Physical and mechanical properties of Robinia pseudoacacia wood in artificial forests

-

摘要:目的刺槐作为我国重要的速生用材树种,被广泛应用于北方人工林种植,深入研究刺槐木材的物理力学性质,为刺槐人工林建设经营以及木材的高效精细化利用提供科学依据。方法本文对采自于山东省东营市刺槐林场的4株不同树龄人工林刺槐沿树干等分成0.65 m长若干小段并顺序编号,测定和分析每段木材的物理性质(气干密度、全干密度、基本密度)、力学性质(顺纹抗压强度、横纹径向全部抗压强度、横纹弦向全部抗压强度、抗弯强度、抗弯弹性模量)以及化学组分(纤维素、半纤维素、木质素)含量,并通过SEM电镜扫描图对各段木材的微观构造进行对比分析。结果刺槐木材的气干密度、全干密度、基本密度、顺纹抗压强度、横纹全部抗压强度(径向、弦向)、抗弯强度、抗弯弹性模量均随树龄的增大而增加,随树干位置增高呈现先增大后减小的规律。将木材气干密度与顺纹抗压强度、横纹(径向、弦向)全部抗压强度、抗弯强度、抗弯弹性模量分别进行线性和幂函数拟合,两种模型均能很好地拟合试验结果,拟合度R2值为0.865~0.895。各段木材化学组分中纤维素含量随树龄及树干高度位置的变化规律与木材各项力学性质的变化规律相似。木材的微观构造中导管占比率随树龄增大而减少,随树干高度位置增加呈现出先减后增的变化规律。结论10年生、15年生、20年生、25年生刺槐木材的气干密度、顺纹抗压强度、抗弯强度、抗弯弹性模量均为中级以上,是良好的家具和建筑用材。在利用时应充分考虑不同树龄木材和树干不同位置的差别。密度作为影响木材力学性质的直接要素,可根据相关方程通过刺槐木材的密度值估算部分力学性质的数值。刺槐木材纤维素含量与木材各项宏观力学性质相关度很高,而木材导管占比率的差异则从微观构造上揭示了木材密度变化的内在机理。Abstract:ObjectiveRobinia pseudoacacia, as an important fast-growing timber tree species in China, is widely used in plantation in northern China. In order to provide a scientific basis for the construction and management of Robinia pseudoacacia plantation and efficient and meticulous utilization of wood, it is very necessary to further study the physical and mechanical properties of Robinia pseudoacacia wood.MethodIn this paper, 4 different tree-age plantations of Robinia pseudoacacia collected from the coastal forest farm of Dongying, Shandong Province of eastern China were divided into 0.65 m long segments along the tree trunk and numbered in sequence. The physical properties (air-dry density, absolute-dry density and basic density) and mechanical properties (compressive strength parallel to grain, radial compression entire strength perpendicular to grain, the tangential compression entire strength perpendicular to grain, bending strength, bending elastic modulus) and chemical components (cellulose, hemicellulose and lignin) content of wood in different ages and varied heights were measured and analyzed.The microscopic structure of each section of wood was compared and analyzed by scanning electron microscope.ResultThe results showed that wood air-dry density, absolute-dry density, basic density, compressive strength parallel to grain and compression (entire) strength perpendicular to grain(radial and tangential), bending strength, bending elastic modulus all increased with tree age increasing, and with the increase of trunk height position, the above variables increased first and then decreased. The wood air-dry density was fitted by linear and power functions fitting to the compressive strength, the transverse compressive strength, the bending strength and the bending modulus of elasticity. It was found that the two models can fit the experimental results well, and the fitting R2 was 0.865-0.895. The changing rules of cellulose content in chemical components of each wood segment with tree age and trunk height position were similar to those of each mechanical property of wood. In the microstructure of wood, the ratio of duct decreased with the increase of tree age, and showed a rule of decreased first and then increased with the increase of trunk height position.ConclusionThe results show that the air-dry density, compressive strength parallel to grain, bending strength, bending elastic modulus of 10 years old, 15 years old, 20 years old and 25 years old Robinia pseudoacacia wood were all above intermediate level and these are good furniture and building wood. The difference in varied tree age and varied trunk height position should be taken into full consideration when utilizing wood. As a direct factor influencing the mechanical properties of wood, density can be used to estimate partial mechanical properties of Robinia pseudoacacia wood according to the relevant equations. The cellulose content of Robinia pseudoacacia wood is highly correlated with the macro mechanical properties of wood, while the difference of wood duct occupation ratio reveals the intrinsic reason of wood density change from microscopic structure.

-

Keywords:

- Robinia pseudoacacia /

- density /

- mechanical property /

- chemical composition /

- micro structure

-

我国木材供给严重不足,近年来持续大幅度增长的木材进口量使我国成为世界第一大木材进口国[1]。同时我国木材的利用率低,人工林经营管理粗放[2]。作为一种非均质的、各向异性的天然高分子材料,木材的物理力学性质研究对合理利用木材和工程设计都起到重要作用[3]。木材的生长特点决定其轴向材性复杂且多变,木材的力学性质在轴向上的变化与径向、弦向相比更为明显和重要[4]。深入研究不同树龄木材轴向材性的差异,充分利用木材强度,是提高木材利用效率的有效途径。

作为我国重要的速生用材树种,刺槐(Robinia pseudoacacia)生长快、抗干旱、耐瘠薄、木质坚硬,在北方地区被广泛用于人工林种植。国外对刺槐木材材性做了很多研究,Adamopoulos等[5]对刺槐幼龄材材性和成熟材进行了对比,结果表明成熟材的抗弯强度和抗弯弹性模量均大于幼龄材。Niklas等[6]的研究表明刺槐木材树干中部的密度与刚度比值最大,顶部和基部较小。Pollet等[7]对比了刺槐与柚木、橡木的材性,发现刺槐木材的各项力学性质均高于柚木和橡木。但国内刺槐材性的相关研究较少,针对刺槐木材物理力学性质的研究不够全面和深入。

为系统研究人工林刺槐木材的物理力学性质,本文选取4株不同树龄的人工林刺槐,沿高度将树干精细地划分成段,对不同树龄、不同高度位置处木材的主要物理力学性质和化学组分进行了测定和分析。同时对比观察了各树龄刺槐不同位置木材微观电镜图,通过对比木材密度与力学性质的相关性以及化学组分的变化规律,结合微观结构分析,初步探索刺槐木材物理力学性质产生差异的机理,以期为人工林刺槐木材高效、精细化利用以及人工林科学经营提供理论依据。

1. 材料和方法

1.1 试验地概况

试材采自山东省东营市河口区孤岛镇军马五分场人工刺槐林(118°41′58″ E、37°47′18″ N),海拔8 m,自20世纪80年代初开始种植,现刺槐人工林林面积超过200 hm2。试验地属于暖温带大陆性季风气候,年平均气温为12.3 ℃,年降水量500~600 mm,降水主要集中于6—9月,年光照2 600~2 800 h。年均空气湿度83%,累年平均风速为4 m/s。林地土壤为冲积性黄土母质在海浸母质上沉淀而成,机械组成以粉沙为主[8]。

1.2 试验材料

刺槐人工林在造林经过25年发育,林木达到成熟阶段[9]。为对比不同成长阶段树龄对物理力学性质的影响,本试验结合孤岛镇军马五分场人工刺槐林的林分特点,选取树龄分别为10、15、20、25年的生长正常且无病虫害样木4株,样木概况见表 1。为准确掌握木材物理力学性质细致的轴向变化,综合考虑试件尺寸、树干生长特点以及锯材方法,选定刺槐树干每段锯材长65 cm。

表 1 试验样木概况Table 1. General survey of sample trees样木编号

Sample tree No.树龄

Tree-age/a树高

Tree height/m枝下高

Clear bole height/m胸径

DBH/cm划分段数

Partition number1 10 5.9 3.8 12.2 6 2 15 6.8 4.0 16.4 6 3 20 10.5 5.7 21.7 8 4 25 12.4 7.2 24.3 11 1.3 试件制作及试验方法

选取不同树龄标准木4株伐倒后,每株从根部起每隔65 cm分段锯材并顺序编号。根据国家标准GB/T 1928~39—2009《木材物理力学性质测定试验方法》,锯材在室温下干燥至本地平衡含水率后,按标准将其加工成供测试物理力学性能所用的无暇小试件。作为典型的显心材树种,刺槐边材只有2~3个年轮,本研究中试件均取自样木心材。试验分段取件,每段上每项试验取8个试件进行平行试验。加工试件过程中,收集每株刺槐各段木材100 g纯净木屑在(105±3) ℃下干燥至质量不再变化,而后用FZ102型植物粉碎机磨成细末,过筛截取40~60目木粉用做化学试验原料。在每株刺槐各段横截面不同部位取8个3 mm×3 mm×3 mm的顺纹木块,保证每个试样横切面至少包含1个年轮跨度。每个木块软化后用Bright 8000型切片机将其横向截面切平并在(105±3) ℃下干燥至质量不再变化,以备SEM(scanning electron microscope,扫描电子显微镜)观察使用。

刺槐木材抗弯强度采用10 t万能材料试验机(WDW-100E)测定,其他力学性质采用微型控制电子万能试验机(MMW-50)测定。试验前利用恒温恒湿箱(LHS-150SC)调整试样含水率到12%左右。刺槐木材密度的测定依据国家标准GB/T 1933—2009《木材密度测定方法》进行,木材气干密度和全干密度试件的体积利用精度为0.001 mm游标卡尺测量计算所得;木材基本密度试件的体积由排水法测得。气干密度和力学试验数据按规定换算为含水率为12%的基本数据。化学实验中综纤维素、酸溶木素和酸不溶木素的测定分别按照国家标准GB/T 2677.10—1995、GB/T 10337—2008和GB/T 2677.8—1994进行,硝酸乙醇纤维素含量的测定采用硝酸乙醇法[10],木质素含量为酸溶木素和酸不溶木素含量之和,半纤维素含量取综纤维素含量与纤维素含量的差值[11]。用于微观电镜观察的试件表面喷金处理后,放置于场发射电子显微镜(Hitachi S-3400N Ⅱ)内观察分析。所得试验数据均取各段的平均值,利用Excel软件进行拟合回归分析。

2. 结果与分析

2.1 刺槐木材的密度

2.1.1 不同树龄刺槐木材的密度

木材密度是木材性质中的一项重要指标。通常可以根据木材密度判断木材的工艺性质及其他物理性质[12]。不同树龄刺槐木材的各项密度见表 2,各树龄刺槐密度随树干高度变化见图 1。由表 2可知3种密度均随树龄的增大而增大。对比3项密度随树龄的变化,25年生刺槐木材的气干密度、全干密度和基本密度比10年生分别增加了5.11%、8.35%和6.76%,说明树龄对全干密度的影响最大。各树龄段3项密度的增长量均较小,气干密度和基本密度均为15~20年树龄段增长最多,20年生木材比15年生木材的气干密度增加2.05%,基本密度增加2.66%。全干密度则为10~15年树龄段增长最多,15年生木材比10年生的全干密度增加3.34%。

表 2 树龄对木材物理力学性质的影响Table 2. Influence of tree age on the physical and mechanical properties of wood项目

Item10年生木材

10 years old wood15年生木材

15 years old wood20年生木材

20 years old wood25年生木材

25 years old wood气干密度Air-dry density/(g·cm-3) 0.725±0.009 0.733±0.010 0.748±0.008 0.762±0.012 全干密度Absolute-dry density/(g·cm-3) 0.659±0.010 0.681±0.009 0.696±0.009 0.718±0.013 基本密度Basic density/(g·cm-3) 0.592±0.007 0.602±0.010 0.618±0.010 0.632±0.008 顺纹抗压强度Compressive strength parallel to grain/MPa 49.202±2.119 53.314±1.918 55.370±2.016 60.342±2.416 横纹径向全部抗压强度Radial compression(entire)strength perpendicular to grain/MPa 10.788±0.534 11.499±0.691 12.507±0.676 13.802±0.736 横纹弦向全部抗压强度Tangential compression(entire) strength perpendicular to grain/MPa 11.337±0.521 12.509±0.459 13.038±0.493 14.926±0.605 抗弯强度Bending strength/MPa 94.102±5.929 97.162±4.297 116.074±5.246 126.059±6.217 抗弯弹性模量Bending elastic modulus/GPa 8.929±0.397 9.128±0.434 11.286±0.513 12.084±0.510 注:表中物理力学性质的数值均为整株样木的平均值。Note: the numerical values of physical and mechanical properties in the table are the average value of the whole tree. 对比各株样木在同一离地高度处木材的密度,刺槐木材3项密度值均随树龄增加而增大。以各株第3段(木材胸径处附近)木材气干密度为例,25年生木材的气干密度比10年生木材增加3.07%。根据《木材的主要物理力学性质分级表》[3],10年生、15年生和20年生刺槐木材的平均气干密度(含水率12%时)达到Ⅲ级,25年生刺槐木材的平均气干密度(含水率12%时)达到Ⅳ级。

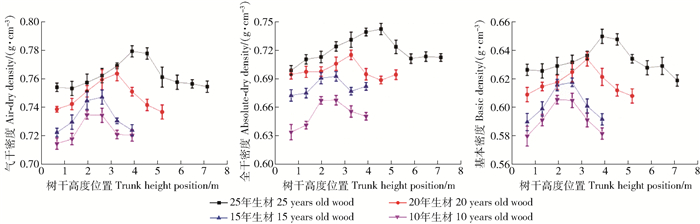

2.1.2 不同高度位置的刺槐木材密度

由图 1可知,刺槐木材的气干密度、全干密度、基本密度在轴向均随树干高度均呈现先增后减的趋势,即以树干中部的密度较大,基部和顶部较小。这与梁宏温等[13]研究的马占相思木材密度变化规律相同。对比3项密度在不同树干位置的大小,树干基部和顶部两端数值略有起伏,平均值接近。不同树龄刺槐木材的各项密度最大值基本都出现在树干正中偏上的位置。以25年生刺槐为例,沿树干高度自下而上共划分11段,其中,中间第6段气干密度平均值最大为0.779 g/cm3,顶部第11段平均值最小为0.754 g/cm3,最大值比最小值增加3.32%,整体呈现先逐渐增加,中间达到最大,而后逐渐减小的趋势。

2.2 刺槐木材的力学性质

2.2.1 不同树龄刺槐木材的力学性质

不同树龄刺槐木材主要力学性质的测定统计结果见表 2,各树龄木材力学性质沿树干高度的细致变化见图 2。随着刺槐树龄的增加,木材各项力学性质均呈增大趋势。在顺纹抗压强度上,强度增长最多的为20~25年树龄段,25年生比20年生刺槐增加8.98%;在横纹全部抗压强度上,无论径向或弦向,均为20~25年树龄段木材强度增长最多,25年生比20年生刺槐分别增加10.35%和14.48%;在抗弯强度上和在抗弯弹性模量上,增长最多的为15~20年树龄段,20年生比15年生刺槐分别增加19.46%和23.64%。25年生刺槐木材的顺纹抗压强度、横纹径向全部抗压强度、横纹弦向全部抗压强度、抗弯强度、抗弯弹性模量分别比10年生木材增加22.64%、27.94%、31.66%、33.96%、35.33%。这说明成长期树龄对抗弯弹性模量及抗弯强度影响最大。

对比不同树龄刺槐在同一离地高度处木材的力学性质,相同离地高度位置处刺槐木材的顺纹抗压强度、横纹径向全部抗压强度、横纹弦向全部抗压强度、抗弯强度和抗弯弹性模量均随树龄增加而增大,以各株木材第3段(木材胸径处附近)的抗弯强度为例,25年生木材第3段抗弯强度比10年生木材第3段抗弯强度增加22.41%。对照《木材主要物理力学性质分级表》[3],10年生和15年生人工林刺槐木材气干密度、顺纹抗压强度、抗弯强度和抗弯弹性模量均达到Ⅲ级;20年生刺槐木材的气干密度达到Ⅳ级,顺纹抗压强度、抗弯强度和抗弯弹性模量为Ⅲ级;25年生刺槐木材的顺纹抗压强度和抗弯强度均达到Ⅳ级,抗弯弹性模量属Ⅲ级。

2.2.2 不同高度位置刺槐木材的力学性质

由图 2可知,每项力学性质的轴向变化曲线各有不同,细致的划分能准确地呈现出各力学性质的轴向变化规律。不同树龄刺槐木材顺纹抗压强度、横纹径向全部抗压强度、横纹弦向全部抗压强度、抗弯强度和抗弯弹性模量沿树干高度呈现相似的变化规律,随树干高度的增加均为先增大后减小。各树龄木材顺纹抗压强度、横纹径向全部抗压强度、横纹弦向全部抗压强度的最大值均出现在树干正中偏上位置,而抗弯强度和抗弯弹性模量最大值出现在树干正中部,树干两端木材的各项力学性质数值基本持平。

同样以25年生刺槐木材为例,树干自下而上共11段,木材顺纹抗压强度、横纹径向全部抗压强度和横纹弦向全部抗压强度的最大值均为第7段木材的平均值,分别比相应的最小值增加17.57%、22.75%和15.32%。抗弯强度和抗弯弹性模量均为第6段木材的平均值最大,第11段平均值最小,最大值比最小值分别增加12.61%和16.56%。可见树干不同高度位置处木材的各项力学性质均有较大差异。

3. 讨论

3.1 刺槐密度与力学性质的关系

木材的力学性质与构成木材物质的数量及构造有密切关系[14]。作为衡量单位体积物质数量多少的标志,木材密度对力学性质有很大影响。随着树龄增大及树干高度增加,刺槐木材的顺纹抗压强度、横纹径向全部抗压强度、横纹弦向全部抗压强度、抗弯强度以及抗弯弹性模量都有着与木材密度基本相同的变化规律,此前很多学者研究了木材密度与力学强度的关系,不同的研究者结论有所差异。Newlin等[15]于1919年就已经指出密度与力学性质间存在着Y= aXb(a、b为常数)的关系,Zhang[16]则认为用线性方程式Y=a+bX(a、b为常数)能更好地描述两者关系。

木材密度测定方法简单方便,所以根据木材的密度估算其力学性质,在经济上和科学研究上均有意义[17]。为进一步确定刺槐木材气干密度与各项力学性能指标间的相关关系,本文采用Y=a+bX和Y=aXb两种模型对刺槐木材的气干密度与各项力学性质指标关系进行回归分析,结果见表 3。可见无论是线性还是幂函数回归均能很好地拟合实验结果,相关拟合度R2值在0.865~0.895之间,这与邵卓平等[18]对湿地松木材的相关研究结论一致。实际应用中为方便计算,建议采用线性回归公式,可通过刺槐木材的密度快速估算其力学强度。

表 3 木材气干密度与力学性质之间相关分析Table 3. Correlation analysis between wood air-dry density and mechanical properties力学性质

Mechanical property相关方程

Regression equation残余平方和

Residual sum of squares拟合度

Fitting degree (R2)顺纹抗压强度Compression strength parallel to grain σ=250.468 7ρ-133.726 5 93.332 0.895 σ=143.86ρ3.406 2 78.631 0.892 横纹径向全部抗压强度Radial compression (entire) strength perpendicular to grain σ=74.110 4ρ-43.575 2 6.513 0.881 σ=44.052ρ4.534 5.154 0.886 横纹弦向全部抗压强度Tangential compression (entire) strength perpendicular to grain σ=80.713 9ρ-47.624 5 8.338 0.872 σ=48.283ρ4.601 9 9.712 0.865 抗弯强度Bending strength σ=784.220 2ρ-480.899 1 784.397 0.883 σ=507.19ρ5.426 1 835.868 0.879 抗弯弹性模量Bending elastic modulus E=76.221 3ρ-46.837 2 6.856 0.881 E=49.466ρ5.470 6 9.673 0.875 3.2 刺槐木材化学组分与力学性质的关系

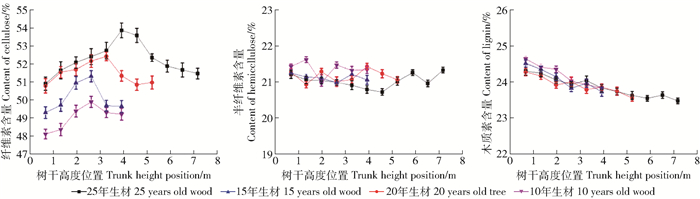

木材化学组成是木材材性的一个重要方面,它影响着木材的物理力学性质、天然耐久性、材色和木材的加工利用性能[12]。作为组成细胞壁的主要化学成分,纤维素、半纤维素和木质素在细胞壁中的分布、结合方式以及各组分自身的性能对木材细胞壁及其宏观力学性能有着重要的影响,因此研究木材的主要化学成分是系统研究木材物理力学性质变异规律的一项必要的基础工作[19]。试验测得不同树龄4棵刺槐木材的主要化学成分见表 4。由表 4可知,刺槐木材中纤维素含量随树龄的增大而增加,纤维素含量增长最快为15~20年树龄段,20年生木材比15年生增加2.65%;半纤维素含量随树龄增大无明显差异,4株刺槐木材的均值为21.16%;木质素含量随树龄增大呈减少趋势,但减少幅度很小,以15~20年树龄段木材木质素含量减少最多,20年生木材比15年生也仅减少0.79%。

表 4 各树龄木材主要化学成分对比Table 4. Comparison of main chemical composition of different tree-age woods% 化学组分

Chemical component10年生木材

10 years old wood15年生木材

15 years old wood20年生木材

20 years old wood25年生木材

25 years old wood纤维素Cellulose 49.052±0.347 50.107±0.439 51.470±0.502 52.156±0.579 半纤维素Hemicellulose 21.358±0.131 21.125±0.154 21.161±0.167 21.001±0.204 木质素Lignin 24.217±0.177 24.110±0.227 23.918±0.213 23.865±0.287 注:表中纤维素、半纤维素和木质素含量均以绝干材为基准,数值为整株样木的平均值。Notes: the content of cellulose, hemicellulose and lignin in the table are benchmarked against absolutely dry wood, and the average value of the whole wood is used for the test value. 3种化学组分随树龄及沿树高轴向变异见图 3。由图可知,刺槐木材中纤维素含量在轴向上呈现中间高、两端低的分布规律,最大值出现在树干中部,基部和顶部含量相近,这与刘成倩等[20]研究枫香木材纤维素含量的轴向变化规律相同。木材中半纤维素含量随树干位置增高无明显变化规律;木质素含量由树基往上基本呈现逐渐减少的趋势,但减少幅度很小,这与崔贺帅等[21]研究杞柳木质素含量的轴向变化规律相同。

纤维素是细胞壁的主要化学成分,在细胞壁中充当骨架物质,是细胞壁强度的主要来源,木质素贯穿于纤维素纤维之间用以强化细胞壁,半纤维素则作为过渡组分,是连接纤维素和木质素的界面偶联剂[22]。刺槐木材3项化学组分中纤维素含量随树龄和轴向的变化与木材顺纹抗压强度、横纹全部抗压强度(径向、弦向)、抗弯强度、抗弯弹性模量的变化规律十分相似。且不同树龄、不同部位处刺槐木材纤维素含量差异明显,而木质素含量和半纤维素含量差异均很小。本文对刺槐木材纤维素含量与木材顺纹抗压强度、横纹径向全部抗压强度、横纹弦向全部抗压强度、抗弯强度、抗弯弹性模量分别进行了线性回归分析,结果表明刺槐木材纤维素含量与上述各项强度的线性拟合度因子R2分别为0.851、0.865、0.873、0.885和0.901,且Sig值均小于0.000 1。可见刺槐木材纤维素含量与各项力学强度呈显著正相关,这说明刺槐木材纤维素含量随树龄和树干高度位置的变化是木材宏观力学性质产生差异的内在原因。

3.3 刺槐木材微观构造与密度的关系

试验结果表明刺槐木材的密度与各项力学性质间相关性很强,证明木材密度确实与力学性质有密切的关系。而木材作为天然高分子材料,其密度变化的本质源于内部微观构造的差异。为进一步探究刺槐木材物理力学性质变化的根本原因,本研究利用电子扫描显微镜对4株不同树龄刺槐树干各段的试件进行观察。

姜笑梅等[23]发现杨树木材的导管数量越多,其基本密度越小。我们选取不同树龄刺槐木材各段横截面等放大倍数且具有代表性的SEM图像,通过生物图像分析软件(IPP)对图像进行分析对比,结果表明刺槐木材的微观构造中导管分布占比随树干高度及树龄表现出规律变化。如图 4所示,图 4a为10年生树干基部第1段试件的横截面SEM图,其导管数量多且密集,导管占比率为51.21%;图 4b为25年生树干基部第1段试件的横截面SEM图,其导管数量较图 4a有明显减少,但大导管直径增大,导管占比率为47.63%;图 4c为25年生树干中部第6段试件的横截面SEM图,其导管数量较图 4b无明显变化,但大导管直径减小,导管占比率为42.17%。

各树龄木材导管占比率轴向变异情况见图 5,由图 5可知随着树龄的增大,刺槐木材导管占比率减少;轴向上随着树干位置的增高,刺槐木材导管占比率呈现先减小后增加的趋势。这与木材密度随树龄及树干高度位置的变化规律相反。对刺槐木材导管占比率与木材气干密度、全干密度、基本密度分别进行了线性回归分析,结果表明刺槐木材导管占比率与3项密度的线性拟合度因子R2分别为0.904、0.859和0.918,3项Sig值均小于0.000 1,表明刺槐木材导管占比率与木材密度呈显著负相关。这一结论与刺槐木材导管的结构特点相吻合。刺槐是典型的环孔材,导管数量众多,而导管作为一个直径较大的空腔管状组织,其密度明显小于其他组织[12]。所以刺槐木材导管占比率的变异从微观结构上解释了各树龄不同位置处木材密度产生差异的原因。

4. 结论

树龄对刺槐木材物理力学性质影响较大,10年生和15年生人工林刺槐木材气干密度、顺纹抗压强度、抗弯强度和抗弯弹性模量均属中级;20年生刺槐木材的气干密度属高级,顺纹抗压强度、抗弯强度和抗弯弹性模量属中级;25年生刺槐木材的气干密度、顺纹抗压强度、抗弯强度均属高级,抗弯弹性模量属中级。刺槐木材顺纹抗压强度、横纹径向全部抗压强度、横纹弦向全部抗压强度、抗弯强度和抗弯弹性模量均随所在树干位置的增高先增大后减小,最大值出现在树干中部偏上位置,两端数值基本持平。不同高度位置处木材各项力学性质的最大值和最小值相差平均20%左右。利用刺槐木材时,应充分考虑树干不同高度位置木材材性的差异,结合各项力学性质的轴向变异规律精细化选材,提高利用效率。

通过试验我们发现,刺槐木材密度与力学性质有密切的关系。本研究采用的线性函数和幂函数两种模型均能很好地拟合刺槐木材气干密度与力学性质指标的相关关系,为方便计算,实际应用中建议采用线性模型进行预估。同时,纤维素作为细胞壁强度的主要来源,其含量与木材各项力学性质均呈高度正相关,这说明刺槐木材纤维素含量随树龄和树干高度位置的变化可能是木材宏观力学性质的产生差异的内在原因。刺槐木材微观结构中导管占比率的差异则导致木材密度随树龄和树干高度位置产生规律性变化。

-

表 1 试验样木概况

Table 1 General survey of sample trees

样木编号

Sample tree No.树龄

Tree-age/a树高

Tree height/m枝下高

Clear bole height/m胸径

DBH/cm划分段数

Partition number1 10 5.9 3.8 12.2 6 2 15 6.8 4.0 16.4 6 3 20 10.5 5.7 21.7 8 4 25 12.4 7.2 24.3 11 表 2 树龄对木材物理力学性质的影响

Table 2 Influence of tree age on the physical and mechanical properties of wood

项目

Item10年生木材

10 years old wood15年生木材

15 years old wood20年生木材

20 years old wood25年生木材

25 years old wood气干密度Air-dry density/(g·cm-3) 0.725±0.009 0.733±0.010 0.748±0.008 0.762±0.012 全干密度Absolute-dry density/(g·cm-3) 0.659±0.010 0.681±0.009 0.696±0.009 0.718±0.013 基本密度Basic density/(g·cm-3) 0.592±0.007 0.602±0.010 0.618±0.010 0.632±0.008 顺纹抗压强度Compressive strength parallel to grain/MPa 49.202±2.119 53.314±1.918 55.370±2.016 60.342±2.416 横纹径向全部抗压强度Radial compression(entire)strength perpendicular to grain/MPa 10.788±0.534 11.499±0.691 12.507±0.676 13.802±0.736 横纹弦向全部抗压强度Tangential compression(entire) strength perpendicular to grain/MPa 11.337±0.521 12.509±0.459 13.038±0.493 14.926±0.605 抗弯强度Bending strength/MPa 94.102±5.929 97.162±4.297 116.074±5.246 126.059±6.217 抗弯弹性模量Bending elastic modulus/GPa 8.929±0.397 9.128±0.434 11.286±0.513 12.084±0.510 注:表中物理力学性质的数值均为整株样木的平均值。Note: the numerical values of physical and mechanical properties in the table are the average value of the whole tree. 表 3 木材气干密度与力学性质之间相关分析

Table 3 Correlation analysis between wood air-dry density and mechanical properties

力学性质

Mechanical property相关方程

Regression equation残余平方和

Residual sum of squares拟合度

Fitting degree (R2)顺纹抗压强度Compression strength parallel to grain σ=250.468 7ρ-133.726 5 93.332 0.895 σ=143.86ρ3.406 2 78.631 0.892 横纹径向全部抗压强度Radial compression (entire) strength perpendicular to grain σ=74.110 4ρ-43.575 2 6.513 0.881 σ=44.052ρ4.534 5.154 0.886 横纹弦向全部抗压强度Tangential compression (entire) strength perpendicular to grain σ=80.713 9ρ-47.624 5 8.338 0.872 σ=48.283ρ4.601 9 9.712 0.865 抗弯强度Bending strength σ=784.220 2ρ-480.899 1 784.397 0.883 σ=507.19ρ5.426 1 835.868 0.879 抗弯弹性模量Bending elastic modulus E=76.221 3ρ-46.837 2 6.856 0.881 E=49.466ρ5.470 6 9.673 0.875 表 4 各树龄木材主要化学成分对比

Table 4 Comparison of main chemical composition of different tree-age woods

% 化学组分

Chemical component10年生木材

10 years old wood15年生木材

15 years old wood20年生木材

20 years old wood25年生木材

25 years old wood纤维素Cellulose 49.052±0.347 50.107±0.439 51.470±0.502 52.156±0.579 半纤维素Hemicellulose 21.358±0.131 21.125±0.154 21.161±0.167 21.001±0.204 木质素Lignin 24.217±0.177 24.110±0.227 23.918±0.213 23.865±0.287 注:表中纤维素、半纤维素和木质素含量均以绝干材为基准,数值为整株样木的平均值。Notes: the content of cellulose, hemicellulose and lignin in the table are benchmarked against absolutely dry wood, and the average value of the whole wood is used for the test value. -

[1] 田明华, 史莹赫, 黄雨, 等.中国经济发展、林产品贸易对木材消耗影响的实证分析[J].林业科学, 2016, 52(9):113-123. http://d.old.wanfangdata.com.cn/Periodical/lykx201609014 Tian M H, Shi Y H, Huang Y, et al. An empirical analysis of effects of economic development and forest product trade on wood consumption in China[J].Scientia Silvae Sinicae, 2016, 52(9):113-123. http://d.old.wanfangdata.com.cn/Periodical/lykx201609014

[2] 刘世荣, 杨予静, 王晖.中国人工林经营发展战略与对策:从追求木材产量的单一目标经营转向提升生态系统服务质量和效益的多目标经营[J].生态学报, 2018, 38(1): 1-10. doi: 10.3969/j.issn.1673-1182.2018.01.001 Liu S R, Yang Y J, Wang H. Development strategy and management countermeasures of planted forests in China: transforming from timber-centered single objective management towards multi-purpose management for enhancing quality and benefits of ecosystem services[J]. Acta Ecologica Sinica, 2018, 38(1): 1-10. doi: 10.3969/j.issn.1673-1182.2018.01.001

[3] 李坚.木材科学研究[M].北京:科学出版社, 2009:183. Li J.Wood science research[M]. Beijing: Science Press, 2009:183.

[4] Reiterer A, Sinn G, Stanzl-Tschegg S E. Fracture characteristics of different wood species under mode Ⅰ loading perpendicular to the grain[J]. Materials Science & Engineering A, 2002, 332(1):29-36.

[5] Adamopoulos S, Passialis C, Voulgaridis E. Strength properties of juvenile and mature wood in black locust (Robinia pseudoacacia) [J]. Wood & Fiber Science Journal of the Society of Wood Science & Technology, 2007, 39(2):241-249.

[6] Niklas K J. Size- and age-dependent variation in the properties of sap and heartwood in black locust (Robinia pseudoacacia L.) [J]. Annals of Botany, 1997, 79(5):473-478.

[7] Pollet C, Verheyen C, Hébert J, et al. Physical and mechanical properties of black locust (Robinia pseudoacacia) wood grown in Belgium[J]. Canadian Journal of Forest Research, 2012, 42(5):831-840. doi: 10.1139/x2012-037

[8] 陈印平, 夏江宝, 赵西梅, 等.黄河三角洲典型人工林土壤碳氮磷化学计量特征[J].土壤通报, 2017, 48(2):392-398. http://d.old.wanfangdata.com.cn/Periodical/trtb201702020 Chen Y P, Xia J B, Zhao X M, et al. Effect of different plantation types on soil ecological stoichiometry in Yellow Delta[J]. Chinese Journal of Soil Science, 2017, 48(2):392-398. http://d.old.wanfangdata.com.cn/Periodical/trtb201702020

[9] 邓磊, 张文辉.黄土沟壑区刺槐人工林的天然发育规律[J].林业科学, 2010, 46(12):15-22. doi: 10.11707/j.1001-7488.20101203 Deng L, Zhang W H. Natural development pattern of Robinia pseudoacacia plantations in loess hilly region[J]. Scientia Silvae Sinicae, 2010, 46(12):15-22. doi: 10.11707/j.1001-7488.20101203

[10] 任世学, 姜贵全, 屈红军.植物纤维化学实验教程[M].哈尔滨:东北林业大学出版社, 2008: 53-54. Ren S X, Jiang G Q, Qu H J. Plant fibre chemistry experiment[M]. Harbin: Northeast Forestry University Press, 2008: 53-54.

[11] 葛晓雯, 王立海, 侯捷建, 等.褐腐杨木微观结构、力学性能与化学成分的关系研究[J].北京林业大学学报, 2016, 38(10):112-122. doi: 10.13332/j.1000-1522.20160098 Ge X W, Wang L H, Hou J J, et al. Relationship among microstructure, mechanical properties and chemical compositions in Populus cathayana sapwood during brown-rot decay[J]. Journal of Beijing Forestry University, 2016, 38(10):112-122. doi: 10.13332/j.1000-1522.20160098

[12] 李坚.木材科学[M].北京:科学出版社, 2014:241. Li J. Wood science [M]. Beijing: Science Press, 2014:241.

[13] 梁宏温, 徐峰, 牟继平.马占相思木材物理力学性质的研究[J].广西农业生物科学, 2004, 23(4): 325-329. http://www.cnki.com.cn/Article/CJFDTOTAL-GXNB200404016.htm Liang H W, Xu F, Mou J P. Studies on the wood physical-mechanical properties of Acacia mangium Willd[J]. Journal of Guangxi Agricultural and Biological Science, 2004, 23(4): 325-329. http://www.cnki.com.cn/Article/CJFDTOTAL-GXNB200404016.htm

[14] 成俊卿.木材学[M].北京:中国林业出版社, 1985:176. Cheng J Q.Wood science[M]. Beijing: China Forestry Publishing House, 1985:176.

[15] Newlin J A, Wilson T R. The relation of the shrinkage and strength properties of wood to its specific gravity[J]. USDA Technical Bulletin, 1919, 676:1-35.

[16] Zhang S Y. Wood specific gravity-mechanical property relationship at species level[J]. Wood Science & Technology, 1997, 31:181-191. doi: 10.1007/BF00705884

[17] 江泽慧, 姜笑梅.木材结构与其品质特性的相关性[M].北京:科学出版社, 2008:228-230. Jiang Z H, Jiang X M. The correlation between wood structure and its quality characteristics[M]. Beijing: Science Press, 2008: 228-230.

[18] 邵卓平, 董宏敢, 张治国, 等.湿地松木材物理力学性质研究[J].安徽农业大学学报, 2000, 27(1): 64-66. doi: 10.3969/j.issn.1672-352X.2000.01.016 Shao Z P, Dong H G, Zhang Z G, et al. Study on physical and mechanical proper ties of Pinus elliottii[J]. Journal of Anhui Agricultural University, 2000, 27(1): 64-66. doi: 10.3969/j.issn.1672-352X.2000.01.016

[19] 张双燕.化学成分对木材细胞壁力学性能影响的研究[D].北京: 中国林业科学研究院, 2011: 9-12. Zhang S Y.Chemical components effect on mechanical properties of wood cell wall [D]. Beijing: Chinese Academy of Forestry, 2011: 9-12.

[20] 刘成倩, 王传贵, 李媛媛, 等.枫香木材化学成分及其在高度上的变异规律[J].安徽农业大学学报, 2017, 44(6):1043-1046. http://www.cnki.com.cn/Article/CJFDTOTAL-ANHU201706017.htm Liu C Q, Wang C G, Li Y Y, et al. The chemical components of Liquidambar formosana and their longitudinal variation[J]. Journal of Anhui Agricultural University, 2017, 44(6):1043-1046. http://www.cnki.com.cn/Article/CJFDTOTAL-ANHU201706017.htm

[21] 崔贺帅, 杨淑敏, 刘杏娥, 等.杞柳的化学成分及其木质素微区分布的研究[J].林产化学与工业, 2016, 36(5):120-126. doi: 10.3969/j.issn.0253-2417.2016.05.018 Cui H S, Yang S M, Liu X E, et al. Chemical composition and lignin distribution of Salix integra[J]. Chemistry and Industry of Forest Products, 2016, 36(5):120-126. doi: 10.3969/j.issn.0253-2417.2016.05.018

[22] 王传贵, 江泽慧, 费本华, 等.化学成分对木材细胞壁纵向弹性模量和硬度的影响[J].北京林业大学学报, 2012, 34(3): 107-110. http://j.bjfu.edu.cn/article/id/9765 Wang C G, Jiang Z H, Fei B H, et al. Effects of chemical components on longitudinal MOE and hardness of wood cell wall[J]. Journal of Beijing Forestry University, 2012, 34(3): 107-110. http://j.bjfu.edu.cn/article/id/9765

[23] 姜笑梅, 殷亚方, 浦上弘幸.北京地区I-214杨树木材解剖特性与基本密度的株内变异及其预测模型[J].林业科学, 2003, 39(6):115-121. doi: 10.3321/j.issn:1001-7488.2003.06.019 Jiang X M, Yin Y F, Hiroyuki U. Variation within tree of wood anatomical properties and basic density of I-214 poplar in Beijing area and their relationship modelling equations[J]. Scientia Silvae Sinicae, 2003, 39(6):115-121. doi: 10.3321/j.issn:1001-7488.2003.06.019

-

期刊类型引用(17)

1. 高杰. 天然林保护对生态系统服务功能的影响. 农业灾害研究. 2024(02): 232-234 .  百度学术

百度学术

2. 力佳琪,麦强盛,王俊超. 玉白顶自然保护区森林生态价值评估. 农业与技术. 2024(18): 67-71 .  百度学术

百度学术

3. 潘丰十,牛香,郭珂. 呼伦贝尔市典型生态产品禀赋与价值化实现路径优化. 林业科学. 2024(12): 146-157 .  百度学术

百度学术

4. 严雨桐,陈花丹,游巍斌,刘进山,蔡昌棠,何东进. 基于能值分析的天宝岩泥炭沼泽生态系统服务价值评估. 生态与农村环境学报. 2023(03): 335-343 .  百度学术

百度学术

5. 李保杰,褚帅,顾和和. 淮海经济区生态系统服务价值时空分异特征研究. 地域研究与开发. 2023(02): 167-172 .  百度学术

百度学术

6. 魏媛,吴长勇,洪林. 碳中和导向下贵州省森林资源生态价值评估及生态补偿研究. 自然资源情报. 2023(04): 44-50 .  百度学术

百度学术

7. 赵玉堂. 普达措国家公园森林生态系统服务价值评估与分析. 林业调查规划. 2023(03): 208-213 .  百度学术

百度学术

8. 邓紫君,刘鑫,祖浩然,苏闪闪,陈颖,罗俊毅,闫文德,张翔,王明旭. 湖南省森林型国家级自然保护区森林生态系统服务功能价值评估. 湖南林业科技. 2023(04): 72-80 .  百度学术

百度学术

9. 李连强,杨会侠,丁国泉,李虹谕,白荣芬,王品. 辽宁仙人洞国家级自然保护区森林生态服务物质量评估及权衡与协同. 北京林业大学学报. 2023(09): 83-94 .  本站查看

本站查看

10. 白晓航,施佳颖. 黑龙江丰林国家级自然保护区红松+紫椴+硕桦群系优势树种生态位特征与种间联结分析. 园林. 2023(10): 14-21 .  百度学术

百度学术

11. 李超,谢飞,苏学威,罗传文. 凉水国家级自然保护区森林生态系统服务功能评估. 中国林副特产. 2023(06): 17-18 .  百度学术

百度学术

12. 党俊. 移植栽培技术在自然保护区天然林保护工程生态修复中的应用. 环境保护与循环经济. 2023(12): 68-71 .  百度学术

百度学术

13. 张颖,刘平辉,朱传民,张林颖. 基于NPP的抚州市生态系统服务功能重要性评价. 贵州农业科学. 2022(02): 133-140 .  百度学术

百度学术

14. 胡建忠. 对我国系统种植开发沙棘的回顾与建议. 防护林科技. 2022(04): 75-77 .  百度学术

百度学术

15. 王晓康. 山西省关帝山国有林区森林生态系统服务功能价值估算研究. 中国农学通报. 2022(23): 49-55 .  百度学术

百度学术

16. 任志华,秦磊. 黑龙江省乡村振兴战略实施下的乡村发展策略. 规划师. 2022(09): 139-144 .  百度学术

百度学术

17. 张卫民. 中国自然保护地生态资产核算框架研究. 自然保护地. 2021(02): 22-30 .  百度学术

百度学术

其他类型引用(15)

下载:

下载: