Effects of thermal treatment on deformation fixation and properties of surface densified wood

-

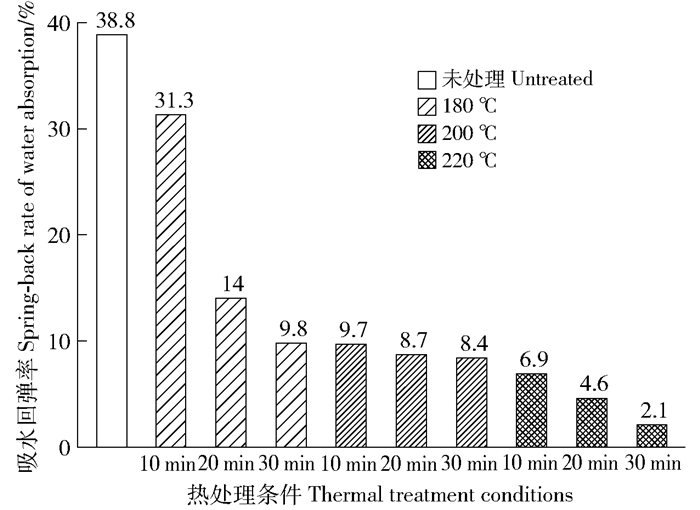

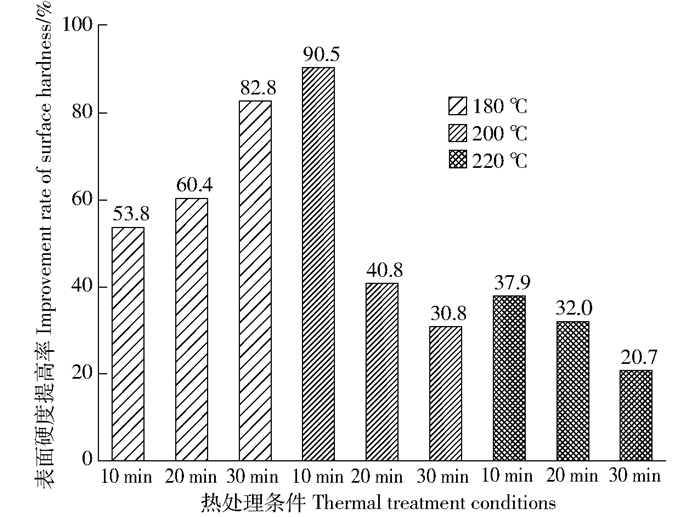

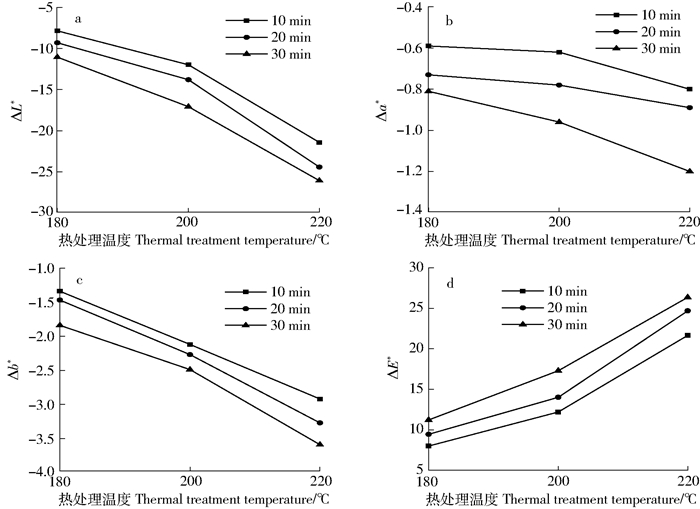

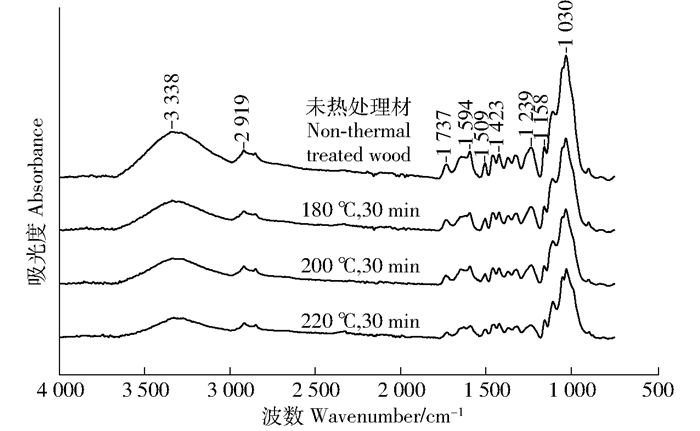

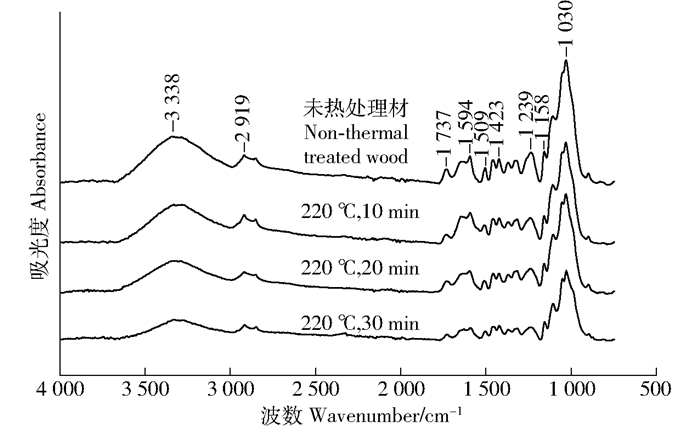

摘要:目的高温热处理是一种广泛使用的木材压缩变形固定方法,以往研究中大多对木材进行整体热处理,但整体热处理方式耗时长能耗大,且表面密实材仅仅是表面几毫米的密实层需要固定,因此有必要探究一种适合表面密实材的变形固定方法。方法本研究采用热压机对表面密实材进行表面热处理,并对不同条件处理后的试件进行回弹率、表面硬度、耐磨性、材色的测定和红外光谱分析,探讨热处理对表面密实材变形固定和性能的影响。结果热处理对固定木材表面的压缩变形效果显著,且吸湿、吸水和水煮回弹率均随着处理温度的升高或处理时间的延长而降低。当温度高于200 ℃,延长处理时间会造成木材表面硬度和耐磨性的降低。随着热处理温度的升高或处理时间的延长,表面密实材的明度差、红绿轴色品指数差和黄蓝轴色品指数差的绝对值增大,色差增大,材色变深。热处理后各吸收峰的吸光度均呈现降低的趋势,且随热处理温度的升高和处理时间的延长降低越明显,在高温作用下木材3大组成成分纤维素、半纤维素和木素由于热解反应导致其含量降低,另外影响木材尺寸稳定性的羟基和羰基的数量也相应减少。结论热处理可以对表面密实材进行有效地变形固定,但提高处理温度或延长处理时间会导致木材表面硬度和耐磨性的降低以及材色的变化。Abstract:ObjectiveThermal treatment at high temperature is a widely used method for deformation fixation of compressed wood. Wood is always treated as a whole in previous studies, but wood treated as a whole takes a long time and wastes a lot of energy, and only a few millimeters of surface densified layer need to be fixed. Therefore, it is necessary to explore a method for deformation fixation of surface densified wood.MethodIn this study, hot press was used for surface thermal treatment of surface densified wood, then spring-back, surface hardness, abrasion resistance, wood color and chemical composition of the specimens treated by different conditions were measured, effects of thermal treatment on deformation fixation and properties of surface densified wood were discussed.ResultThe results showed that: effects of thermal treatment on deformation fixation of surface densified wood were significant, spring-back of moisture absorption, water absorption and water boiling absorption all decreased with the increase of processing temperature and the extension of processing time. Surface hardness and abrasion resistance would be reduced when processing temperature was above 200℃ and processing time was extended. With the increase of processing temperature and the extension of processing time, the absolute value of brightness, red green ratio index and yellow blue ratio index increased, chromatic aberration also increased, wood color got darker. Absorbance of each absorption peak decreased after thermal treatment, and the decrease was more obvious with the increase of processing temperature and the extension of processing time. Cellulose, hemicellulose and lignin of wood were reduced because of pyrolysis reaction, and the number of hydroxyl groups and carbonyl groups affecting the dimensional stability of wood also correspondingly decreased under high temperature.ConclusionThermal treatment could effectively fix the deformation of surface densified wood, however, increasing processing temperature and extending processing time would lead to the decrease of hardness and abrasion resistance of wood surface, and the change of wood color.

-

Keywords:

- thermal treatment /

- deformation fixation /

- hardness /

- abrasion resistance /

- wood color /

- chemical composition

-

-

表 1 奥古曼试件的红外光谱特征吸收峰及其归属

Table 1 Location and assignment of FT-IR absorption peaks of Okoume

特征吸收峰波数

haracteristics absorbtion wavenumber/cm-1振动模式及归属

Vibration mode and ownership3 338 O—H伸展振动O—H stretching vibration 2 919 C—H伸展振动(脂肪族) C—H stretching vibration(aliphatic) 1 737 C—O伸展振动(聚木糖) C—O stretching vibration(polyxylose) 1 594 苯环的碳骨架振动(木质素) Carbon skeleton vibration of benzene ring(lignin) 1 509 芳环的碳骨架振动(木质素) Carbon skeleton vibration of aromatic ring(lignin) 1 423 CH2剪式振动(纤维素)、CH2弯曲振动(木质素) CH2 scissoring vibration(cellulose),CH2 bending vibration(lignin) 1 239 苯环氧键Ar—O伸缩振动(木质素) Stretching vibration of benzene epoxy bond Ar—O(lignin) 1 158 C—O—C伸缩振动(纤维素和半纤维素) C—O—C stretching vibration(cellulose and hemicellulose) 1 030 C—O伸缩振动(纤维素和半纤维素)、乙酰基中的烷氧键伸缩振动C—O stretching vibration(cellulose and hemicellulose), stretching vibration of alcoxy bond in acetyl groups -

[1] Tjeerdsma B F, Militiz H. Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood[J]. Holz Als Roh-Und Werkstoff, 2005, 63(2): 102-111. doi: 10.1007/s00107-004-0532-8

[2] 王洁瑛, 赵广杰, 杨琴玲, 等.饱水和气干状态杉木的压缩成型及其热处理永久固定[J].北京林业大学学报, 2000, 22(1): 72-75. doi: 10.3321/j.issn:1000-1522.2000.01.015 Wang J Y, Zhao G J, Yang Q L, et al. Compression and permanent fixation with heat treatment of China fir under water-saturated condition and air-dried condition[J]. Journal of Beijing Forestry University, 2000, 22(1): 72-75. doi: 10.3321/j.issn:1000-1522.2000.01.015

[3] 陈太安, 徐忠勇, 王昌命, 等.热处理对表层压缩云南松木材性能的影响[J].木材工业, 2012, 26(5): 45-48. doi: 10.3969/j.issn.1001-8654.2012.05.011 Chen T A, Xu Z Y, Wang C M, et al. Effect of heat treatment on properties of surface-densified Pinus yunnanensis samples[J]. China Wood Industry, 2012, 26(5): 45-48. doi: 10.3969/j.issn.1001-8654.2012.05.011

[4] Laine K, Rautkari L, Hughes M, et al. Reducing the set-recovery of surface densified solid Scots pine wood by hydrothermal post-treatment[J]. European Journal of Wood and Wood Products, 2013, 71(1): 17-23. doi: 10.1007/s00107-012-0647-2

[5] 邹国政.速生杨木表面密实、定型工艺的研究[D].南京: 南京林业大学, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10298-1015809294.htm Zou G Z. Study on surface compression and fixing deformation of fast-growing poplar lumber[D]. Nanjing: Nanjing Forestry University, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10298-1015809294.htm

[6] 高志强, 张耀明, 吴忠其, 等.加压热处理对表层压缩杨木变形回弹的影响[J].木材工业, 2017, 31(2): 24-28. http://d.old.wanfangdata.com.cn/Periodical/mcgy201702006 Gao Z Q, Zhang Y M, Wu Z Q, et al. Effect of pressurized heat treatment on spring-back of surface compressed poplar wood[J]. China Wood Industry, 2017, 31(2): 24-28. http://d.old.wanfangdata.com.cn/Periodical/mcgy201702006

[7] 夏捷.毛白杨木材层状压缩位置和厚度可控性及其变形固定[D].北京: 中国林业科学研究院, 2014. http://cdmd.cnki.com.cn/Article/CDMD-82201-1014331755.htm Xia J. Controllability of location and thickness and deformation fixation of Populus layered compression[D]. Beijing: Chinese Academy of Forestry, 2014. http://cdmd.cnki.com.cn/Article/CDMD-82201-1014331755.htm

[8] 王艳伟, 黄荣凤, 张耀明.水热控制下杨木的表层密实化及固定技术[J].木材工业, 2012, 26(2): 18-21. http://www.cnki.com.cn/Article/CJFDTotal-MCGY201202006.htm Wang Y W, Huang R F, Zhang Y M. Surface densification and heat fixation of Chinese white poplar by hydro-thermal control[J]. China Wood Industry, 2012, 26(2): 18-21. http://www.cnki.com.cn/Article/CJFDTotal-MCGY201202006.htm

[9] Yi X H, Kinoshita N, Yoshinobu M, et al. Sugi rotary veneers compressed by hydro-thermal treatment with an airtight device using moisture in the veneers[J]. Journal of the Society of Materials Science, Japan, 2004, 53(6): 686-691. doi: 10.2472/jsms.53.686

[10] 韩英磊.木材及其处理材耐光色牢度的研究[D].北京: 中国林业科学研究院, 2012. http://cdmd.cnki.com.cn/Article/CDMD-82201-1012423560.htm Han Y L. Study on colorfastness to light of wood and modified wood[D]. Beijing: Chinese Academy of Forestry, 2012. http://cdmd.cnki.com.cn/Article/CDMD-82201-1012423560.htm

[11] Inoue. The large deformation of wood transverse grain and permanent fixation of deformation[D]. Kyoto: Kyoto University, 1994.

[12] 陈太安, 蒋明, 王昌命, 等.后期热处理对压缩木尺寸稳定性的影响[J].西南林业大学学报, 2011, 31(4): 77-79. doi: 10.3969/j.issn.2095-1914.2011.04.016 Chen T A, Jiang M, Wang C M, et al. Effect of post-heat treatment on dimensional stability of compressed wood[J]. Journal of Southwest Forestry University, 2011, 31(4): 77-79. doi: 10.3969/j.issn.2095-1914.2011.04.016

[13] 唐晓淑.热处理变形固定过程中杉木压缩木材的主成分变化及化学应力松弛[D].北京: 北京林业大学, 2004. http://d.wanfangdata.com.cn/Thesis/Y668363 Tang X S. Influence of heat fixation on the major components and chemical stress relaxation of compressed Chinese fir wood[D]. Beijing: Beijing Forestry University, 2004. http://d.wanfangdata.com.cn/Thesis/Y668363

[14] 朱林峰, 刘元, 罗玉华, 等.粗皮桉不同家系木材的表面视觉性质[J].中南林业科技大学学报, 2004, 24(4): 41-46. doi: 10.3969/j.issn.1673-923X.2004.04.026 Zhu L F, Liu Y, Luo Y H, et al. Study of the surface visual quality of different genealogies of Eucalyptus pellita[J]. Journal of Central South Forestry University, 2004, 24(4): 41-46. doi: 10.3969/j.issn.1673-923X.2004.04.026

[15] 汤顺青.色度学[M].北京:北京理工大学出版社, 1990: 97-102. Tang S Q. Colorimetric[M]. Beijing: Beijing Institute of Technology Press, 1990: 97-102.

[16] 黄荣凤, 吕建雄, 曹永建, 等.高温热处理对毛白杨木材化学成分含量的影响[J].北京林业大学学报, 2010, 32(3): 155-160. http://j.bjfu.edu.cn/article/id/9395 Huang R F, Lü J X, Cao Y J, et al. Impact of heat treatment on chemical composition of Chinese white poplar wood[J]. Journal of Beijing Forestry University, 2010, 32(3): 155-160. http://j.bjfu.edu.cn/article/id/9395

[17] Stamm A J. Wood and cellulose science[M]. New York: Wood Press, 1964.

[18] Tjeerdsma B F, Militiz H. Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood[J]. Holz Als Roh-Und Werkstoff, 2005, 63(2): 102-111. doi: 10.1007/s00107-004-0532-8

[19] 李贤军, 刘元, 高建民, 等.高温热处理木材的FTIR和XRD分析[J].北京林业大学学报, 2009, 31(增刊1): 104-107. http://www.cnki.com.cn/Article/CJFDTOTAL-BJLY2009S1023.htm Li X J, Liu Y, Gao J M, et al. FTIR and XRD for wood with high-temperature heating treatment[J]. Journal of Beijing Forestry University, 2009, 31(Suppl.1): 104-107. http://www.cnki.com.cn/Article/CJFDTOTAL-BJLY2009S1023.htm

-

期刊类型引用(4)

1. 张苗苗,罗于洋,王树森,张丽娜,马成功,于胜利,王景圆. 内蒙古旺业甸华北落叶松人工林空间结构分析及其优化. 西北林学院学报. 2024(01): 81-87+107 .  百度学术

百度学术

2. 荆媛,魏爽,史文辉,马梓贺,王德宇,戎可. 天然次生林中小斑啄木鸟的取食偏好. 野生动物学报. 2024(01): 84-94 .  百度学术

百度学术

3. 孙宇,刘盛,田佳歆,程福山,赵士博,王诗俊. 基于空间结构优化的长白落叶松人工林分间伐模型构建. 中南林业科技大学学报. 2023(01): 72-83 .  百度学术

百度学术

4. 刘鑫,黄浪,卿东升,李建军. 基于Voronoi空间单元的林分空间结构智能优化研究. 林业资源管理. 2023(04): 27-35 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: