Mechanism of NaCl effect on diffusion of water molecules in Cunninghamia lanceolata

-

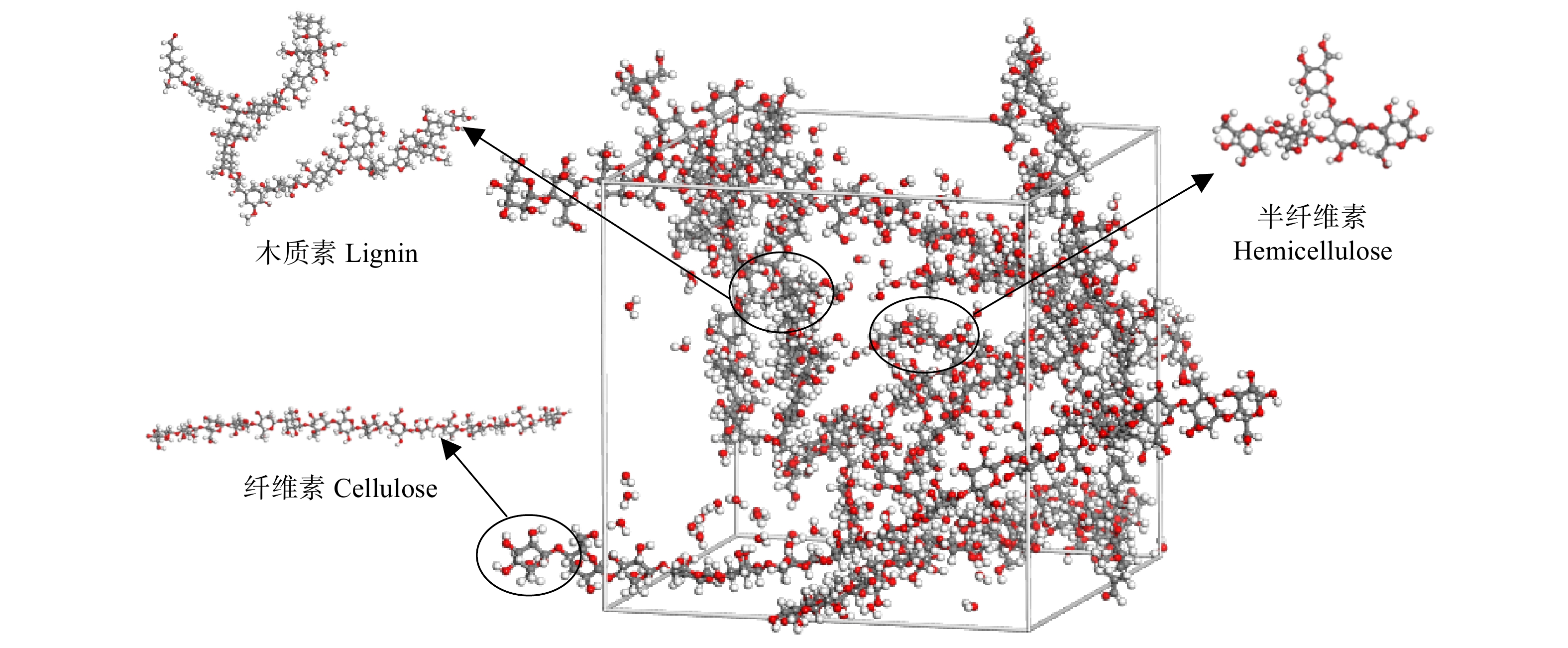

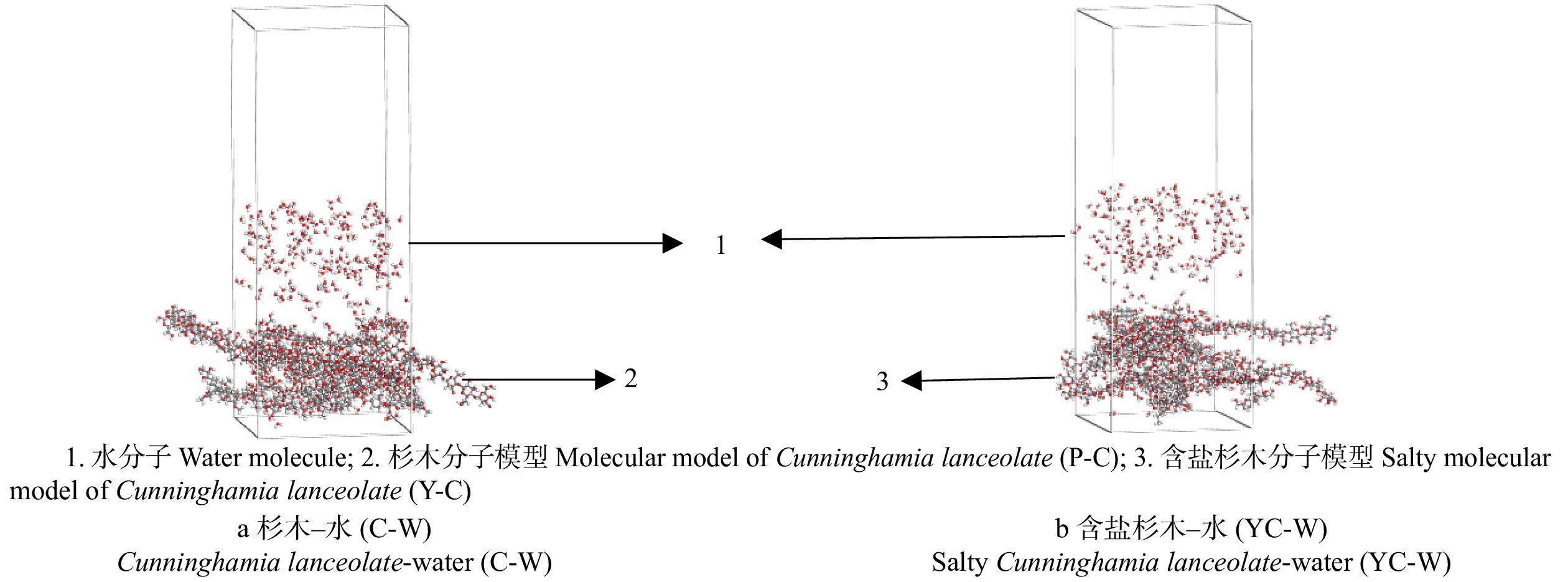

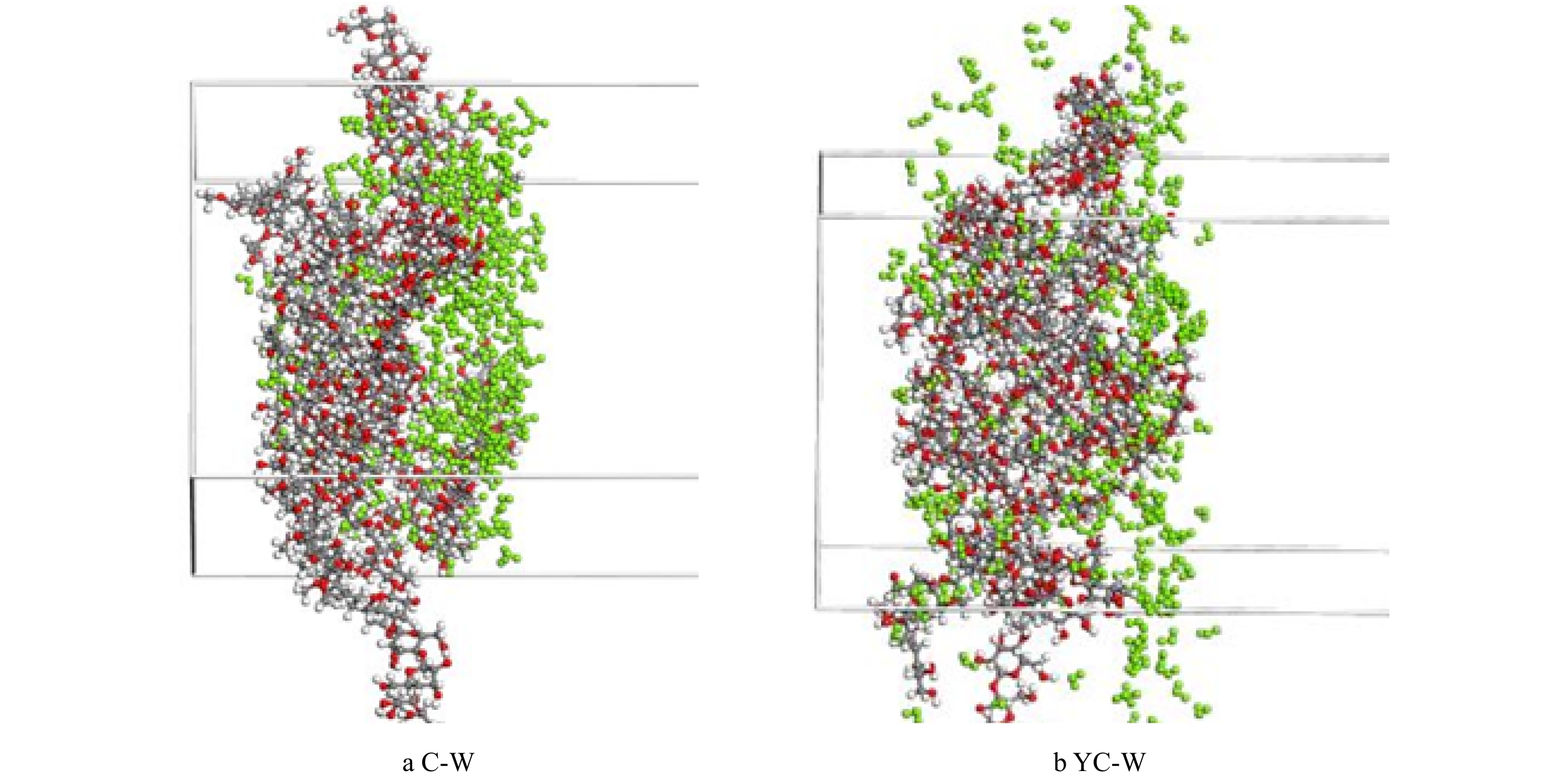

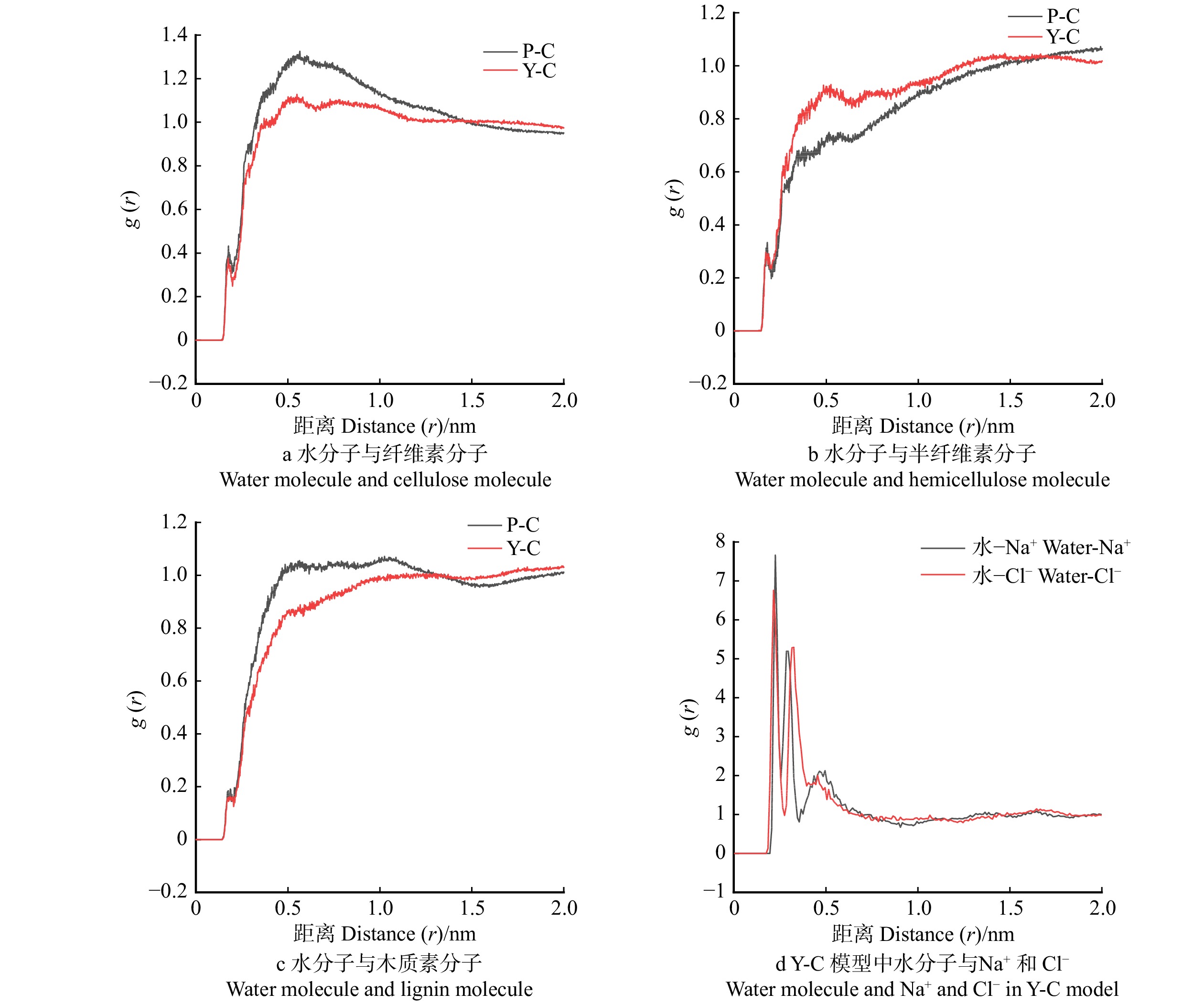

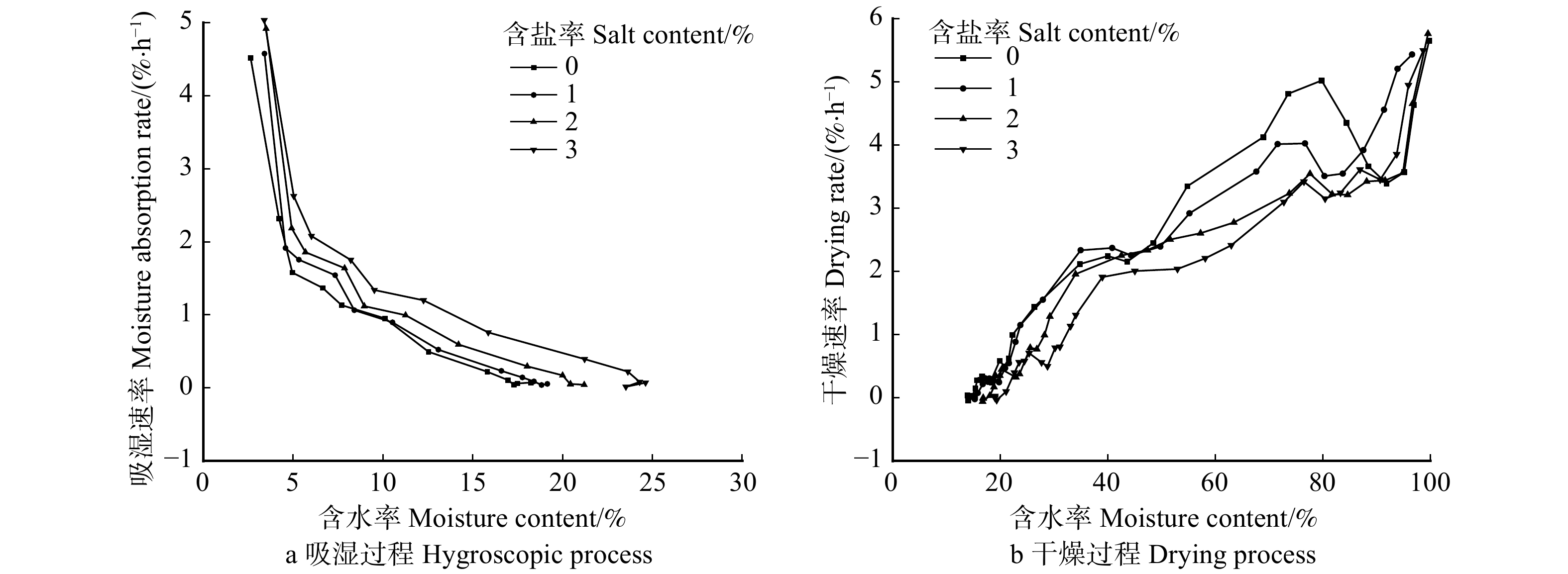

摘要:目的 NaCl的存在会改变木材中水分子的扩散行为,使水分子“易进入”或“难扩散”,从而影响了木材的吸湿性和平衡含水率。研究其影响机理对含盐木质文物的保护具有重要意义。方法 以杉木为研究对象,制作了不同含盐率的杉木试件,开展吸湿与干燥试验,探究盐分对杉木中水分扩散的宏观影响规律;建立了杉木的分子模型,采用分子动力学(MD)模拟方法分别研究了水分子进入含盐与不含盐两种模型的过程,以及水分子在两种模型中的扩散行为。通过平衡构型、相对浓度分布等参数分析水分子进入两种模型结果的差异;通过均方位移、吸附能、径向分布函数、氢键等参数分析两种模型中的水分子与纤维素分子、半纤维素分子、木质素分子等杉木主要组成成分之间的相互作用关系,定性解释了盐分影响杉木中水分扩散的微观机理。结果 试验结果表明杉木试件的吸湿速率随着含盐率的升高而增大;在含水率低于80%范围内,干燥速率随含盐率的升高而减小。MD模拟结果表明,水分子更容易进入含有NaCl的杉木分子模型中,但NaCl会抑制水分子在杉木分子模型中的扩散。模型中各分子之间的相互作用分析结果显示,NaCl与水分子间有很强的吸附作用,但会降低水分子与杉木之间作用强度。结论 NaCl使杉木对水分子的束缚作用降低,但其对水分子的强吸附作用导致了水分子“易进入”与“难扩散”现象。Abstract:Objective The existence of NaCl can change the diffusion behavior of water molecules in wood, making water molecules “easy to enter” or “difficult to diffuse”, thus affecting the moisture absorption and equilibrium moisture content of wood. It is of great significance to study the mechanism of its influence on the protection of salty wooden cultural relics.Method Taking Cunninghamia lanceolata as the research object, the samples with different salt content were made, and the moisture absorption and drying experiments were carried out to explore the macro effect of salt on water diffusion in Cunninghamia lanceolata. The molecular model of Cunninghamia lanceolata was established. The molecular dynamics (MD) simulation method was used to study the process of water molecules entering into the two models with and without salt, and the diffusion behavior of water molecules in the two models. The difference between the two models was analyzed by equilibrium configuration and relative concentration distribution. Based on the mean square displacement, adsorption energy, radial distribution function, hydrogen bond and other parameters, the interaction relationship between water molecules and cellulose, hemicellulose, lignin and other main components of Chinese fir in the two models were analyzed, and the microscopic mechanism of water diffusion affected by salt was qualitatively explained.Result The results showed that the moisture absorption rate of Cunninghamia lanceolata increased with the increase of salt content. When the water content was lower than 80%, the drying rate decreased with the increase of salt content. MD simulation results showed that water molecules were easier to enter the molecular model of Cunninghamia lanceolata containing NaCl, but NaCl can inhibit the diffusion of water molecules in the molecular model of Cunninghamia lanceolata. The results of the interaction analysis among the molecules in the model showed that NaCl can reduce the interaction strength between water molecules and cellulose molecules, hemicellulose molecules, but the interaction strength between lignin and water molecules was enhanced, and the overall performance was that the interaction strength between Cunninghamia lanceolata molecules and water molecules was reduced.Conclusion NaCl can reduce the binding effect of Cunninghamia lanceolata on water molecules, but its strong adsorption on water molecules leads to the phenomenon of “easy entry” and “difficult diffusion” of water molecules.

-

Keywords:

- NaCl /

- water molecular diffusion /

- Cunninghamia lanceolata /

- molecular dynamics

-

-

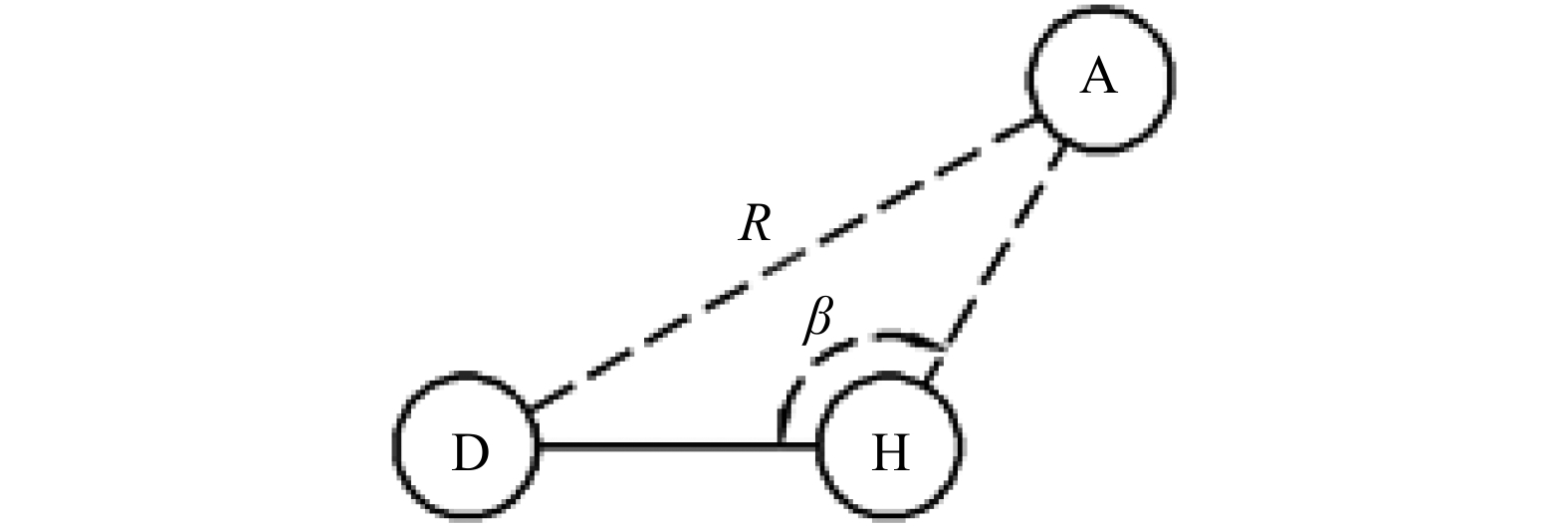

图 8 氢键判定几何标准示意图

原子D代表施主,以化学键与氢原子H相连,原子A代表受主,与氢原子形成氢键,R为施主与受主之间距离,β为施主、氢原子和受主形成的夹角。The atom D represents the donor, which can form a chemical bond with a hydrogen atom H. The atom A represents the acceptor, which can form a hydrogen bond with a hydrogen atom H. R is the distance between the donor and the acceptor, and β is the angle formed by the donor, hydrogen atom and the acceptor.

Figure 8. Schematic diagram of geometric standard for hydrogen bond determination

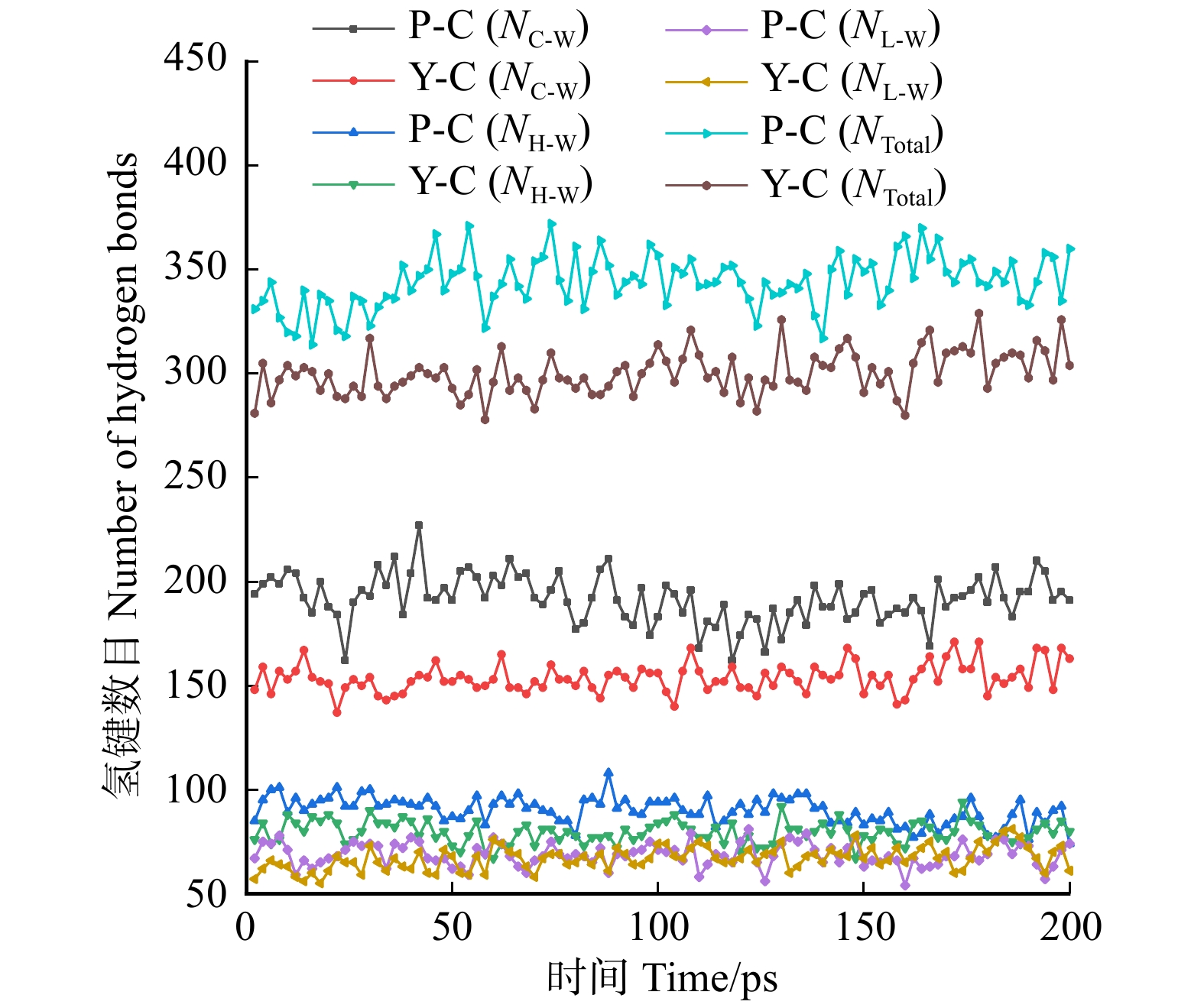

图 9 氢键数目统计

NC-W为纤维素与水分子之间氢键数,NH-W为半纤维素与水分子之间氢键数,NL-W为木质素与水分子之间氢键数,NTotal为杉木与水分子间总氢键数。 NC-W is the number of hydrogen bonds between cellulose and water molecules, NH-W is the number of hydrogen bonds between hemicellulose and water molecules, NL-W is the number of hydrogen bonds between lignin and water molecules, and NTotal is the total number of hydrogen bonds between Cunninghamia lanceolate and water molecules.

Figure 9. Statistics of the number of hydrogen bonds

表 1 杉木与水分子间的吸附能

Table 1 Adsorption energy between Cunninghamia lanceolate and water molecules

kcal/mol 能量

Energy杉木分子模型

Molecular model of

Cunninghamia lanceolate (P-C)含盐杉木分子模型

Salty molecular model of

Cunninghamia lanceolate (Y-C)杉木–水

Cunninghamia

lanceolate-water杉木–水

Cunninghamia

lanceolate-water含盐杉木–水

Salty Cunninghamia

lanceolate-water总吸附能

Total adsorption energy (ETotal)−1 314.79 −1 111.25 −1 830.58 范德华力吸附能

van der Waals adsorption energy (EVdW)99.51 89.01 186.624 静电力吸附能

Electrostatic adsorption energy (EEle)−1 348.915 −1 189.26 −2 006.05 -

[1] Magnus S, Farideh J, Ingmar P, et al. Deterioration of the seventeenth century warship Vasa by internal formation of sulphuric acid[J]. Nature, 2002, 415: 893. doi: 10.1038/415893a

[2] Bjurhager I, Halonen H, Lindfors E L, et al. State of degradation in archeological oak from the 17th century vasa ship: substantial strength loss correlates with reduction in (Holo) cellulose molecular weight[J]. Biomacromolecules, 2012, 13(8): 2521. doi: 10.1021/bm3007456

[3] 张然, 成小林, 潘路, 等. 铁质文物常用除锈试剂的除锈效率及其腐蚀性的比较研究[J]. 文物保护与考古科学, 2020, 32(3):17−27. Zhang R, Cheng X L, Pan L, et al. Comparative study of rust removal efficiency and corrosiveness of commonly-used reagents for iron artifacts[J]. Sciences of Conservation and Archaeology, 2020, 32(3): 17−27.

[4] 卢衡, 张绍志, 刘东坡, 等. 出土、出水饱水木质文物冷冻干燥研究进展[J]. 文物保护与考古科学, 2020, 32(6):126−137. Lu H, Zhang S Z, Liu D P, et al. Research progress of freeze drying for unearthed/salvaged waterlogged wooden archaeological artifacts[J]. Sciences of Conservation and Archaeology, 2020, 32(6): 126−137.

[5] 陈家昌, 黄霞, 陈晓琳, 等. 出土饱水木质文物的腐蚀病害类型与保护研究进展[J]. 材料导报, 2015, 29(11):96−101. Chen J C, Huang X, Chen X L, et al. Corrosion type and conservation of archaeological waterlogged wood[J]. Materials Reports, 2015, 29(11): 96−101.

[6] 马尔妮, 赵广杰. 木材的干缩湿胀−从平衡态到非平衡态[J]. 北京林业大学学报, 2006, 28(5):133−138. doi: 10.3321/j.issn:1000-1522.2006.05.024 Ma E N, Zhao G J. Hygroexpansion of wood: from equilibrious state to non-equilibrious state[J]. Journal of Beijing Forestry University, 2006, 28(5): 133−138. doi: 10.3321/j.issn:1000-1522.2006.05.024

[7] Yang T T, Ma E N. Comparison of dynamic sorption and hygroexpansion of wood by different cyclic hygrothermal changing effects[J]. Journal of the Korean Wood Science and Technology, 2016, 44(2): 191−203. doi: 10.5658/WOOD.2016.44.2.191

[8] 费利华, 沈大娲. 泉州湾宋代海船船木的盐分检测与分析[J]. 福建文博, 2015(3):65−68. Fei L H, Shen D W. Salt detection and analysis of sea-going ship wood in Quanzhou Bay in Song Dynasty[J]. Fujian Culture Museum, 2015(3): 65−68.

[9] Nelson R M, Jr. Diffusion of bound water in wood part 2: a model for isothermal diffusion[J]. Wood Science and Technology, 1986, 20(3): 235−251. doi: 10.1007/BF00350982

[10] Hunter A J. On movement of water through wood: the diffusion coefficient[J]. 1993, 27(6): 401-408.

[11] 伊松林, 张璧光, 常建民. 木材真空–浮压干燥过程中自由水迁移特性[J]. 北京林业大学学报, 2003, 25(4):59−63. doi: 10.3321/j.issn:1000-1522.2003.04.013 Yi S L, Zhang B G, Chang J M. Characteristics of free water movement in wood drying process under vacuum-floating pressure[J]. Journal of Beijing Forestry University, 2003, 25(4): 59−63. doi: 10.3321/j.issn:1000-1522.2003.04.013

[12] 郭月红, 何正斌, 林作新, 等. 汽蒸处理过程中木材内部水分的迁移动力初探[J]. 北京林业大学学报, 2014, 36(5):131−135. Guo Y H, He Z B, Lin Z X, et al. Water migration force inner wood during steam treatment process[J]. Journal of Beijing Forestry University, 2014, 36(5): 131−135.

[13] Eitelberger J, Hofstetter R. Multiscale homogenization of wood transport properties: diffusion coefficients for steady-state moisture transport[J]. Wood Material Science & Engineering, 2010, 5(2): 97−103.

[14] Zhan J F, Gu J Y, Cai Y C. Analysis of moisture diffusivity of larch timber during convective drying condition by using Crank’s method and Dincer’s method[J]. Journal of Forestry Research, 2007, 18(3): 199−202. doi: 10.1007/s11676-007-0040-x

[15] 何正斌, 郭月红, 伊松林, 等. 木材超声波–真空协同干燥的动力学研究[J]. 北京林业大学学报, 2012, 34(2):133−136. He Z B, Guo Y H, Yi S L, et al. Preliminary study of wood ultrasound-vacuum combined drying dynamics[J]. Journal of Beijing Forestry University, 2012, 34(2): 133−136.

[16] da Silva W P, da Silva L D, e Silva C M D P S, et al. Nascimento. Optimization and simulation of drying processes using diffusion models: application to wood drying using forced air at low temperature[J]. Wood Science and Technology, 2011, 45(4): 787−800. doi: 10.1007/s00226-010-0391-x

[17] Gatica Y A, Salinas C H, Ananias R A. Modeling conventional one-dimensional drying of radiata pine based on the effective diffusion coefficient[J]. Latin American Applied Research, 2011, 41(2): 183−189.

[18] 杨亮庆. 枫桦圆盘预处理及干燥特性研究[D]. 哈尔滨: 东北林业大学, 2011. Yang L Q. The research of preprocessing and dyring characteristics of B. costata disk[D]. Harbin: Northeast Forestry University, 2011.

[19] 刘清芝, 杨登峰, 胡仰栋. 水和盐分子在反渗透膜内扩散过程的分子模拟[J]. 高等学校化学学报, 2009, 30(3):568−572. doi: 10.3321/j.issn:0251-0790.2009.03.027 Liu Q Z, Yang D F, Hu Y D. Water and salts molecular simulation of diffusion process in reverse osmosis membrane[J]. Chemical Research in Chinese Universities, 2009, 30(3): 568−572. doi: 10.3321/j.issn:0251-0790.2009.03.027

[20] Hou D S, Li D K, Yu J, et al. Insights on capillary adsorption of aqueous sodium chloride solution in the nanometer calcium silicate channel: a molecular dynamics study[J]. Journal of Physical Chemistry, 2017(8): 1−39.

[21] 纪松灿, 钱晓炜, 曾飞祥, 等. 利用分子动力学模拟水和盐在磺化聚苯乙烯–乙烯/丁烯–苯乙烯膜内的扩散行为[J]. 西安交通大学学报, 2019, 53(2):170−178. Ji S C, Qian X W, Zeng F X, et al. Water and salt diffusion behavior of sulfonated poly (styrene-ethylene/butylene-styrene) block copol ymer membrane with molecular dynamic simulation[J]. Journal of Xi’an Jiaotong University, 2019, 53(2): 170−178.

[22] Du D Y, Tang C, Yang L, et al. Molecular dynamics simulation on the distribution and diffusion of different sulfides in oil-paper insulation systems[J]. Journal of Molecular Liquids, 2020(314): 1−7.

[23] Kang W, Chung W Y. Liquid water diffusivity of wood from the capillary pressure-moisture relation[J]. Journal of Wood Science, 2009, 55(2): 91−99. doi: 10.1007/s10086-008-1009-x

[24] Mazeau K. Molecular dynamics simulation of bulk native crystalline and amorphous structures of cellulose[J]. Journal of Physical Chemistry B, 2003, 107(10): 2394−2403. doi: 10.1021/jp0219395

[25] 李新宇, 张明辉. 利用X射线衍射法探究木材含水率与结晶度的关系[J]. 东北林业大学学报, 2014, 42(2):96−99. doi: 10.3969/j.issn.1000-5382.2014.02.023 Li X Y, Zhang M H. Relationship of wood moisture content and the degree of crystallinity by X-ray diffraction[J]. Journal of Northeast Forestry University, 2014, 42(2): 96−99. doi: 10.3969/j.issn.1000-5382.2014.02.023

[26] Berglund J, Azhar S, Lawoko M, et al. The structure of galactoglucomannan impacts the degradation under alkaline conditions[J]. Cellulose, 2019, 26(3): 2155−2175. doi: 10.1007/s10570-018-1737-z

[27] Adler E. Lignin chemistry: past, present and future[J]. Wood Science & Technology, 1977, 11(3): 169−218.

[28] 孙珂, 漆楚生, 汪莉君, 等. 杉木纤维素的热稳定性及热分解动力学参数[J]. 林产工业, 2018, 45(4):40−44. Sun K, Qi C S, Wang L J, et al. Thermal stability and decomposition kinetics of parameters of Chinese fir cellulose[J]. China Forest Products Industry, 2018, 45(4): 40−44.

[29] 王佩卿, 余俊, 李民栋. 水杉木材半乳糖基–葡萄甘露聚糖的结构研究[J]. 南京林学院学报, 1986(2):66−73. Wang P Q, Yu J, Li M D. Study on the structure of galactosyl glucomannan from Metasequoia glyptostroboides wood[J]. Journal of Nanjing Institute of Forestry, 1986(2): 66−73.

[30] Zhang J W, Tang C, Wang Q, et al. Analysis of nano-SiO2 affecting the acids diffusion in the interface between oil and cellulose paper[J]. Chemical Physics, 2020(529): 1−6.

[31] Jorgensen L. Perspective on “equation of state calculations by fast computing machines”[J]. Theoretical Chemistry Accounts, 2000(103): 225−227.

[32] Nishiyama Y, Sugiyama J J, Chanzy H, et al. Crystal structure and hydrogen bonding system in cellulose Iα from synchrotron X-ray and neutron fiber diffraction[J]. Journal of the American Chemical Society, 2003, 125(47): 14300−14306. doi: 10.1021/ja037055w

[33] 孙会刚. 水分对油纸绝缘热老化及寿命的影响与热老化程度表征研究[D]. 重庆: 重庆大学, 2011. Sun H G. Study on influence of moisture on thermal aging & life and thermal aging condition evaluation of oil-paper insulation[D]. Chongqing: Chongqing University, 2011.

[34] Yin F, Tang C, Li X, et al. Effect of moisture on mechanical properties and thermal stability of meta-aramid fiber used in insulating paper[J]. Polymers, 2017, 9(10): 1−14.

-

期刊类型引用(3)

1. 范舟,田波,张庆辉,侯涛,唐鹏. 基于分子动力学的元素硫吸附扩散行为研究. 石油化工. 2024(06): 839-847 .  百度学术

百度学术

2. 柯玉彪,孙天礼,黄仕林,刘建仪,田波,范舟. 元素硫在溶硫剂中扩散溶解行为的分子动力学模拟. 当代化工. 2024(09): 2201-2207 .  百度学术

百度学术

3. 徐佳佳,李京予,张润华,马尔妮. 基于分子动力学模拟的木材细胞壁与水分相互作用研究进展. 高分子材料科学与工程. 2024(08): 165-173 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: