Research progress on the effect of water on pore structure of wood cell wall

-

摘要:

木材是一种具有多级孔隙结构的天然可再生资源,其孔隙构造尤其是细胞壁孔隙结构至关重要。细胞壁孔隙结构的研究是木材加工的理论基础,对于提高木材综合利用率具有重要的现实意义。本文简要介绍了木材孔隙的种类及其表征技术,在此基础上梳理了水分对木材细胞壁孔隙结构影响的相关研究成果,总结了目前由水分引发的木材细胞壁孔隙结构变化领域仍存在的一些问题与挑战,对未来的发展方向及其前景进行展望,以期为深入揭示木材与水分的相互作用提供参考。

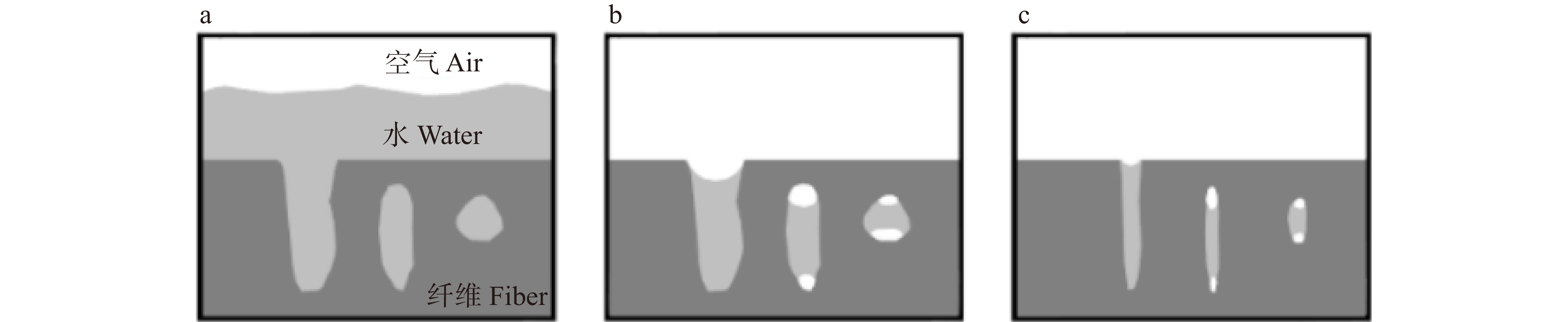

Abstract:Wood is a kind of natural renewable resource with multi-pore structure. Its pore structure, especially the cell wall pore structure, is highly important, which is a fundamental scientific issue in wood processing, with practical significance for improving the comprehensive utilization rate of wood. In this paper, the types of pores in wood and their characterization techniques were briefly introduced. On this basis, research progress concerning the effect of water on the pore structure of wood cell wall was reviewed. Existing problems and challenges in the field of pore structure changes of wood cell wall induced by water were summarized, and the future work and prospects were prospected, with the wish of providing new insights and deep understanding for revealing the interaction between wood and water.

-

Keywords:

- wood pore /

- cell wall /

- wood water /

- pore structure /

- pore characterization

-

-

表 1 木材中介观空隙的直径大小

Table 1 Diameter size of mesoscopic voids in wood

空隙种类 Type of void 直径 Diameter/nm 具缘纹孔塞缘小孔(针叶材) Small pores in the margo of bordered pit (softwood) 20 ~ 8 000 单纹孔纹孔膜小孔(针叶材) Small pores in the membrane of single pit (softwood) 50 ~ 300 细胞壁中空隙(干燥状态) Voids in the cell wall (dry state) 2 ~ 10 细胞壁中空隙(湿润状态) Voids in the cell wall (wet state) 1 ~ 10 微纤丝间隙(润胀状态) Microfibril gaps (swollen state) 2.0 ~ 4.5 注:引自文献[3]。Note: cited from reference [3]. 表 2 不同孔隙表征方法的适测孔径范围

Table 2 Range of suitable pore sizes for different pore characterisation methods

项目

Item压汞法

Mercury intrusion porosimetry气体吸附法

Gas adsorption isotherms溶质排斥法

Solute exclusion差示扫描热孔计法

Differential scanning calorimetry thermoporosimetry核磁共振冷孔计法

Nuclear magnetic resonance cryoporometry孔径范围

Pore diameter range/nm50 ~ 5 000 0.3 ~ 300.0 0.8 ~ 586.0 3.9 ~ 582.0 2.6 ~ 396.0 注:引自文献[5]。Note: cited from reference [5]. -

[1] 中户莞二. 木材の空隙構造[J]. 材料(日), 1973, 22(241): 903−907. Kanji N. Pore structure of wood[J]. Materials, 1973, 22(241): 903−907.

[2] 赵广杰. 木材中的纳米尺度、纳米木材及木材–无机纳米复合材料[J]. 北京林业大学学报, 2002, 24(5/6): 204−207. Zhao G J. Nano-dimensions in wood, nano-wood, wood and inorganic nano-composites[J]. Journal of Beijing Forestry University, 2002, 24(5/6): 204−207.

[3] 马尔妮, 赵广杰. 木材物理学专论[M]. 北京: 中国林业出版社, 2012. Ma E N, Zhao G J. Special topics on wood physics[M]. Beijing: China Forestry Publishing House, 2012.

[4] Everett D H. Manual of symbols and terminology for physicochemical quantities and units, appendix II: definitions, terminology and symbols in colloid and surface[J]. Chemistry Pure and Applied Chemistry, 1972, 31(4): 577−638. doi: 10.1351/pac197231040577

[5] 王哲, 王喜明. 木材多尺度孔隙结构及表征方法研究进展[J]. 林业科学, 2014, 50(10): 123−133. Wang Z, Wang X M. Research progress of multi-scale pore structure and characterization methods of wood[J]. Scientia Silvae Sinicae, 2014, 50(10): 123−133.

[6] Pfriem A, Zauer M, André W. Alteration of the pore structure of spruce ( Picea abies (L.) Karst.) and maple ( Acer pseudoplatanus L.) due to thermal treatment as determined by helium pycnometry and mercury intrusion porosimetry[J]. Holzforschung, 2009, 63(1): 94−98. doi: 10.1515/HF.2009.027

[7] Chang S S, Bruno C, Julien R, et al. Mesoporosity as a new parameter for understanding tension stress generation in trees[J]. Journal of Experimental Botany, 2009, 60(11): 3023−3030. doi: 10.1093/jxb/erp133

[8] 苌姗姗, 胡进波, Clair Bruno, 等. 氮气吸附法表征杨木应拉木的孔隙结构[J]. 林业科学, 2011, 47(10): 137−143. Chang S S, Hu J B, Bruno C, et al. Pore structure characterization of poplar tension wood by nitrogen adsorption-desorption method[J]. Scientia Silvae Sinicae, 2011, 47(10): 137−143.

[9] Burghoff H G, Pusch W. Characterization of water structure in cellulose acetate membranes by calorimetric measurements[J]. Journal of Applied Polymer Science, 1979, 23(2): 473−484. doi: 10.1002/app.1979.070230217

[10] Berthold J, Rinaudo M, Salme´n L. Association of water to polar groups-estimations by an adsorption model for ligno-cellulosic materials[J]. Colloids and Surfaces A, 1996, 112(2−3): 117−129. doi: 10.1016/0927-7757(95)03419-6

[11] Zauer M, Kretzschmar J, Grossmann L. Analysis of the pore-size distribution and fiber saturation point of native and thermally modified wood using differential scanning calorimetry[J]. Wood Science and Technology, 2014, 48: 177−193. doi: 10.1007/s00226-013-0597-9

[12] Zhong X, Ma E N. A novel approach for characterizing pore size distribution of wood cell wall using differential scanning calorimetry thermoporosimetry[J]. Thermochimica Acta, 2022, 718(179380): 1−6.

[13] Li J Y, Ma E N. Characterization of water in wood by time-domain nuclear magnetic resonance spectroscopy (TD-NMR): a review[J]. Forests, 2021, 12: 886. doi: 10.3390/f12070886

[14] 李文郁, 尹健昊, 王健, 等. 低场核磁共振技术在水泥基材料中的理论模型及应用[J]. 硅酸盐学报, 2022, 50(11): 2992−3008. Li W Y, Yin J H, Wang J, et al. Principles and applications of low-field nuclear magnetic resonance in cementitious materials[J]. Journal of the Chinese Ceramic Society, 2022, 50(11): 2992−3008.

[15] Li X, Zhao Z. Time domain-NMR studies of average pore size of wood cell walls during drying and moisture adsorption[J]. Wood Science and Technology, 2020, 54(5): 1241−1251. doi: 10.1007/s00226-020-01209-x

[16] Ge X, Myers M T, Liu J, et al. Determining the transverse surface relaxivity of reservoir rocks: a critical review and perspective[J]. Marine and Petroleum Geology, 2021, 126: 104934. doi: 10.1016/j.marpetgeo.2021.104934

[17] Kalliat M, Kwak C Y, Schmidt P W, et al. Small angle X-ray scattering measurement of porosity in wood following pyrolysis[J]. Wood Science and Technology, 1983, 17(4): 241−257. doi: 10.1007/BF00349913

[18] Felhofer M, Bock P, Singh A, et al. Wood deformation leads to rearrangement of molecules at the nanoscale[J]. Nano Letters, 2020, 20(4): 2647−2653. doi: 10.1021/acs.nanolett.0c00205

[19] Fengel D. The ultrastructure of cellulose from wood-part 2: problems of the isolation of cellulose[J]. Wood Science and Technology, 1970, 4: 15−35. doi: 10.1007/BF00356234

[20] Li J Y, Ma E N. 2D time-domain nuclear magnetic resonance (2D TD-NMR) characterization of cell wall water of Fagus sylvatica and Pinus taeda L.[J]. Cellulose, 2022, 29: 8491−8508. doi: 10.1007/s10570-022-04789-y

[21] Stone J E, Scallan A M, Aberson G M A. A study of cell wall structure by nitrogen adsorption[J]. Pulp and Paper Magazine of Canada, 1965, 66: 407−414.

[22] 沢辺攻, 森和雄, 武内保. 木材細胞膜の微細空隙構造[J]. 木材学会志, 1973, 19(2): 55−62. Osamu S, Kazuo M, Tamotsu T. Micro-pore structure in cell wall of wood[J]. Journal of the Japan Wood Research Society, 1973, 19(2): 55−62.

[23] 沢辺攻. 溶媒置換乾燥した木材およびセルロースのポロシティと空隙構造(第2報)[J]. 木材学会志, 1978, 24(11): 828−832. Osamu S. Porosity and pore structure of wood and cellulose dried after solvent-replacement II[J]. Journal of the Japan Wood Research Society, 1978, 24(11): 828−832.

[24] 沢辺攻. 膨潤木綿セルロース繊維の空隙構造[J]. 木材学会志, 1980, 26(4): 262−267. Osamu S. Pore structure in swollen cotton cellulose fibers: effects of treatment with sodium hydroxide[J]. Journal of the Japan Wood Research Society, 1980, 26(4): 262−267.

[25] 罗文圣, 赵广杰. 木材细胞壁的空隙构造及物质的输运过程[J]. 北京林业大学学报, 2001, 23(2): 85−89. Luo W S, Zhao G J. Pore structure of cell wall of wood and transport processes of substance[J]. Journal of Beijing Forestry University, 2001, 23(2): 85−89.

[26] Stone J E. The porous of wood and fibers[J]. Pulp and Paper Magazine of Canada, 1964, 65(1): 3−12.

[27] Hui L, Liu Z, Ni Y. Characterization of high-yield pulp (HYP) by the solute exclusion technique[J]. Bioresource Technology, 2009, 100(24): 6630−6634. doi: 10.1016/j.biortech.2009.07.055

[28] 费本华, 赵勇, 侯祝强, 等. 干燥过程中木材内部孔隙度变化的初步研究[J]. 北京林业大学学报, 2005, 27(增刊1): 1−4. Fei B H, Zhao Y, Hou Z Q, et al. Changes of wood interior porosity during the drying process[J]. Journal of Beijing Forestry University, 2005, 27(Suppl. 1): 1−4.

[29] Grigsby W J, Kroese H, Dunningham E A. Characterisation of pore size distributions in variously dried Pinus radiata: analysis by thermoporosimetry[J]. Wood Science and Technology, 2013, 47(4): 737−747. doi: 10.1007/s00226-013-0537-8

[30] Park S, Venditti R A, Jameel H, et al. Changes in pore size distribution during the drying of cellulose fibers as measured by differential scanning calorimetry[J]. Carbohydrate Polymers, 2006, 66(1): 97−103. doi: 10.1016/j.carbpol.2006.02.026

[31] Borrega M, Karenlämpi P P. Cell wall porosity in Norway spruce wood as affected by high-temperature drying[J]. Wood and Fiber Science, 2011, 43(2): 206−214.

[32] Aarne N, Kontturi E, Laine J. Influence of adsorbed polyelectrolytes on pore size distribution of a water-swollen biomaterial[J]. Soft Matter, 2012, 8(17): 4740−4749. doi: 10.1039/c2sm07268h

[33] 仲翔, 张少军, 马尔妮. 不同含水率状态下木材细胞壁孔径分布变化[J]. 北京林业大学学报, 2021, 43(11): 128−136. doi: 10.12171/j.1000-1522.20210260 Zhong X, Zhang S J, Ma E N. Variation in pore size distribution of wood cell wall under different moisture states[J]. Journal of Beijing Forestry University, 2021, 43(11): 128−136. doi: 10.12171/j.1000-1522.20210260

[34] 仲翔. 全含水率范围内水分引发的木材细胞壁孔隙结构变化研究[D]. 北京: 北京林业大学, 2022. Zhong X. Study on structural changes in cell wall pores of wood induced by water within full moisture content range [D]. Beijing: Beijing Forestry University, 2022.

[35] 高鑫, 蔡家斌, 金菊婉, 等. 利用核磁共振测定木材润胀细胞壁的水分含量与孔径分布[J]. 南京林业大学学报: 自然科学版, 2017, 41(2): 150−156. Gao X, Cai J B, Jin J W, et al. Bound water content and pore size diameter distribution in swollen cell walls determined by NMR cryoporometry[J]. Journal of Nanjing Forestry University: Natural Sciences Edition, 2017, 41(2): 150−156.

[36] Li J Y, Ma E N, Yang T, et al. Differences between hygroscopicity limit and cell wall saturation investigated by LF-NMR on southern pine ( Pinus spp.)[J]. Holzforschung, 2019, 73(10): 911−921. doi: 10.1515/hf-2018-0257

[37] Östlund Å, Köhnke T, Nordstierna L, et al. NMR cryoporometry to study the fiber wall structure and the effect of drying[J]. Cellulose, 2010, 17: 321−328. doi: 10.1007/s10570-009-9383-0

[38] 周云洁. 基于时域核磁共振技术的木材孔径分布研究[D]. 呼和浩特: 内蒙古农业大学, 2015. Zhou Y J. Study of wood pore size distribution based on time-domain nuclear magnetic resonance [D]. Hohhot: Inner Mongolia Agricultural University, 2015.

[39] 李新宇. 利用时域核磁共振技术研究木材孔隙分布及水分运动[D]. 呼和浩特: 内蒙古农业大学, 2017. Li X Y. The pore distribution and water movement in wood studied by time domain nuclear magnetic resonance technique [D]. Hohhot: Inner Mongolia Agricultural University, 2017.

[40] Bailey P J, Preston R D. Some aspects of softwood permeability[J]. Holzforschung, 1969, 23(4): 113−120. doi: 10.1515/hfsg.1969.23.4.113

[41] 王瑜瑶, 马尔妮. 不同预处理方法对木材细胞壁孔隙结构影响研究[J]. 北京林业大学学报, 2023, 45(11): 140−151. Wang Y Y, Ma E N. Study on the effect of different pretreatment methods on the pore structure of wood cell wall[J]. Journal of Beijing Forestry University, 2023, 45(11): 140−151.

[42] Shi J, Avramidis S. Water sorption hysteresis in wood (Ⅱ): mathematical modeling-functions beyond data fitting[J]. Holzforschung, 2017, 71(9): 317−326.

[43] Shi J, Avramidis S. Water sorption hysteresis in wood Ⅲ physical modeling by molecular simulation[J]. Holzforschung, 2017, 71(9): 733−741. doi: 10.1515/hf-2016-0231

[44] Shi J, Avramidis S. Dried cell wall nanopore configuration of douglas-fir, western red cedar and aspen heartwoods[J]. Wood Science and Technology, 2018, 52(4): 1025−1037. doi: 10.1007/s00226-018-1011-4

[45] Shi J, Avramidis S. Evolution of wood cell wall nanopore size distribution in the hygroscopic range[J]. Holzforschung, 2019, 73(10): 899−910. doi: 10.1515/hf-2018-0198

[46] Papadopoulos A N, Hill C A S, Gkaraveli A. Determination of surface area and pore volume of holocellulose and chemically modified wood flour using the nitrogen adsorption technique[J]. Holz als Roh-und Werkstoff, 2003, 61(6): 453−456. doi: 10.1007/s00107-003-0430-5

[47] Kulasinski K. Physical and mechanical aspects of moisture adsorption in wood biopolymers investigated with atomistic simulations[D]. Zurich: Eidgenössische Technische Hochschule Zürich, 2015.

[48] Paajanen A, Zitting A, Rautkari L, et al. Nanoscale mechanism of moisture-induced swelling in wood microfibril bundles[J]. Nano Letters, 2022, 22: 5143−5150.

[49] 王凯清, 周子懿, 马尔妮. 基于糠醇改性的木材细胞壁孔隙变化对水分的影响研究[J]. 北京林业大学学报, 2023, 45(9): 127−136. doi: 10.12171/j.1000-1522.20230156 Wang K Q, Zhou Z Y, Ma E N. Study on the effect of cell wall pore changes on water of wood modified by furfuryl alcohol[J]. Journal of Beijing Forestry University, 2023, 45(9): 127−136. doi: 10.12171/j.1000-1522.20230156

-

期刊类型引用(6)

1. 赵钰婷,陈冬瑶,杨柳,李晶楠,宁广亮,姜静. 白桦四倍体×紫雨桦二倍体杂交种子活力及杂种子代生长特性分析. 温带林业研究. 2025(01): 1-8 .  百度学术

百度学术

2. 刘笑,杜琬莹,张云秀,唐成名,李华伟,夏海勇,樊守金,孔令安. NO_3~–缓解小麦根部NH_4~+毒性机理. 植物学报. 2024(03): 397-413 .  百度学术

百度学术

3. 魏尚霖,李晨蕾,廖柏勇,程俊森,代文魁,姜维,王溢,李永泉. 高州油茶与小果油茶种仁蛋白质组差异比较. 经济林研究. 2024(03): 10-24 .  百度学术

百度学术

4. 程俊森,王溢,李永泉,魏尚霖,李超楠,姜维,黄润生. 基于Label-free技术的高州油茶铝胁迫蛋白质组学研究. 中南林业科技大学学报. 2023(08): 169-181 .  百度学术

百度学术

5. 韦庆钰,黄海龙,吴纯泽,苏嘉熙,卫星. 3种倍性青杨扦插苗对覆膜滴肥的生长响应. 南京林业大学学报(自然科学版). 2021(05): 93-101 .  百度学术

百度学术

6. 王溢. 基于label-free技术的青杨3个叶位叶片比较蛋白质组学分析. 华中农业大学学报. 2019(04): 8-19 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: