An intermittent conventional drying schedule for 30 mm-thick Eucalyptus obliqua lumbers

-

摘要:目的 产自澳大利亚的斜叶桉木材渗透性极低,常规干燥过程中极易开裂、皱缩,难以保证质量。本研究在常规干燥工艺中引入间歇处理,制定常规间歇干燥基准,缩短斜叶桉锯材干燥时间的同时提升其干燥质量。方法 采用100 ℃试验法测定斜叶桉木材干燥缺陷等级,拟定干燥初终期条件。结合Keylwerth研究,用图表法得到初步常规干燥基准,干燥30 mm厚斜叶桉锯材。根据干燥初期锯材表面的皱缩程度,设置间歇处理,修订原基准。依据GB/T 6491—2012《锯材干燥质量》,从含水率梯度、弯曲、开裂程度、皱缩等方面评价锯材干燥质量。结果 本研究中斜叶桉试件平均基本密度为(558 ± 21) kg/m3。综合弦切和径切试件测得的缺陷等级,评定斜叶桉木材干燥缺陷等级为初期开裂4级,内裂5级和截面变形5级。据此拟定30 mm厚斜叶桉锯材常规干燥基准的初始温度为46 ℃,初期干湿球温差为1.5 ℃,后期最高温度为67 ℃。干燥过程中试件平均含水率为37.7%、34.4%和24.4%时,观察到严重皱缩,做了3次间歇处理,处理时长分别为16、8和8 h。试件从61.0%的平均初含水率干燥到10.8%的终含水率,共耗时20 d,平均干燥速率为0.10%/h。试件厚度方向含水率偏差为0.70%,可见干燥缺陷指标中顺弯、翘弯、扭曲、纵裂、内裂均达到一级标准,但试件横弯和皱缩较严重,仅能达到三级标准。结论 100 ℃试验法表明:由皱缩导致的截面变形为斜叶桉木材最为严重的干燥缺陷,且径切板的皱缩程度要大于弦切板。在依据100 ℃试验制定的初步干燥基准中加入间歇处理,能够较为有效地缓解和抑制皱缩。本研究中干燥的30 mm厚斜叶桉锯材仍然存在少量皱缩,未达到GB/T 6491—2012中锯材干燥质量二级指标。但是,干燥时间比传统的大气干燥 + 常规干燥的联合干燥方式减少约90%,且干燥质量有所提高。本研究推荐的常规间歇干燥基准可为斜叶桉锯材的实际应用提供科学依据。Abstract:Objective The Eucalyptus obliqua wood from Australia has extremely low permeability and is extremely prone to crack and shrink in the conventional drying process, and it is difficult to ensure the quality. In this study, the intermittent treatment was introduced into the conventional kiln drying process, and an intermittent conventional drying schedule was established, which shortened the drying time of E. obliqua lumbers and improved the drying quality as well.Method The drying characteristics and possible drying defects were obtained by the 100 ℃-test method proposed by Tarazawa. Combined with Keylwerth’s chart method, the preliminary drying schedule for 30 mm thick E. obliqua lumbers was proposed. Intermittent treatments were applied based on the extent of collapse observed on the sample surface at the early stage of drying. The final drying quality of lumber samples was evaluated according to GB/T 6491−2012 “Drying Quality of Lumbers” from the aspect of moisture content gradient, degree of bending, checking and collapse.Result The average basic density of E. obliqua samples in this study was (558 ± 21) kg/m3. Based on the defect grades from the flatsawn and quartersawn 100 ℃-test samples, the final defect grade of E. obliqua wood was evaluated as “Grade-4” for the initial checking, “Grade-5” for the internal checking and “Grade-5” for the cross-section deformation. The initial temperature of the conventional drying schedule for 30 mm thick E. obliqua lumber was set at 46 ℃ with the wet-bulb depression of 1.5 ℃, and the final maximum temperature was set at 67 ℃. During the drying process, severe collapse was observed when the average moisture content of the specimens was 37.7%, 34.4% and 24.4%, and three batches of intermittent treatments were followed with the treatment time of 16, 8 and 8 h, respectively. The specimens were dried from an average initial moisture content of 61.0% to a final one of 10.8% in a total of 20 d, with an average drying rate of 0.10%/h. The moisture content deviation in the thickness direction of the specimen was 0.70%. Most drying defects such as spring, bow, twisting, surface and internal checks of the specimens met the first-class standard, but cupping and collapse of the specimen were more serious, only meeting Grade-3 standard.Conclusion The 100 ℃-test shows that the cross-section deformation caused by collapse is the most serious drying defect of E. obliqua woods, and the collapse extent of the quartersawn samples is greater than that of the flatsawn samples. Adding intermittent treatments to the preliminary conventional drying schedule based on the 100 ℃-test could effectively alleviate and prevent further collapse development effectively. A small amount of collapse still occurs on the 30 mm-thick E. obliqua specimens dried in this study, therefore not meeting the Grade-2 drying quality in GB/T 6491−2012, which is usually required by most enterprises in China. However, the drying time was reduced approximately 90% compared with that of the traditional combined air and conventional kiln drying method, and the drying quality was improved. The intermittent drying schedule recommended in this study can provide insights into the actual drying of E. obliqua woods in the industry.

-

Keywords:

- Eucalyptus obliqua /

- 100 ℃-test /

- intermittent drying schedule /

- collapse

-

近年来,产自澳大利亚塔斯马尼亚群岛的斜叶桉(Eucalyptus obliqua)逐渐成为我国重要进口商品材。该木材密度较高(气干密度约为760 kg/m3)、色泽好、纹理清晰、加工性能优良,在家具、室内装饰以及地板市场均有广泛应用前景[1]。但该木材渗透性极差,极易皱缩[2-3],为澳大利亚最难干燥的树种之一[4]。相比于国产速生桉木的干燥特性,如大花序桉(E. cloeziana)[5]、尾巨桉(E. urophylla × E. grandi)[6]、柠檬桉(E. citriodora)和圆角桉 (E. umbellate)[7]等,斜叶桉属于更难干燥树种。

目前,在澳大利亚当地企业普遍采用大气干燥 加 常规干燥的联合干燥方式。大气干燥到含水率20%左右,耗时1 ~ 2年,然后常规干燥1 ~ 2个月[8]。我国干燥企业场地面积小、周转周期短,很难接受以上联合干燥方式。Redman等[2-4]通过一系列斜叶桉干燥特性的研究以及常规干燥和真空干燥的试验,制定了较为可行的真空干燥基准,在不降低干燥质量的前提下可将30 mm厚锯材干燥时间缩减至1个月。在澳大利亚,对于35 m3 的中型干燥窑和50 m3的大型干燥窑,真空干燥的成本为常规干燥的4倍左右。特种干燥成本高,很难在我国干燥企业中推广。

也有部分国内干燥企业自行研究斜叶桉锯材的干燥基准,但是干燥周期长、皱缩严重、木材损耗大、干燥成本高、效果也不佳,因此解决斜叶桉干燥工艺技术问题迫在眉睫。本研究采用日本寺泽真教授提出的快速试验法100 ℃试验法 [9-10]获得斜叶桉木材的干燥特性,制定初步干燥基准。再鉴于间歇干燥处理工艺在缓解桉木皱缩方面的研究成果[11-14],尝试在初步制定的常规干燥基准中引入间歇处理,以期提高斜叶桉干燥质量、缩短干燥时间,为斜叶桉干燥生产企业提供适宜工艺基准。

1. 材料和方法

1.1 研究材料

原料取自澳大利亚进口斜叶桉原木,由上海立岳实业有限公司提供。将原木锯制成820 mm(轴向) × 100 mm(弦向) × 30 mm(径向)和820 mm(轴向) × 100 mm(径向) × 30 mm(弦向)的板材后运送至实验室,用保鲜膜包裹后室温保存。板材初始含水率范围为50% ~ 75%。

1.2 研究方法

1.2.1 密度和体积干缩率的测定

将板材加工成20 mm (轴向) × 8 mm(弦向) × 8 mm(径向)的刨光小试件。试件长度方向为木材纹理方向,宽度和厚度不区分径 、弦向,主要用于绝干密度和体积干缩率的测定。试件加工完后用天平测其质量,精确到0.0001 g;并测其长、宽、厚,精确到0.02 mm。考虑到斜叶桉易皱缩,选取的试件尺寸比常规密度试件要小。此外,试件先在40和60 ℃下分别干燥6 h后,再将温度升至103 ℃干燥,直至一小时内质量变化率 < 0.05% (绝干质量约为1 g),认为试件达到绝干,再次测定试件质量和尺寸。所取样本数为73个。

1.2.2 100 ℃试验制定初步干燥基准

选取材色正常、纹理通直、无节子、虫眼和裂纹等明显缺陷的板材,加工成200 mm(轴向) × 100 mm(弦向) × 20 mm(径向)的弦切(板)试件10块,编号为T1 ~ T10;200 mm(轴向) × 100 mm(径向) × 20 mm(弦向)的径切(板)试件8块, 编号为R1 ~ R8。

首先进行试件尺寸、质量测量,分别精确至0.1 mm 、0.1 g。将测量后的试件,沿纹理方向竖直放入电热鼓风式恒温干燥箱,在(100 ± 2) ℃下进行干燥。干燥初期每小时观测1次,称质量及记录初期开裂情况,包括端裂、端表裂、表裂、表端裂和贯通裂数量以及长宽。当裂纹开始愈合时,改为每4 h观测1次,此时不再观测开裂情况,只测质量。直至试件连续2次的称量结果差值变化率不超过0.02%时,干燥结束,待所有试件冷却至室温后从箱中取出。自长度方向中部横向截断,观测试件内裂情况,并测量截面变形程度。根据统计出的木材开裂、变形情况,依据试件中出现的最严重的干燥缺陷评定质量等级,编制出100 ℃试验质量分析等级表,确定干燥基准的初始和终了温度及初期干湿球温差[15]。再结合Keylwerth研究,用图表法制定初步常规干燥基准[15]。

一般100 ℃试验要求试件为弦切板[15]。主要考虑到弦切板射线薄壁组织沿着厚度方向,会加快干燥,但相比于径切板更易产生各种干燥缺陷。然而斜叶桉,非常容易皱缩,试验发现径切板更易产生这一缺陷。如果按照常规弦切试件的结果,在干燥缺陷等级评定中皱缩这一项的等级将降低,体现不出实际干燥过程中皱缩的严重程度,从而导致制定的基准偏硬且易出现皱缩现象。事实上,早在90年代初期,何定华等[16]用100 ℃试验研究木材干燥特性及窑干基准的研究中,已建议在100 ℃实验中,增加径锯板试件,记录弦、径板干燥速率差异。

1.2.3 干燥工艺试验

选取材色正常、无虫眼和裂纹等明显缺陷的板材5块,编号为M1 ~ M5。在5块板材端头分别截去100 ~ 120 mm后,再截取2块10 mm左右含水率试片,利用烘干法测量其含水率。通过此含水率估算出5块试材的绝干质量。然后将5块板材的两端面用玻璃胶涂封。记录下初始质量后置入调温调湿箱(DF-HS-500型,南京德孚实验设备有限公司)中干燥。箱内温、湿度采用温湿度计testo 608-H2校准,其温度读数精度为±0.5 ℃,湿度为±2%。每日早、晚将板材取出称重。据此推算出当时含水率后,参考拟定的干燥基准设置调温调湿箱温湿度。观测到裂纹时,适当地调低温度;观测到明显皱缩时,做间歇处理,即调温调湿箱停止工作,但不取出试材,待皱缩有所恢复后调温调湿箱重新启动工作。含水率约为40%、35%、25%和18%时,从试材端部截取10 mm左右的分层含水率试片,在厚度方向均匀分成5层,采用烘干法测得厚度方向含水率分布。当含水率降至10%时,干燥结束。参考GB/T 6491—2012《锯材干燥质量》对干燥的木材进行质量评定。

2. 结 果

2.1 斜叶桉密度和体积干缩率

测得斜叶桉试件的平均基本密度为(558 ± 21) kg/m3,平均绝干密度为(651 ± 36) kg/m3,平均体积全干缩率为(13.3 ± 3.7)%。虽然经过40、60、103 ℃的梯度干燥,试件尺寸也比常规的密度试件小,但54.8%的样品体积全干缩率 > 18.5%,部分试件表面观察到明显皱缩,故排除在绝干密度以及干缩率平均值计算之外。

2.2 斜叶桉100 ℃试验结果

100 ℃试验所得的斜叶桉试件开裂情况和干燥缺陷等级见表1,其干燥缺陷分级参考文献 [17]。

表 1 斜叶桉100 ℃实验干燥缺陷等级Table 1. Grades of drying defects in the 100 ℃-test for E. obliqua samples试件编号

Sample No.初期开裂情况

Initial checking condition内裂情况

Internal checking condition初期开裂等级

Initial checking

grade内裂等级

Internal checking

grade截面变形等级

Cross-section deformation

grade截面变形

Cross-section deformation/

mmT1 短细表裂7条;短端表裂3条

7 short and fine surface checks and 3 short end-surface checks宽裂4条;细裂16条

4 wide checks and 16 fine checks2 5 4 3.31 T2 短细表裂3条;短端表裂1条;

贯通裂1条

3 short and fine surface checks; 1 short end-surface check; 1end splitting宽裂5条;细裂7条

5 wide checks and 7 fine checks4 4 4 2.64 T3 短细表裂16条;长端表裂2条,短端表裂3条

16 short and fine surface checks; 2 long and 3 short end-surface checks宽裂7条;细裂12条

7 wide checks and 12 fine checks4 5 4 3.39 T4 短端表裂1条

1 short and fine surface check宽裂3条;细裂4条

3 wide checks and 4 fine checks1 3 5 3.84 T5 长细表裂4条,短细表裂28条;长端表裂1条,短端表裂4条;贯通裂1条

4 long and fine surface checks, 28 short and fine surface checks; 1 long and 4 short end-surface checks; 1 end splitting宽裂6条;细裂15条

6 wide checks and 15 fine checks4 5 4 2.50 T6 短细表裂16条;短端表裂5条;

贯通裂1条

16 short and fine surface checks;

5 short end-surface checks; 1 end splitting宽裂7条;细裂17条

7 wide checks and 17 fine checks4 5 4 2.65 T7 短细表裂5条;短端表裂2条

5 short and fine surface checks;

2 short end-surface checks宽裂8条;细裂13条

8 wide checks and 13 fine checks2 5 4 3.41 T8 短细表裂5条;短端表裂3条

5 short and fine surface checks;

3 short end-surface checks宽裂9条;细裂11条

9 wide checks and 11 fine checks2 5 4 2.86 T9 短细表裂3条;短端表裂5条

3 short and fine surface checks;

5 short end-surface checks宽裂7条;细裂15条

7 wide checks and 15 fine checks2 5 4 2.86 T10 短细表裂1条;短端表裂4条

1 short and fine surface checks;

4 short end-surface checks宽裂4条;细裂13条

4 wide checks and 13 fine checks2 4 4 2.14 R1 无裂纹

No check宽裂2条;细裂15条

2 wide checks and 15 fine checks1 4 5 4.87 R2 无裂纹

No check宽裂3条;细裂11条

3 wide checks and 11 fine checks1 4 5 5.04 R3 无裂纹

No check宽裂4条;细裂10条

4 wide checks and 10 fine checks1 4 5 5.46 R4 无裂纹

No check宽裂1条;细裂15条

1 wide check and 15 fine checks1 4 5 4.87 R5 长侧裂1条;长端侧裂1条;短端表裂3条

1 long lateral check;1 long end-lateral check; 3 short end-surface checks宽裂1条;细裂12条

1 wide check and 12 fine checks1 4 5 3.90 R6 短细侧裂5条

5 short and fine lateral check宽裂3条;细裂9条

3 wide check and 9 fine checks1 4 5 4.54 R7 短细侧裂1条

1 short and fine lateral check宽裂1条;细裂12条

1 wide check and 12 fine checks1 4 5 4.60 R8 短细侧裂1条

1 short and fine lateral check细裂12条

12 fine checks1 4 5 5.00 注:表中T1 ~ T10为弦切试件,其中T4偏径切;R1 ~ R8为径切试件,其中R5、R6略偏弦切。Notes: T1–T10 in the above table are flatsawn samples, of which T4 is partially quartersawn; R1–R8 are quartersawn samples, of which R5 and R6 are partially flatsawn. 对于弦切试件,试件初期开裂变异性较大,从1级到4级不等,其中T2、T5和T6出现严重贯通裂。中国林业科学研究院修订的分级量化指标[17]中对“贯通裂”并未说明,本研究中做“宽裂”处理,进行等级评定。弦切试件普遍存在严重的由皱缩导致的截面变形和内裂,其中试件T1、T5、T6以及T8 ~ T10内裂最宽处都达到了3 mm。T4的截面变形比其余9个试件都要大,仔细检查试件后发现,该试件偏径切,故在最终的等级评定中排除,不予考虑。斜叶桉弦切试件最终干燥缺陷等级评定为初期开裂4级,内裂5级,截面变形4级。

相比于弦切试件,径切试件初期开裂明显改善,内裂程度略有改善,但出现了更为严重的皱缩导致的截面变形。大多数试件干燥初期2 h 内出现了明显的皱缩,最终的截面变形深度甚至超过了5 mm,超过大多数常见树种截面变形量。需要注意的是,径切试件在干燥初期,裂纹更倾向于发生在端部侧面,形成“侧裂”,或由端面延伸至侧面形成“端侧裂”,见试件R5 ~ R8。考虑到在实际加工过程中,侧面裂纹可以通过锯切、刨切等方式处理掉而不会使整体失效,等级评定中,按“短端表裂”处理。虽然径切试件内裂中属于宽裂范畴的数量明显减少,仅有一块试件(R2)内裂最宽处达到3 mm,但是由于截面变形更为严重,不少试件(R2 ~ R4)在截面变形最大处裂成两半。斜叶桉径切试件最终干燥缺陷等级评定为初期开裂1级,内裂4级,截面变形5级。

综合弦切板和径切板100 ℃试验测得的缺陷等级,评定斜叶桉木材最终缺陷等级为初期开裂4级,内裂5级和截面变形5级。

2.3 斜叶桉试用干燥基准

根据斜叶桉100 ℃试验最终缺陷等级,参照100 ℃试验法中缺陷等级与干燥条件关系[15]拟定出干燥基准初始温度、初期干湿球温差以及后期最高温度(表2)。

表 2 100 ℃试验缺陷程度与干燥条件的关系Table 2. Recommended initial and final drying conditions based on the 100 ℃-test初步拟定干燥条件

Initially assumed

drying condition100 ℃试验等级100 ℃-test grade 最终干燥条件

Final drying condition初期开裂(4级)

Initial checking (grade 4)内裂(5级)

Internal checking (grade 5)截面变形(5级)

Cross-section deformation (grade 5)初始温度

Initial temperature/℃50 45 45 46 初期干湿球温差

Initial wet-bulb depression/℃2.0 2.5 2.5 1.5 后期最高温度

Final highest temperature/℃80 70 70 67 考虑到100 ℃试验中出现了极为严重的皱缩现象,在表2基础上将初期干湿球温差降低为1.5 ℃,提高初期相对湿度以缓解皱缩。适当提高初始温度为46 ℃,加快干燥速度。此外,降低后期最高温度为67 ℃,减缓内裂和皱缩的发生。最终确定的30 mm厚斜叶桉锯材试用干燥基准见表3。表3中其余参数参考Keylwerth图表[15]拟定,干燥梯度取值为2.0,纤维饱和点(本研究中取40%)以上干燥介质平衡含水率取值为20.0%,纤维饱和点以下按5.0%含水率变化间隔划分干燥基准调整梯度。

表 3 30 mm 厚斜叶桉锯材试用干燥基准Table 3. Preliminary drying schedule for 30 mm-thick E. obliqua lumbers含水率调节

Moisture content (MC) adjustment干球温度

Dry-bulb temperature/℃干湿球温度差

Wet-bulb depression/℃平衡含水率

Equilibrium MC/%相对湿度

Relative humidity/%干燥至50%

Dry to 50%46 1.5 20.0 92 干燥至40%

Dry to 40%50 1.5 20.0 92 从40%干燥至35%

From 40% to 35% by drying50 2.5 18.0 87 从35%干燥至30%

From 35% to 30% by drying52 4.0 15.0 80 从30%干燥至25%

From 30% to 25% by drying55 7.0 10.5 68 从25%干燥至20%

From 25% to 20% by drying58 11.0 8.0 54 从20%干燥至15%

From 20% to 15% by drying63 17.0 5.5 40 干燥至15%以下

Below 15% by drying67 22.0 4.0 30 2.4 间歇干燥工艺试验

2.4.1 间歇处理和锯材干燥曲线

干燥工艺试验参考表3中给出的试用干燥基准,并根据干燥过程中观察到的样品缺陷对温、湿度做适当调整。此外在干燥初期观察到严重皱缩缺陷时,做间歇处理,即调温调湿箱停止工作,样品放于其中不取出。一般2 h内温度会缓慢降至室温(大约25 ℃),相对湿度接近100%。间歇处理后,调温调湿箱启动工作,回到干燥基准中温、湿度。

本试验中30 mm厚斜叶桉锯材从61.0%平均初含水率干燥到10.8%终含水率,共耗时20 d,平均干燥速率为0.10%/h,其干燥曲线及干燥过程中温、湿度变化如图1所示。图1干燥曲线中含水率为M2 ~ M5试件均值(M1试件在干燥过程中有水滴落在表面,对干燥进程造成很大影响,故舍去数据)。干燥过程中共有3次间歇处理,图1中标注为A、B和C,对应含水率为37.7%、34.4%和24.4%,处理时间分别为16、8和8 h。 A、B和C处,温度存在明显的先下降再上升的波动,湿度存在明显的先上升后下降的波动;而波动过程中含水率几乎保持不变或略有下降。

此外,干燥过程中作了2次中间处理,图1中标注为D和E,对应含水率为37.0%和24.3%,以及终了调湿处理(图1中F)。第一次中间处理(D)安排在间歇处理(B)后,以期进一步缓解皱缩和样品厚度方向的含水率梯度。试验中观察到间歇处理带来的皱缩的缓解,然而紧随其后的中间处理对皱缩并未起到明显改善作用。

2.4.2 锯材干燥质量和推荐基准

30 mm 厚斜叶桉锯材干燥质量见表4,试件平均终含水率为10.8%,厚度方向含水率偏差为0.70%,可见干燥缺陷指标中顺弯、翘弯、扭曲、纵裂、内裂均达到一级标准,但试件横弯和皱缩较严重,仅能达到三级标准。横弯可以在实际干燥中通过在材堆顶部加重物的方式有效缓解,较易提高到二级标准,但荷重会使干燥前期近弦面产生附加拉应力,加剧其表裂,纵裂度会降级。皱缩仍然是最为严重的干燥缺陷,且和100 ℃试验的结果一致,径切板皱缩深度(2.40 mm)要远大于弦切板 (0.46 mm)。虽然该研究中斜叶桉锯材质量尚未达到GB/T 6491—2012《锯材干燥质量》二级标准,但是干燥时间比传统的大气干燥 + 常规干燥的联合干燥方式缩减了约90%,且干燥质量有所提高[18]。此外,本研究中干燥时间和质量与Redman 等提出的真空干燥方式[18]相当。

表 4 30 mm 厚斜叶桉锯材干燥质量Table 4. Drying quality for 30 mm-thick E. obliqua lumbers项目

Item终含水率

Final moisture content/%厚度上含水率偏差

Moisture content deviation on thickness/%翘曲度

Warp degree/%扭曲度

Twist degree/%纵裂度

Longitudinal fissure degree/%内裂个数

Number of internal check皱缩深度

Collapse depth/mm顺弯 Bow 横弯 Cupping 翘弯 Spring 平均值

Mean value10.8 0.7 0 1.56 0.32 0 0 0 1.34 等级 Grade 2 1 1 3 1 1 1 1 3 表5 为依据本研究确定的30 mm厚斜叶桉锯材推荐干燥基准。因为径切板相比于弦切板更易发生皱缩,实际操作过程中,含水率以及应力检验板应该选取初始含水率低的径切板。

表 5 30 mm 厚斜叶桉锯材推荐干燥基准Table 5. Recommended drying schedule for 30 mm-thick E. obliqua lumbers处理

Treatment干球温度

Dry-bulb

temperature/℃干湿球温度差

Web-bulb

depression/℃平衡含水率

Equilibrium MC/%相对湿度

Relative humidity/%处理时间

Treatment time/hMC干燥至40%

Dry to 40% of MC46 3 16.0 85 间歇处理1

Intermittent treatment 125 0 30.0 100 12 MC从40%干燥至35%

From 40% to 35% of MC by drying50 3 16.0 83 间歇处理2

Intermittent treatment 225 0 30.0 100 12 MC从35%干燥至30%

From 35% to 30% of MC by drying50 4 14.0 79 MC从30%干燥至25%

From 30% to 25% of MC by drying50 5 12.5 76 间歇处理3

Intermittent treatment 325 2 17.2 85 12 MC从25%干燥至20%

From 25% to 20% of MC52 6 11.5 71 MC从20%到15%

From 20% to 15% of MC by drying54 6 11.5 72 中间处理

Intermediate treatment54 3 16.0 84 12 MC干燥至15%以下

Below 15% of MC by drying60 8 10.0 65 终了调湿处理

Final humidifying treatment65 3 15.5 86 8 3. 讨 论

3.1 径切板皱缩严重的原因

100 ℃试验以及后续的干燥试验均发现:径切试件更易发生严重的皱缩,且早材区的皱缩更为显著。图2为代表性径切板试件(已从中部锯开),呈现出条沟型 + 均匀型 + 内裂型皱缩的综合皱缩模式。

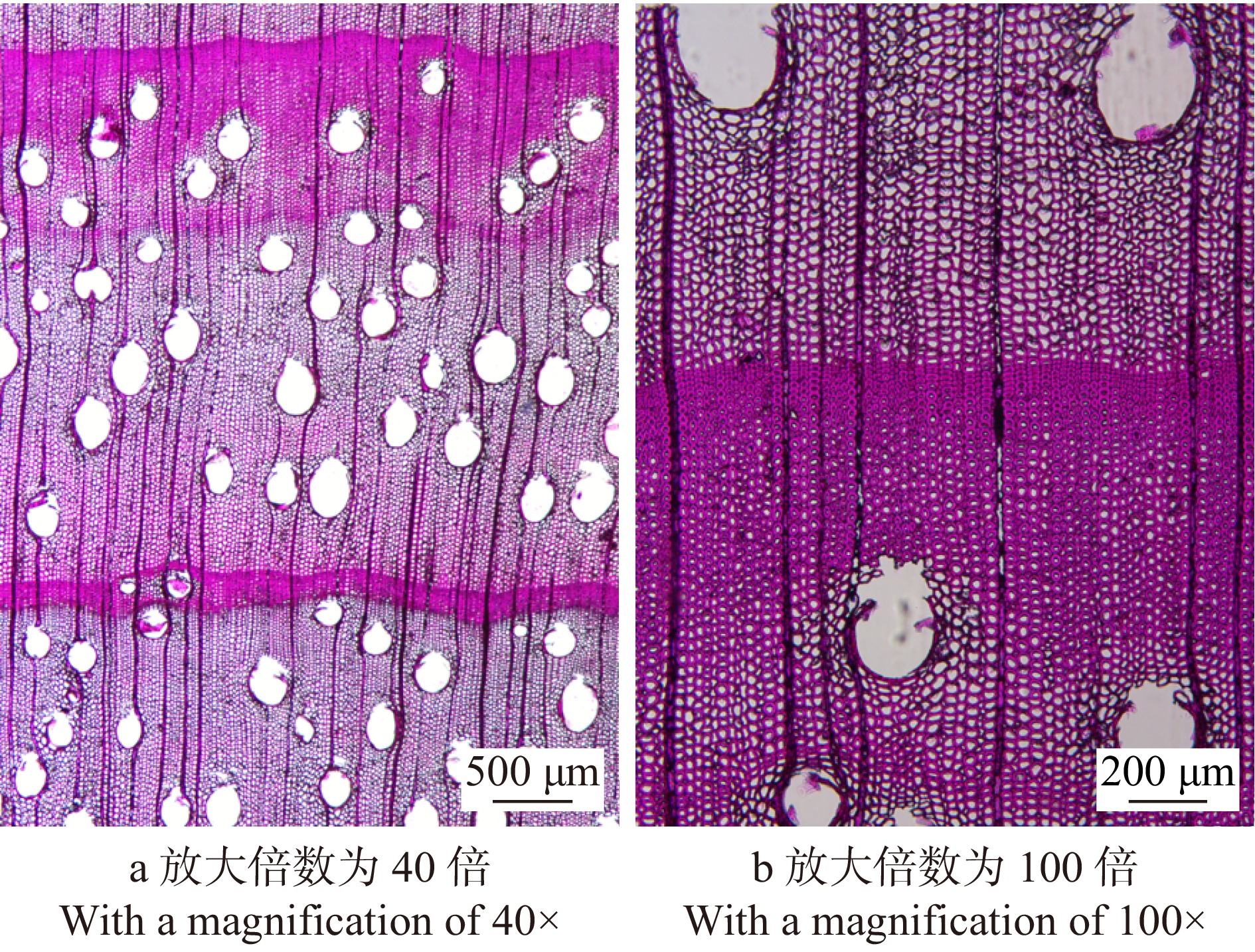

图3 为斜叶桉木材的横切面放大图,可以看出早晚材急变,早材纤维细胞(图3中浅色区域)厚度远小于晚材(图3中深色区域)。所以早材细胞的横向抗压强度远小于晚材,更易发生皱缩。此外,早材纤维细胞横截面更大,细胞上纹孔数量更多,更容易因为水分移动通过纹孔膜上的微纳米级孔隙[19]产生大的毛细张力而发生皱缩。再者,对于径切试件而言,干燥过程中水分主要移动方向为弦向,即试件厚度方向。

因纤维管胞上具缘纹孔通常径面壁较多,当水分沿弦向移动、且在该处形成凹液面时,会产生比沿径向移动在弦面壁处更大的毛细张力,进一步加剧皱缩发生。因而观察到径切试件更为严重的皱缩。

3.2 高温间歇干燥应用前景

在一次偶然的100 ℃试验非常规操作中,试件在100 ℃下每运行13 h后,关闭烘箱7 h,此期间试件未拿出烘箱。观察到试件初期开裂和皱缩明显恢复,最终试件无内裂,截面变形等级升至2 ~ 3级,干燥质量大幅提升,如图4所示。这给我们提供了高温干燥 + 间歇处理的新的干燥思路。早在1979年,梁世镇等[20]曾用与此类似的高温干燥 + 间歇处理的干燥方式试验了产自广东雷州的柠檬桉(E. citriodora)、隆缘桉(E. exserta)和雷一桉(E. Leizhou),提出了快速干燥易皱缩、开裂的桉木的可行性。结合本研究中观察到的间歇处理对皱缩有缓解作用,高温间歇干燥用于斜叶桉的干燥还是具备良好前景的,值得进一步深入研究。

4. 结 论

(1) 100 ℃试验表明:由皱缩导致的截面变形为斜叶桉木材最为严重的干燥缺陷,且径切板的皱缩程度要大于弦切板。对于易发生皱缩的桉类木材,宜在试件中加入径切板,更好地辅助干燥基准的制定。

(2) 在100 ℃试验制定的初步干燥基准中适时加入间歇处理,能够较为有效地缓解和抑制皱缩。本研究推荐的间歇处理含水率为40%、35%和25%,处理时间为12 h。高温间歇干燥用于斜叶桉的干燥可能有良好前景,值得进一步深入研究。

(3) 本研究中干燥的30 mm厚斜叶桉锯材仍然存在少量皱缩。横弯未达到GB/T 6491—2012《锯材干燥质量》中锯材干燥质量二级指标,与实验室干燥试材少,没有压重物有关。但是,干燥时间比传统的大气干燥 + 常规干燥的联合干燥方式减少约90%。

-

表 1 斜叶桉100 ℃实验干燥缺陷等级

Table 1 Grades of drying defects in the 100 ℃-test for E. obliqua samples

试件编号

Sample No.初期开裂情况

Initial checking condition内裂情况

Internal checking condition初期开裂等级

Initial checking

grade内裂等级

Internal checking

grade截面变形等级

Cross-section deformation

grade截面变形

Cross-section deformation/

mmT1 短细表裂7条;短端表裂3条

7 short and fine surface checks and 3 short end-surface checks宽裂4条;细裂16条

4 wide checks and 16 fine checks2 5 4 3.31 T2 短细表裂3条;短端表裂1条;

贯通裂1条

3 short and fine surface checks; 1 short end-surface check; 1end splitting宽裂5条;细裂7条

5 wide checks and 7 fine checks4 4 4 2.64 T3 短细表裂16条;长端表裂2条,短端表裂3条

16 short and fine surface checks; 2 long and 3 short end-surface checks宽裂7条;细裂12条

7 wide checks and 12 fine checks4 5 4 3.39 T4 短端表裂1条

1 short and fine surface check宽裂3条;细裂4条

3 wide checks and 4 fine checks1 3 5 3.84 T5 长细表裂4条,短细表裂28条;长端表裂1条,短端表裂4条;贯通裂1条

4 long and fine surface checks, 28 short and fine surface checks; 1 long and 4 short end-surface checks; 1 end splitting宽裂6条;细裂15条

6 wide checks and 15 fine checks4 5 4 2.50 T6 短细表裂16条;短端表裂5条;

贯通裂1条

16 short and fine surface checks;

5 short end-surface checks; 1 end splitting宽裂7条;细裂17条

7 wide checks and 17 fine checks4 5 4 2.65 T7 短细表裂5条;短端表裂2条

5 short and fine surface checks;

2 short end-surface checks宽裂8条;细裂13条

8 wide checks and 13 fine checks2 5 4 3.41 T8 短细表裂5条;短端表裂3条

5 short and fine surface checks;

3 short end-surface checks宽裂9条;细裂11条

9 wide checks and 11 fine checks2 5 4 2.86 T9 短细表裂3条;短端表裂5条

3 short and fine surface checks;

5 short end-surface checks宽裂7条;细裂15条

7 wide checks and 15 fine checks2 5 4 2.86 T10 短细表裂1条;短端表裂4条

1 short and fine surface checks;

4 short end-surface checks宽裂4条;细裂13条

4 wide checks and 13 fine checks2 4 4 2.14 R1 无裂纹

No check宽裂2条;细裂15条

2 wide checks and 15 fine checks1 4 5 4.87 R2 无裂纹

No check宽裂3条;细裂11条

3 wide checks and 11 fine checks1 4 5 5.04 R3 无裂纹

No check宽裂4条;细裂10条

4 wide checks and 10 fine checks1 4 5 5.46 R4 无裂纹

No check宽裂1条;细裂15条

1 wide check and 15 fine checks1 4 5 4.87 R5 长侧裂1条;长端侧裂1条;短端表裂3条

1 long lateral check;1 long end-lateral check; 3 short end-surface checks宽裂1条;细裂12条

1 wide check and 12 fine checks1 4 5 3.90 R6 短细侧裂5条

5 short and fine lateral check宽裂3条;细裂9条

3 wide check and 9 fine checks1 4 5 4.54 R7 短细侧裂1条

1 short and fine lateral check宽裂1条;细裂12条

1 wide check and 12 fine checks1 4 5 4.60 R8 短细侧裂1条

1 short and fine lateral check细裂12条

12 fine checks1 4 5 5.00 注:表中T1 ~ T10为弦切试件,其中T4偏径切;R1 ~ R8为径切试件,其中R5、R6略偏弦切。Notes: T1–T10 in the above table are flatsawn samples, of which T4 is partially quartersawn; R1–R8 are quartersawn samples, of which R5 and R6 are partially flatsawn. 表 2 100 ℃试验缺陷程度与干燥条件的关系

Table 2 Recommended initial and final drying conditions based on the 100 ℃-test

初步拟定干燥条件

Initially assumed

drying condition100 ℃试验等级100 ℃-test grade 最终干燥条件

Final drying condition初期开裂(4级)

Initial checking (grade 4)内裂(5级)

Internal checking (grade 5)截面变形(5级)

Cross-section deformation (grade 5)初始温度

Initial temperature/℃50 45 45 46 初期干湿球温差

Initial wet-bulb depression/℃2.0 2.5 2.5 1.5 后期最高温度

Final highest temperature/℃80 70 70 67 表 3 30 mm 厚斜叶桉锯材试用干燥基准

Table 3 Preliminary drying schedule for 30 mm-thick E. obliqua lumbers

含水率调节

Moisture content (MC) adjustment干球温度

Dry-bulb temperature/℃干湿球温度差

Wet-bulb depression/℃平衡含水率

Equilibrium MC/%相对湿度

Relative humidity/%干燥至50%

Dry to 50%46 1.5 20.0 92 干燥至40%

Dry to 40%50 1.5 20.0 92 从40%干燥至35%

From 40% to 35% by drying50 2.5 18.0 87 从35%干燥至30%

From 35% to 30% by drying52 4.0 15.0 80 从30%干燥至25%

From 30% to 25% by drying55 7.0 10.5 68 从25%干燥至20%

From 25% to 20% by drying58 11.0 8.0 54 从20%干燥至15%

From 20% to 15% by drying63 17.0 5.5 40 干燥至15%以下

Below 15% by drying67 22.0 4.0 30 表 4 30 mm 厚斜叶桉锯材干燥质量

Table 4 Drying quality for 30 mm-thick E. obliqua lumbers

项目

Item终含水率

Final moisture content/%厚度上含水率偏差

Moisture content deviation on thickness/%翘曲度

Warp degree/%扭曲度

Twist degree/%纵裂度

Longitudinal fissure degree/%内裂个数

Number of internal check皱缩深度

Collapse depth/mm顺弯 Bow 横弯 Cupping 翘弯 Spring 平均值

Mean value10.8 0.7 0 1.56 0.32 0 0 0 1.34 等级 Grade 2 1 1 3 1 1 1 1 3 表 5 30 mm 厚斜叶桉锯材推荐干燥基准

Table 5 Recommended drying schedule for 30 mm-thick E. obliqua lumbers

处理

Treatment干球温度

Dry-bulb

temperature/℃干湿球温度差

Web-bulb

depression/℃平衡含水率

Equilibrium MC/%相对湿度

Relative humidity/%处理时间

Treatment time/hMC干燥至40%

Dry to 40% of MC46 3 16.0 85 间歇处理1

Intermittent treatment 125 0 30.0 100 12 MC从40%干燥至35%

From 40% to 35% of MC by drying50 3 16.0 83 间歇处理2

Intermittent treatment 225 0 30.0 100 12 MC从35%干燥至30%

From 35% to 30% of MC by drying50 4 14.0 79 MC从30%干燥至25%

From 30% to 25% of MC by drying50 5 12.5 76 间歇处理3

Intermittent treatment 325 2 17.2 85 12 MC从25%干燥至20%

From 25% to 20% of MC52 6 11.5 71 MC从20%到15%

From 20% to 15% of MC by drying54 6 11.5 72 中间处理

Intermediate treatment54 3 16.0 84 12 MC干燥至15%以下

Below 15% of MC by drying60 8 10.0 65 终了调湿处理

Final humidifying treatment65 3 15.5 86 8 -

[1] Wallis N K. Australian timber handbook[M]. Sydney: Angus and Robertson, 1963.

[2] Redman A L, Bailleres H, Turner I, et al. Mass transfer properties (permeability and mass diffusivity) of four Australian hardwood species[J]. BioResources, 2012, 7(3): 3410−3424.

[3] Redman A L, Bailleres H, Turner I, et al. Characterisation of wood-water relationships and transverse anatomy and their relationship to drying degrade[J]. Wood Science and Technology, 2016, 50(4): 739−757. doi: 10.1007/s00226-016-0818-0

[4] Redman A L, Bailleres H, Perré P, et al. A relevant and robust vacuum-drying model applied to hardwoods[J]. Wood Science and Technology, 2017, 51(4): 701−719. doi: 10.1007/s00226-017-0908-7

[5] 周桥芳, 胡传双, 涂登云, 等. 大花序桉干燥特性与干燥工艺研究[J]. 林业机械与木工设备, 2018, 46(1): 5. doi: 10.3969/j.issn.2095-2953.2018.01.009 Zhou Q F, Hu C S, Tu D Y, et al. Drying characteristics and drying process of Eucalyptus cloeziana wood[J]. Forestry Machinery & Woodworking Equipment, 2018, 46(1): 5. doi: 10.3969/j.issn.2095-2953.2018.01.009

[6] 刘媛, 卢翠香, 黄腾华, 等. 桉树无性系大径材干燥特性分析[J]. 南方农业学报, 2017, 48(5): 5. doi: 10.3969/j.issn.2095-1191.2017.05.023 Liu Y, Lu C X, Huang T H, et al. Drying characteristics of Eucalyptus clones with large-diameter[J]. Journal of Southern Agriculture, 2017, 48(5): 5. doi: 10.3969/j.issn.2095-1191.2017.05.023

[7] 刘元, 吴义强, 乔建政, 等. 桉树人工林木材的干燥特性及干燥基准研究[J]. 中南林业科技大学学报, 2002, 22(4): 44−49. doi: 10.3969/j.issn.1673-923X.2002.04.015 Liu Y, Wu Y Q, Qiao J Z, et al. A study of drying characteristics and drying schedules of Eucalyptus plantation wood[J]. Journal of Central South Forestry University, 2002, 22(4): 44−49. doi: 10.3969/j.issn.1673-923X.2002.04.015

[8] 赵荣军, 江泽慧, 费本华, 等. 澳大利亚桉树木材加工利用研究现状[J]. 世界林业研究, 2003, 16(3): 58−61. doi: 10.3969/j.issn.1001-4241.2003.03.012 Zhao R J, Jiang Z H, Fei B H, et al. Present studies on processing and utilization of eucalypt wood in Australia[J]. World Forestry Research, 2003, 16(3): 58−61. doi: 10.3969/j.issn.1001-4241.2003.03.012

[9] 戴于龙, 黄月瑞, 刘渝, 等. 推广预测木材干燥基准的百度试验法的可行性探讨[J]. 北京林学院学报, 1985, 7(1): 19−29. Dai Y L, Huang Y R, Liu Y, et al. Feasibility of a new method for determination of kiln-drying schedule of wood[J]. Journal of Beijing Forestry College, 1985, 7(1): 19−29.

[10] 寺泽真. 木材干燥的简单决定法[J]. 木材工业(日本), 1965(5): 216−221. Terazawa S. A simple method for determination of kiln-drying schedule of wood[J]. Wood Industry (Japan), 1965(5): 216−221.

[11] Yang L, Liu H, Cai Y, et al. A novel method of studying the collapsed cell of eucalyptus wood using X-ray CT scanning[J]. Drying Technology, 2019, 37(12): 1597−1604. doi: 10.1080/07373937.2018.1519572

[12] Yang L, Liu H. A review of Eucalyptus wood collapse and its control during drying[J]. BioResources, 2018, 13(1): 2171−2181.

[13] Phonetip K, Ozarska B, Belleville B, et al. Comparing two intermittent drying schedules for timber drying quality[J]. Drying Technology, 2019, 37(2): 186−197. doi: 10.1080/07373937.2018.1445638

[14] Phonetip K, Brodie G I, Ozarska B, et al. Drying timber in a solar kiln using an intermittent drying schedule of conventional laboratory kiln[J]. Drying Technology, 2019, 37(10): 1300−1312.

[15] 高建民, 王喜明. 木材干燥学 [M]. 第二版. 北京: 科学出版社, 2018. Gao J M, Wang X M. Wood drying[M]. 2nd ed. Beijing: Science Press, 2018.

[16] 何定华, 林文洁. 24种南方阔叶树材的干燥特性及窑干基准[J]. 木材工业, 1990, 4(4): 12−18. doi: 10.19455/j.mcgy.1990.04.003 He D H, Lin W J. The drying characteristics and kiln drying schedules on 24 species of hardwood from south China[J]. China Wood Industry, 1990, 4(4): 12−18. doi: 10.19455/j.mcgy.1990.04.003

[17] 何清慧. 木材干燥基准简易确定法: 百度试验法[J]. 木材工业, 1998, 12(6): 39−41. He Q H. A simple method for determination of kiln-drying schedule of wood: 100 ℃-test[J]. China Wood Industry, 1998, 12(6): 39−41.

[18] Redman A L, Bailleres H, Gilbert B P, et al. Finite element analysis of stress-related degrade during drying of Corymbia citriodora and Eucalyptus obliqua[J]. Wood Science and Technology, 2018, 52(1): 67−89. doi: 10.1007/s00226-017-0955-0

[19] Shi J, Avramidis S. Dried cell wall nanopore configuration of Douglas-fir, western red cedar and aspen heartwoods[J]. Wood Science Technology, 2018, 52(4): 1025−1037.

[20] 广东省雷州林业局, 南京林产工业学院木材干燥实验室, 中国林业科学研究院热带林业科学研究所. 雷州桉木的高温干燥试验[J]. 南京林产工业学院学报, 1979, 22(1/2): 1−13. The Forestry Office of Leizhou, Guangdong Province, Laboratory of Wood Drying, Nanjing Technological College of Forest Products, Institute of Tropical Forest, Chinese Academy of Forest Science. On the high-temperature drying of Eucalyptus wood[J]. Journal of Nanjing Technological College of Forest Products, 1979, 22(1/2): 1−13.

-

期刊类型引用(2)

1. 曹树扬,施静波,董友明,吕建雄. 不同温度下斜叶桉木材吸湿、解吸等温线与热力学性质. 化工进展. 2024(09): 5095-5105 .  百度学术

百度学术

2. 马登泽. 新型便携式电力绝缘修枝锯的研制. 电气技术与经济. 2023(03): 122-124 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: