Effects of platen temperature on moisture state in poplar lumber during hot-press drying

-

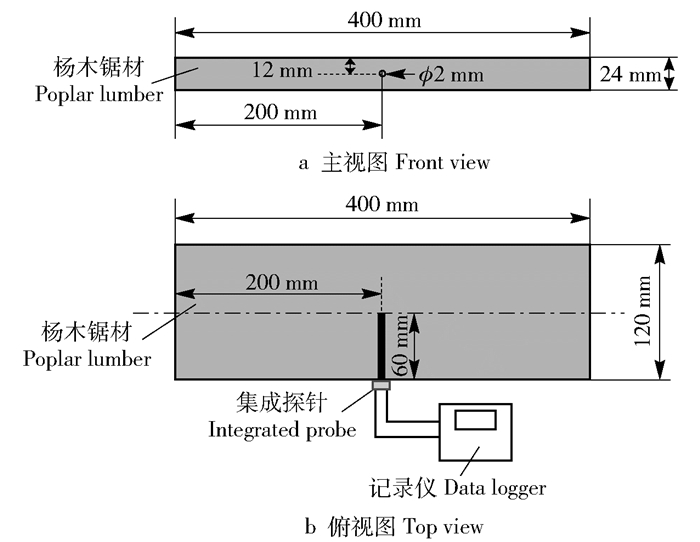

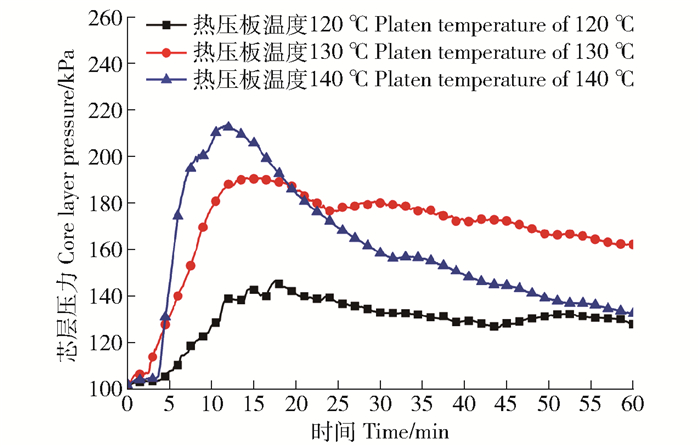

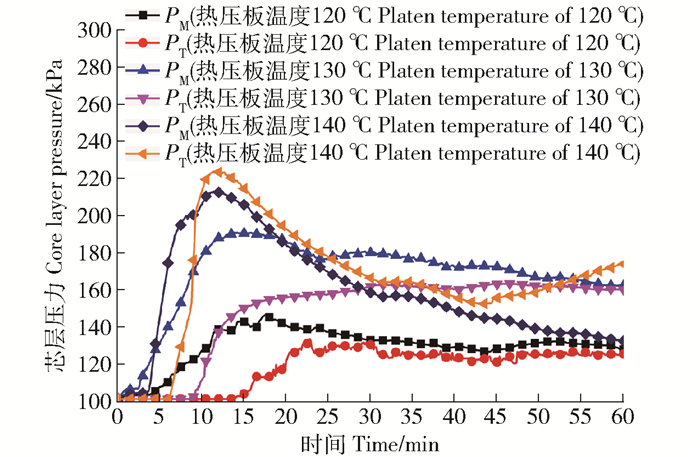

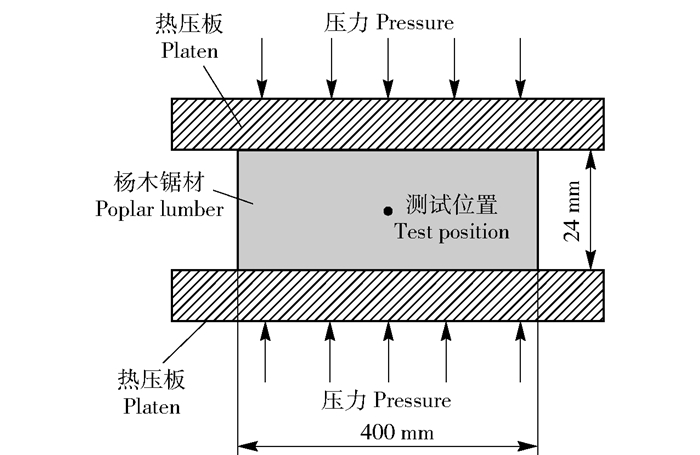

摘要:目的对热压干燥过程中杨木锯材芯层温度和压力进行测试,探究热压板温度对热压干燥过程中杨木锯材芯层温度和压力等参数及水分状态的影响,为热压干燥机理研究提供依据。方法采用集成探针同步测量并记录热压干燥过程中杨木锯材芯层温度和压力,通过对杨木锯材芯层压力测量值与测量温度对应的饱和蒸汽压力值(压力理论值)进行对比分析,进而推测热压板温度对热压干燥过程中杨木锯材水分状态的影响。结果当热压板温度从120℃升高到140℃时,杨木锯材芯层压力峰值从146.4kPa增大到213.1kPa,相应温度峰值从102.8℃升高到123.7℃,温度和压力同时达到峰值,到达峰值时间从17.5min缩短到11.6min。当热压板温度为120和130℃时,含水率高于纤维饱和点的杨木锯材芯层水分为过压的未饱和水,热压干燥后杨木锯材芯层终含水率(48.55%和49.88%)高于纤维饱和点;当热压板温度升高到140℃时,杨木锯材芯层自由水受热汽化形成水蒸气,并随着蒸汽温度的升高由饱和状态转化为过热状态,热压干燥后杨木锯材芯层终含水率(27.70%)低于纤维饱和点。结论热压干燥过程中热压板温度越高,杨木锯材芯层温度和压力达到的峰值越高,峰值持续时间越短。热压干燥过程中含水率高于纤维饱和点的杨木锯材水分状态根据热压板温度不同,可为液态水(过压的未饱和水)、饱和水蒸气或过热蒸汽状态。Abstract:ObjectiveIn order to provide basis for analyzing hot-press drying mechanism, the temperature and pressure in poplar lumber (Populus tomentosa) were monitored during hot-press drying, and the effects of platen temperature on temperature, pressure and moisture state in the core layer of poplar lumber were further investigated.MethodTemperature and pressure in the core layer of poplar lumber were measured with the integrated probe and real-time recorded with a data logger at the same time in hot-press drying, and the effects of platen temperature on moisture state were further analyzed in accordance with the comparison of measured pressure and saturated pressure (theoretical pressure) of vapor calculated with measured temperature in poplar lumber.ResultWith the increase of platen temperature from 120 to 140℃, the peak value of pressure increased from 146.4 to 213.1kPa, whereas that of temperature increased from 102.8 to 123.7℃. The temperature and pressure reached peak values at the same time, and the time to peak values decreased from 17.5 to 11.6min. The moisture in the core layer of poplar lumber with moisture content (MC) beyond fiber saturation point (FSP) was unsaturated water under overpressure condition with the platen temperatures of 120℃ and 130℃, the final MC (48.55% and 49.88%) of core layer was greater than FSP. The heat was transferred from platens to the core layer and resulted in the vaporization of free water in poplar lumber when the platen temperature increased to 140℃. State of the steam in core layer of poplar lumber changed from the saturation state to superheated state with the further increase of steam temperature, and the final core MC (27.70%) was lower than FSP.ConclusionIt was concluded that the higher the platen temperature was, the higher the peak temperature and pressure reached, and the shorter the duration time for keeping peak pressure was in hot-press drying. When the poplar lumber's MC was greater than FSP, the moisture state in poplar lumber may be liquid state (unsaturated water under overpressure condition), saturated steam or superheated steam states depends on different platen temperature levels in hot-press drying.

-

Keywords:

- poplar lumber /

- hot-press drying /

- temperature /

- pressure /

- moisture state

-

-

表 1 杨木锯材热压干燥前后的含水率分布

Table 1 Moisture content (MC) distribution in poplar lumber before and after hot-press drying

热压板温度

Platen temperature/℃初含水率

Initial MC/%终含水率

Final MC/%表层终含水率

Final MC of surface layer/%芯层终含水率

Final MC of core layer/%120 51.76 39.68 23.09 48.55 130 47.42 35.33 28.66 49.88 140 38.08 16.64 12.35 27.70 -

[1] Schrepfer V, Schweingruber F H. Anatomical structures in reshaped press-dried wood[J]. Holzforschung, 1998, 52(6): 615-622. doi: 10.1515/hfsg.1998.52.6.615

[2] 刘志军, 李颜军.高温热压干燥对紫椴小径材材性的影响[J].林产工业, 2002, 29(4): 16-18. doi: 10.3969/j.issn.1001-5299.2002.04.005 Liu Z J, Li Y J. Effect of platen drying process on properties of Amur linden smallwood[J]. China Forest Products Industry, 2002, 29(4): 16-18. doi: 10.3969/j.issn.1001-5299.2002.04.005

[3] 汪佑宏, 顾炼百, 王传贵, 等.木材热压干燥及表面强化研究综述[J].林业科技开发, 2005, 19(3): 13-15. doi: 10.3969/j.issn.1000-8101.2005.03.004 Wang Y H, Gu L B, Wang C G, et al. A review on press drying and surface strengthening of lumber[J]. China Forestry Science and Technology, 2005, 19(3): 13-15. doi: 10.3969/j.issn.1000-8101.2005.03.004

[4] 焦德贤, 金成道, 张亚锋.木板热压干燥应力研究[J].木材加工机械, 2005, 16(6): 23-24, 34. doi: 10.3969/j.issn.1001-036X.2005.06.007 Jiao D X, Jin C D, Zhang Y F. Study on the stress of lumber in the process of hot press drying[J]. Wood Processing Machinery, 2005, 16(6): 23-24, 34. doi: 10.3969/j.issn.1001-036X.2005.06.007

[5] Unsal O, Canada Z, Korkut S. Wettability and roughness characteristics of modified wood boards using a hot-press[J]. Industrial Crops and Products, 2011, 34(3): 1455-1457. doi: 10.1016/j.indcrop.2011.04.024

[6] 邬飞宇, 李丽丽, 王喜明.樟子松材干燥密实炭化一体化技术的优化[J].东北林业大学学报, 2015, 43(4): 82-86. doi: 10.3969/j.issn.1000-5382.2015.04.018 Wu F Y, Li L L, Wang X X. Trinity technology optimization of drying, densifying and charring of Pinus sylvestris[J]. Journal of Northeast Forestry University, 2015, 43(4): 82-86. doi: 10.3969/j.issn.1000-5382.2015.04.018

[7] Bramhall G. Mathematical model for lumber drying (Ⅰ): principles involved[J]. Wood Science, 1979, 12(1): 14-21. http://agris.fao.org/agris-search/search.do?recordID=US7934509

[8] Bramhall G. Mathematical model for lumber drying (Ⅱ): the model[J]. Wood Science, 1979, 12(1): 22-31. http://agris.fao.org/openagris/search.do?recordID=US19800540536

[9] Hunter A J, Sutherland J W. The evaporation of water from wood at high temperatures[J]. Wood Science and Technology, 1997, 31(2): 73-76. doi: 10.1007/BF00705922

[10] 周永东, 傅峰, 李贤军, 等.微波处理对桉木应力及微观构造的影响[J].北京林业大学学报, 2009, 31(2): 146-150. doi: 10.3321/j.issn:1000-1522.2009.02.024 Zhou Y D, Fu F, Li X J, et al. Effects of microwave treatment on residue growth stress and microstructure of Eucalyptus urophylla[J]. Journal of Beijing Forestry University, 2009, 31(2): 146-150. doi: 10.3321/j.issn:1000-1522.2009.02.024

[11] 何正斌, 郭月红, 伊松林, 等.木材超声波-真空协同干燥的动力学研究[J].北京林业大学学报, 2012, 34(2): 133-136. http://j.bjfu.edu.cn/article/id/9741 He Z B, Guo Y H, Yi S L, et al. Preliminary study of wood ultrasound-vacuum combined drying dynamics[J]. Journal of Beijing Forestry University, 2012, 34(2): 133-136. http://j.bjfu.edu.cn/article/id/9741

[12] 汪佑宏.马尾松速生材热压干燥及表面强化[D].南京: 南京林业大学, 2003. Wang Y H. Press drying and surface strengthening of fast-growing Pinus massoniana lumber[D]. Nanjing: Nanjing Forestry University, 2003.

[13] Tang Y F, Pearson R G, Hart C A, et al. A numerical model for heat transfer and moisture evaporation processes in hot-press drying: an integral approach[J]. Wood and Fiber Science, 1994, 26(1): 78-90. http://cn.bing.com/academic/profile?id=8d68167b1aa38a7eec01d89d2e729a28&encoded=0&v=paper_preview&mkt=zh-cn

[14] 汪佑宏, 顾炼百, 王传贵, 等.马尾松锯材在热压干燥过程中的传热规律[J].南京林业大学学报(自然科学版), 2005, 29(4): 33-36. doi: 10.3969/j.issn.1000-2006.2005.04.008 Wang Y H, Gu L B, Wang C G, et al. Regularity of heat transfer during press drying of Pinus massoniana lumber[J]. Journal of Nanjing Forestry University (Natural Sciences Edition), 2005, 29(4): 33-36. doi: 10.3969/j.issn.1000-2006.2005.04.008

[15] 赵喜龙.人工林杨树木材皱缩恢复工艺与机理研究[D].呼和浩特: 内蒙古农业大学, 2013. Zhao X L. Study on the collapse recovery technology and mechanism of poplar plantation[D]. Hohhot: Inner Mongolia Agricultural University, 2013.

[16] 严家騄, 王永青.工程热力学[M]. 2版.北京:中国电力出版社, 2014: 181-182. Yan J L, Wang Y Q. Engineering thermodynamics[M]. 2nd ed. Beijing: China Electric Power Press, 2014: 181-182.

[17] 苗平, 王晓敏, 魏思文, 等. 3种预处理方法改善杨木渗透性的对比研究[J].安徽农业大学学报, 2012, 39(4): 489-492. http://d.old.wanfangdata.com.cn/Periodical/ahnydxxb201204002 Miao P, Wang X M, Wei S W, et al. Effects of three pretreatment methods on improving the permeability of poplar wood[J]. Journal of Anhui Agricultural University, 2012, 39(4): 489-492. http://d.old.wanfangdata.com.cn/Periodical/ahnydxxb201204002

[18] 鲍永泽, 周永东.柳杉锯材过热蒸汽干燥与常规干燥的比较[J].林业科学, 2017, 53(1): 88-93. http://d.old.wanfangdata.com.cn/Periodical/lykx201701011 Bao Y Z, Zhou Y D. Comparation between superheated steam drying and conventional drying of Chinese cedar lumber[J]. Scientia Silvae Sinicae, 2017, 53(1): 88-93. http://d.old.wanfangdata.com.cn/Periodical/lykx201701011

[19] 李贤军.木材真空-微波干燥特性的研究[D].北京: 北京林业大学, 2005. Li X J. Research on characteristics of wood microwave-vacuum drying[D]. Beijing: Beijing Forestry University, 2005.

[20] Pang S. Some considerations in simulation of superheated steam drying of softwood lumber[J]. Drying Technology, 1997, 15(2): 651-670. doi: 10.1080/07373939708917252

[21] Haque M N. Analysis of heat and mass transfer during high-temperature drying of Pinus radiate[J]. Drying Technology, 2007, 25(2): 379-389. doi: 10.1080/07373930601184551

[22] Wisniak J. Historical development of the vapor pressure equation from dalton to antoine[J]. Journal of Phase Equilibria, 2001, 22: 622. doi: 10.1007/s11669-001-0026-x

-

期刊类型引用(6)

1. 张友谊,李松柏,钟磊. 基于地形因子的震后泥石流降雨阈值分析. 科学技术与工程. 2024(32): 13708-13717 .  百度学术

百度学术

2. 曹永强,张若凝,范帅邦. 辽宁省降雨型泥石流环境特征及分类预警. 华北水利水电大学学报(自然科学版). 2022(02): 60-68 .  百度学术

百度学术

3. 曹永强,张若凝,李玲慧,路洁,宁月. 辽宁省泥石流与不同时间尺度下降水因子的关系研究. 灾害学. 2021(03): 51-56 .  百度学术

百度学术

4. 乔建平. 降雨型滑坡泥石流灾害预警原理及系统结构. 人民长江. 2020(01): 50-55+74 .  百度学术

百度学术

5. 胡凯衡,魏丽,刘双,李秀珍. 横断山区泥石流空间格局和激发雨量分异性研究. 地理学报. 2019(11): 2303-2313 .  百度学术

百度学术

6. 凌訸,陶蓉,白晓华. 平凉鸭儿沟泥石流形成过程及特征分析. 甘肃水利水电技术. 2017(01): 18-21 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: