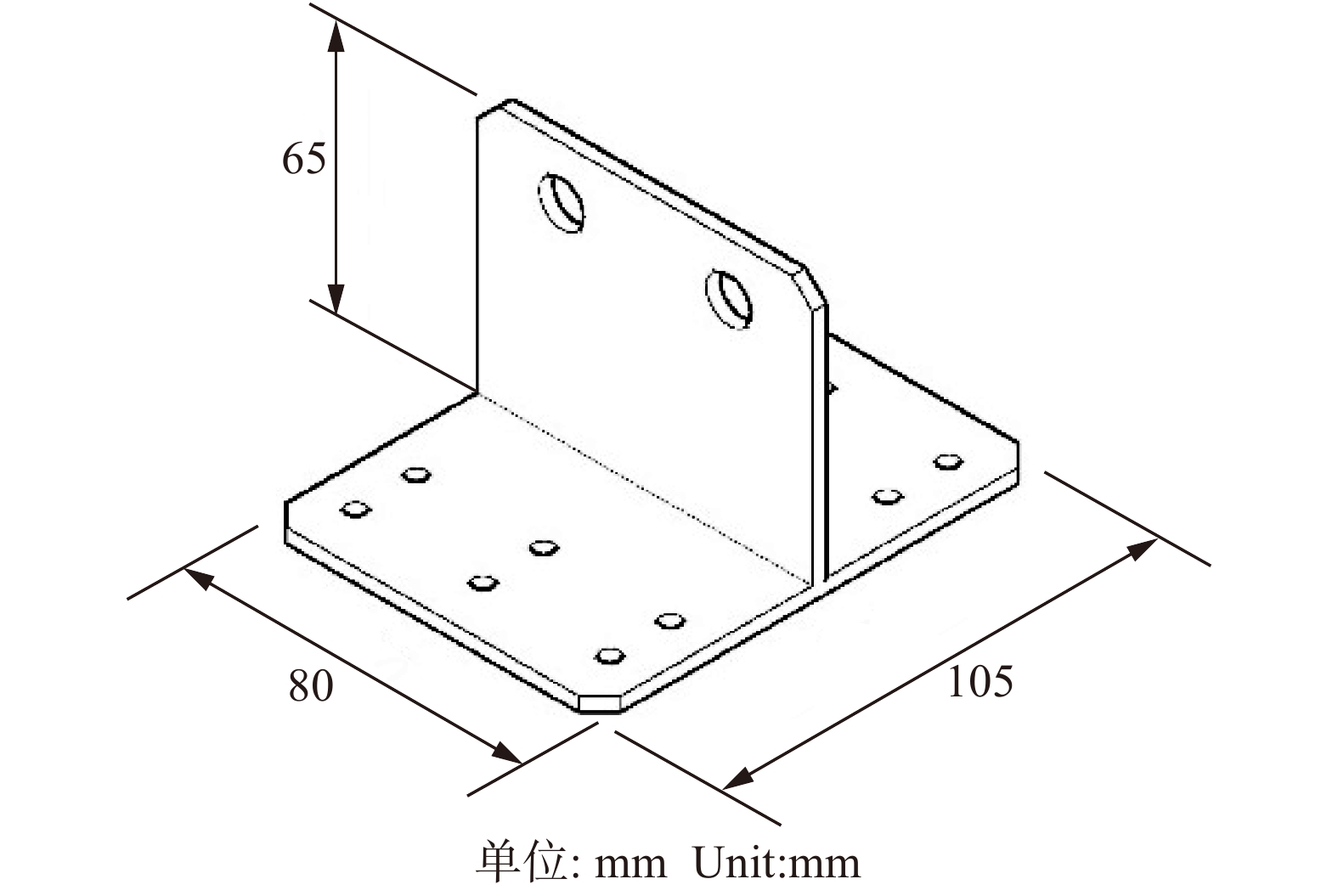

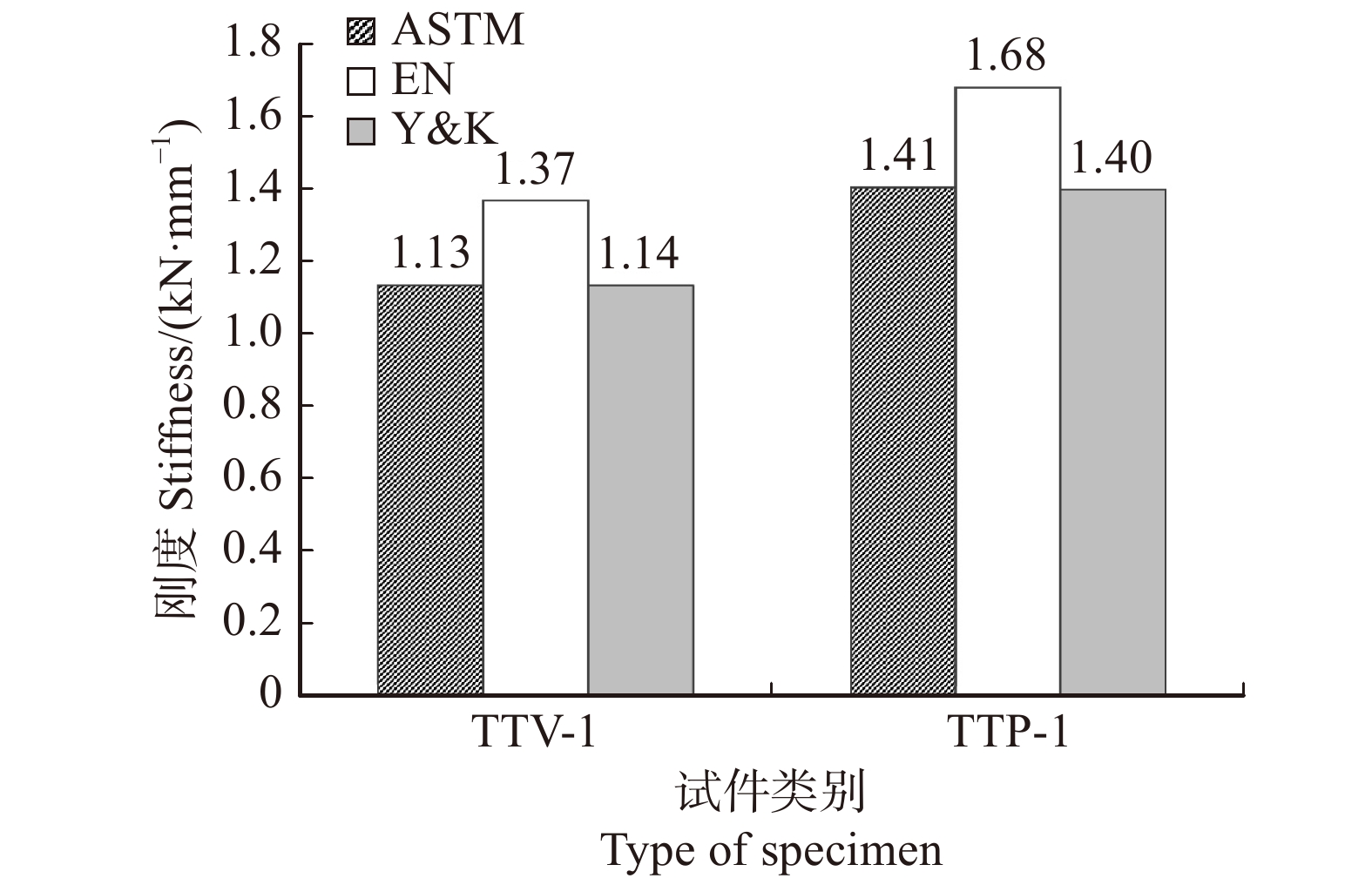

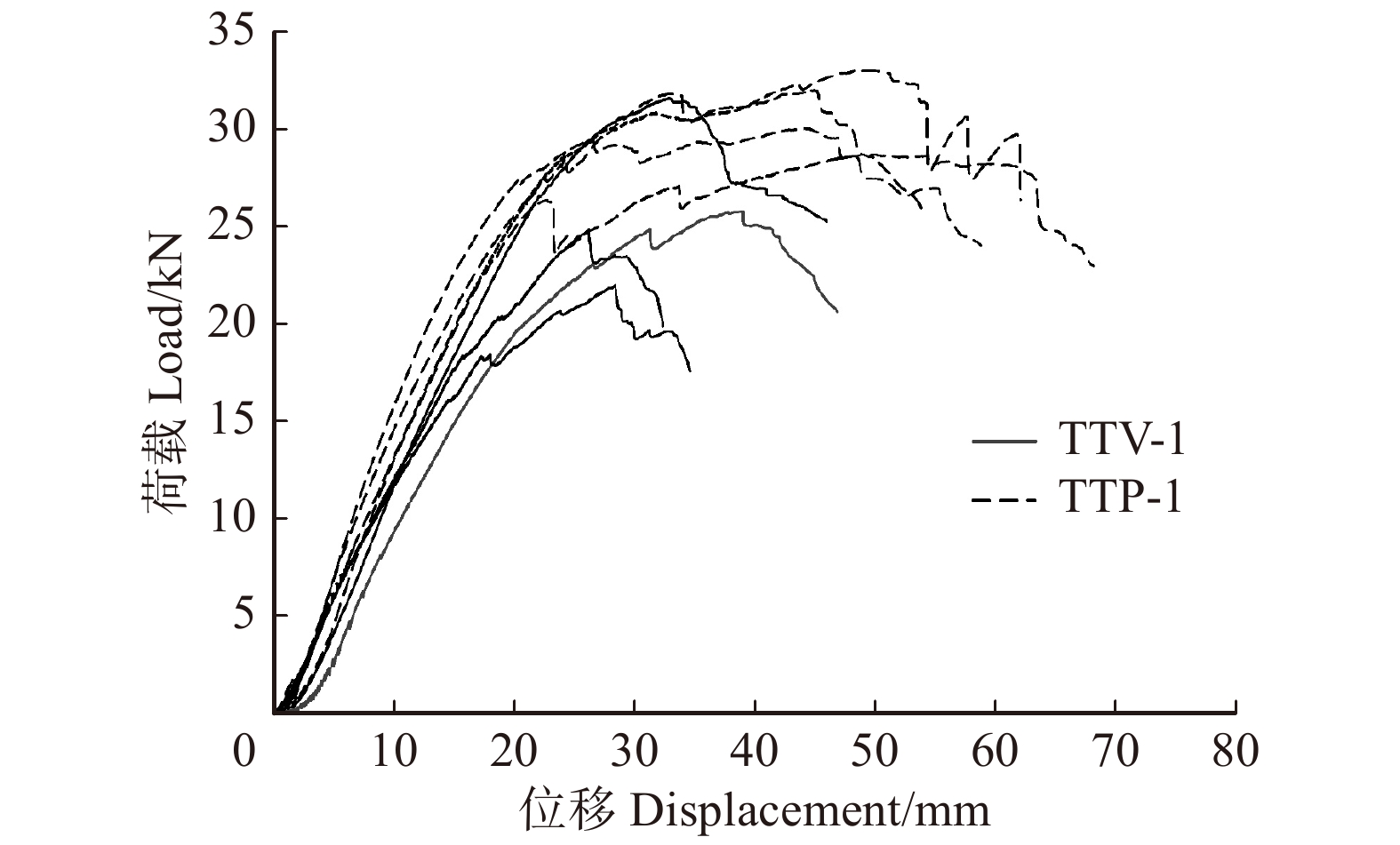

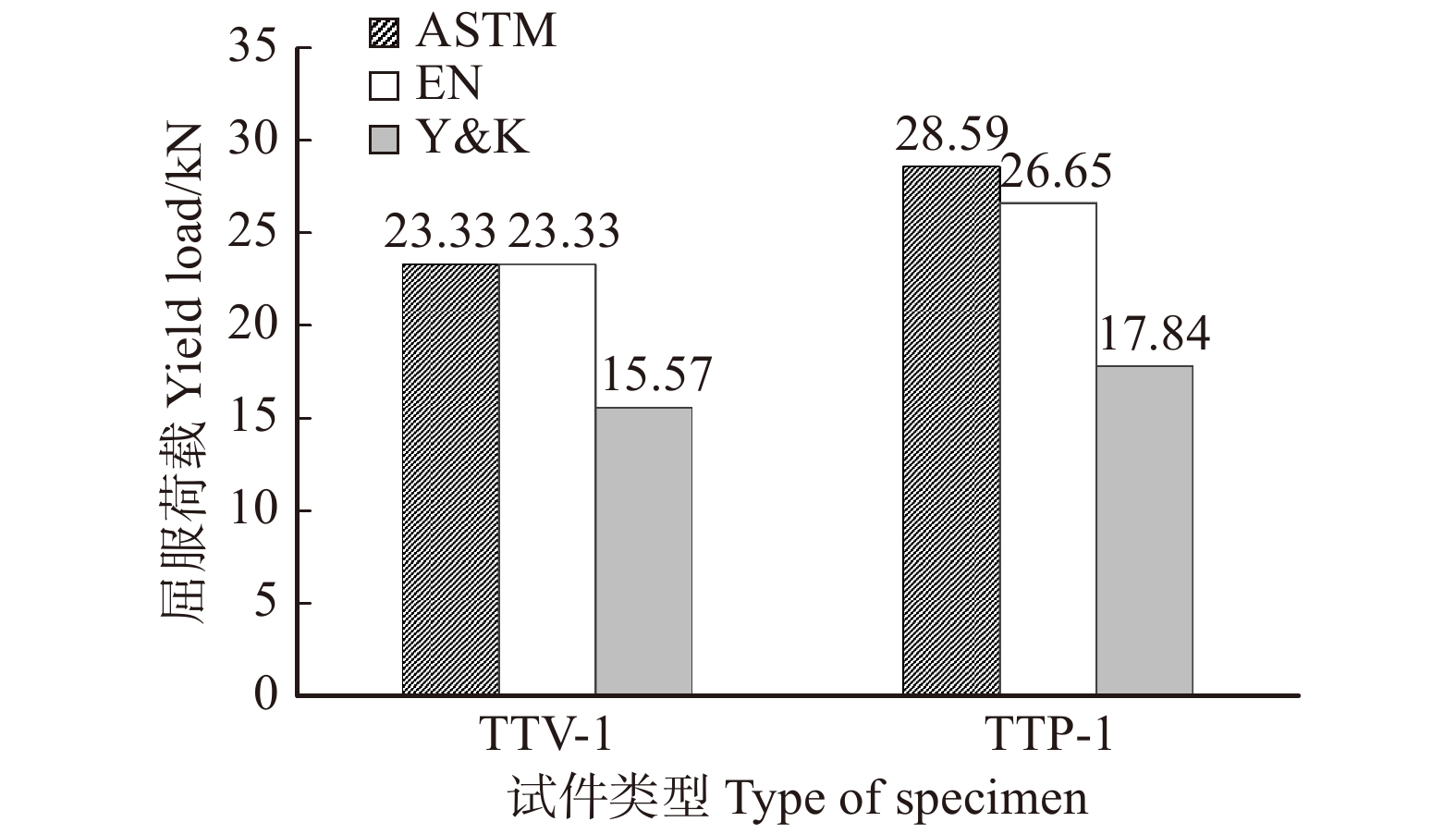

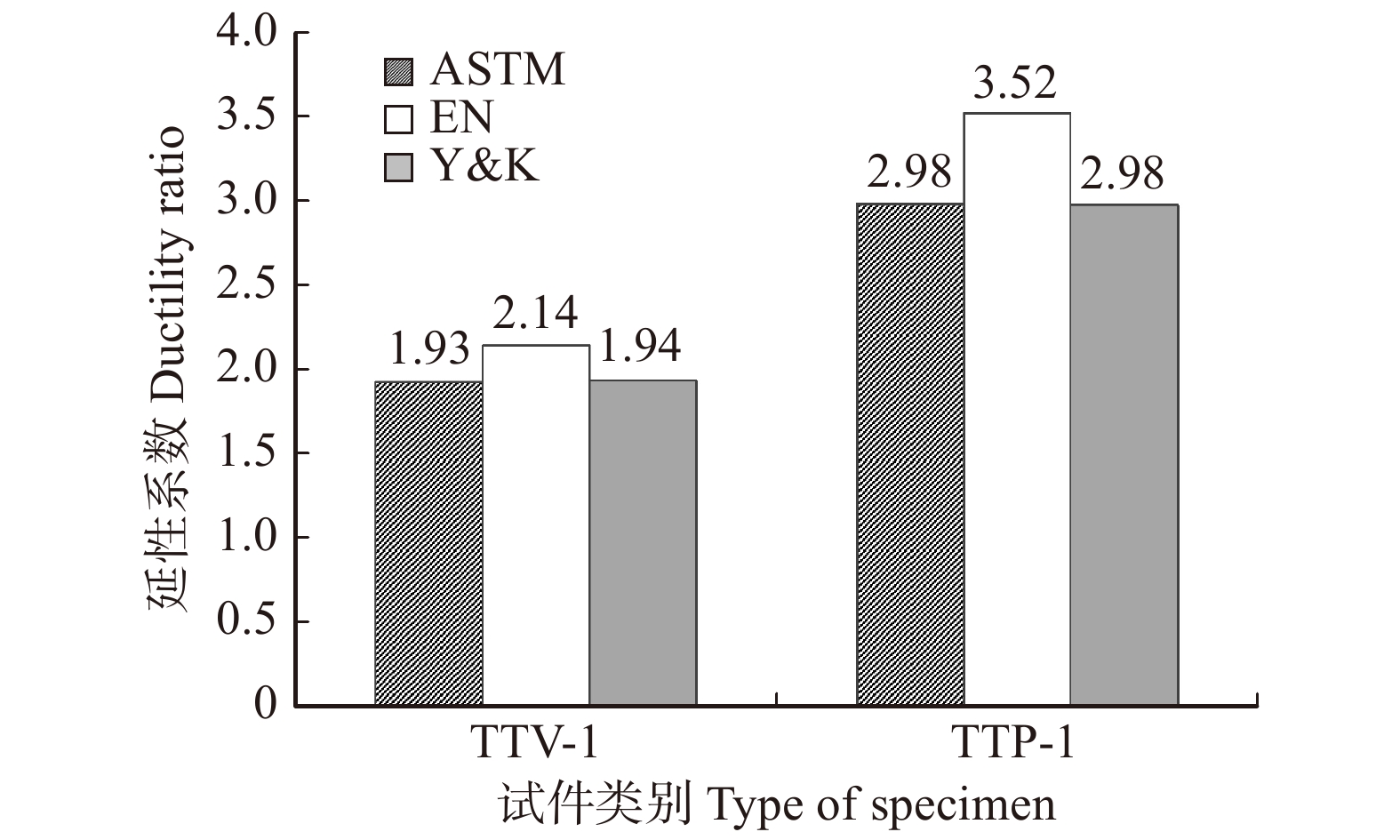

摘要:目的力学特征值分析法是评价结构力学性能的有效方法。在木结构领域,以北美ASTM E2126标准,欧洲EN 12512标准和日本Y&K法的3种评估方法接受度较高。正交胶合木(CLT)被认为是一种可建造多高层木结构建筑的重要木质复合材料,目前针对其材料本身特性的研究较为广泛,但是针对其连接系统的开发和研究尚处于初期阶段。方法本研究设计了一种用于CLT墙体和楼板连接的T型金属连接件,结合对该连接件构造的抗剪试件试验结果,分别采用上述3种分析方法对节点刚度、屈服点特性和延性系数等力学性能参数进行了对比分析。结果Y&K法所得屈服点性质与另两种方法所得点相差较大,EN法计算所得刚度值和延性值略大于另两种方法,ASTM法和EN法在屈服荷载数值的差异性受试验曲线特征影响较大。结论综合比较以上对比结果,对于本文设计的CLT墙体−楼板节点,以及其他力−变形曲线发展较为平缓、破坏模式为延性破坏的木结构节点,Y&K法分析结果更具有实际工程应用意义。Abstract:ObjectiveMechanical characteristic analysis method is an effective way to evaluate structure mechanical performance. In research of wood structure field, three analysis methods are widely accepted, which are method involved in ASTM E2126, EN 12512 and Y&K method. Cross-laminated timber (CLT) is considered as an important wood composite to build high-rise wood constructions in the future. Researches on CLT material properties have been launched over years, but tests on CLT connection system mechanical performance and development are still in early stage.MethodIn this research, a T-shape metal connector was used to connect CLT wall and floor panel. Based on the shear test results, mechanical characteristic values such as stiffness, yield point and ductility ratio were determined by applying those three methods.ResultThe comparison results between methods show that the yield point calculated from Y&K is differ from other two methods, the stiffness value and ductility ratio results of EN method are higher, and the difference between ASTM method and EN method is affected by the test curve.ConclusionFor an overall consideration, Y&K method has more practical engineering reference meaning for the type of CLT wall-to-panel connection tested here and those wood structures that have similar test curve shape and ductile failure mode.

-

Keywords:

- characteristic analysis method /

- ASTM method /

- EN method /

- Y&K method /

- CLT wall-floor joint /

- shear test

-

-

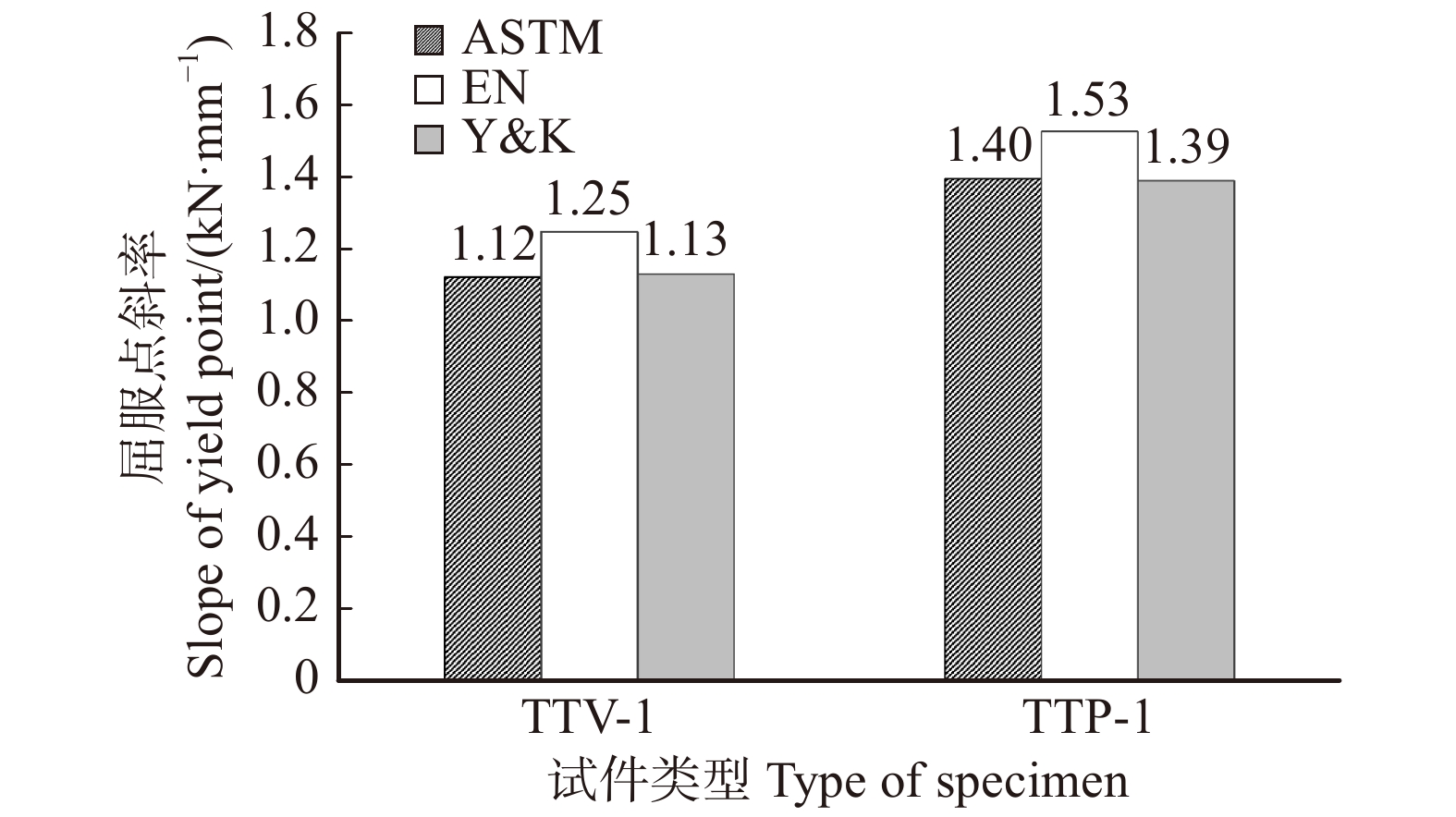

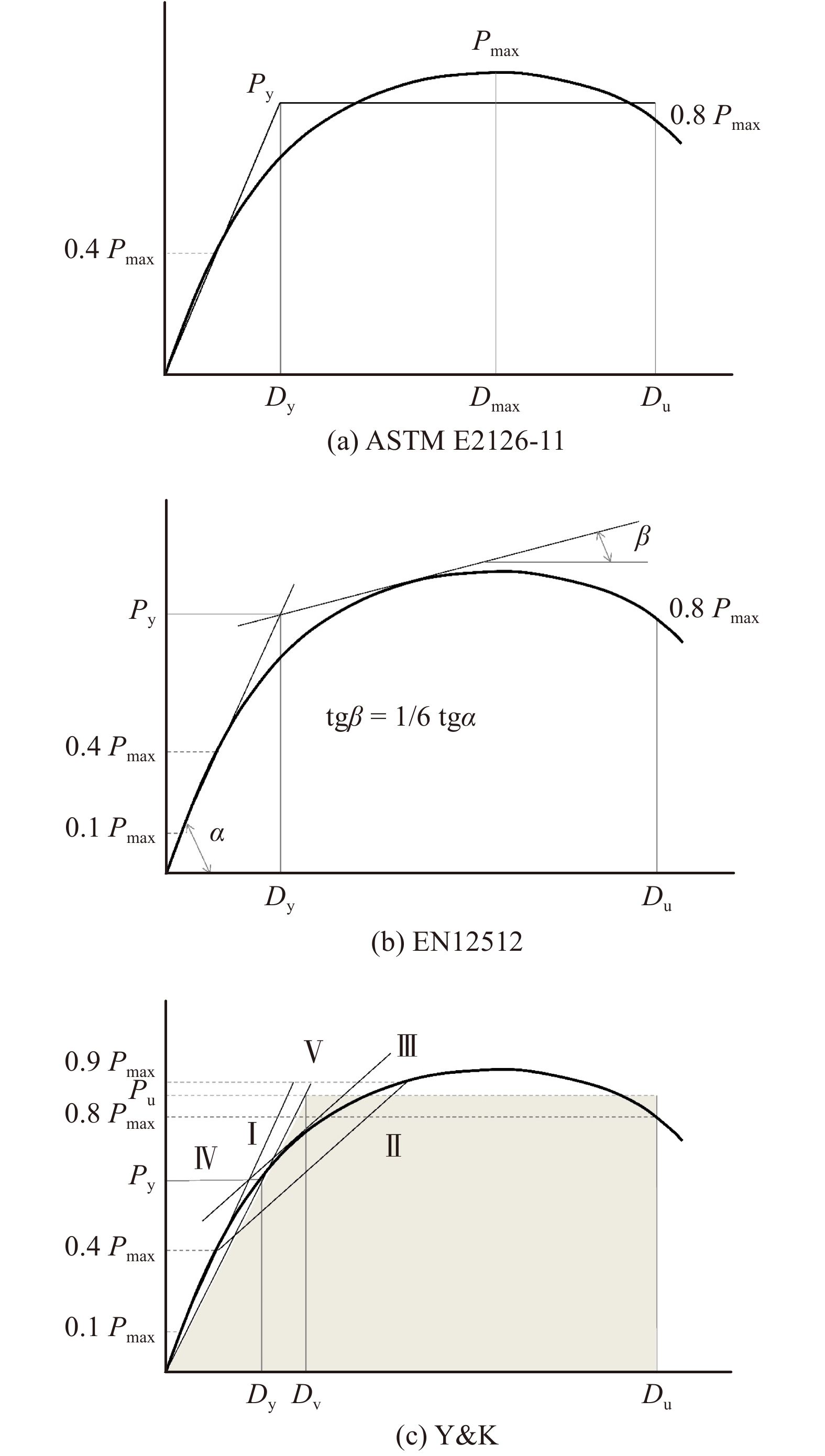

图 1 3种力学特征值分析方法绘图过程

Pmax为最大承载力;0.1Pmax、0.4Pmax、0.8Pmax、0.9Pmax分别为0.1、0.4、0.8和0.9倍最大承载力;Py为屈服荷载;Pu为极限荷载;Dmax为最大承载力对应位移;Dy为屈服位移;Du为极限位移;Dv为降伏点位移;α为EN法初始刚度所在直线与X轴夹角;β为EN法作图角度,数值上tgβ=1/6tgα;Ⅰ ~ Ⅴ为Y&K法作图时涉及的直线。Pmax, maximum load carrying capacity; 0.1Pmax, 0.4Pmax, 0.8Pmax, 0.9Pmax mean 0.1, 0.4, 0.8, 0.9 times maximum load carrying capacity, respectively; Py, yield load; Pu, ultimate load; Dmax, displacement correspond to the maximum load carrying capacity; Dy, yield displacement; Du, ultimate displacement; Dv, another yield displacement purposed in Y&K method; α, slope of initial stiffness; β, an angle parameter purposed in EN method, which tgβ =1/6tgα; Ⅰ−Ⅴ, lines required in Y&K method during analysis process.

Figure 1. Commonly used characteristic analysis methods

表 1 屈服荷载、屈服位移和比值

Table 1 Results of yield load, yield displacement and ratio

试件类型 Type of specimen 物理量 Parameter ASTM EN Y&K TTV-1 屈服荷载 Yield load /kN 23.33 23.33 15.57 变异系数 Coefficient of variation 0.17 0.18 0.11 屈服位移 Yield displacement /mm 20.79 18.69 13.77 变异系数 Coefficient of variation 0.21 0.16 0.13 屈服荷载与位移比值 Ratio between yield load and yield displacement 1.12 1.25 1.13 TTP-1 屈服荷载 Yield load/kN 28.59 26.65 17.84 变异系数 Coefficient of variation 0.06 0.06 0.13 屈服位移 Yield displacement /mm 20.48 17.46 12.84 变异系数 Coefficient of variation 0.11 0.13 0.17 屈服荷载与位移比值 Ratio between yield load and yield displacement 1.40 1.53 1.39 -

[1] American Society for Testing Materials (ASTM). ASTM E2126-11: Standard test methods for cyclic (reversed) load test for shear resistance of vertical elements of the lateral force resisting systems for buildings[S]. West Conshohocken: ASTM International, 2011.

[2] European Committee for Standardization. EN 12512-2001: Timber structures–test methods–cyclic testing of joints made with mechanical fasteners[S]. Brussels: European Committee for Standardization, 2001.

[3] Yasumura M, Kawai N. Estimating seismic performance of wood-framed structures: proceedings of 5th WCTE [C]. Montreux: Press Polytechniques et Universitaires Romandes, 1998: 564−571.

[4] Jeong G Y, Song J K. Evaluation of structural properties of dovetail connections under tensile load using three methods of data analysis[J]. Journal of Materials in Civil Engineering, 2017, 29(10): 06017011. doi: 10.1061/(ASCE)MT.1943-5533.0001992

[5] 刘慧芬, 何敏娟, 高承勇. 木结构销类连接的屈服点和延性定义方法比较[J]. 特种结构, 2015(3):1−5. Liu H F, He M J, Gao C Y. Comparison of determination methods of yield point and ductility for wood structure dowel type connection[J]. Special Structure, 2015(3): 1−5.

[6] Muñoz W, Mohammad M, Salenikovich A, et al. Need for a harmonised approach for calculations of ductility of timber assemblies: proceedings of the 41th CIB W18 Meeting [C]. St. Andrews: Universität Karlsruhe, 2008.

[7] Fragiacomo M, Dujic B, Sustersic I. Elastic and ductile design of multi-storey crosslam massive wooden buildings under seismic actions[J]. Engineering Structures, 2011, 33(11): 3043−3053. doi: 10.1016/j.engstruct.2011.05.020

[8] Jorissen A, Fragiacomo M. General notes on ductility in timber structures[J]. Engineering Structures, 2011, 33(11): 2987−2997. doi: 10.1016/j.engstruct.2011.07.024

[9] Brandner R, Flatscher G, Ringhofer A, et al. Cross laminated timber (CLT): overview and development[J]. European Journal of Wood and Wood Products, 2016, 74(3): 331−351. doi: 10.1007/s00107-015-0999-5

[10] Gavric I, Fragiacomo M, Ceccotti A. Cyclic behavior of CLT wall systems: experimental tests and analytical prediction models[J]. Journal of Structural Engineering, 2015, 141(11): 04015034. doi: 10.1061/(ASCE)ST.1943-541X.0001246

[11] 贾苑, 乔菁, 张佳男, 等. CLT墙体−楼板T型连接件节点力学性能研究[J]. 北京林业大学学报, 2018, 40(10):123−130. Jia Y, Qiao J, Zhang J N, et al. Mechanical performance of CLT wall-to-floor joints with T connector[J]. Journal of Beijing Forestry University, 2018, 40(10): 123−130.

[12] American National Standards Institution (ANSI)/The Engineered Wood Association(APA). PRG 320-2012: Standards for performance-rated cross-laminated timber [S]. Tacoma: ANSI/APA, 2012.

-

期刊类型引用(2)

1. 苏岫,王祥,宋德瑞,李飞,杨正先,张浩. 基于改进光谱角法的红树林高分遥感分类方法研究. 海洋环境科学. 2021(04): 639-646 .  百度学术

百度学术

2. 陈冀岱,牛树奎. 多时相高分辨率遥感影像的森林可燃物分类和变化分析. 北京林业大学学报. 2018(12): 38-48 .  本站查看

本站查看

其他类型引用(3)

下载:

下载: