Properties of wood-based composite phase change heat storage materials with Cu particles to enhance heat conduction

-

摘要:目的 高导热的填料虽然能够提升木质基复合相变储热材料的储放热速率,但存在的易团聚现象无法使其均匀分散于材料内部。本研究旨在利用溶液还原法,由内而外地在轻木基体内原位生成单分散的金属铜颗粒,为提高木质基复合相变储热材料的储放热性能探索绿色、经济的道路。方法 首先利用酸性亚氯酸钠溶液对轻木进行脱木素处理以提高其对相变材料的封装效率。然后利用CuSO4溶液与抗坏血酸溶液在脱木素轻木内利用溶液还原法多次循环制备单分散金属Cu颗粒,并将反应完全后的轻木利用真空浸渍法与石蜡(PW)制备具有Cu颗粒强化导热的木基复合相变储热材料。采用场发射电子显微镜(SEM)、红外光谱分析(FTIR)、X射线衍射仪(XRD)、差式扫描量热仪(DSC)、导热系数测试仪和温度巡检仪对材料的微观、结晶、化学结构及储放热性能进行评价。结果 轻木经脱木素处理后其对石蜡的封装效率从64.9%提升至了82.6%。经过抗坏血酸对Cu2+的还原作用,在轻木基体内原位制造出了Cu。然而循环次数过少,Cu不能均匀地分布在木材基体内,而过多的循环次数则会过量地影响轻木对相变材料的封装效果;其中3次的循环次数最为合适,以此所制备的复合相变储热材料导热系数提升了1.76倍,熔融与凝固潜热分别高达143.7、142.9 J/g,同时储热与放热时间分别缩短了23.7%与32.6%,展现出了更好的温度调节潜力。结论 利用溶液还原法能够有效地在轻木基体内均匀制备金属Cu颗粒,并且以3次循环制备的Cu颗粒强化导热的木基复合相变储热材料储放热性能较好。Abstract:Objective Although high thermal conductivity fillers can improve the heat storage and release rate of wood-based phase change heat storage composite materials. The agglomeration of nanoparticles is not conducive to their uniform dispersion in the material. The purpose of this paper is to use the solution reduction method to in-situ generate monodisperse copper particles in the balsa wood (Ochroma pyramidale) matrix from the inside to outside, so as to develop a green and economic way to improve the heat storage and release properties of phase change heat storage wood-based composite materials.Method Firstly, the balsa wood was delignified with acid sodium chlorite solution to improve the packaging efficiency of phase change materials. Then, the monodisperse Cu particles were prepared by the solution reduction method in delignified balsa wood with CuSO4 solution and ascorbic acid solution by cyclic reaction, and the paraffin wax (PW) was added to the wood-based composite by vacuum impregnation method. Field emission electron microscope (SEM), infrared spectroscopy (FTIR), X-ray diffraction (XRD), differential scanning calorimeter (DSC), thermal conductivity tester and temperature inspection instrument were used to evaluate the microstructure, crystallization, chemical structure and heat storage and release properties of the materials.Result After delignification, the encapsulation efficiency of balsa wood increased from 64.9% to 82.6%. After the reduction of Cu2+ by ascorbic acid, Cu was produced in-situ in the balsa wood matrix. However, if the number of cycles was too small, Cu can not be evenly distributed in the wood matrix, and if the number of cycles was too large, the packaging effect of balsa wood on phase change materials will be excessively affected. The three cycles were the most appropriate. The thermal conductivity of the composite phase change heat storage material prepared by this method was increased by 1.76 times, the melting and solidification latent heat were as high as 143.7 and 142.9 J/g, respectively, and the heat storage and heat release time were shortened by 23.7% and 32.6%, respectively, showing a better potential for temperature regulation.Conclusion The solution reduction method can effectively prepare Cu particles uniformly in the balsa wood matrix, and the wood-based composite phase change heat storage material with Cu particles prepared by three cycles to enhance heat conduction has good heat storage and release performance.

-

Keywords:

- balsa wood /

- copper /

- heat conduction /

- composite phase change heat storage material

-

相变材料(phase change material,PCM)在其相态转变过程中能够吸收或者释放大量热能而被广泛应用于热能存储与热管理系统中[1]。石蜡(paraffin wax,PW)作为最常见的有机固–液型相变材料之一,由于其化学稳定性好、无相分离现象、相变过程中体积变化小等优点吸引了大量学者的关注[2-3]。然而低导热率和液相状态下易渗漏的问题严重限制了石蜡这类有机固–液型PCM在热能存储与热管理系统中的实际应用性能[4-6]。有关研究表明,利用木材的三维多孔结构与相变材料之间产生的范德华力、氢键作用、毛细作用和表面张力能够解决PCM因形状不稳定而产生的易渗漏问题[7-8]。但是木材中存在着堵塞的孔隙,限制了相变材料在其内的封装效率[9],同时木材较低的导热率无法满足热能存储与热管理系统对相变材料高效储放热速率的需求。为此,对于复合材料导热性能的改善成为了木质基复合相变储热领域的研究热点。其中,有学者指出:木材在碳化过程中,碳原子在空间上向后排列形成无定形碳,并逐渐转变为石墨化结构,这能极大地提升基体导热性能。Yang等[10]最早将木材碳化后直接作为相变材料的封装基体,复合材料的导热性能有效地提升了114.4%。Zhou等[11]利用脱木素碳化木对相变材料进行封装,所制得的复合相变储热材料不仅表现出高达89.24%封装效率,其导热性也较优越。但木材的高温碳化不仅能耗巨大,对设备也有极高的要求,同时木材在碳化过程中会丧失其原本的力学强度,这显然不利于产品的实际应用效果。近年来,将高导热纳米颗粒作为导热填料这一绿色环保且不破坏木质基体性能的导热增强方式逐渐吸引了研究学者的目光。Lin等[12]将石墨烯添加到超支化聚氨酯浸渍的木材中,添加石墨烯后,复合材料的导热系数达到0.417 W/(m·K),与纯木材相比提高了约414%。孟杨[13]将银纳米颗粒引入了木质基复合相变储热材料,有效地将复合材料的导热系数提升了1.9倍。

然而这些高导热的纳米颗粒在木质基复合相变储热材料基体内存在着分布不均匀的问题,这主要可归因于两点:纳米颗粒在相变材料中与相变材料共混进行浸渍过程中易团聚沉积[14];木材基体内存在着大量尺寸大于相变材料而小于纳米颗粒的微纤丝间隙与纹孔孔隙[15],在浸渍的过程中纳米颗粒容易被阻挡在孔隙外,这进一步影响了高导热的纳米颗粒在木材中分布的均匀性,从而限制了导热性能的提升。

溶液还原法被认为是一种可行的、简便的制备金属纳米颗粒的方法,其常见的还原剂有水合肼、甲醛和抗坏血酸,与前两者相比抗坏血酸因其绿色环保,反应条件温和且无安全隐患而广受关注。此前,Wu等 [16]在适宜的pH值和反应温度下利用抗坏血酸还原Cu2+,制备出了高纯度非团聚的微米级单分散铜颗粒。微米级尺寸颗粒虽有效避免了团聚现象,但显然不适用于由外而内的浸渍过程。

本研究以轻木作为相变材料的封装基体,利用抗坏血酸作为硫酸铜溶液的还原剂在木材基体内原位生成金属Cu颗粒,由内而外地解决高导热纳米颗粒在木材中分布的不均匀性问题。为提高木质基体的孔隙率和Cu离子的稳定性,采用脱除木质素的方式,打开细胞壁封闭的孔道。本研究为探索绿色环保的复合相变储热材料导热增强提供新的研究思路和理论依据。

1. 材料和方法

1.1 材 料

轻木(Ochroma pyramidale),密度为0.16 g/cm3,尺寸为20 mm(长) × 20 mm(宽) × 6 mm(厚),购自珠海德驰科技有限公司。石蜡(paraffin wax,PW),购自上海麦克林生化科技有限公司,型号P815421。亚氯酸钠(NaClO2,分析纯)、冰醋酸(分析纯)、无水乙醇购自安徽泽升科技有限公司。五水硫酸铜(CuSO4·5H2O,分析纯)与抗坏血酸(分析纯)购自北京市通广精细化工公司。

1.2 轻木脱木素处理

首先,将轻木木块(natural balsa wood,NW)利用去离子水反复冲洗以去除灰尘等污染物。然后将清洗后的NW放入的质量分数为10%的亚氯酸钠溶液中,用冰醋酸将溶液pH值调节为4.6后,转移至80 ℃的集热式恒温控磁力搅拌器内进行脱木素处理,反应2.5 h后利用去离子水反复冲洗以去除残余化学药剂。将洗净的轻木转移至−18 ℃的冰箱中冷冻18 h后利用冷冻干燥机进行48 h的冷冻干燥,干燥完成后得到脱木素的轻木(delignified balsa wood,LW)。

1.3 Cu的原位生成

首先,将LW浸泡入质量分数为10%的五水硫酸铜溶液中,然后将其置于真空度为−0.1 MPa的真空烘箱内并反复进行充气与抽真空,直至木块沉入液体底部。将浸泡完硫酸铜溶液的木块转移至质量分数为3%的抗坏血酸溶液中进行金属铜的制备,并利用氨水将溶液pH调节为6,其反应温度为70 ℃,反应时间为2 h。然后将反应完毕的木块利用去离子水反复冲洗后按1.2的方法进行冷冻干燥,干燥完成后得到金属Cu负载的轻木(balsa wood loaded with copper particles,wood-Cu)。重复以上步骤1、3、5次,分别得到1次溶液还原法制备的(wood-Cu)1、3次溶液还原法制备的(wood-Cu)3和5次溶液还原法制备的(wood-Cu)5。

1.4 复合相变储热材料的制备

首先,将wood-Cu置于熔融的PW中,并转移至温度为70 ℃且真空度为−0.1 MPa的真空烘箱中,每30 min进行一次充气与抽真空并循环8次,以确保wood-Cu内完全充满PW。为了去除wood-Cu表面过量的PW,将封装完石蜡的木块用滤纸包裹并转移至70 ℃加热台上,每20 min更换一次滤纸,直至木块前后两次质量差小于0.01 g,得到Cu颗粒强化导热的木基复合相变储热材料 (wood-based composite phase-change heat storage materials with Cu particles to enhance heat conduction,wood-Cu-PW),其中(wood-Cu)1、(wood-Cu)3、(wood-Cu)5制备的复合相变储热材料分别为(wood-Cu)1-PW、(wood-Cu)3-PW、(wood-Cu)5-PW。将NW与LW重复以上步骤分别得到NW-PW与LW-PW。复合相变储热材料的封装效率按照下式计算:

ω=m1−m0m1×100% (1) 式中:ω为封装效率(%);m0为封装前木块的质量(g);m1为复合材料的质量(g)。每组实验平行5次,取均值。Cu颗粒强化导热的木基复合相变储热材料制备流程如图1所示。

![]() 图 1 Cu颗粒强化导热的木基复合相变储热材料制备流程图NW. 天然轻木;LW. 脱木素轻木;wood-Cu. 铜颗粒负载的轻木;wood-Cu-PW. Cu颗粒强化导热的木基复合相变储热材料。NW, natural balsa wood; LW, delignified balsa wood; wood-Cu, balsa wood supported by copper particles; wood-Cu-PW, wood-based composite phase-change heat storage materials with Cu particles to enhance heat conduction.Figure 1. Schematic diagram of the preparation of wood-based composite phase-change heat storage materials with Cu particles to enhance heat conduction

图 1 Cu颗粒强化导热的木基复合相变储热材料制备流程图NW. 天然轻木;LW. 脱木素轻木;wood-Cu. 铜颗粒负载的轻木;wood-Cu-PW. Cu颗粒强化导热的木基复合相变储热材料。NW, natural balsa wood; LW, delignified balsa wood; wood-Cu, balsa wood supported by copper particles; wood-Cu-PW, wood-based composite phase-change heat storage materials with Cu particles to enhance heat conduction.Figure 1. Schematic diagram of the preparation of wood-based composite phase-change heat storage materials with Cu particles to enhance heat conduction1.5 测试与表征

样品的微观形貌利用SU8010场发射扫描电子显微镜(scanning electron microscope,SEM)检测,加速电压5 kV,检测前对样品进行喷金处理。并用场发射扫描电镜配套的能量色散X射线谱(energy dispersive spectrometer,EDS)获得特定元素的分布图。样品的化学结构利用FST135傅里叶红外光谱仪(Fourier transform infrared spectroscopy,FTIR)进行测试,扫描范围400 ~ 4 000 cm−1。样品的结晶结构利用Bruker D8 ADVANCE X射线衍射仪(X-ray Diffraction,XRD)进行检测,扫描速度5 (°)/min,扫描范围5° ~ 70°。样品的相变性能利用TA-DSC250差式扫描量热仪(differential scanning calorimeter,DSC)进行检测,升降温速率5 (°)/min。依据GB/T 32064—2015《建筑用材料导热系数和热扩散系数瞬态平面热源测试法》利用DRE-2C导热系数测试仪对材料的导热系数进行测试,每组测试平行5次,取均值。利用XMT-300温度巡检仪在升降温过程中对材料芯层的温度进行测量,升温过程中热源为70 ℃水浴锅,降温过程为室温环境。脱木素前后轻木的壁腔比测试方法如下:将轻木按顺纹方向劈成火柴棍大小后,采用离析法[17]分离成单根纤维。在Axio Imager Z2电动显微系统下测量轻木细胞壁腔比指标,测量数量为30根。

2. 结果与讨论

2.1 轻木液体渗透性的提高

图2a、2b显示:轻木表面颜色随着木质素的脱除,从黄色变为了白色。这是因为木质素中含有大量构成木材颜色的显色与助色基团[18],故而随着木质素的脱除,木材最直观的变化体现在其宏观颜色的改变。而从图2c脱木素前后轻木的红外光谱图中可以进一步观察到,代表木质素的典型特征峰(1 591、1 500、1 462 cm−1)消失。这充分表明了木质素得到了脱除。为了进一步探究脱木素对轻木基体的影响,利用SEM对NW与LW的微观结构进行了表征,结果如图2d ~ 2g所示。NW整体呈现出了三维蜂窝状网络结构,其各个细胞腔体被厚度为1 ~ 3 μm的双层细胞壁分隔,同时可以观察到细胞壁上分布着大量纹孔。值得注意的是,这些在木材生长过程中负责水分和养料横向输送的通道部分显现出了闭塞的状态,这显然不利于真空浸渍过程中石蜡在轻木机体内的渗透。木质素作为木材细胞壁的三大组成成分之一,广泛分布于细胞壁的各个层级之中。其中,木质素在细胞壁细胞角隅与胞间层区域内相对含量浓度最高[19]。故而,在经过酸性亚氯酸钠脱木素处理后,轻木细胞壁明显变薄,这也导致其壁腔比从0.24下降至0.21。同时壁层之间开始分离,并且在细胞角隅最为明显。这些变化为PW的封装提供了较大的开放空间。值得注意的是,LW细胞壁上随机分布的纹孔随着木质素的脱除变得通透,这为CuSO4溶液和相变储热材料浸渍“生物质三维高孔隙率材料”构筑了开敞的渗透通道。而具体的提升效果从图2h ~ 2i脱木素轻木与天然轻木制备的复合相变储热材料SEM图中可以得到体现。对比NW-PW与LW-PW的SEM图可以发现,PW在轻木细胞腔内从部分填满变成了完全填满,这也就造成了轻木对PW的封装效率从64.9%提升到了82.6%。

![]() 图 2 脱木素对轻木及其制备的复合相变材料的影响PW为石蜡;NW-PW为天然轻木与石蜡制备的复合相变储热材料;LW-PW为脱木素轻木与石蜡制备的复合相变储热材料。PW is paraffin wax. NW-PW is a composite phase change heat storage material prepared from natural balsa wood and paraffin wax. LW-PW is a composite phase change heat storage material prepared by delignified balsa wood and paraffin wax.Figure 2. Effects of delignification on balsa wood and its composite phase change materials

图 2 脱木素对轻木及其制备的复合相变材料的影响PW为石蜡;NW-PW为天然轻木与石蜡制备的复合相变储热材料;LW-PW为脱木素轻木与石蜡制备的复合相变储热材料。PW is paraffin wax. NW-PW is a composite phase change heat storage material prepared from natural balsa wood and paraffin wax. LW-PW is a composite phase change heat storage material prepared by delignified balsa wood and paraffin wax.Figure 2. Effects of delignification on balsa wood and its composite phase change materials2.2 Cu颗粒的负载和复合材料导热性能分析

为了提高木质基复合相变储热材料的导热性能,本研究采用CuSO4溶液对脱木素轻木进行浸泡后,在适宜的pH值及反应温度下利用抗坏血酸(又称维生素C)对Cu2+进行原位还原制造了金属铜颗粒。其中,单分散的金属Cu颗粒的形成可以通过两步机制来进行:首先部分Cu2+被还原而产生初级粒子,然后聚集成更大的最终产物。而聚集过程存在着扩散限制和反应限制过程,初级粒子必须克服能量障碍才能有效地与生长的粒子碰撞。如果反应速度过快,快速形成大量的铜核会导致颗粒过小,容易被氧化,故而选用还原性较温和的抗坏血酸作为还原剂显然更加合适。正如图3a所示,所制备的单分散金属Cu颗粒整体呈现出由小颗粒生长聚集而形成的微米级大颗粒。而从图3b ~ 3d EDS检测结果中可以发现:在铜颗粒范围内,相对于Cu元素,O元素含量几乎可忽略不计。这表明所生成的单分散金属Cu颗粒为Cu单质,且在制备过程中并未发生氧化。

为了保证所产生的金属Cu颗粒足够形成连通的导热通路,对轻木基体分别进行了多次的Cu制备。其中,经过1、3、5次循环反应后,轻木基体变化如图4所示。经过1次循环后轻木颜色往红棕色转变,其基体内出现了微米级别的铜颗粒,但数量较少且分布较为稀疏。而随着循环次数的增加,轻木颜色逐步加深,其基体内的铜颗粒数量也上升且分布逐渐紧密搭接却并未发生团聚现象。经过计算得知,Cu颗粒在轻木中的质量百分数随着循环次数的增加分别达到了7%、15%与19%。而从复合材料的电镜图中可观察到,石蜡均匀分布在轻木基体内,表明铜颗粒的负载并不会影响石蜡与轻木的相容性。而值得注意的是,随着循环次数的增多,轻木基体对石蜡的封装效率分别降低至76.4%、72.9%和69.3%,这可能是因为形成的铜颗粒占据了一部分体积的同时也堵塞了部分孔隙,影响了石蜡在轻木基体内的渗透性。纯石蜡的导热系数为0.23 W/(m·K),而脱木素轻木的导热系数为0.08 W/(m·K)(顺纹方向)。随着一次溶液还原法制备的Cu颗粒的负载,复合材料的导热系数从LW-PW的 0.21 W/(m·K)提升至了(wood-Cu)1-PW的0.26 W/(m·K),提升效果并不明显。这是因为1次循环的溶液还原法制备的铜颗粒在木质基相变储热材料中以“孤岛”的形式分布,传热网络较松散,因此导热性能提升不明显[20]。而随着循环次数的增加,Cu颗粒的含量逐步增多,有效的导热网络在木质基复合相变储热材料中成功构筑,故而材料的导热系数分别提升至(wood-Cu)3-PW的0.37 W/(m·K)、(wood-Cu)5-PW的0.39 W/(m·K)。从封装效率和导热系数的变化结合经济效益可知,循环3次后的wood-Cu作为石蜡的封装基体显然更加适合,因此下文将着重以3次循环的材料进行分析。

![]() 图 4 多次溶液循环法对轻木及制备的复合相变储热材料的影响(wood-Cu)1、(wood-Cu)3、(wood-Cu)5 分别代表1次溶液还原法制备的wood-Cu、3次溶液还原法制备的wood-Cu和5次溶液还原法制备的wood-Cu;(wood-Cu)1 -PW、(wood-Cu)3-PW、(wood-Cu)5-PW分别代表(wood-Cu)1、(wood-Cu)3、(wood-Cu)5制备的复合相变储热材料。(wood-Cu)1, (wood-Cu)3 and (wood-Cu)5 represent wood-Cu prepared by one cycle of solution reduction method, wood-Cu prepared by three cycles of solution reduction methods and wood-Cu prepared by five cycles of solution reduction methods, respectively. (wood-Cu)1-PW, (wood-Cu)3-PW and (wood-Cu)5-PW represent the composite phase change heat storage materials prepared by (wood-Cu)1, (wood-Cu)3 and (wood-Cu)5, respectively.Figure 4. Effects of multiple solution circulation on balsa wood and its composite phase change heat storage materials

图 4 多次溶液循环法对轻木及制备的复合相变储热材料的影响(wood-Cu)1、(wood-Cu)3、(wood-Cu)5 分别代表1次溶液还原法制备的wood-Cu、3次溶液还原法制备的wood-Cu和5次溶液还原法制备的wood-Cu;(wood-Cu)1 -PW、(wood-Cu)3-PW、(wood-Cu)5-PW分别代表(wood-Cu)1、(wood-Cu)3、(wood-Cu)5制备的复合相变储热材料。(wood-Cu)1, (wood-Cu)3 and (wood-Cu)5 represent wood-Cu prepared by one cycle of solution reduction method, wood-Cu prepared by three cycles of solution reduction methods and wood-Cu prepared by five cycles of solution reduction methods, respectively. (wood-Cu)1-PW, (wood-Cu)3-PW and (wood-Cu)5-PW represent the composite phase change heat storage materials prepared by (wood-Cu)1, (wood-Cu)3 and (wood-Cu)5, respectively.Figure 4. Effects of multiple solution circulation on balsa wood and its composite phase change heat storage materials2.3 复合相变储热材料的相变性能

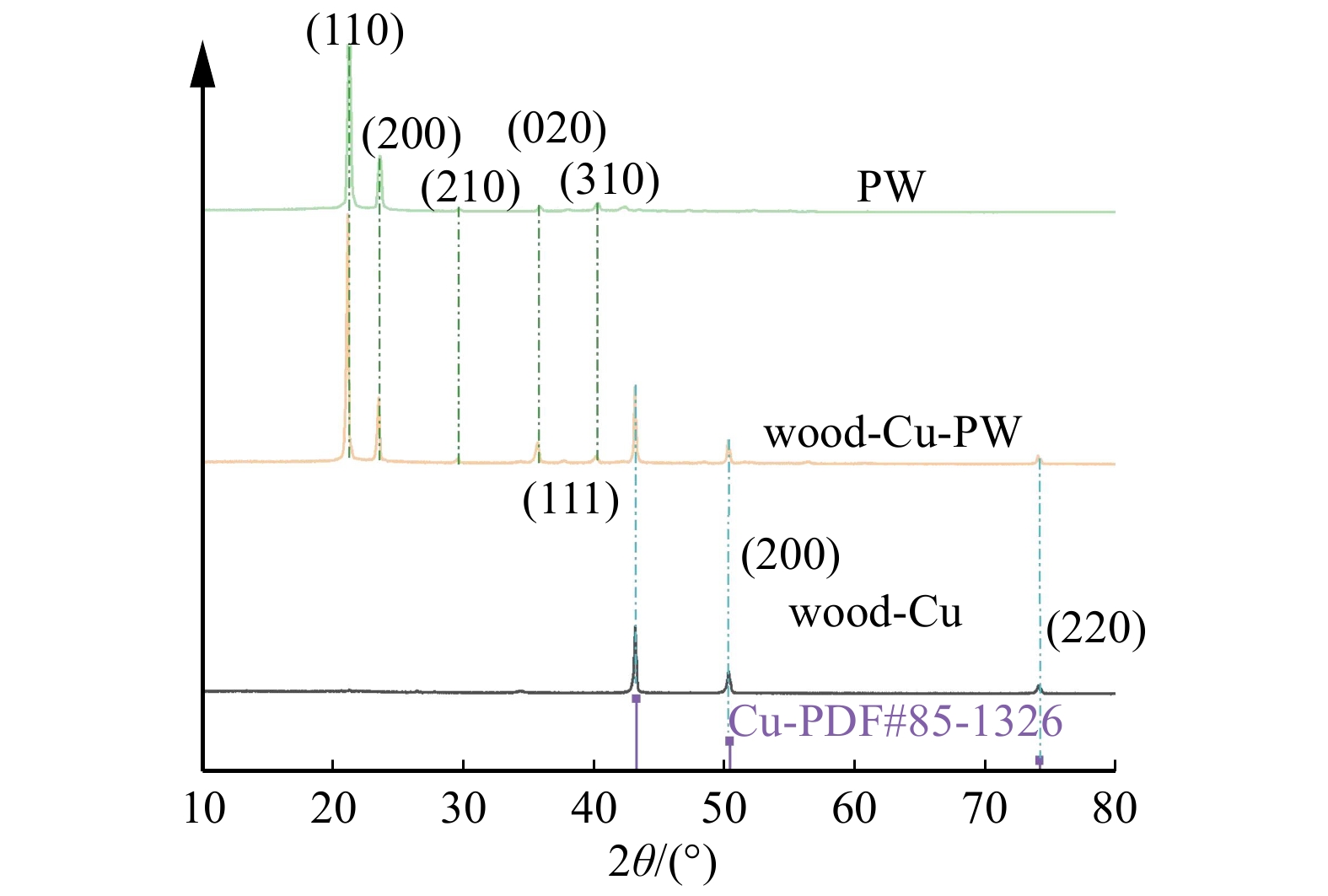

为了探究wood-Cu对相变材料产生的潜在影响,利用XRD对材料进行了进一步的研究,结果如图5所示。从wood-Cu的XRD图谱中可以发现:在43.3°、50.4°、74.1°出现了新的衍射峰分别对应了Cu的(111)、(200)、(220)晶面,这与Cu的标准卡片(PDF#85-1326)相一致,证实了图4中轻木细胞腔内生成的颗粒为单质金属Cu。而在wood-Cu-PW的XRD图谱中除却wood-Cu的衍射峰外,出现了属于PW的(110)、(200)、(210)、(020)、(310)晶面所对应的衍射峰,表明PW被wood-Cu成功封装;除此以外并未发现新的衍射峰,表明PW与wood-Cu之间无化学反应仅存在物理结合,这对保持PW原有的性能有着重要意义。

各个材料的DSC曲线见图6,而相变温度和相变潜热等参数见表1。从图6a中可以观察到各个材料的DSC曲线均展现出两个吸热和放热峰。这与石蜡高度一致,表明石蜡为各个复合材料中的主要储放热物质。其中,温度较低的峰为石蜡的固–固相变过程,此峰相变潜热较低;而温度较高的峰代表了石蜡的固–液相变过程,其较高的相变潜热为材料高效的储放热奠定了基础。从表1中可以看出,脱木素处理后随着封装效率的提升,轻木与石蜡所制备的木质基复合相变储热材料的熔融与凝固潜热分别从129.5、128.6 J/g提升至161.4、160.3 J/g。而随着Cu颗粒在轻木基体内的负载,占据了部分体积及孔隙,造成了wood-Cu-PW封装效率的下降。wood-Cu-PW的熔融与凝固潜热虽然不及LW-PW,但仍然分别高达143.7、142.9 J/g。通常情况下,利用复合相变储热材料的理论封装效率与实际封装效率的比值来展示封装基体对相变材料的影响程度(η,%)[9],具体如式2所示。

表 1 不同试样的DSC测试结果Table 1. DSC test results of different samples试样

Sample熔融过程

Melting process凝固过程

Solidification processTm1/℃ Tm2/℃ ΔHm/(J·g−1) Ts1/℃ Ts2/℃ ΔHs/(J·g−1) PW 24.5 45.6 201.7 51.3 32.4 201.5 NW-PW 25.2 45.9 129.5 51.5 33.5 128.6 LW-PW 24.8 47.4 161.4 51.6 30.9 160.3 wood-Cu-PW 24.7 45.7 143.7 51.6 33.8 142.9 (wood-Cu-PW)200 25.3 45.8 141.1 51.7 33.4 140.9 注:Tm1为材料熔融过程中的固—固转变温度;Tm2为材料熔融过程中的固—液转变温度;ΔHm为材料的熔融潜热;Ts1为材料凝固过程中的液—固转变温度;Ts2为材料凝固过程中的固—固转变温度;ΔHs为材料的凝固潜热。Notes: Tm1 is the solid-solid change temperature during material melting; Tm2 is the solid-liquid change temperature during material melting; ΔHm is the melting latent heat of materials; Ts1 is the liquid-solid change temperature during solidification of materials; Ts2 is the solid-solid change temperature during material solidification; ΔHs is the latent heat of solidification of materials. η=ωTωA×100% (2) 式中:ωT为理论封装效率(%),通过DSC测出的复合材料的相变潜热与纯石蜡的相变潜热的比值计算得到;ωA为实际封装效率(%),通过式(1)计算得到的封装效率。

经过计算,NW-PW的η值高达98.9%,相反LW-PW值下降至96.8%。这可能是因为在脱木素后,轻木基体暴露了大量的羟基,这些羟基与非极性的PW之间存在着排斥型的弱相互作用力;同时,轻木基体内因为脱木素增加的与PW分子尺寸大小相似的纳米级孔隙,对封装在内的PW产生了纳米级孔隙作用进而影响了部分PW分子的相变行为[21-22]。而随着Cu颗粒的负载,wood-Cu-PW的η值提升至97.6%。这得益于轻木基体内生成的Cu颗粒对部分羟基和孔隙的掩盖,弱化了那部分排斥型的弱相互作用力及纳米级孔隙作用。上述结果说明了Cu颗粒的负载,不仅能够提高木质基复合相变储热材料的导热性能,对弱化基体对相变材料的影响效果也起到了促进的作用。

为了考察wood-Cu-PW的热循环稳定性,将其进行了200次冷—热循环实验。从图6b中可以看出,材料在200次冷—热循环试验前后的DSC曲线变化不大。而表1则显示,材料在200次冷—热循环试验前后的熔融和凝固潜热分别仅减少了1.8%与1.3%,这可能是由于复合材料表面孔隙内极少量未被吸附住的PW的泄露,但数值几乎可以忽略不计,表明wood-Cu-PW具有较好的热循环稳定性能。而从表2中可以很明显地看出:本研究所制备的木质基复合相变储热材料,其相变潜热及导热系数均优于大多数木质基复合相变储热材料。

表 2 各类木质基复合相变材料性能对比Table 2. Performance comparison of different wood-based composite phase change heat storage material试样类型 Sample type 相变潜热

Latent heat/(J·g−1)导热系数

Thermal conductivity/(W·m−1·K−1)参考文献

Reference脱木素轻木−石蜡−铜颗粒

Delignified balsa wood-paraffin wax- copper particle143.7 0.370 本文

This paper花旗松–聚乙二醇

Douglas fir- polyethylene glycol73.59 [23] 杨木–聚乙二醇

Poplar-polyethylene glycol94.9 [24] 脱木素雪松–(葵酸和棕榈酸)

Delignified cedar-(caproic acid and palmitic acid)90.9 [7] 碳化木–石蜡

Carbonized wood-paraffin wax206.3 0.182 [25] 碳化木粉–聚乙二醇–(Fe3O4和石墨烯)

Carbonized wood flour-polyethylene glycol-(Fe3O4 and graphene)98.1 0.225 [26] 木粉–石蜡–石墨

Wood flour-paraffin wax-graphite45.9 0.320 [27] 木屑–聚乙二醇–膨胀石墨

Wood chips-polyethylene glycol-expanded graphite145.3 0.143 [28] 2.4 复合相变储热材料的储放热性能

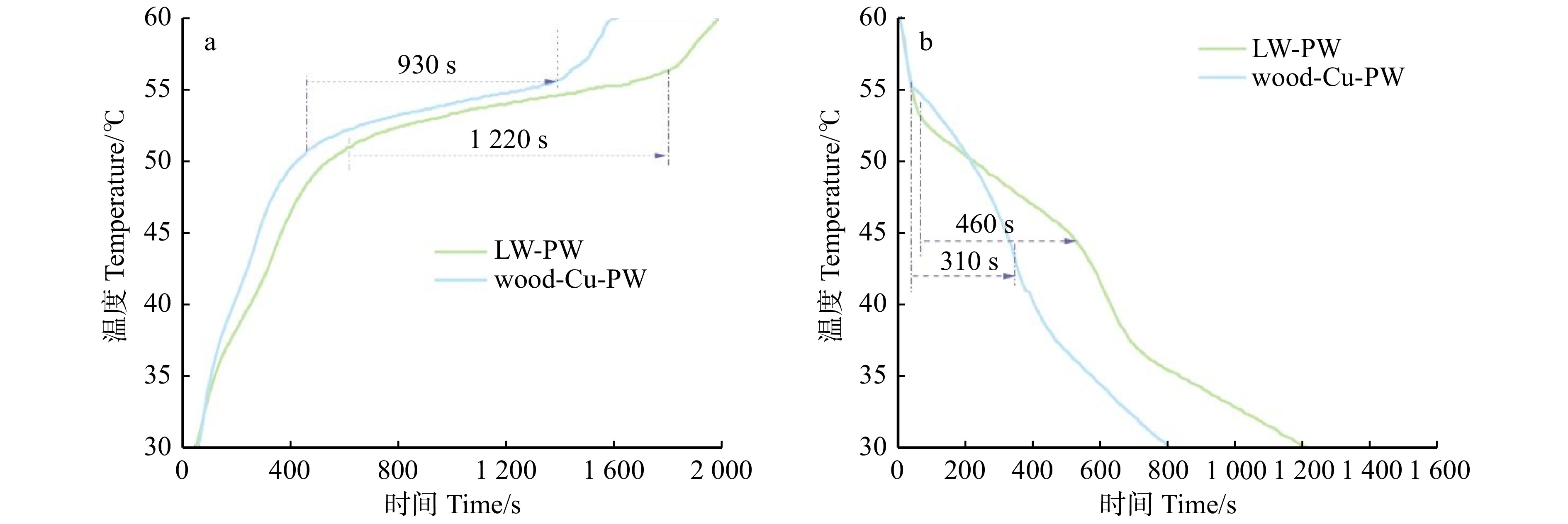

复合相变储热材料的相变潜热决定了其储放热的总量,而材料的储放热效率则取决于其本身的导热系数,为此利用温度巡检仪分别对LW-PW与wood-Cu-PW的升降温过程进行了记录,结果如图7所示。LW-PW与wood-Cu-PW在分别到达升温与降温阶段的固液相变温度区间时升降温速率均明显变缓,表明LW-PW与wood-Cu-PW内的PW正在进行相态的转变而大量地储存或者释放热量。在图7a材料的升温过程可以观察到:LW-PW内的PW的熔融过程持续了1 220 s,而wood-Cu-PW却缩短到了930 s。而在图7b材料的降温过程可以观察到:LW-PW内的PW的熔融过程持续了460 s,而wood-Cu-PW却缩短到了310 s。综上结果表明,虽然材料的封装效率下降了9.7%,但随着热量传递网络的构筑,材料的导热性能大幅度提升,材料的升降温过程中储放热速率分别提升了23.7%与32.6%,展现出了更好的温度调节潜力。

3. 结 论

(1)轻木经脱木素处理后其细胞壁变薄,壁腔比减小,同时纹孔变得通透,对石蜡的封装效率从64.9%提升至82.6%。

(2)经过抗坏血酸对Cu2+的还原反应,在轻木基体内原位制造出了金属Cu颗粒。然而循环次数过少,Cu不能均匀地分布在木材基体内,而过多的循环次数则会过量地影响轻木对相变材料的封装效果;其中循环3次最为合适,以此所制备的复合相变储热材料熔融及凝固潜热分别高达143.7、142.9 J/g,且导热系数提升了1.76倍。

(3)wood-Cu-PW在升降温过程中储放热速率较LW-PW分别提升了23.7%与32.6%,展现出了更好的温度调节能力,具有在建筑节能领域较好的应用潜力。

-

图 1 Cu颗粒强化导热的木基复合相变储热材料制备流程图

NW. 天然轻木;LW. 脱木素轻木;wood-Cu. 铜颗粒负载的轻木;wood-Cu-PW. Cu颗粒强化导热的木基复合相变储热材料。NW, natural balsa wood; LW, delignified balsa wood; wood-Cu, balsa wood supported by copper particles; wood-Cu-PW, wood-based composite phase-change heat storage materials with Cu particles to enhance heat conduction.

Figure 1. Schematic diagram of the preparation of wood-based composite phase-change heat storage materials with Cu particles to enhance heat conduction

图 2 脱木素对轻木及其制备的复合相变材料的影响

PW为石蜡;NW-PW为天然轻木与石蜡制备的复合相变储热材料;LW-PW为脱木素轻木与石蜡制备的复合相变储热材料。PW is paraffin wax. NW-PW is a composite phase change heat storage material prepared from natural balsa wood and paraffin wax. LW-PW is a composite phase change heat storage material prepared by delignified balsa wood and paraffin wax.

Figure 2. Effects of delignification on balsa wood and its composite phase change materials

图 4 多次溶液循环法对轻木及制备的复合相变储热材料的影响

(wood-Cu)1、(wood-Cu)3、(wood-Cu)5 分别代表1次溶液还原法制备的wood-Cu、3次溶液还原法制备的wood-Cu和5次溶液还原法制备的wood-Cu;(wood-Cu)1 -PW、(wood-Cu)3-PW、(wood-Cu)5-PW分别代表(wood-Cu)1、(wood-Cu)3、(wood-Cu)5制备的复合相变储热材料。(wood-Cu)1, (wood-Cu)3 and (wood-Cu)5 represent wood-Cu prepared by one cycle of solution reduction method, wood-Cu prepared by three cycles of solution reduction methods and wood-Cu prepared by five cycles of solution reduction methods, respectively. (wood-Cu)1-PW, (wood-Cu)3-PW and (wood-Cu)5-PW represent the composite phase change heat storage materials prepared by (wood-Cu)1, (wood-Cu)3 and (wood-Cu)5, respectively.

Figure 4. Effects of multiple solution circulation on balsa wood and its composite phase change heat storage materials

表 1 不同试样的DSC测试结果

Table 1 DSC test results of different samples

试样

Sample熔融过程

Melting process凝固过程

Solidification processTm1/℃ Tm2/℃ ΔHm/(J·g−1) Ts1/℃ Ts2/℃ ΔHs/(J·g−1) PW 24.5 45.6 201.7 51.3 32.4 201.5 NW-PW 25.2 45.9 129.5 51.5 33.5 128.6 LW-PW 24.8 47.4 161.4 51.6 30.9 160.3 wood-Cu-PW 24.7 45.7 143.7 51.6 33.8 142.9 (wood-Cu-PW)200 25.3 45.8 141.1 51.7 33.4 140.9 注:Tm1为材料熔融过程中的固—固转变温度;Tm2为材料熔融过程中的固—液转变温度;ΔHm为材料的熔融潜热;Ts1为材料凝固过程中的液—固转变温度;Ts2为材料凝固过程中的固—固转变温度;ΔHs为材料的凝固潜热。Notes: Tm1 is the solid-solid change temperature during material melting; Tm2 is the solid-liquid change temperature during material melting; ΔHm is the melting latent heat of materials; Ts1 is the liquid-solid change temperature during solidification of materials; Ts2 is the solid-solid change temperature during material solidification; ΔHs is the latent heat of solidification of materials. 表 2 各类木质基复合相变材料性能对比

Table 2 Performance comparison of different wood-based composite phase change heat storage material

试样类型 Sample type 相变潜热

Latent heat/(J·g−1)导热系数

Thermal conductivity/(W·m−1·K−1)参考文献

Reference脱木素轻木−石蜡−铜颗粒

Delignified balsa wood-paraffin wax- copper particle143.7 0.370 本文

This paper花旗松–聚乙二醇

Douglas fir- polyethylene glycol73.59 [23] 杨木–聚乙二醇

Poplar-polyethylene glycol94.9 [24] 脱木素雪松–(葵酸和棕榈酸)

Delignified cedar-(caproic acid and palmitic acid)90.9 [7] 碳化木–石蜡

Carbonized wood-paraffin wax206.3 0.182 [25] 碳化木粉–聚乙二醇–(Fe3O4和石墨烯)

Carbonized wood flour-polyethylene glycol-(Fe3O4 and graphene)98.1 0.225 [26] 木粉–石蜡–石墨

Wood flour-paraffin wax-graphite45.9 0.320 [27] 木屑–聚乙二醇–膨胀石墨

Wood chips-polyethylene glycol-expanded graphite145.3 0.143 [28] -

[1] Huang X, Chen X, Li A, et al. Shape-stabilized phase change materials based on porous supports for thermal energy storage applications[J]. Chemical Engineering Journal, 2019, 356: 641−661. doi: 10.1016/j.cej.2018.09.013

[2] Gulfam R, Zhang P, Meng Z. Advanced thermal systems driven by paraffin-based phase change materials: a review[J]. Applied Energy, 2019, 238: 582−611. doi: 10.1016/j.apenergy.2019.01.114

[3] Kahwaji S, Johnson M B, Kheirabadi A C, et al. A comprehensive study of properties of paraffin phase change materials for solar thermal energy storage and thermal management applications[J]. Energy, 2018, 162: 1169−1182. doi: 10.1016/j.energy.2018.08.068

[4] Lin Y, Zhu C, Alva G, et al. Microencapsulation and thermal properties of myristic acid with ethyl cellulose shell for thermal energy storage[J]. Applied Energy, 2018, 231: 494−501. doi: 10.1016/j.apenergy.2018.09.154

[5] Heyhat M M, Mousavi S, Siavashi M. Battery thermal management with thermal energy storage composites of PCM, metal foam, fin and nanoparticle[J]. Journal of Energy Storage, 2020, 28: 101235. doi: 10.1016/j.est.2020.101235

[6] Fan L, Khodadadi J M. Thermal conductivity enhancement of phase change materials for thermal energy storage: a review[J]. Renewable and Sustainable Energy Reviews, 2011, 15(1): 24−46. doi: 10.1016/j.rser.2010.08.007

[7] Sarı A, Hekimoğlu G, Tyagi V V. Low cost and eco-friendly wood fiber-based composite phase change material: development, characterization and lab-scale thermoregulation performance for thermal energy storage[J]. Energy, 2020, 195: 116983. doi: 10.1016/j.energy.2020.116983

[8] Xia R, Zhang W, Yang Y, et al. Transparent wood with phase change heat storage as novel green energy storage composites for building energy conservation[J]. Journal of Cleaner Production, 2021, 296: 126598. doi: 10.1016/j.jclepro.2021.126598

[9] Meng Y, Majoinen J, Zhao B, et al. Form-stable phase change materials from mesoporous balsa after selective removal of lignin[J]. Composites Part B: Engineering, 2020, 199: 108296. doi: 10.1016/j.compositesb.2020.108296

[10] Yang H, Wang Y, Yu Q, et al. Low-cost, three-dimension, high thermal conductivity, carbonized wood-based composite phase change materials for thermal energy storage[J]. Energy, 2018, 159: 929−936. doi: 10.1016/j.energy.2018.06.207

[11] Zhou M, Wang J, Zhao Y, et al. Hierarchically porous wood-derived carbon scaffold embedded phase change materials for integrated thermal energy management, electromagnetic interference shielding and multifunctional application[J]. Carbon, 2021, 183: 515−524. doi: 10.1016/j.carbon.2021.07.051

[12] Lin X, Jia S, Liu J, et al. Fabrication of thermal energy storage wood based on graphene aerogel encapsulated polyethylene glycol as phase change material[J]. Materials Research Express, 2020, 7(9): 095503. doi: 10.1088/2053-1591/abb261

[13] 孟杨. 木基定型复合相变材料的构筑与功能强化[D]. 北京: 北京林业大学, 2021. Meng Y. Preparation and multifunctional innovation of wood-based form-stable composite phase change materials[D]. Beijing: Beijing Forestry University, 2021.

[14] 刘杰梅, 王宁, 宋亚伟, 等. 赤藻糖醇基相变材料热性能的实验研究[J]. 现代化工, 2020, 40(6): 66−71. Liu J M, Wang N, Song Y W, et al. Experimental study on thermal properties of erythritol-based phase change materials[J]. Modern Chemical Industry, 2020, 40(6): 66−71.

[15] 刘文静, 张玉君. 细胞壁空隙对木材性能及加工利用的影响[J]. 世界林业研究, 2021, 34(2): 44−48. Liu W J, Zhang Y J. Effects of pore structure in cell wall on wood properties and processing utilization[J]. World Forestry Research, 2021, 34(2): 44−48.

[16] Wu S. Preparation of fine copper powder using ascorbic acid as reducing agent and its application in MLCC[J]. Materials Letters, 2007, 61(4−5): 1125−1129. doi: 10.1016/j.matlet.2006.06.068

[17] 唐爽, 孙照斌, 马长明. 冀北山区不同坡向白桦木材解剖特性径向变异研究[J]. 西南林业大学学报(自然科学), 2018, 38(3): 157−165. Tang S, Sun Z B, Ma C M. Radial variation of anatomical properties of Betula platyphylla wood in different slope directions of northern Hebei Province[J]. Journal of Southwest Forestry University (Natural Sciences), 2018, 38(3): 157−165.

[18] 周凡, 高鑫, 付宗营, 等. 黑木相思木材化学组分对其颜色株内变异的影响[J]. 中南林业科技大学学报, 2021, 41(6): 42−50. Zhou F, Gao X, Fu Z Y, et al. Effect of chemical components on wood color variation of Acacia melanoxylon[J]. Journal of Central South University of Forestry & Technology, 2021, 41(6): 42−50.

[19] 李柬龙, 陈胜, 李海潮, 等. 轻木细胞壁超微结构与力学性能关系研究[J]. 北京林业大学学报, 2022, 44(2): 115−122. doi: 10.12171/j.1000-1522.20210410 Li J L, Chen S, Li H C, et al. Relationship between cell wall ultrastructure and mechanical properties of balsa wood[J]. Journal of Beijing Forestry University, 2022, 44(2): 115−122. doi: 10.12171/j.1000-1522.20210410

[20] 张仲彬, 朱长林. 碳纳米管–氮化硼/肉豆蔻酸复合相变材料的蓄热性能研究[J]. 中国电机工程学报, 2021, 41(13): 4585−4594. Zhang Z B, Zhu C L. Study on the Thermal storage performance for carbon nanotubes-boron nitride/myristic acid composite phase change material[J]. Proceedings of the Chinese Society for Electrical Engineering, 2021, 41(13): 4585−4594.

[21] Zhang Y, Zheng S, Zhu S, et al. Evaluation of paraffin infiltrated in various porous silica matrices as shape-stabilized phase change materials for thermal energy storage[J]. Energy Conversion and Management, 2018, 171: 361−370. doi: 10.1016/j.enconman.2018.06.002

[22] Wang C, Feng L, Li W, et al. Shape-stabilized phase change materials based on polyethylene glycol/porous carbon composite: the influence of the pore structure of the carbon materials[J]. Solar Energy Materials and Solar Cells, 2012, 105: 21−26. doi: 10.1016/j.solmat.2012.05.031

[23] Li Y, Li X, Liu D, et al. Fabrication and properties of polyethylene glycol-modified wood composite for energy storage and conversion[J]. BioResources, 2016, 11(3): 7790−7802.

[24] Jiang L, Lei Y, Liu Q, et al. Facile preparation of polyethylene glycol/wood-flour composites as form-stable phase change materials for thermal energy storage[J]. Journal of Thermal Analysis and Calorimetry, 2019, 139(1): 137−146.

[25] Pan X, Zhang N, Yuan Y, et al. Balsa-based porous carbon composite phase change material with photo-thermal conversion performance for thermal energy storage[J]. Solar Energy, 2021, 230: 269−277. doi: 10.1016/j.solener.2021.10.046

[26] Chao W, Yang H, Cao G, et al. Carbonized wood flour matrix with functional phase change material composite for magnetocaloric-assisted photothermal conversion and storage[J]. Energy, 2020, 202: 117636. doi: 10.1016/j.energy.2020.117636

[27] Li J, Xue P, Ding W, et al. Micro-encapsulated paraffin/high-density polyethylene/wood flour composite as form-stable phase change material for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2009, 93(10): 1761−1767. doi: 10.1016/j.solmat.2009.06.007

[28] Yang H, Wang Y, Liu Z, et al. Enhanced thermal conductivity of waste sawdust-based composite phase change materials with expanded graphite for thermal energy storage[J]. Bioresources and Bioprocessing, 2017, 4(1): 1−12. doi: 10.1186/s40643-016-0134-4

-

期刊类型引用(6)

1. 刘芮,王振兴,张文静,张生德,张清华. 储热材料研究现状及相变储热研究进展. 电机与控制应用. 2024(02): 44-60 .  百度学术

百度学术

2. 陈松武,黄海英,禤示青,刘晓玲,陈桂丹,王浏浏. “双碳”背景下木材加工产业的发展重点与方向的研讨. 浙江林业科技. 2024(04): 112-116 .  百度学术

百度学术

3. 韦溶军,王志闯,王雪纯,王婷欢,王振宇,何正斌,伊松林. 锡铋合金/肉豆蔻酸制备具有金属外壳的储能木材. 北京林业大学学报. 2024(08): 25-33 .  本站查看

本站查看

4. 庞群艳,胡纲正,李文轩,贺磊,邱竑韫,黄慧,何文. 纳米铜热处理竹材制备及其防霉性能. 林业工程学报. 2024(06): 37-43 .  百度学术

百度学术

5. 鲍伟,王胜捷,蒲万兴,宋子豪. 复合相变材料导热性能与套管式相变储热单元翅片结构优化. 农业工程学报. 2024(23): 303-312 .  百度学术

百度学术

6. 何林韩,刘晓玲,陈松武,罗玉芬,王浏浏. 木质基复合相变材料的研究现状与发展趋势. 化工新型材料. 2023(S2): 525-531 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: